STUDIES ON SELECTIVITY IN THE PAUSON-KHAND REACTION OF ISOCARBACYCLIN

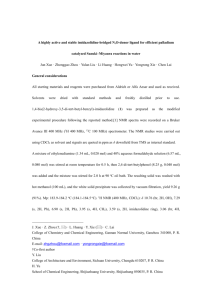

advertisement