Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

Contents lists available at ScienceDirect

Journal of Unconventional Oil and Gas Resources

journal homepage: www.elsevier.com/locate/juogr

Regular Articles

Coalbed methane produced water screening tool for treatment technology

and beneficial use

Megan H. Plumlee a,⇑, Jean-François Debroux a, Dawn Taffler a, James W. Graydon a, Xanthe Mayer b,

Katharine G. Dahm b,1, Nathan T. Hancock b, Katie L. Guerra b,1, Pei Xu b,2, Jörg E. Drewes b,3, Tzahi Y. Cath b,⇑

a

b

Kennedy/Jenks Consultants, San Francisco, CA 94107, United States

Colorado School of Mines, Golden, CO 80401, United States

a r t i c l e

i n f o

Article history:

Received 8 June 2013

Revised 1 November 2013

Accepted 13 December 2013

Available online 28 December 2013

Keywords:

Produced water

Beneficial use

Environment

Treatment costs

Coal bed methane

a b s t r a c t

Produced water is a byproduct of oil and gas production and represents the largest volume waste stream

in the oil and gas industry. Due to the high demand for water and the costs associated with current produced water disposal practices, energy companies and local water users are interested in cost-effective

alternatives for beneficial use of produced water. The main objective of this study was to apply a previously developed and publicly available coalbed methane produced water screening tool to two simulated

case studies to determine site-specific produced water treatment technologies and beneficial use options,

as well as costs, using realistic conditions and assumptions. Case studies were located in the Powder River

(Wyoming) and San Juan (New Mexico) Basins. Potential beneficial uses evaluated include crop irrigation,

on-site use, potable use, and instream flow augmentation. The screening tool recommended treatment

trains capable of generating the water quality required for beneficial use at overall project costs that were

comparable to or less than existing produced water disposal costs, given site-specific conditions and

source (raw produced) water quality. In this way, the tool may be used to perform a screening-level cost

estimate for a particular site to determine whether the costs per barrel for beneficial use are more or less

than site-specific disposal costs. The demonstrated technical and economic feasibility provide incentives

to address the institutional and legal challenges associated with beneficial use of produced water.

Ó 2013 Elsevier Ltd. All rights reserved.

Introduction

Water is generated as a byproduct of oil and gas production and

represents the largest volume waste stream in the industry (GWI,

2011). For coalbed methane (CBM) (coalbed natural gas), produced

water is pumped to the surface during well development and production, dewatering the formation to enable release of gas from the

coal seams. CBM production in the western United States (US) has

grown significantly during the past two decades and will play a key

role in the nation’s energy portfolio in the future. Water produced

during gas extraction must be managed and disposed of according

to state and federal regulatory and permit requirements, and

⇑ Corresponding authors. Address: Kennedy/Jenks Consultants, 303 Second St.,

Suite 300 South, San Francisco, CA 94107, United States. Tel.: +1 (415) 243 2471

(M.H. Plumlee). Address: Department of Civil and Environmental Engineering,

Colorado School of Mines, 1500 Illinois St., Golden, CO 80401, United States.

Tel.: +1 (303) 273 3402 (T.Y. Cath).

E-mail addresses: MeganPlumlee@KennedyJenks.com (M.H. Plumlee), tcath@

mines.edu (T.Y. Cath).

1

Present address: Bureau of Reclamation, Denver, CO 80225, United States.

2

Present address: New Mexico State University, Las Cruces, NM 88011, United

States.

3

Present address: Technische Universität München, 85748 Garching, Germany.

2213-3976/$ - see front matter Ó 2013 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.juogr.2013.12.002

therefore produced water is a significant factor in the profitability

of oil and gas production wells. Once the cost of managing and disposing of produced water reaches a critical threshold relative to

the value of extracted gas, the CBM well is ‘‘shut in’’ (gas production is discontinued). Produced water disposal is typically via deep

well injection or treatment and discharge, and therefore represents

an operational challenge, an environmental risk, and a major cost

for energy companies (NRC, 2010).

Faced with increasing regulations, discharge water quality

requirements, and costs associated with current disposal practices,

energy companies are interested in cost-effective alternatives for

disposal or beneficial use of their produced water. Produced water

quantity, supply duration, and quality are key factors in evaluating

potential beneficial uses. Beneficial use of produced water has the

potential to minimize environmental impacts while providing a

cost effective alternative to disposal, enhancing longevity and

therefore gas recovery of CBM and gas shale fields. It also represents a new water source, potentially significant for the arid and

semi-arid west of the United States and other regions around the

globe. However, beneficial use of produced water faces many technical, economic, regulatory, and institutional challenges.

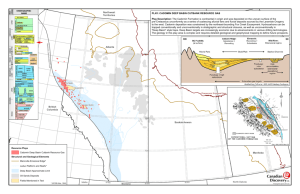

More than 80% of current US CBM production takes place in the

Rocky Mountain region, which includes the Powder River and San

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

Juan Basins (Fig. 1). These two basins capture and contrast the

known range of produced water quantity, quality, and management in western CBM basins (NRC, 2010) and were therefore selected as the locations for the case studies evaluated. The Powder

River Basin extends between Wyoming and Montana, encompassing more than 25,000 square miles. The number of wells, gas production, and associated water production in the basin have

increased dramatically since 1997. CBM and co-produced water

are extracted from coal layers in the Paleocene Fort Union Formation and the overlying Eocene Wasatch Formation. The coal beds in

the Fort Union Formation are on average 25 feet thick (NRC, 2010;

Rice et al., 2002). The San Juan Basin covers approximately 7500

square miles in northwestern New Mexico and southwestern Colorado, with the majority located in the New Mexico portion of the

basin (Fig. 1). Much of the CBM development in the San Juan Basin

began in the 1980s, and by 2009, over 7000 CBM wells were active

in the basin (NRC, 2010). The main methane-bearing unit is the

Fruitland Formation, with CBM production at depths ranging from

550 to 4000 feet (NRC, 2010). The average thickness of coal seams

is 6–9 feet with a maximum of 40 feet (ALL, 2003).

The main objective of the present study was to apply a previously developed and publicly available spreadsheet-based screening tool for CBM produced water to two simulated case studies

to determine site-specific produced water treatment technologies

and beneficial use options, using realistic conditions and assumptions. Potential beneficial uses that were evaluated include crop

23

irrigation, on-site use, potable use, and instream flow augmentation, among others.

Methodology

Case studies development

Two simulated case studies were evaluated using the Produced

Water Treatment and Beneficial Use Screening Tool (Screening

Tool). The Screening Tool was previously developed by the

Colorado School of Mines, Kennedy/Jenks Consultants, Stratus

Consulting, and Argonne National Laboratory as a decision framework to aid in the evaluation of CBM produced water treatment

and use given particular site conditions and user preferences

(CSM/AQWATEC, 2013a). The Screening Tool was developed as part

of an effort to address a lack of public information on selecting and

applying technologies to treat produced water for beneficial use,

increasingly important as interest in beneficial use of produced

water grows (Stewart and Takaichi, 2007). The Screening Tool

and related information are available on the project website

(CSM/AQWATEC, 2013b), including a case study report that

provides screenshots of the tool. Potential users include energy

companies and water practitioners that are interested in reducing

the disposal costs associated with, and the beneficial use of,

produced water.

