Homework #4 Do problems 10.1, 10.3, & 10.5 on pages 234-235.

advertisement

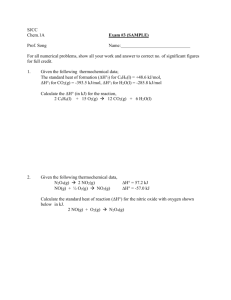

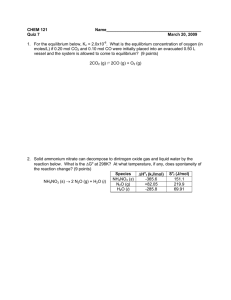

Homework #4 Do problems 10.1, 10.3, & 10.5 on pages 234-235. CBEN 408 Spring 2016 -1- March 19, 2016 Solutions Problem #10.1 (10 points) Feed gas enters an amine treating unit at a rate of 100 MMscfd (2.68 × 106 m3/d). The gas contains 5% CO2 and no H2S. The treater uses 18 wt% MEA solution. Assume the lean amine contains 0.12 mol CO2/mol of amine and the rich amine contains 0.45 mol CO2/mol amine. To meet the pipeline specification of 2% CO2, what minimum lean amine flow rate in gpm (m3/h) is required? Amine properties are given in Appendix B. Solution The table to the right shows the specified values, intermediate results, & final result (686 gpm) for this problem. 1,2 Inlet Outlet Absorbed Outlet Specifications CO2 (mol%) 2.0% Composition (mol%) Sweet Gas CO2 Total 95.0% 5.0% 100.0% 98.0% 2.0% 100.0% Sweet Gas CO2 Total 95.00 5.00 100.00 95.00 1.94 96.94 CO2 MEA 9.150 3.548 Gas Rate (MMscfd) 3.06 3.06 Rate (lb.mol/min) Loadings (mol acid gas/mol amine) Rich Lean Pickup = Rich - Lean Lean Amine (wt%) Lean Amine density (lb/gal) Mol Wt 0.45 0.12 0.33 18.0% 8.40 MEA Lean Amine Rate (lb/min) Lean Amine Rate (gal/min) 5.602 16.975 61.08 5,760.3 685.7 There are a couple calculations that should be noted: • The allowable amount of CO2 in the outlet gas can be directly calculated knowing that the amount of hydrocarbons remains the same (i.e., they are not absorbed). So: = yCO2 NC CO2 yCO2 C C ⇒ N = N(C CO2 C C 1 M yCO2 N(C + NCO2 = 0.02 = ( 95) 1.94 MMscfd 1 M 0.02 Note that the numbers shown may be slightly different from hand calculations because of the number of digits retained in intermediate calculations. 2 The pure component parameters used are from Tables B.1 & B.15 as well as Figure B.1 in the Kidnay, et. al. text book. 1 CBEN 408 Spring 2016 -2- March 19, 2016 • • • The amount of CO2 absorbed in the amine is the difference between that in the Inlet gas & that in the Outlet gas. The pickup by the amine solution is the difference between the rich loading & the lean loading (i.e., the residual CO2 in the lean amine solution after stripping as much CO2 as possible). The required molar flowrate of the amine (in the MEA/water solution) is found from the amount of CO2 absorbed & the pickup: NC CO2 NC MEA = LCO2/MEA • M1 M1 scf min 6 scf CO2 379.46 24 ⋅ 60 3.06 ×10 day lb.mol day lb.mol MEA = 16.975 mol CO2 min 0.33 mol MEA The required mass flowrate of the total lean amine solution (MEA & water) is found from the this molar amount of MEA: Solvent = m N MEA MMEA wMEA lb.mol MEA lb 16.975 61.08 lb min lb.mol = 5760 0.20 min and the required standard liquid volumetric flowrate is found using the liquid density: lb 5760 m Solvent min 686 gal * V = = = Solvent * lb min ρSolvent 8.40 gal CBEN 408 Spring 2016 -3- March 19, 2016 Problem #10.3 (10 points) The 18 wt% MEA used in the treating unit in Exercise 10.1 is replaced with 31 wt% DEA solution. If the lean amine contains 0.05 mol CO2/mol of amine and the rich amine contains 0.38 mol of CO2/mol of amine, how much will the required lean amine solution flow rate change (based on density at 60°F (15°C))? Solution The table to the right shows the specified values, intermediate results, & final result lean solvent flowrate for this problem. 1,2 Since the flowrate found in Problem #1 was 686 gpm of 18% MEA, the flowrate will change by 22 gpm less 31% DEA (a decrease of 3%). Inlet Outlet Absorbed Outlet Specifications CO2 (mol%) 2.0% Composition (mol%) Sweet Gas CO2 Total 95.0% 5.0% 100.0% 98.0% 2.0% 100.0% Sweet Gas CO2 Total 95.00 5.00 100.00 95.00 1.94 96.94 CO2 DEA 9.150 3.548 Gas Rate (MMscfd) 3.06 3.06 Rate (lb.mol/min) Loadings (mol acid gas/mol amine) Rich Lean Pickup = Rich - Lean Lean Amine (wt%) Lean Amine density (lb/gal) Mol Wt 0.38 0.05 0.33 31.0% 8.67 DEA Lean Amine Rate (lb/min) Lean Amine Rate (gal/min) 5.602 16.975 105.14 5,757.4 664.1 There are a couple things to note about the calculations: • The amount of CO2 absorbed in the amine is the difference between that in the Inlet gas & that in the Outlet gas. • Even though the rich & lean loadings are different between the two solvents the pickup will be the same, 0.33 mol CO2/mol amine. This means that the molar flowrate of each amine within its total solvent will be the same. • The required mass flowrate of the total lean amine solution is essentially the same between the two cases. The 3% reduction in volumetric flow comes from the 3% difference in the mass densities. Note that the numbers shown may be slightly different from hand calculations because of the number of digits retained in intermediate calculations. 