Building Consistency Meeting

advertisement

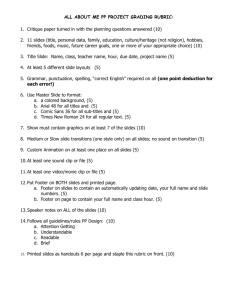

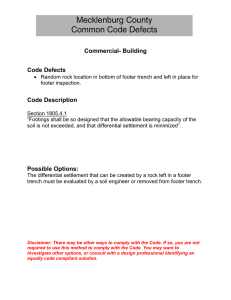

Building Consistency Meeting Residential Date: 8/4/2004 Recorder: Danny Wooten, minutes prepared by: Jeff Griffin Staff present: Jeff Griffin; Jim Mullis; Gene Morton; Harold Sinclair; Ron Dishman; Danny Wooten; Steve Kellen; Kirk Aten Public present: Bob Mckee(Ryan); Stu Jelenick (Greenfiber); Mike Mcgee (Mcgee Bros); Wayne Carter (Mulvaney Homes); Frank Burke (Grimmer-Kempf & Assoc); Bob Otto (R.E. Otto & Sons, Inc-NARI); Jim Welsh/Lee Daggerhart (BRI of Charlotte); David Schwiemon (Public); Patty Springer (WR Grace); Edwin Woods (Centex Homes); Duane Johns (Advanced Renovations); John Andrejko/Jeff Kieffer/ Wanda McCarthy (Eastwood Homes); Shawn Polakiewicz (Saussey Burbank); Scott Dirkschneider/Trent Basso (Meeting Street); James Welsh (BRI); Max Smith (Westfield Homes). Topics/Subject Decisions/Conclusions/Actions Old Business Reviewed roof ventilation issues Last month we passed out a formal interpretation that is on DOI’s website in dealing with residential attic space ventilation requirements. A few days later and before the minutes went out this issue was discussed in detail with the state and some application concerns and how to handle. This meeting reviewed the July minutes citing examples. Rafter notching Discussed the issue with rafter notches again and that the overhang is considered a Cantilever per DOI. Section 802.7 also indicates as a cantilever and that the remaining portion of the rafter cannot be less than 3 ½”net. This issue needs to be watched closely in the field and measurement must be taken from end of saw cuts. Some rafters bearing full 3 1/2 “ on walls are being cut incorrectly and builders asked to discuss with framers. See attached drawings below for example. Insulation Issue was brought up again about where this stands with the building Vapor Barrier code council as far as removal of requirement from code. This will be discussed at the September 13 & 14 meeting in Hickory and appears that council is in favor of moving this issue forward. Will advise of any changes. New Business Suspended deck stair stringers Issue rose about suspended deck stair stringers and how they should be permanently attached. There is no specific reference to this application in appendix M but based on several sites that have had problems simply nailing will not support stairs in some applications. The attached photos are a representation of the problem; these stairs were to a new deck only 8 months old when they fell. This is an issue where the stringers are nailed to a suspended band board below the outer floor joist (usually with drop 2x6 vertical boards) to use this joist as the last riser in a flight of stairs. These applications will need to be bolted with ¼” or 3/8” galvanized through bolts with nuts and washers. Also the outer floor joist will need to be restrained against rotation at tension side of member (bottom) to prevent stringers that are nailed from coming loose. Proper anchorage at the base of the stairs is also important to prevent movement. A formal interpretation is being reviewed on this issue. Inspectors have been advised to look for the above on future inspections to insure that application will remain in place. ASTM E-2112 flashing requirements Partial footer pours (cold joints) Garage lug interior sheathing application Discussed the new reference standard that was approved by the NC Building Code Council at their June meeting (see minutes attached). Please note that according to the language that in the absence of MFG installation instruction that the ASTM E-2112 standard will apply. If you’re a builder who has a tested product in which the MFG provides specific flashing requirements for installation (like many vinyl windows), those instructions will apply. This Standard will be listed in the text R708.3 and reference standards Chapter 43. Discussed the concern with partial footer pours. For residential construction all footers should be ready for complete continuous pour. This would include townhouse, in some cases approved by field inspector, a partial pour can be allowed if the cold joint in footer is bulk headed off and proper steel to tie together is placed. Normally in required 2000 psf load conditions this consists of 2-#4 bars 10’ (usually a 20’ bar cut in half) as a standard engineering practice for the cold joint, this needs to be discussed with inspector for specific site conditions. For loads above 2000psf a soil engineer is required to specify how cold joints will be handled in footer. When approved by the inspector the bulk heads and steel must be in place. Discussed inspection procedure for garage lugs that require OSB sheathing on the interior per DOI allowance of reduced brace panel length (50%) rule. In order for us to see the header, jack studs and anchors at the lugs this plywood must be left off at frame check. It can be very loosely nailed in place (1 side, 2-3 nails) so that plywood/osb can be pulled back to check, this was a concern raised by 1 builder as to material theft issues. Keep in mind that these structural elements must be visible for frame check, at insulation time all interior required sheathing must be completely installed and nailed off. Next meeting is on September 1st in Woods conference room at 8:00am, 700 N. Tryon St.