Given CBM produced water volume, quality, anticipated supply

duration, and other conditions, the Screening Tool was used to

determine treatment technology alternatives and costs, potential

beneficial uses, and overall project costs for these uses. The Screening Tool also predicts treated water quality for the recommended

treatment train. The simulated case studies use data and information that are representative of the selected site locations. This

information was developed using interviews with representatives

of two energy companies, literature review, and data analysis. Sufficient information was collected or assumed to utilize all aspects

of the Screening Tool. Because local regulations control the allowed

produced water disposal methods or beneficial uses to an energy

company, an evaluation of relevant Wyoming and New Mexico

regulations (where the case studies take place) was conducted

and a summary is available in the Supporting information (SI).

Screening Tool inputs

Fig. 1. Selected coalbed methane basins in the Rocky Mountain region of the

western US.

The Screening Tool evaluates potential beneficial use projects

using four modules: Water Quality Module (WQM), Treatment

Selection Module (TSM), Beneficial Use Selection Module (BSM),

and Beneficial Use Economic Module (BEM). A description of the

modules is available in the Screening Tool User’s Manual

(CSM/AQWATEC, 2013c), and the flow of data is illustrated in

Fig. 2. Inputs to the WQM include the project location, produced

water quality, and average and peak flow rates from the well field

available for beneficial use. For produced water quality, the user

may input known water quality or use default water quality based

on the location from an extensive produced water quality database

that was developed to support the Screening Tool (CSM/AQWATEC,

2013a; Dahm et al., 2011). Peak flow rate is used by the Screening

Tool to size the treatment influent storage facility, and for the

present case studies, was estimated as a 50% increase of the average flow rate to account for operation of additional wells or wells

at peak (initial) flow. For the Powder River Basin case study, water

quality data available for wells in the region were input to the

WQM (see screenshot of Screening Tool step in Fig. 3), whereas

for the San Juan Basin case study, default water quality available

in the Screening Tool was selected based on project location (see

screenshot in Fig. 4).

24

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

Fig. 2. Flow of information through the four modules of the Screening Tool

(CSM/AQWATEC, 2013c).

In addition to data imported from the WQM, the TSM requires scoring based on the importance determined by the user

for 12 screening criteria (i.e., footprint, energy demand, modularity, capital cost, etc.; see screenshot in Fig. 5 for example),

as well as information on the preferred percent water recovery

for any desalination technologies. The preferable treatment approach for produced water depends on the beneficial use. Several potential beneficial uses may be considered (NRC, 2010;

ALL, 2003, 2006). The Screening Tool groups beneficial uses into

five categories listed in the first column of Table 1, and uses a

set of water quality criteria for key parameters for each of the

five categories. For example, the TDS criterion for Category 2

(crop irrigation) is 5000 mg/L, compared to 500 mg/L for Category 5 (potable use). In addition to the treated water quality

criteria, the influent quality (produced water source) from the

WQM, and the above user-input screening criteria, the TSM selects treatment technologies based on an analysis of over 40

produced water treatment technologies reported previously

(CSM/AQWATEC, 2009).

Inputs to the BSM include data generated by the TSM, information on the anticipated produced water supply duration and

reliability, and the estimated current cost of produced water

disposal ($/barrel (bbl)) for comparison to the beneficial use costs.

Based on these inputs, the BSM estimates treatment costs and

scores project feasibility (more details are provided in

Section ‘Beneficial uses’).

The BEM requires information on the selected overall beneficial

use project, such as land area and infrastructure required, in

addition to the information generated in the WQM, TSM, and

BSM. Based on these inputs, the BEM estimates the overall project

costs. Additionally, the BEM provides a range of the estimated

potential value of the produced water for the selected beneficial

use ($mil/year), as well as estimated environmental and social benefits ($mil/year), to provide further context for the estimated costs.

The value ranges are provided in the tool for each beneficial use

and were based on input from one of the tool developers (Stratus

Consulting) with expertise in water resources valuation (Stratus

Consulting, 2006). An exhaustive presentation of the assumptions

and analysis for determining the value of the water and associated

benefits is outside the scope of this article. The estimated value of

environmental and social benefits are intended to provide a broad

assessment of potential opportunities that may be available to

support the beneficial reuse of produced water.

Many of the case study inputs are presented with the results

below, and more detailed information on the inputs and screen

shots of the module outputs are available online (CSM/AQWATEC,

2013b).

Background on case study locations

Produced water volume and quality

The average water production rate during CBM extraction for

the 1995–2005 period in the Powder River Basin was 2.2 bbl per

thousand cubic feet (MCF) of gas, compared to 0.03 bbl per MCF

Fig. 3. Produced water quality data for Powder River Basin case study (screenshot of WQM output). Notes: Water quality data input from Dahm et al. (2011) or, if no data was

available, from the Screening Tool WQM database.

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

25

Fig. 4. Produced water quality data for San Juan Basin case study (screenshot of WQM output). Notes: Water quality data input from the Screening Tool WQM database.

Fig. 5. TSM selection criteria user scores for the Powder River Basin case study (screenshot).

Table 1

Potential beneficial uses and preferred treatment trains for the Powder River Basin, Wyoming case study from the Treatment Selection Module (TSM) of the Produced Water

Treatment and Beneficial Use Screening Tool.

Screening tool category beneficial use

Preferred treatment traina

1

2

3

4

No treatment required

Anion IX

Anion IX

Chemical disinfection, media filter, tight NF (brine disposal: deep well injection)

– Livestock watering; impoundments; dust control

– Crop irrigation; non-potable use

– Constructed wetlands

– Surface water discharge/instream flow augmentation;

fisheries

5 – Potable use; aquifer storage and recovery (ASR)

Chemical disinfection, media filter, tight NF, chemical disinfection (brine disposal: deep well

injection)

Anion IX = anion exchange; ASR = aquifer storage and recovery; NF = nanofiltration.

a

Descriptive information for each unit process is available in CSM/AQWATEC (CSM/AQWATEC, 2009).

in the San Juan Basin (Osborne and Adams, 2005), where one bbl is

equal to 42 US gallons (159 L). Based on average data, water

production from San Juan Basin CBM wells is 25 bbl/day per well

(USGS, 2000). The amount of water produced from an individual

26

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

CBM extraction well typically declines over the course of gas production (e.g., approximately 10 years, see Fig. 6). For a group of

wells or a well field, the total water production available for beneficial use depends on management practices such as the timing of

bringing new wells online while others are being shut in or their

water production rate declines. Well spacing ranges approximately

40–80 acres per well in the Powder River Basin (ALL, 2003) and

160–320 acres per well in the San Juan Basin (Bryner, 2002). A produced water supply may be maintained by the operation of new

wells within the well field or nearby.