2 The pure component parameters used are from Tables B.1 & B.15 as well as Figure B.1 in the Kidnay, et. al. text book. 1 CBEN 408 Spring 2016 -4- March 19, 2016 Problem #10.5 (20 points) The gas entering an MDEA treating unit contains 0.5 mol% H2S and 8 mol% CO2. Inlet flow rate is 120 MMscfd (3.22 × 106 m³/d). The treater inlet pressure is 1000 psig (70 barg). The plant dehydrates the gas and then sells it as pipeline-quality gas. The pipeline specification requires that the gas contain no more than 0.25 g/100 scf (6 mg/Nm3) of H2S and a maximum of 2% mol CO2. a. Assuming that the rich MDEA holds 0.4 mol of acid gas/mol of MDEA and the lean amine contains essentially no H2S and 0.005 mol of CO2/mol amine, what is the minimum amine circulation required (gpm [m3/h]) to obtain pipeline-quality gas? b. How much sulfur (LTD (tonnes/day)) would be produced from the acid gas leaving the treater, assuming 99.95% sulfur recovery? (See Chapter 16 for a discussion of sulfur recovery.) Solution The table to the right shows the specified values, intermediate results, & final results. 1,2 The key results are: • Minimum MDEA flow is 1033 gpm. • The amount of sulfur produced from the SRU (Sulfur Recovery Unit) is 23 LTPD (long tons per day, where 1 long ton is 2200 lb). Note that the numbers shown may be slightly different from hand calculations because of the number of digits retained in intermediate calculations. 2 The pure component parameters used are from Tables B.1 & B.15 as well as Figure B.1 in the Kidnay, et. al. text book. 1 CBEN 408 Spring 2016 -5- March 19, 2016 There are a couple calculations that should be noted • The H2S spec on the outlet gas is a ratio of mass H2S to the total moles of gas. The mass units of “grains” is not one normally used; a grain is 1/7000 of a lb. This can be converted to a molar ratio: −1 lb scf 0.25 lb H2S 34.082 379.49 lb.mol lb.mol 7000 y= = 3.98 ×10−6 , H2S 100 scf • essentially 4.0 ppmv. The allowable amounts of CO2 & H2S in the outlet gas can be calculated after first equating the hydrocarbon rate in both the inlet sour gas & the outlet sweet gas (i.e., we assume that the hydrocarbons are not dissolved in the amine solution). From the inlet: NC (C = yCO2 yCO2 )Sweet NC Sweet = yCO2 yCO2 )Sour NC Sour (1 −− (1 −− NC (C = (1 M yCO2 M yCO2 )Sweet NC Sweet = (1 M 0.08 M 0.005)(120 MMscfd ) NC Sour = = 109.8 MMscfd (109.8 MMscfd ) NC (C = (1 M yCO2 M yCO2 )Sour (1 M 0.02 M 0.00000398 ) = 112.04 MMscfd (Note that the amount of H2S is so small that it does not significantly affect the overall amount of sweet gas is produced.) So the molar flow of the acid gases out of the absorber will be: = NC CO2,Sweet yCO2,Sweet = NC Sweet Gas = N y= (2S,Sweet (2S,Sweet NSweet • = (0.02 )(112.04 ) 2.24 MMscfd = (0.00000398 )(112.04 ) 0.00045 MMscfd The required amount of MDEA solution is from an additive effect for the pickup of both the CO2 & the H2S: CBEN 408 Spring 2016 -6- March 19, 2016 NC CO2 = NC MDEA • LCO2/MDEA + NC H2S LH2S/MDEA scf H2S 6 scf CO2 0.5996 ×106 M1 M1 7.36 ×10 day day scf min = + 379.46 24 ⋅ 60 mol CO2 mol H2S lb.mol day 0.395 0.40 mol MDEA mol MDEA lb.mol MDEA = 36.836 min The required mass flowrate of the total lean amine solution (MDEA & water) is found from this molar amount of MDEA & the concentration of the lean amine. The concentration was not given in the problem statement. We will use the highest normal concentration (50 wt%) since that will lead to the lowest circulation rate: Solvent = m N MDEA MMDEA wMDEA lb.mol MDEA lb 36.836 119.16 lb min lb.mol = 8779 0.50 min The required standard liquid volumetric flowrate is found using the liquid density: lb 8779 m gal Solvent min V = = = 1,033 * lb min ρSolvent 8.50 gal The SRU (Sulfur Recovery Unit) converts H2S to sulfur on a mole-to-mole basis. So the mass rate of sulfur recovered uses the molecular weight of sulfur & the recovery efficiency of the SRU: * Solvent • −1 lb.mol S lb min lb long ton S = m 0.9995 ⋅ 1.097 23 32.06 24 ⋅ 60 2200 = min lb.mol day long ton day The required standard liquid volumetric flowrate is found using the liquid density: CBEN 408 Spring 2016 -7- March 19, 2016