QEMSCAN analysis - Example Report Cu-bearing Mill Products

advertisement

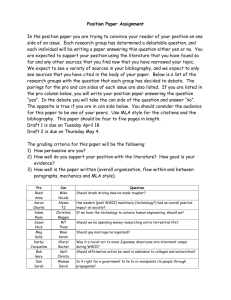

QEMSCAN analysis Example Report Cu-bearing Mill Products By Dr. Katharina Pfaff Department of Geology Colorado School of Mines 1516 Illinois Street, Room 119 Golden, Colorado 80401 USA kpfaff@mines.edu January 21, 2013 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Table of Contents Executive Summary ...............................................................................................................2 Project Background................................................................................................................3 Sample Preparation and Measurements .................................................................................3 Results....................................................................................................................................4 Grain Images ....................................................................................................................4 Mineralogy .......................................................................................................................7 Particle size distribution...................................................................................................9 Cumulative Particle Size Distribution .................................................................... 9 Grain size distribution of bornite, chalcopyrite, and covellite .......................................10 Bornite .................................................................................................................. 10 Chalcopyrite.......................................................................................................... 10 Covellite................................................................................................................ 11 Locking/liberation characteristics of bornite, chalcopyrite, and covellite .....................11 Mineral association ........................................................................................................13 1 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Executive Summary In January of 2013, three samples of Cu-bearing mill products were analyzed at the QEMSCAN Facility at Colorado School of Mines. One sample was a copper flotation concentrate (Cu con), one sample was of partially roasted copper floatation concentrate (Cu con – part roast), and one sample was of leach residue. The copper flotation concentrate mainly consists of chalcopyrite and pyrite, with minor concentrations of FeCu sulfate, Cu-mica/Cu-clay, quartz, K-feldspar, plagioclase, muscovite, Ca sulfate, and chlorite group minerals (Tables 1 and 2, Fig. 4). The sample of partially roasted copper concentrate (Cu con – part roast) consists mainly of FeCu oxide, FeCu sulfate, Fe oxides/hydroxides, and quartz. This sample also contains minor concentrations of copper sulfide minerals, cuprite, Ca sulfate, and silicate minerals (Tables 1 and 2, Fig. 4). The sample of leach residue consists mainly of FeCu oxide, Fe oxide/hydroxide, and bornite. This sample also contains minor concentrations of associated copper sulfides, cuprite, Ca sulfate, pyrite, and silicate minerals (Tables 1 and 2, Fig. 4). Particle sizes for all three samples vary from 4 μm to >120 μm (Fig. 5). Cumulative particle size distribution analysis shows the samples of partial roast and leach residue to have comparable particle size distributions (Fig. 6). Grain sizes for bornite (in volume %) range from <4 μm to 80 μm, with the majority of grains occurring in the <4 μm to 30 μm size range (Fig. 7). Grain sizes of chalcopyrite range from <4 μm to >120 μm, with most grains occurring in the 6 μm to 45 μm size range (Fig. 8). Grain sizes for covellite range from <4 μm to 15 μm, and show a bimodal size distribution (Fig. 9). Bornite is almost entirely locked in all samples, while covellite is fully locked in all samples (Fig. 10 and 12). Chalcopyrite is dominantly locked in the partial roast and leach residue samples, but shows a range of liberation in the sample of copper flotation concentrate (Fig. 11). 