With respect to water quality, the major constituents of interest

in produced water are the salt content (as total dissolved solids

[TDS] and conductivity), oil and grease, total organic carbon, various inorganic and organic chemicals, and naturally occurring

radioactive material (CSM/AQWATEC, 2013d). The salt content of

produced water can range from as high as 170,000 mg/L TDS,

which is approximately five times the concentration of seawater,

to as low as 200 mg/L TDS, which is below the EPA secondary

drinking water standard (500 mg/L TDS) (NRC, 2010; Rice et al.,

2002; CSM/AQWATEC, 2013d). Compared to CBM produced water

from the Powder River Basin in Wyoming and Montana, produced

water from the San Juan Basin in Colorado and New Mexico is high

in salinity, with TDS concentrations that can sometimes exceed

100,000 mg/L. Therefore, produced water from the San Juan Basin,

without treatment, is expected to exceed water quality standards

for drinking water, agricultural irrigation, and livestock watering

applications (NRC, 2010).

Existing disposal infrastructure

Information on existing produced water disposal practices is

not necessary to run the CBM produced water Screening Tool,

but was reviewed for informational purposes based on case study

interviews and literature review.

In the Powder River Basin, multiple disposal options for produced water may be exercised by a single energy company in a given area (ALL, 2003, 2006). Disposal methods and uses that require

treatment are generally avoided where possible given the cost of

water treatment and the fact that no revenue is typically received

for produced water delivery (e.g., for irrigation and livestock

watering by local ranchers). The primary disposal options in the

state of Wyoming are direct discharge to surface waters with or

without treatment, depending on water quality, injection (such

as into a deep well or using shallow, subsurface drip systems), or

disposal into impoundments, referred to as pits or reservoirs in

Wyoming regulations (NRC, 2010; Wyoming SEO, 2011; WOGCC,

2011; Wyoming DEQ, 2011). A description of the Wyoming CBM

regulatory framework is provided in the SI. Even though stream

discharge may be considered beneficial use (i.e., instream flow

augmentation), operators view it as disposal.

In a typical scenario, an operator will construct a pipeline network to transport water from wells to various disposal routes

and uses, none of which usually produce revenue. The pipelines

are located 6 feet underground and deliver water produced from

a single well, if it is in a geographically remote location, or more

often from a group of nearby wells (e.g., up to 100 wells), to a trunk

line. The produced water discharges are comingled regardless of

water quality, which can vary for different wells. Water is rarely

delivered by gravity and must be pumped. Depending on the distance between clusters of wells and disposal routes, as well as limitations imposed by local land owners or other factors, water may

be transported over distances ranging from less than a mile to

more than 20 miles. Water may be delivered to multiple endpoints

including on or offsite treatment plants if treatment is required for

disposal compliance, to stream discharge, to a deep injection well,

or most commonly, to impoundments.

A typical Powder River Basin operator may manage hundreds

of impoundments near wells and groups of wells ranging in

capacity from less than 1 acre-foot (1233 m3) to up to 100 acrefeet (123,000 m3). Photographs of a produced water aeration

structure (for treatment) and nearby impoundment are provided

in Fig. 7. Impounded water evaporates and infiltrates into the

ground as a means of disposal. Wyoming regulations require

groundwater monitoring beneath the impoundments. From

impoundments, some water may be diverted to beneficial uses

such as irrigation by local ranchers, livestock watering, or on-site

uses (e.g., road dust control, drilling, and enhancing wells). For

untreated irrigation water where water quality is sometimes

unsuitable for ranchers, the produced water may be treated by

gypsum addition to reduce sodium adsorption ratio (SAR) and

salting of the soils.

In contrast to CBM producers in the Powder River and other basins who rely on a combination of multiple disposal options, the

primary disposal option in the San Juan Basin is deep well injection

with minimal treatment (NRC, 2010). A 2002 study indicated that

99.9% of produced water in the San Juan Basin is injected (Bryner,

2002). This is due to the relatively low volumes and high salinity of

produced water in the San Juan Basin. However, deep well injection is a costly disposal method and provides no significant benefit.

Most producers temporarily store the produced water in aboveground storage tanks prior to injection. Treatment by chlorination

is required prior to injection to address bacterial contamination,

Barrels of Produced Water Per Day (bbl/d)

1400

Well 1

1200

Well 2

Well 3

1000

Well 4

Well 5

800

Well 6

600

Well 7

Well 8

400

Well 9

Well 10

200

Mean

0

0

2

4

6

8

10

12

Time (years)

Fig. 6. Mean water production curves (bbl/d) over the life of CBM wells (Powder River Basin case study).

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

27

Fig. 7. Produced water aeration structures in the Powder River Basin used to remove iron and manganese prior to impoundment.

and filtration is commonly conducted to prevent plugging of the

injection well (NRC, 2010).

Deep injection wells in the San Juan Basin are either companyowned or commercially operated. To transport produced water

from the storage tanks to the injection wells, operators use pipelines or commercial trucking services, depending upon the location

of the well. Aquifer replenishment and enhanced gas recovery may

be ancillary benefits of well injection (NRC, 2010). With respect to

produced water disposal, a description of the New Mexico CBM

regulatory framework is available in the SI.

Hydraulic fracturing

In the course of completing this study, hydraulic fracturing was

identified as a key potential beneficial use of interest for the San

Juan Basin produced water. Hydraulic fracturing is a well stimulation process that uses water to enhance natural gas recovery. Produced water is increasingly recognized as a source water and is

being used for hydraulic fracturing, driven by high produced water

disposal costs coupled with water scarcity (AWI, 2011). Fluids and

sand are injected under pressure into the formation to form fractures and pathways for gas (or oil, in the case of oil production)

to reach the well. Then the gas, fracturing fluids, and produced

water are pumped to the surface (flowback) for recovery and disposal. Estimates of the fluids recovered range from 15% to 80%

(i.e., a portion of the water used for hydraulic fracturing returns

to the surface in the flowback, along with produced water [groundwater]) (AWI, 2011; EPA, 2004).

Hydraulic fracturing is infrequently used in the Powder River

Basin where the natural permeability of the methane-bearing formations is high, but it is commonly used in the San Juan Basin

(NRC, 2010). Each well may require fracturing at multiple depths,

and each fracturing event requires thousands of barrels of water,

depending on the fracturing method used. Required volumes range

from 50,000 to 350,000 gallons in a coalbed formation (EPA, 2004)

to 2–6 million gallons per well in a shale formation (AWI, 2011;

Stewart, 2011; EPA, 2010). Currently, water from the San Juan

and Animas Rivers is used as the base fluid for hydraulic fracturing

in the San Juan Basin (Huang et al., 2005). Alternatively, produced

water from adjacent wells can be beneficially used for fracturing

operations. Produced water volume from a given well will typically

exceed the volume required for hydraulic fracturing of that well,

and thus excess water is available for other beneficial uses or must

be disposed. These other beneficial uses may be considered using

the Screening Tool.

