Memo MECKLENBURG COUNTY

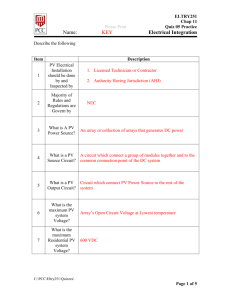

advertisement