2 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Project Background In January of 2013, three samples of Cu-bearing mill products were analyzed at the QEMSCAN Facility at Colorado School of Mines. The samples were named copper concentrate (Cu con), copper concentrate – partial roast (Cu con – part roast), and leach residue. The aims of the analyses are to: 1. Quantify the modal mineralogy; 2. Calculate the particle size distribution; 3. Calculate the grain size distribution; 4. Quantify the locking and liberation characteristics; 5. Quantify mineral associations in the samples. Sample Preparation and Measurements 1. Each sample was split into representative aliquots using a rotary micro-riffler. 2. Sized graphite was added to mitigate particle agglomeration, preferred orientation and settling. Subsequently, all samples were mounted in a 30-mm block with epoxy-resin and left to cure. 3. The blocks were ground and polished to obtain a flat surface for X-ray analysis. 4. The blocks were carbon coated to establish an electrically conductive surface. 5. The samples were analyzed at a 2.5 µm resolution in Particle Analysis (PMA) mode. 3 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Results Grain Images Fig. 1: False color QEMSCAN image of sample Cu con. 4 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Fig. 2: False color QEMSCAN image of sample Cu con – part roast. 5 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Fig. 3: False color QEMSCAN image of leach residue sample. 6 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Mineralogy The sample of copper concentrate (Cu con) consists mainly of chalcopyrite (72.8%) and pyrite (15.3%). The remainder of the sample consists of minor concentrations of FeCu sulfate, Cu-mica/Cu-clay, quartz, K-feldspar, plagioclase, muscovite, Ca sulfate, and chlorite group minerals. The sample of partially roasted copper concentrate (Cu con – part roast) consists mainly of FeCu oxide (54%), FeCu sulfate (12%), Fe oxides/hydroxides (6.9%), and quartz (5.1 %). This sample also contains minor concentrations of copper sulfide minerals, cuprite, Ca sulfate, and silicate minerals. The sample of leach residue consists mainly of FeCu oxide (56.3%), Fe oxide/hydroxide (9.7%), FeCu sulfate (9.1%), and bornite (8.7%). This sample also contains minor concentrations of associated copper sulfides, cuprite, Ca sulfate, pyrite, and silicate minerals. Table 1: Mineral Groups Mineral Chalcopyrite Bornite Chalcocite/Digenite Covellite FeCu Oxide Cu Oxide (Cuprite) FeCu Sulfate Cu Sulfate Cu-mica/clay Fe Oxide/Hydroxide Pyrite Quartz K-Feldspar Plagioclase Muscovite Ca Sulfate Chlorite Others Chemical Composition CuFeS2 Cu5FeS4 Cu2S/Cu9S5 CuS Undifferentiated FeCu Oxide Cu2O Undifferentiated FeCu Sulfate Undifferentiated Cu Sulfate Cu-mica/Cu-clay Undifferentiated Fe Oxide/Hydroxide FeS2 SiO2 KAlSi3O8 (Na,Ca)(Si,Al)4O8 KAl2(Si3Al)O10 Gypsum/Anhydrite Clinochlore/Chamosite individual unidentified pixels 7 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Table 2: Modal mineral abundance (Volume %) Leach residue Cu con - part roast Chalcopyrite 2.6 4.1 Bornite 8.7 4.2 Chalcocite/Digenite 1.9 1.7 Covellite 0.2 0.1 FeCu Oxide 56.3 54.0 Cu Oxide (Cuprite) 0.8 1.4 FeCu Sulfate 9.1 12.0 Cu Sulfate 0.1 0.9 Cu-mica/clay 3.2 4.3 Fe Oxide/Hydroxide 9.7 6.9 Pyrite 0.2 0.2 Quartz 3.5 5.1 K-Feldspar 1.4 1.7 Plagioclase 0.9 1.4 Muscovite 0.6 0.5 Ca Sulfate 0.1 0.4 Chlorite Others 0.9 1.0 Cu con 72.8 2.6 1.5 15.3 2.7 1.9 1.5 0.4 0.1 0.1 0.9 Cu con: Minerals Chalcopyrite Bornite Chalcocite/Digenite Covellite FeCu Oxide Cu Oxide (Cuprite) FeCu Sulfate Cu Sulfate Cu-mica/clay Fe Oxide/Hydroxide Pyrite Quartz K-Feldspar Plagioclase Muscovite Ca Sulfate Chlorite Others Cu con - part roast: Leach residue: 0 10 20 30 40 50 60 Volume (%) 70 80 90 100 Fig. 4: Graphic illustration of the modal mineral abundance in Volume % in Cu con, Cu con - part roast, and leach residue samples. 8 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Particle size distribution 20 18 16 Volume % 14 12 Cu Con Cu Con - Part roast Leach Residue 10 8 6 4 2 68 810 10 -1 5 15 -2 0 20 -2 5 25 -3 0 30 -3 5 35 -4 0 40 -4 5 45 -5 0 50 -6 0 60 -7 0 70 -8 0 80 -9 90 0 -1 10 00 012 0 >1 20 <4 46 0 Particle size in micron Fig. 5: Particle size distribution in volume %. Cumulative Particle Size Distribution Cumulative Particle Size Distribution 100 90 80 Volume % 70 60 Cu Con Cu con - part roast Leach residue 50 40 30 20 10 810 10 -1 5 15 -2 0 20 -2 5 25 -3 0 30 -3 5 35 -4 0 40 -4 5 45 -5 0 50 -6 0 60 -7 0 70 -8 0 80 -9 0 90 -1 0 10 0 012 0 >1 20 68 <4 46 0 Particle size in micron Fig. 6: Cumulative particle size distribution curve. 