____________ ________________ 2.830J / 6.780J / ESD.63J Control of Manufacturing Processes (SMA... MIT OpenCourseWare

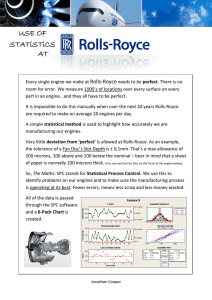

advertisement

MIT OpenCourseWare

http://ocw.mit.edu

____________

2.830J / 6.780J / ESD.63J Control of Manufacturing Processes (SMA 6303)

Spring 2008

For information about citing these materials or our Terms of Use, visit: ________________

http://ocw.mit.edu/terms.

Control of

Manufacturing Processes

Subject 2.830/6.780/ESD.63

Spring 2008

Lecture #7

Shewhart SPC & Process Capability

February 28, 2008

Manufacturing

1

Applying Statistics to Manufacturing:

The Shewhart Approach

Text removed due to copyright restrictions. Please see the Abstract

of Shewhart, W. A. “The Applications of Statistics as an Aid in

Maintaining Quality of a Manufactured Product.” Journal of the

American Statistical Association 20 (December 1925): 546-548.

Manufacturing

2

Applying Statistics to Manufacturing:

The Shewhart Approach

Text removed due to copyright restrictions. Please see the Abstract

of Shewhart, W. A. “The Applications of Statistics as an Aid in

Maintaining Quality of a Manufactured Product.” Journal of the

American Statistical Association 20 (December 1925): 546-548.

Manufacturing

3

Applying Statistics to Manufacturing:

The Shewhart Approach (circa 1925)*

• All Physical Processes Have a Degree of Natural

Randomness

• A Manufacturing Process is a Random Process if all

“Assignable Causes” (identifiable disturbances) are

eliminated

• A Process is “In Statistical Control” if only “Common

Causes” (Purely Random Effects) are present.

Manufacturing

4

“In-Control”

...

i+2

m

i

T

e

i+1

Each Sample is

from Same Parent

i

Manufacturing

5

“Not In-Control”

...

i+2

m

i

T

e

i+1

i

Manufacturing

The Parent

Distribution is Not

The Same at

Each Sample

6

“Not In-Control”

...

Bi-Modal

Mean Shift + Variance Change

m

i

T

e

Mean Shift

What will appear in “Samples”?

Manufacturing

7

Xbar and S Charts

• Shewhart:

– Plot sequential average of process

• Xbar chart

• Distribution?

– Plot sequential sample standard deviation

• S chart

• Distribution?

Manufacturing

8

Data Sampling and Sequential Averages

• Given a sequence of process outputs xi:

j

j+1

j+2

...

sample interval ΔT

• A sequential sample of size n

n measurements

at sample j

Manufacturing

• Take at intervals ΔT

• Sample index j

9

Data Sampling

j

j+1

j+2

...

sample interval ΔT

jΔT + n

n measurements

1

xj =

xi

at sample j

n i = ( j− 1) ΔT +1

∑

sample j mean

jΔT +n

Sj

Manufacturing

2

1

2

=

(x i − x j ) sample j variance

∑

n − 1 i = ( j −1)ΔT

10

Subgroups

j

j+1

j+2

...

• Within Subgroup Statistics

n measurements

at sample j

– xbar j , Sj

• Between Subgroup Statistics

– Average of xbarj

– Variance of xbar(j)

Manufacturing

11

Plot of xbar and S

Random Data n=5

xbar

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

11

12

13

14

15

16

17

18

19

20

Sample Number

S

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

1

2

3

4

5

6

7

8

9

10

Run number

Manufacturing

12

Overall Statistics

0.9

0.8

0.7

0.6

0.5

0.4

1 N

x = ∑ xj

N i =1

0.3

0.2

0.1

0

1

2

3

4

5

6

7

Grand Mean

8

9

10

11

12

13

14

15

16

17

18

19

20

18

19

20

Sample Number

0.45

0.4

0.35

0.3

0.25

1 N

S = ∑ Sj

N i =1

0.2

0.15

0.1

0.05

Grand Standard Deviation

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Run number

Manufacturing

13

Setting Chart Limits

• Expected Ranges

– Grand mean and Variance

• (based on what data and how many data points?)