Results and discussion

Powder River Basin, Wyoming

Produced water volume and quality

The Powder River Basin simulated case study focuses on produced water from an assumed group of 400 wells operating in an

80-square mile area in the Wyoming part of the basin. The

assumed well spacing is relatively large at approximately 130 acres

per well. The anticipated life of this well field and associated water

production, in terms of the longevity of the gas resource, is

10–20 years, depending upon the continued development of

additional wells within the well field area.

The produced water volume, quality, and existing disposal

approach utilized for the case study are representative of energy

companies operating in the basin. A mean production curve

(Fig. 6) was developed by averaging produced water quantity data

for ten CBM wells having at least a ten-year history, available from

the Montana Online Oil and Gas Information System for Big Horn

County (DNRC, 2010) located in the Powder River Basin. The production curve is consistent with production behavior described

by energy companies during case study interviews. Operators stagger the initiation of new wells in order to manage and minimize

the total volume and variability of produced water from a well

field, because water production is highest at the early stage of well

production. Additional constraints, such as wildlife-related permitting restrictions, may limit new well construction to certain periods. The case study produced water volume available for

beneficial use from the 400-well field was estimated assuming

the mean well production curve (Fig. 6) and yearly initiation of

new wells according to an assumed permitting schedule over a

20 year period, resulting in an average total water production of

45,000 bbl/d (1.9 MGD; 2120 acre feet per year; 7200 m3/d). This

value was input to the WQM of the Screening Tool.

Average produced water quality utilized for the case study is

provided in Fig. 3 and was based on water quality data for approximately 90 wells in the Powder River Basin in Wyoming (Dahm

et al., 2011). The average TDS concentration of the dataset is

912 mg/L, which is less than the limit for beneficial use for irrigation in Wyoming (2000 mg/L) and for livestock watering (5000 mg/

28

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

L), and would generally be considered fresh water (<1000 mg/L

TDS) (NRC, 2010). The average conductivity and SAR are 1493 lS/

cm and 12.9, respectively. Based on these parameters, the

produced water has a slight to moderate infiltration hazard with

respect to irrigation (Ayers et al., 1985). With respect to stream

discharge, the average conductivity meets standards for the Powder River in Wyoming (Montana DEQ, 2003; based on requirements for downstream Montana), but the average SAR exceeds

the standard and thus the produced water requires treatment prior

to any stream discharge.

Treatment technology

For the Powder River Basin case study, the Screening Tool recommended the treatment trains listed in Table 1 for the five beneficial use categories. No treatment is necessary in this case for

uses such as dust control and livestock watering, but treatment

is recommended for other beneficial use categories. For all categories, product water quality using the recommended treatment

meets the category water quality criteria, with brines ranging from

2400 to 3600 mg/L TDS for an influent quality of 1200 mg/L TDS

(using 75th percentile constituent concentration values for conservative design). Alternative treatment trains are also recommended

by the Screening Tool for each category (not shown), which the

user may choose to carry forward for further beneficial use and

economic evaluation in later modules. The recommended brine

(a high-TDS, concentrated waste stream) disposal method is deep

well injection, which may not require costly well construction if

an injection well is already available to the operator, such as from

previous injection of anion exchange wastewater from produced

water treatment (e.g., EMIT Technologies system (CSM/AQWATEC,

2009)) for disposal compliance.

The water quality criteria used by the TSM are representative of

general requirements for beneficial uses, and therefore may differ

in some cases from site-specific user requirements. With respect

to the Powder River Basin case study, for example, Wyoming regulations specify effluent limitations of 2000 mg/L chloride,

3000 mg/L sulfate, and 5000 mg/L TDS for stream discharge and

water accessible to livestock and/or wildlife (CSM/AQWATEC,

2013e). Additionally, stream discharge to the Powder River must

not exceed a monthly average conductivity of 2000 lS/cm and an

SAR of 5.0 during the irrigation season (NRC, 2010; Wyoming

DEQ, 2003) to protect downstream uses of surface water for irrigation in Montana. However, the influent produced water quality for

the case study already meets the chloride, sulfate, TDS, and conductivity criteria. The TSM-predicted product water quality for

SAR exceeds the regulatory limit, and therefore post-treatment

(SAR adjustment) may be required for beneficial use by stream discharge and crop irrigation. This evaluation demonstrates that for

Table 2

Summary of the Beneficial Use Selection Module (BSM) results for the Powder River Basin case study. Feasibility is scored from

most feasible (5) to least feasible (1).

29

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

site-specific water quality criteria not captured by the Screening

Tool, if any, evaluation of TSM-predicted product water quality

against these criteria will be required.

Beneficial uses

All of the produced water (45,000 bbl/day; 2120 acre feet per

year; 7200 m3/d) from the Powder River Basin well field in the case

study is theoretically available for beneficial use, excluding the volume of any brine produced. While treatment may be used to address water quality requirements, the total water quantity and,

importantly, the anticipated duration and reliability of the supply,

have a significant bearing on the feasibility of beneficial use. For

the Powder River Basin case study BSM inputs, the water quantity

range was 1–5 MGD (3785–19,000 m3/d), the supply timing/reliability was indicated as ‘‘consistent’’ for (at least) 5 years, and

the base flow duration was indicated as (at least) five years. These

inputs were selected based on an anticipated well field life of 10–

20 years, given that 30-year time frames are the next-highest BSM

input choice.

Using this information, the BSM of the Screening Tool scores the

feasibility for each of those three criteria (water quantity, timing/

reliability, and duration), resulting in a net feasibility for each beneficial use. Also estimated are the potential economic value, capital

cost for treatment equipment, and power consumption. The Powder River Basin case study beneficial uses were all at least moderately feasible, as summarized in Table 2. Assumptions that provide

the basis for the feasibility and other scores are provided in graphs

and tables in the Screening Tool. As an example, the score of 3.7 for

potable use was based on equally-weighted scores of 5, 3, and 3 for

water quantity, supply timing/reliability, and duration of supply,

respectively. The weighting can be changed by the user. Water

quantity received a high score based on the Screening Tool

assumption of maximum feasibility when the flow is at least 1

MGD. The supply reliability and duration are moderate (consistent

base flow for at least 5 years); therefore, the Screening Tool assumes a score of 3 for each. These are qualitative assumptions

translated into a quantitative score based on professional

experience and judgment of the tool developers. In this case, large

flow projects are preferable to initiate a potable use project due to

regulatory requirements, public perception, and technical issues.

Though aquifer storage and recovery (ASR) has a relatively high

treatment capital cost (Table 2), it ranked the highest in terms of

project feasibility and highly for potential value, with moderate

power consumption. Potable use and non-potable use screening

results were similar to ASR except for lower project feasibility. Surface water discharge/instream flow augmentation ranked highest

in potential economic value (i.e., to potential downstream users)

with moderate feasibility and power consumption, though at a

high treatment capital cost. Crop irrigation had a fairly high feasibility with some potential value at a low treatment capital cost,

though at a relatively high power consumption. As reported in

the TSM Output, the relatively high power consumption (also for

constructed wetland and non-potable use) is due to the anion exchange unit process in the recommended treatment train for these

beneficial uses.