9 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Grain size distribution of bornite, chalcopyrite, and covellite Bornite Bornite 100 90 80 Volume % 70 60 Cu con 50 Cu con - part roast Leach residue 40 30 20 10 >120 100-120 90-100 80-90 70-80 60-70 50-60 45-50 40-45 35-40 30-35 25-30 20-25 15-20 10-15 8-10 6-8 4-6 <4 0 Grain size in micron Fig. 7: Grain size distribution of bornite. Chalcopyrite Chalcopyrite 50 45 40 Volume % 35 30 Cu con 25 Cu con - part roast Leach residue 20 15 10 5 >120 100-120 90-100 80-90 70-80 60-70 50-60 45-50 40-45 35-40 30-35 25-30 20-25 15-20 10-15 8-10 6-8 4-6 <4 0 Grain size in micron Fig. 8: Grain size distribution of chalcopyrite. 10 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Covellite Covellite 100 90 80 Volume % 70 60 Cu con 50 Cu con - part roast Leach residue 40 30 20 10 >120 100-120 90-100 80-90 70-80 60-70 50-60 45-50 40-45 35-40 30-35 25-30 20-25 15-20 10-15 8-10 6-8 4-6 <4 0 Grain size in micron Fig. 9: Grain size distribution of covellite. Locking/liberation characteristics of bornite, chalcopyrite, and covellite A mineral is completely liberated if >90% of the particle consists only of the respective mineral. A mineral is ‘locked’ if the area of the respective mineral is <30% in the entire particle, everything in between is called ‘middling’. These numbers do not reflect how easy it is to liberate a mineral by e.g., grinding the material. Analysis of liberation degree shows bornite to be fully locked in the Cu concentrate. In the partial roast and leach residue samples, most of the bornite is locked, with 3.5% and 14.5% occurring as middling’s, respectively. Chalcopyrite shows a range of liberation in the Cu concentrate sample, but is dominantly locked in the partial roast and leach residue samples. Covellite is fully locked in all three samples. 11 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Bornite 100 90 80 Volume % 70 60 Cu Con 50 Cu con - part roast Leach residue 40 30 20 10 0 Liberated Middling Locked Fig. 10: Locking and liberation of bornite. Chalcopyrite 100 90 80 Volume % 70 60 Cu Con 50 Cu con - part roast Leach residue 40 30 20 10 0 Liberated Middling Locked Fig. 11: Locking and liberation of chalcopyrite. 12 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Covellite 100 90 80 Volume % 70 60 Cu Con 50 Cu con - part roast Leach residue 40 30 20 10 0 Liberated Middling Locked Fig. 12: Locking and liberation of covellite. Mineral association Cu Con 100 90 80 Volume % 70 60 Chalcopyrite Bornite Covellite 50 40 30 20 10 C ha lc op C yr ha ite lc oc Bo ite rn /D ite ig en C ite ov Fe e C llite u Fe O C xid u Su e C lfat u e Fe Cu Sul f a O -m te xi de ica/ c /H l yd ay ro xi de Py rit e Q K- uar Fe tz l Pl dsp ag a io r cl M as us e c C ovit a Su e lfa C te hl or it O e th er s 0 minerals Fig. 13: Mineral associations in volume % in sample Cu con sample. 13 C ha lc op C yr ha it lc oc Bo e ite rn /D ite ig en C ite ov Fe C el u O Cu lite xi O de x (C ide Fe up r C u ite) Su C lfa u te Fe C S u u O -m lfat e xi de ica /H /cla yd y ro xi de Py rit Q e u Ka Fe rtz l d Pl s ag pa io r c M las us e c C ovi a t Su e lfa C te hl or it O e th er s Volume % ha lc op C yr ha it lc oc Bo e ite rn /D i te ig en C ite ov Fe C el u O Cu lite xi O de x (C ide Fe up r C u ite) Su C lfa u te Fe C S u ulfa O xi mic te de a /H /cla yd y ro xi de Py rit Q e u Ka F e rt z l d Pl s ag pa io r c M las us e c C o vi a t Su e lfa C te hl or it O e th er s C Volume % Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 Cu con - partial roast 100 90 80 70 60 50 40 Chalcopyrite Bornite Covellite 30 20 10 0 minerals Fig. 14: Mineral associations in volume % in sample Cu con – part roast. Leach Residue 100 90 80 70 60 50 40 Chalcopyrite Bornite Covellite 30 20 10 0 minerals Fig. 15: Mineral associations in volume % in leach residue sample. 14 Client: None Project Title: Example Report Survey Code: N/A Date: 1/21/13 The mineralogical data reported in this study directly reflect the best possible analysis of the materials provided. All efforts were made to ensure the highest level of quality control for the materials provided. Certain factors beyond the control of this laboratory may include: sample selection and representivity of materials, sample preparation by other laboratories, small sample size, small grain size close to the resolution of the system, and statistical representation of trace phases. The QEMSCAN Facility is not responsible for any further interpretation or application of the data other than that contained herein, and application to larger sample populations may not be valid without further analysis. Information regarding laboratory operations, quality control and quality assurance is available on request. 15