• Confidence Intervals

– Intervals of + n Standard Deviations

– Most Typical is + 3σ (US) or 0.1% (Europe)

Manufacturing

14

Chart Limits - Xbar

• If we knew σx then:

1

σx =

σx

n

• But Since we Estimate the Sample Standard

Deviation, then

E(S j ) = C4 σ x

where

Manufacturing

(Sj is a biased estimator)

⎛ 2 ⎞

C4 = ⎝

n − 1⎠

1/ 2

Γ(n / 2)

Γ((n − 1) / 2)

15

Chart Limits xbar chart

With this “correction” we can set limit at ±3σxbar

Or set a confidence interval of 99.7%

Or a test significance of 0.3%

UCL = x + 3

S

C4 n

For the example n=5

Manufacturing

LCL = x − 3

C4 = (0.5)

1/ 2

S

C4 n

Γ(2.5)

1.33

= 0.707

= 0.94

Γ(2)

1

16

Chart Limits S

The variance of the estimate of S can be shown

to be:

2

σ S = σ 1 − C4

So we get the chart limits:

S

2

UCL = S + 3

1 − C4

C4

S

2

LCL = S − 3

1 − C4

C4

Manufacturing

17

Example xbar

1

0.9

UCL

0.8

0.7

0.6

Grand

0.5

0.4

Mean

0.3

0.2

LCL

0.1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

sample number

Manufacturing

18

Example S

0.7

0.6

UCL

0.5

0.4

Grand S

0.3

0.2

0.1

LCL

0

1

2

3

Manufacturing

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

19

Detecting Problems

from Running Data

• Appearance of data

– Confidence Intervals

– Frequency of extremes

– Trends

Manufacturing

20

The 8 rules from Devor et al

(Based on Confidence Intervals)

•

•

•

•

Prob. of data in a band

Based on Periodicity

Based on Linear Trends

Based on Mean Shift

Manufacturing

21

Test for “Out of Control”

• Extreme Points

– Outside ±3σ

• Improbable Points

– 2 of 3 >±2σ

– 4 of 5 >± 1σ

– All points inside ±1σ

Manufacturing

22

Tests for “Out of Control”

• Consistently above or below centerline

– Runs of 8 or more

• Linear Trends

– 6 or more points in consistent direction

• Bi-Modal Data

– 8 successive points outside ±1σ

Manufacturing

23

Applying Shewhart Charting

•

•

•

•

Find a run of 25-50 points that are “in-control”

Compute chart centerlines and limits

Begin Plotting subsequent xbarj and Sj

Apply the 8 rules, or look for trends, improbable

events or extremes.

• If these occur, process is “out of control”

Manufacturing

24

Out of Control

• Data is not Stationary

(μ or σ are not constant)

• Process Output is being “caused” by a disturbance

(common cause)

• This disturbance can be identified and eliminated

– Trends indicate certain types

– Correlation with know events

• shift changes

• material changes

Manufacturing

25

Western Electric Rules

(See Table 4-1)

•

•

•

•

Points outside limits

2-3 consecutive points outside 2 sigma

Four of five consecutive points beyond 1 sigma

Run of 8 consecutive points on one side of

center

Manufacturing

26

“In-Control”

...

i+2

T

e

m

i

i+1

What will chart

look like?

i

Manufacturing

27

“Not In-Control”

...

i+2

T

e

m

i

i+1

What will chart

look like?

i

Manufacturing

28

Detecting Mean Shifts:

Chart Sensitivity

• Consider a real shift of Δμx:

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Sample Number

• How many samples before we can expect to

detect the shift on the xbar chart?

Manufacturing

29

Average Run Length

• How often will the data exceed the ±3σ limits

if Δμx = 0?

Prob(x > μ x + 3σ x ) + Pr ob(x < μ x − 3σ x )

= 3 / 1000

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

-4

Manufacturing

-3

−3σ

0

-2

-1

μ0

1

2

3

+3σ

4

30

Average Run Length

• How often will the data exceed the ±3σ limits

if Δμx = +1σ?