Project costs assumptions

Project costs beyond the treatment capital costs (output by the

BSM) were explored for beneficial uses of interest using the BEM of

the Screening Tool. For example, land may need to be purchased or

leased, pipelines built, and facilities require operations and maintenance (O&M). Three potential beneficial uses were selected to

carry through to the evaluation in the BSM: ASR, surface water

discharge/instream flow augmentation, and crop irrigation. For

all three projects, the project life is assumed to be 15 years, required land is leased (not purchased or previously owned), and

the local interest rate and energy cost are indicated – all user inputs to the Screening Tool. To estimate costs associated with flow

storage and equalization prior to treatment, a storage volume associated with 60 days of peak flow above design capacity was selected. Staff number and control system assumptions were also

input. For ASR, percolation ponds (rather than injection wells)

were selected as the new infrastructure with a project area of

approximately 70 acres (based on an estimate available from the

Screening Tool). For surface water discharge and crop irrigation

projects, a project area of 1-acre (for delivery pipeline and

discharge facility to the stream) and 0-acres (assume land is owned

by rancher), respectively, was assumed. The associated new infrastructure was a discharge facility for surface water discharge, and

retrofits to existing irrigation systems for crop irrigation. The

Table 3

Comparison of three potential project scenarios (beneficial uses) and cost estimates for the Powder River Basin case study from the Beneficial Use Economic Module (BEM).

a

b

[Input] or Output

Units

Beneficial Use Economic Module, project scenarios

[Project name]

–

Percolation ponds

[Location]

–

City A, Wyoming, Powder River Basin

Surface water discharge

Crop irrigation

[Beneficial use]

–

Aquifer Recharge, Storage and Recovery

Surface Water Discharge/ Instream Flow Augmentation

Crop irrigation

Treatment traina

–

Filter-NF-Re-inject

Filter-NF-Re-inject

Anion IX

[Water quantity (design flow)]

mgd

gpm

bbl/day

1.9

1300

45,000

1.9

1300

45,000

1.9

1300

45,000

[Project life]

years

15

15

15

[Interest rate]

%

5%

5%

5%

Estimated project capital cost total

$ million

45

35

30

Annualized capital costs

$mil/year

4.0

3.1

2.5

Annual O&M costs

$mil/year

1.8

1.1

2.1

Total annualized costs

$mil/year

avg $/bblb

5.8

0.35

4.2

0.26

4.5

0.27

Estimated value of produced water

for selected beneficial use

$mil/year

$3.4–$10

$3.8–$15.4

$0.3–$3.1

Estimated environmental benefits

$mil/year

n/a

$0.2–$1.24

n/a

Estimated social benefits

$mil/year

$0.03–$3.94

$0.03–$3.94

$0.07–$3.59

For complete treatment train, see Table 1.

Based on design flow.

30

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

estimated conveyance distance for pipeline construction was five

miles between the produced water source (collected from the well

field using existing water management infrastructure) and the project area for ASR and surface water discharge (e.g., percolation

ponds, stream) and 15 miles for crop irrigation.

Screening-level estimated project costs

A summary of the project costs is presented in Table 3.

Compared to disposal costs for produced water, the results indicate

that beneficial use can be economically competitive. If revenue is

received for the beneficial use, then the comparison becomes

increasingly favorable. The BEM results indicate that the total estimated annualized costs, which include the cost of the treatment

technology and additional costs associated with the beneficial

use project, are $4.2 million per year ($0.26/bbl) for surface water

discharge, $4.5 million per year ($0.27/bbl) for crop irrigation, and

$5.8 million per year ($0.35/bbl) for ASR. The per-barrel estimates

refer to barrels of raw produced water. These low costs may reflect

the relatively high quality of CBM produced water in the Powder

River Basin.

For comparison to these costs of beneficial use, a range of costs

for produced water disposal is reported by operators in the Powder

River Basin. There is no one ‘‘typical’’ disposal cost per barrel that is

representative of all sites. Based on interviews conducted in 2000–

2001 for the area, reported costs range from $0.01/bbl (for utilizing

a pipeline collection system with impoundment discharge), $0.20/

bbl (for pumping to an injection system), to $2/bbl (for hiring a

commercial water hauling service). Estimated values may not take

into account full costs such as weed control for pit maintenance

(Boysen et al., 2002), environmental compliance monitoring, company truck fuel, and chemicals for corrosion and scale control at

injection wells. Approximately 15–18% of produced water in the

Powder River Basin is treated to address SAR and conductivity for

NPDES-permitted discharge, at reported treatment costs of approximately $0.12 to $0.60/bbl (NRC, 2010). In this way, the Screening

Tool may be used to perform a screening-level cost estimate for a

particular site to determine whether the costs per barrel for beneficial use are more or less than site-specific disposal costs. Potential

value of the beneficial use may also be considered (Table 3), which

could significantly offset or even exceed the beneficial use project

costs if realized by seeking revenue or project cost sharing for providing the high quality water to a user.

San Juan Basin, New Mexico

Produced water volume and quality

For the San Juan Basin simulated case study, an area of approximately 550 square miles was assumed to contain over 1500 wells,

with continual development of new wells via increasing well

density and development in new areas. At rates typical for the

San Juan Basin, the total water production for the case study is

approximately 37,500 bbl/day, or 1.6 MGD (1800 acre feet per

year; 6056 m3/d).

Default water quality data available in the Screening Tool was

used for the San Juan Basin produced water quality (Fig. 4). The default San Juan Basin TDS concentration for the Fruitland Formation

is approximately 8000 mg/L. The SAR is also relatively high at 81.

Some organic contaminants (e.g., benzene, xylenes) are present

at low concentrations.

Treatment technology

For the San Juan Basin case study, the Screening Tool recommended the treatment trains listed in Table 4 for the five beneficial

use categories, based on user-input criteria and default influent

(produced water source) quality. The default water quality is

determined from an extensive database that was constructed to

support the Screening Tool, as described in Section ‘Screening Tool

inputs’. The Screening Tool provides estimates of the treated water

and brine water quality, capital costs, power consumption, equipment life, and brine volume produced from each of the treatment

trains. For four of the five beneficial use categories, the Screening

Tool recommended treatment involving an artificial wetland and

thermal distillation (among other unit processes, Table 4). The similarity of recommended treatment trains is driven by the influent

water quality and user-input selection criteria (weighted preferences). Thermal distillation is recommended over membrane treatment (nanofiltration, NF) due to the high TDS of the feed water. In

practice, an engineer may prefer NF/reverse osmosis (RO) followed

by brine distillation for these beneficial use categories. Recognizing

certain limitations of the existing Screening Tool, the next version

(currently under development) will allow the user to define a

treatment technology process (such as by excluding or including

specific processes).

For the San Juan Basin case study, percent recovery was set as

85%, as this higher recovery resulted in a lower cost due to the

decreased brine volume. The TSM provides the anticipated product

water and brine quality for each treatment train/beneficial use

category. With respect to the brine produced from thermal distillation, the TSM indicated a brine concentration and flow rate of

approximately 54,000 mg/L TDS and 5600 bbl/day, respectively

(for 85% recovery). The daily brine volume is larger if the combined

waste streams from other unit treatment processes in the treatment

train are considered (resulting in 10,000–14,000 bbl/day total for

the San Juan Basin case study, depending on the treatment train).

In the course of completing this study, hydraulic fracturing was

identified as a key potential beneficial use of interest for the San

Juan Basin. Water quality requirements for the base water used

in hydraulic fracturing vary depending upon the operator and their

site-specific hydraulic fracturing chemistry (i.e., proprietary

chemicals that will be added to the base water), as well as local

regulations. When river or ground water is used as the base fluid,

disinfection and low levels of organics, TDS (e.g., 500 mg/L),

Table 4

Potential beneficial uses and preferred treatment trains for the San Juan Basin, New Mexico case study from the Treatment Selection Module (TSM).

Screening Tool category beneficial use

Preferred treatment traina

1 – Livestock watering impoundments; dust

control

2 – Crop irrigation; non-potable use

Wetland, UV disinfection, media filter, acid cation IX (H), GAC, thermal distillation (Brine disposal: evaporation

ponds)

Wetland UV disinfection media filter, acid cation IX (H), GAC, thermal distillation (Brine disposal: evaporation

ponds)

Wetland UV disinfection media filter, acid cation IX (H), GAC, thermal distillation (Brine disposal: evaporation ponds

Wetland, UV disinfection, media filter, acid cation IX (H), GAC, thermal distillation (Brine disposal: evaporation

ponds)

UV disinfection, chemical softening coagulation, media filter, acid cation IX (H), thermal distillation, chemical

disinfestion (Brine disposal: evaporation ponds

3 – Constructed wetlands

4 – Surface water discharge/instream flow

augmentation, fisheries

5 – Potable use; ASR

Acid cation IX = acid cation exchange; ASR = aquifer storage and recovery; GAC = granular activated carbon; UV = ultraviolet.

a

Descriptive information for each unit process is available in CSM/AQWATEC (CSM/AQWATEC, 2009).

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

31

Table 5

Summary of the Beneficial Use Selection Module (BSM) results for the San Juan Basin case study. Feasibility is scored from most

feasible (5) to least feasible (1).

naturally occurring radionuclides (NORM), and barium or sulfate

are typically required (Stewart, 2011). However, new chemical

additives for hydraulic fracturing allow the use of higher TDS

water. This provision will be incorporated into the next version

of the Screening Tool. The current version of the Screening Tool

does not explicitly consider hydraulic fracturing as a type of beneficial use, and therefore does not score its feasibility in the BSM

(i.e., Table 5, next section) nor provide project cost estimates for

any necessary (non-treatment) infrastructure in the BEM. Nevertheless, the Screening Tool was valuable to assess potential treatment technologies and costs for this beneficial use by

conservatively assuming that water quality criteria for hydraulic

fracturing are similar to potable use criteria. Therefore, the treatment train recommended for potable use (Table 4) was assumed

to also be appropriate for hydraulic fracturing. Depending on the

operator, potable use criteria may be too stringent for hydraulic

fracturing; however, it represented a conservative choice for this

exercise. The next version of the Screening Tool (currently under

development) will accommodate additional beneficial uses and allow the user to define the target water quality for a specific beneficial use. In the meantime, users may select the beneficial use

category having water quality criteria (which are indicated in the

tool) most similar to their site-specific requirements.

Beneficial uses

For the San Juan Basin case study BSM inputs, the water

quantity range was 1–5 MGD, the supply timing/reliability was

indicated as ‘‘consistent’’ for (at least) 30 years, and the base flow

duration was indicated as (at least) 30 years. The reliability and

duration were based on an anticipated produced water supply life

of 15–20 years, or perhaps as long as 30 years depending on

continued development.

As described in the Powder River Basin case study, the BSM uses

this information to determine a net project feasibility, as well as

potential economic value, capital cost for treatment equipment,

and power consumption for five categories of beneficial use. The

case study beneficial uses were all characterized as highly feasible,

as summarized in Table 5, given that the water quantity is large,

the supply reliability is high, and the duration is long-term. All categories had similar capital costs and energy requirements associated with treatment due to the similar treatment trains

recommended.

Project costs assumptions

For the San Juan Basin case study, surface water discharge/instream augmentation use and hydraulic fracturing were selected

as the beneficial uses of interest for further evaluation and project

32

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

Table 6

Potential project scenarios and cost estimates for the San Juan Basin case study from the Beneficial Use Economic Module (BEM).

[Input] or Output

Units

Beneficial use economic module, project scenarios

[Project name]

–

Surface water discharge

[Location]

–

City B, New Mexico, San Juan Basin

–

Surface water discharge/instream flow augmentation See footnotea

[Beneficial use]

Treatment train

b

Hydraulic fracturing

–

Filter-IX-GAC-Thermal Distillation-Evap

Filter-IX-Thermal Distillation-Evap

[Water quantity (design flow)]

mgd

gpm

bbl/day

1.6

1,100

37,000

1.6

1,100

37,000

[Project life]

years

20

20

[Interest rate]

%

5%

5%

Estimated project capital cost total

$ million

65

51

Annualized capital costs

$mil/year

5.1

4.0

Annual O&M costs

$mil/year

5.0

4.5

Total annualized costs

$mil/year 10.1

avg $/bbl 0.75

8.5

0.63

Estimated value of produced water for selected beneficial use $mil/year

$3.1–$12.7

NAc

Estimated Environmental Benefits

$mil/year

$0.16–$1.02

NAc

Estimated Social Benefits

$mil/year

$0.03–$3.24

NAc

a

Hydraulic fracturing is not a category of beneficial use that is explicitly considered by the Screening Tool. ‘‘Potable Use’’ was selected for beneficial use category because

the water quality criteria employed by the tool for this use are most similar to hydraulic fracturing criteria (driven by relatively low TDS criteria) compared to other Screening

Tool beneficial use categories.

b

For complete treatment train, see Table 4.

c

Related to footnote ‘a’, estimated potential values predicted by the BEM are specific to the beneficial use category, and therefore in this case the values generated relate to

potable use not hydraulic fracturing.

cost assessment in the BEM of the Screening Tool. Surface water

discharge may be of particular interest to some Screening Tool

users for the potential marketing of treated water via surface water

discharge to downstream users. As described previously, hydraulic

fracturing is particularly relevant to the San Juan Basin region.