Prob(x > μ x + 2σ x ) + Prob(x < μ x − 4σ x )

= 0.023 + 0.001 = 24 / 1000

0.45

0.45

Actual

0.4

0.4

0.35

0.35

Assumed

Distribution

0.3

0.3

Distribution

0.25

0.25

-4

Manufacturing

−3σ

-4

-3

0.2

0.2

0.15

0.15

0.1

Δμ

0.1

0.05

0.05

0

-3

-2

-2

-1

μ

-1

0

pe

0

01

12

23

+3σ

34

4

31

Definition

• Average Run Length (arl): Number of runs (or

samples) before we can expect a limit to be

exceeded = 1/pe

– for Δμ = 0

– for Δμ = 1σ

arl = 3/1000 = 333 samples

arl = 24/1000 = 42 samples

Even with a mean shift as large as 1σ, it

could take 42 samples before we know it!!!

Manufacturing

32

Effect of Sample Size n on ARL

• Assume the same Δμ = 1σ

– Note that Δμ is an absolute value

• If we increase n, the Variance of xbar

σx

decreases:

σx =

n

• So our ± 3σ limits move closer together

Manufacturing

33

ARL Example

Original

Distribution

-4

−3σ

-3

0.450.45

0.45

0.40.4

0.4

0.350.35

0.35

0.30.3

0.3

0.250.25

0.25

0.20.2

0.2

0.150.15

0.15

0.10.1

Δμ 0.1

0.050.05

0.05

00

-2

-4

new limits

-3

-1

-4

-2

−3σ∗

-3

-1

μ

0-2

New

Distribution

pe

0

1-1

1

20

31

+3σ∗

422

3

34

+3σ

4

same absolute shift

As n increases pe increases so ARL decreases

Manufacturing

34

Design of the Chart

• Sample size n

– Central Limit theorem

– ARL effects?

• Selection of Reference Data

– Is S at a minimum ?

•

Sample time ΔT

– Cost of sampling

– production without data

– Rapid phenomena

j

...

Sample size and “filtering”

versus response time to

changes

j+1j+2

sample interval ΔT

Manufacturing

35

Limits and Extensions

•

•

•

•

Need for averaging

Assumptions of Normality

Assumption of independence

Pitfalls

– Misinterpretation of Data

– Improper Sampling

• What are alternatives?

– Different Sampling Schemes

– Different Averaging Schemes

– Continuous Update to Improve Statistics

Manufacturing

36

Conclusions

• Hypothesis Testing

– Use knowledge of PDFs to evaluate hypotheses

– Quantify the degree of certainty (a and b)

– Evaluate effect of sampling and sample size

• Shewhart Charts

– Application of Statistics to Production

– Plot Evolution of Sample Statistics x and S

– Look for Deviations from Model

Manufacturing

37

Detection : The SPC Hypothesis

0.9

0.8

0.7

Process

0.6

Y

0.5

0.4

0.3

0.2

0.1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Sample Number

16

17

18

19

20

In-Control

...

...

p(y)

Not

In-Control

Manufacturing

38

Out of Control

• Data is not Stationary

(μ or σ are not constant)

• Process Output is being “caused” by a

disturbance (assignable or special cause)

• This disturbance can be identified and

eliminated

– Trends indicate certain types

– Correlation with know events

• shift changes

• material changes

Manufacturing

39

Use of the S Chart

• Plot of sample Variance

– Variance of the Mean for Shewhart xbar (n>1)

• What Does it Tell Us about State of Control?

– It simply plots the “other” statistic

Manufacturing

40

Consider this Process

Xbar Chart

1

0.9

UCL

0.8

0.7

0.6

0.5

0.4

0.3

0.2

LCL

0.1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

sample number

Manufacturing

41

And the S Chart

0.6

UCL

0.5

0.4

0.3

0.2

0.1

LCL

0

1

2

Manufacturing

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

42

In Control?

Manufacturing

43

Same Process Later in Time

Xbar

1

0.9

UCL

0.8

0.7

0.6

0.5

0.4

0.3

0.2

LCL

0.1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

sample number

Manufacturing

44

Later S Chart

0.6

UCL

0.5

0.4

0.3

0.2

0.1

LCL

0

1

2

Manufacturing

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

45

What Changed??