For surface water discharge, project inputs used to determine

overall project costs included one acre leased from the Bureau of

Land Management (BLM) for the treatment plant and construction

of the discharge facility to the river (which was selected as required new infrastructure). The conveyance distance from treatment to the discharge location was estimated to be 10 miles. For

hydraulic fracturing, the ‘‘potable use’’ beneficial use category

was used to represent hydraulic fracturing for the purposes of

treatment technology selection (as described in Section ‘Treatment

technology’), which automatically carries through to the BEM. The

resulting BEM project cost estimate is considered applicable because potable use-related infrastructure (e.g., pipelines, connection

to potable system) was indicated as not necessary via menu options in the BEM. This left an estimated project cost based solely

on treatment costs and 1-acre land area, plus facility, overhead,

and contingency costs. This is acceptable because hydraulic fracturing is an on-site activity already conducted using an alternate

water source and previously established infrastructure, and therefore additional land and infrastructure are not likely to be required

to employ use of produced water for this beneficial use other than

the treatment technology. For both projects, the project life was

estimated to be 20 years, local interest rates and energy costs were

assumed, and a storage pond with adequate volume for 14 days of

peak flow above design capacity was selected (for flow storage and

equalization prior to treatment).

Screening-level estimated project costs

A summary of the project costs is presented in Table 6.

Compared to disposal costs for produced water, the results indicate

that beneficial use can be economically competitive in the San Juan

Basin. If revenue is received for the beneficial use, then the

comparison becomes increasingly favorable. BEM results indicate

that the total estimated annualized costs, which include the

cost of the treatment technology and any additional costs associated with the beneficial use project are $10 million per year

($0.75/bbl) for surface water discharge and $8.5 million per year

($0.63/bbl) for hydraulic fracturing. These costs are comparable

to deep well injection costs for disposal of produced water in the

San Juan Basin, which is site-specific and averages $1 to $4 per

barrel. Produced water disposal costs per barrel tend to be higher

for commercially operated wells and/or if commercial trucking

services are used (Huang et al., 2005; Boysen et al., 2002). Screening Tool users estimating project costs for use of produced water

for hydraulic fracturing will also be interested in comparing the

costs to their existing (site-specific) costs for using other sources

of water.

The results of the BEM indicate that the potential beneficial use

projects may be less costly than the current disposal method in the

San Juan Basin. Additionally, for hydraulic fracturing, these costs

would replace the current costs of transporting the alternate water

source (e.g., San Juan River water). With respect to stream discharge, the potential economic value (Table 6) could significantly

offset or even exceed the beneficial use project costs.

Conclusions

Management and disposal of produced water, typically via deep

well injection or treatment and discharge, represents an operational challenge and a major cost for energy companies. The case

studies developed using the Produced Water Treatment and Beneficial Use Screening Tool were based on realistic conditions and

assumptions for the Powder River and San Juan Basins at the time

of the study, and demonstrated the feasibility of various beneficial

uses of produced water. Treatment technologies are available to

treat the produced water to the level of quality required for the

beneficial use, at an overall project cost that may be comparable

to or less than the existing disposal cost.

Further, costs associated with beneficial use may be offset by

potential value, if realized by seeking revenue for provision of

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

the high quality treated produced water. This may be achievable

given the high demand for water and its economic value in the arid

western United States. Example uses include local crop irrigation

and livestock watering, or indirect potable uses such as via ASR.

There are a few known cases in which produced water from oil

and gas activity was marketed and used for potable supplies

(NRC, 2010; Stewart and Takaichi, 2007; Stewart, 2006). Costs

may be offset by on-site use as well, such as for hydraulic fracturing. Unlike livestock watering, irrigation, and nearby potable users,

hydraulic fracturing and other on-site uses are not limited by the

proximity of a potential user to the produced water source and

do not require coordination between the energy company and another party. Water transfer to downstream users via stream discharge is also not limited by the proximity of the user. A

theoretical example is produced water discharged to rivers upstream of reservoirs used for potable water supply. Produced water

from the Powder River Basin is discharged to rivers upstream of

reservoirs and therefore has indirectly augmented these reservoirs

(ALL, 2006), though it has not been marketed or discharged directly

for this purpose.

The next version of the Screening Tool (currently under development) will accommodate additional beneficial uses and allow

the user to define the target water quality for a specific beneficial

use. Additionally, it will allow the user to define a treatment technology process and exclude or include specific processes, if desired.

The first update of the Screening Tool is estimated to be available

by the end of 2014.

While the Screening Tool case studies demonstrate the technical and economic feasibility of beneficial use of produced water,

which is increasingly recognized, there remain institutional and legal challenges, particularly with respect to water rights, water

marketing, and transfer. As an example, interstate water marketing

in the Colorado River Basin is discussed further in the SI. The oil

and gas industry’s unfamiliarity with the water industry, and vice

versa, represents a key challenge (Stewart and Takaichi, 2007).

Examples of other non-technical barriers to implementation of

beneficial use have been summarized in previous publications

(NRC, 2010; ALL, 2006).

The high demand and value of water, availability of cost-effective treatment technologies, and potential cost savings to energy

companies provide the incentives to address these challenges.

Technical and economic assessments like the presented case studies and some example projects (e.g., Stewart and Takaichi, 2007)

have taken steps forward to demonstrate feasibility.

Acknowledgments

The authors thank the Ultra-Deepwater and Unconventional

Natural Gas and Other Petroleum Resources Research and Development Program for funding the project (Grant #07122-12) as part of

the Research Partnership to Secure Energy for America program

administered by the US Department of Energy’s National Energy

Technology Laboratory. The authors also thank the regional participating CBM producers for their technical assistance, support, and

contributions of water quality and quantity data, and thank the

technical advisors of the study: David Stewart, John Veil, and

Wayne Buschmann.

Appendix A. Supplementary data

Supporting information associated with this article can be

found, in the online version, at http://dx.doi.org/10.1016/

j.juogr.2013.12.002.

33

References

ALL, 2003. Handbook on Coal Bed Methane Produced Water: Management and

Beneficial Use Alternatives, ALL Consulting, Ground Water Protection Research

Foundation, US Department of Energy, National Petroleum Technology Office,

Bureau of Land Management, Tulsa, Oklahoma (July).

ALL, 2006. Feasibility Study of Expanded Coal Bed Natural Gas Produced Water

Management Alternatives in the Wyoming Portion of the Powder River Basin,

Phase One. ALL Consulting, National Energy Technology Laboratory, Wyoming

State Planning Office, US Department of Energy (January).

AWI, 2011. Industrial news – drought and regulations push reuse in the shales.

American Water Intelligence 2 (8).

Ayers, R.S., Westcot, D.W., 1985. Water Quality for Agriculture: FAO Irrigation and

Drainage Paper, 29 Rev. 1. Food and Agriculture Organization of the United

Nations, Rome, Italy.

Boysen, D.B., Boysen, J.A., Boysen, J.E., 2002. Creative strategies for produced water

disposal in the Rocky Mountain Region. In: Nineth Annual International

Petroleum Environmental Conference, Albuquerque, NM, October 22–25,

2002. Available at: http://ipec.utulsa.edu/Conf2002/boysen_89.pdf (accessed

16.02.11).

Bryner, G., 2002. Coalbed Methane Development in the Intermountain West:

Primer. Natural Resources Law Center, University of Colorado School of Law,

Boulder, CO. Available at: http://www.colorado.edu/Law/centers/nrlc/

CBM_Primer.pdf (accessed 16.02.11).

CSM/AQWATEC, 2013a. Produced Water Treatment and Beneficial Use Information

Center, Colorado School of Mines (CSM) Advanced Water Technology Center

(AQWATEC).

Available

at:

http://aqwatec.mines.edu/produced_water/

(accessed 23.04.13).

CSM/AQWATEC, 2013b. Produced Water Treatment and Beneficial Use Information

Center: Beneficial Use Matrix – CBM Produced Water Management Tool,

Colorado School of Mines (CSM) Advanced Water Technology Center

(AQWATEC). Available at: http://aqwatec.mines.edu/produced_water/tools/

(accessed 25.07.11).

CSM/AQWATEC, 2013c. Produced Water Treatment and Beneficial Use Information

Center: Instructions and Download Links, Colorado School of Mines (CSM)

Advanced Water Technology Center (AQWATEC). Available at: http://

aqwatec.mines.edu/produced_water/tools/download/ (accessed 15.05.13).

CSM/AQWATEC, 2013d. Produced Water Treatment and Beneficial Use Information

Center: About Produced Water, Colorado School of Mines (CSM) Advanced

Water Technology Center (AQWATEC). Available at: http://aqwatec.mines.edu/

produced_water/intro/pw/ (accessed 08.12.10).

CSM/AQWATEC, 2013e. Produced Water Treatment and Beneficial Use Information

Center: State Regulations, Colorado School of Mines (CSM) Advanced Water

Technology Center (AQWATEC). Available at: http://aqwatec.mines.edu/

produced_water/regs/state/ (accessed 08.12.10).

CSM/AQWATEC, 2009. An Integrated Framework for Treatment and Management of

Produced Water: Technical Assessment of Produced Water Treatment

Technologies, first ed., RPSEA Project 07122-12. Colorado School of Mines

(CSM) Advanced Water Technology Center (AQWATEC). Available at: http://

aqwatec.mines.edu/produced_water/treat/ (accessed 23.04.13).

Dahm, K.G., Guerra, K.L., Xu, P., Drewes, J.E., 2011. A composite geochemical

database for coalbed methane produced water quality in the Rocky Mountain

Region. Environ. Sci. Technol. 45 (18), 7655–7663.

Montana DEQ, 2003. Record of Decision for Montana Statewide Oil and Gas

Environmental Impact Statement, Department of Environmental Quality,

Billings: Montana Board of Oil & Gas Conservation. Available at: http://

bogc.dnrc.state.mt.us/pdf/rodaug7_03.pdf (accessed 14.12.10).

DNRC, Montana Online Oil and Gas Information System, Montana Department of

Natural Resources and Conservation, 2010. Available at: http://

bogc.dnrc.state.mt.us/jdpintro.asp (accessed 07.12.10).

EPA, 2004. Evaluation of Impacts to Underground Sources of Drinking Water by

Hydraulic Fracturing of Coalbed Methane Reservoirs (Final Report), EPA 816-R04-003. United States Environmental Protection Agency. Available at: http://

water.epa.gov/type/groundwater/uic/class2/hydraulicfracturing/

wells_coalbedmethanestudy.cfm (accessed 17.02.11) (June).

EPA, 2010. Hydraulic Fracturing Research Study, EPA/600/F-10/002, United States

Environmental Protection Agency. Available at: http://www.epa.gov/safewater/

uic/pdfs/hfresearchstudyfs.pdf (accessed 24.10.13) (June).

GWI, 2011. Produced water market: Opportunities in the oil, shale and gas sectors

in North America. Global Water Intelligence (March 17).

Huang, F.Y.C., Gundewar, R., Loughridge, B.W., Steed, D., 2005. Feasibility of using

produced water for crosslinked gel-based hydraulic fracturing, SPE Production

Operations Symposium, Oklahoma City, OK, April 16–19, 2005. Society of

Petroleum Engineers. Available at: http://ipec.utulsa.edu/Conf2004/Papers/

huang_gundewar_steed_loughridge.pdf (accessed 16.02.11).

NRC, 2010. Management and Effects of Coalbed Methane Produced Water in the

Western United States. National Research Council of the National Academies,

The National Academies Press, Washington, DC.

Osborne, T.J., Adams, J.E., 2005. Opportunities and limitations of CBNG produced

water management alternatives in the Powder River basin. In: 12th

Annual International Petroleum Environmental Conference, Houston, TX,

November 7–11, 2005. Available at: http://ipec.utulsa.edu/Conf2005/Papers/

Osborne_Opportunities.pdf (accessed 15.05.13).

34

M.H. Plumlee et al. / Journal of Unconventional Oil and Gas Resources 5 (2014) 22–34

Rice, C., Bartos, T., Ellis, M., 2002. Chemical and isotopic composition of water in the

Fort Union and Wasatch formations of the Powder River Basin, Wyoming and

Montana: implications for coalbed methane development. In: Coalbed Methane

of North America – II, Rocky Mountain Association of Geologists, pp. 53–70.

Stewart, D.R., 2006. Developing a new water resource from production water. In:

Proceedings of the 13th International Petroleum Environmental Conference,

San Antonio, TX. Available at: http://www.crwcd.org/media/uploads/

Dave_Steward.pdf (presentation) (accessed 12.02.11).

Stewart, D., 2011. Personal Communication with Kennedy/Jenks Consultants

(February 28).

Stewart, D.R., Takaichi, L., 2007. Beneficial use of produced water—water as a

valuable byproduct. In: Proceedings of the International Petroleum

Environmental Conference, Houston, TX, November 5–9, 2007. Available at:

http://ipec.utulsa.edu/Conf2007/Papers/Stewart_74.pdf (accessed 12.02.11).

Stratus Consulting, 2006. An Economic Framework for Evaluating the Benefits and

Costs of Water Reuse (Final Project Report and User Guidance). Prepared for the

WateReuse Foundation by Stratus Consulting, Bahman Sheikh, Kristin Darr, and

National Water Research Institute.

USGS, 2000. USGS Fact Sheet FS-156-00: Water Produced with Coal-Bed Methane.

United States Geological Survey.

WOGCC, Wyoming Oil and Gas Conservation Commission (Homepage), 2011.

Available at: http://wogcc.state.wy.us/ (accessed 01.03.11).

Wyoming DEQ, Wyoming Department of Environmental Quality, 2011. Available at:

http://deq.state.wy.us/wqd/ (accessed 01.03.11).

Wyoming SEO, Wyoming State Engineer’s Office, 2011. Available at: http://

seo.state.wy.us/ (accessed 01.03.11).