Manufacturing

46

A Different Sequence

Xbar

1

0.9

UCL

0.8

0.7

0.6

0.5

0.4

0.3

0.2

LCL

0.1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

sample number

Manufacturing

47

S Chart

0.6

UCL

0.5

0.4

0.3

0.2

0.1

LCL

0

1

2

Manufacturing

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

48

Use of S Chart

• Detect Changes in Variance of Parent

Distribution

• Distinguish Between Mean and Variance

Changes

Manufacturing

49

Statistical Process Control

• Model Process as a Normal Independent* Random

Variable

• Completely described by μ and σ

• Estimate using xbar and s

• Enforce Stationary Conditions

• Look for Deviations in Either Statistic

• If so ………..?

• Call an Engineer!

Manufacturing

50

Another Use of the

Statistical Process Model:

The Manufacturing -Design Interface

• We now have an empirical model of the

process

0.45

0.4

0.35

0.3

How “good” is the

process?

0.25

0.2

0.15

0.1

0.05

Is it capable of

producing what we

need?

Manufacturing

0

-4

-3

−3σ

-2

-1

0

μ

1

2

3

4

+3σ

51

Process Capability

• Assume Process is In-control

• Described fully by xbar and s

• Compare to Design Specifications

– Tolerances

– Quality Loss

Manufacturing

52

Design Specifications

• Tolerances: Upper and Lower Limits

Characteristic

Dimension

Target

Lower

x*

Specification

Limit

Upper

Specification

Limit

LSL

USL

Manufacturing

53

Design Specifications

• Quality Loss: Penalty for Any Deviation from

Target

QLF = L*(x-x*)2

How to

Calibrate?

x*=target

Manufacturing

54

Use of Tolerances:

Process Capability

• Define Process using a Normal Distribution

• Superimpose x*, LSL and USL

• Evaluate Expected Performance

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

LSL

-4

Manufacturing

-3

−3σ

x* 0

-2

-1

μ0

USL

1

2

3

+3σ

4

55

Process Capability

• Definitions

(USL − LSL)

tolerance range

Cp =

=

6σ

99.97% confidence range

• Compares ranges only

• No effect of a mean shift:

Manufacturing

56

Process Capability: Cpk

C pk

⎛ (USL − μ ) (LSL − μ) ⎞

= min⎝

,

⎠

3σ

3σ

= Minimum of the normalized

deviation from the mean

• Compares effect of offsets

Manufacturing

57

Cp = 1; Cpk = 1

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

-4

Manufacturing

-3

-2

-1

0

1

2

3

4

58

Cp = 1; Cpk = 0

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

-4

-3

-2

Manufacturing

-1

0

1

2

3

4

59

Cp = 2; Cpk = 1

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

-4

Manufacturing

-3

-2

-1

0

1

2

3

4

60

Cp = 2; Cpk = 2

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

-4

Manufacturing

-3

-2

-1

0

1

2

3

4

61

Effect of Changes

• In Design Specs

• In Process Mean

• In Process Variance

• What are good values of Cp and Cpk?

Manufacturing

62

Cpk Table

Manufacturing

Cpk

z

P<LS or

P>USL

1

3

1E-03

1.33

5

3E-07

1.67

4

3E-05

2

6

1E-09

63

The “6 Sigma” problem

P(x > 6σ) = 18.8x10-10

Cp=2

0.45

Cpk=2

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

-4

LSL

−3σ∗

-3

-2

0

-1

0

1

+3σ∗

2

3

4

USL

6σ

Manufacturing

64

The 6 σ problem: Mean Shifts

P(x>4σ) =

Cp=2

31.6x10-6

0.45

Cpk=4/3

0.4

Even with a mean shift of 2σ

we have only 32 ppm out of spec

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

-4

-3

-2

-1

0

1

2

LSL

3

4

USL

4σ

Manufacturing

65

Capability from the Quality Loss Function

QLF = L(x) =k*(x-x*)2

x*

Given L(x) and p(x) what is E{L(x)}?

Manufacturing

66

Expected Quality Loss

E{L(x)} = E[k(x − x*)

2

]

= k [E(x ) − 2E(xx*) + E(x * )]

2

2

= kσ + k( μx − x*)

2

x

Penalizes

Variation

Manufacturing

2

Penalizes

Deviation

67

Process Capability

•

•

•

•

•

The reality (the process statistics)

The requirements (the design specs)

Cp - a measure of variance vs. tolerance

Cpk - a measure of variance from target

Expected Loss- An overall measure of

goodness

Manufacturing

68