Design of a Flux-Switching Electrical Generator for Wind Turbine Systems

advertisement

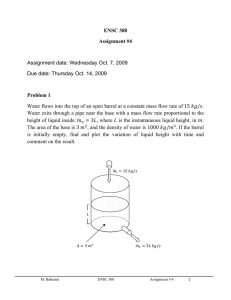

1808 IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 48, NO. 6, NOVEMBER/DECEMBER 2012 Design of a Flux-Switching Electrical Generator for Wind Turbine Systems Javier Ojeda, Marcelo Godoy Simões, Guangjin Li, and Mohamed Gabsi Abstract—This paper proposes a parametric optimization of a flux-switching electrical machine customized for a wind turbine application with a typical operating range for average and low-power wind energy sites. Statistics of wind resources are taken into consideration for the machine design for definition of the turbine power envelope. Both copper and iron losses for three different machine designs are evaluated. A very important consideration taken in this design is the elimination of gearbox requirements for coupling to the turbine. Although the developed approach makes the machine somewhat voluminous, the overall performance is highly improved because a direct-drive flux-switching electrical generator becomes very competitive for small-scale wind turbines. The design methodology presented in this paper will support widespread application of small-scale wind turbines for rural systems, farms, and villages. This paper concludes by demonstrating that a very cost-effective distributed wind system can be approached with this design. Index Terms—AC motor drives, electric machines, wind energy, wind power generation. I. I NTRODUCTION T HIS paper proposes, for the first time, the utilization of a flux-switching electrical machine (used in the past in motoring mode) [1]–[9], as a wind system generator. The focus here is specifically for situations with predominantly low power needs, and with low-wind-speed patterns, as might be found in inland rural areas. A custom-designed approach must be followed, in order to consider the best operating range for low wind velocities, overall optimization, and long-term cost return. In addition, a machine designed for low speed may overpower at higher speed, and mechanical coupling of turbines to generators with gearbox decreases efficiency and impacts overall reliability [10], [11]. A typical wind turbine system has its operating range as shown in Fig. 1. Permanent-magnet generators and self-excited induction generators have been used for low-power wind turbines, squirrel-cage induction generators are usually used for Manuscript received December 19, 2011; revised April 11, 2012 and June 19, 2012; accepted June 27, 2012. Date of publication October 4, 2012; date of current version December 31, 2012. Paper 2011-EMC-777.R2, approved for publication in the IEEE T RANSACTIONS ON I NDUSTRY A PPLICA TIONS by the Electric Machines Committee of the IEEE Industry Applications Society. J. Ojeda, G. Li, and M. Gabsi are with Systèmes et Applications des Technologies de l’Information et de l’Energie, École Normale Supérieure de Cachan–University Paris Sud 11–Centre National de la Recherche Scientifique, UniverSud Paris, 94230 Cachan, France (e-mail: ojeda@satie.ens-cachan.fr; guangjin@satie.ens-cachan.fr; gabsi@satie.ens-cachan.fr). M. G. Simões is with the Department of Electrical Engineering and Computer Science, Colorado School of Mines, Golden, CO 80401-1887 USA (e-mail: mgs@mines.edu). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TIA.2012.2221674 Fig. 1. Control range for a typical wind turbine. medium-power wind turbines, and doubly fed induction generators or synchronous machines are used for high-power wind turbines; very small wind turbine generators are often based on inexpensive permanent-magnet generator machines [12] and typically do not have optimized operation in low-wind-speed range. For these reasons, the flux-switching machine (FSM) may be the best candidate in the special case of low-power lowwind-speed situations. II. T URBINE P OWER C ONTROL Large-scale wind turbines frequently have optimized speed and/or pitch control, but the market for small-scale wind turbines does not accommodate expensive solutions. Gearboxes are typically used in high-power wind turbines, but they impact low-power wind turbines for mainly two reasons: 1) They have low efficiency because of the viscous loss (1% of the rated power per gearbox stage, proportional to the mechanical speed) [13], and 2) they are the major factor (at least 19%) of the downtime in wind turbine generations due to maintenance needs [14]. Therefore, an optimized electric generator should be designed in order to have the best efficiency for a low-wind-velocity operating range, and a direct-drive system would be preferable. Small wind turbines have considerable cost constraints in order to be competitive in rural systems and applications for farms and villages. Typically, small turbine generators are permanent-magnet machines, not optimized for capturing wind energy in the low-wind-speed range (up to about 7 m/s). The use of gearbox impairs the machine capability to further produce power, since the friction losses are extremely significant. Therefore, no turbine control methodology will impact the best operation of the generator in low speed (since most of the turbine control systems only optimize the aerodynamic performance). Therefore, wind energy considerations must be 0093-9994/$31.00 © 2012 IEEE OJEDA et al.: DESIGN OF A FLUX-SWITCHING ELECTRICAL GENERATOR FOR WIND TURBINE SYSTEMS 1809 Fig. 4. Losses for a high-power doubly fed induction generator. Fig. 2. Fig. 3. Wind speed distribution. Rayleigh wind speed distribution. taken in the proper electromagnetic and mechanical design of an electric generator, and it seems that an FSM is the best candidate for such application. III. W IND E NERGY D ESIGN C ONSIDERATIONS Energy captured by the shaft of a wind turbine must be evaluated by the historical wind power intensity (in watts per square meter) in order to access the economical viability of the site. Therefore, it is appropriate to define local wind power as proportional to the distribution of speed occurrence, and a statistically based design should consider the different sites where the turbines will be installed. Thus, with the same annual average speed, very distinct wind power characteristics may affect the optimal design of the generator. Fig. 2 shows a typical curve of wind speed distribution for a given site. If wind speed is lower than 3 m/s (denominated by “calm periods”), the power becomes very low for extraction of energy, and the system is usually stopped. Therefore, calm periods will determine the necessary time for energy capture. Power distribution varies according to the intensity of the wind and with the power coefficient of the turbine. Then, a typical distribution curve of power is assumed to have the form as in Fig. 3. Sites with high average wind speeds do not have calm periods, and there is not much need of storage. However, high wind speed may cause structural problems in the system or in the turbine. Although wind resources can be described by the Weibull distribution, in practice, it is more convenient to use the Rayleigh distribution given by v −( vc )2 2 e . (1) h(v) = c c Such function is shown in Fig. 3 where the “factor c” is defined as the scale factor, related to the number of days with high wind speeds. The higher is “c,” the higher is the number of windy days. Therefore, such parameter represents the statistical nature of wind speed for most practical cases. The vertical axis in Fig. 2 is given in percentage of hours/ year per meter/second. For optimally designing an electrical generator, the random nature of wind distribution in a particular site is considered in order to design the best operating range, defining electrical characteristics such as machine frequency and voltage ratings. The majority of losses occurs because a gearbox is used for matching generator speed with the turbine speed. Therefore, this paper considers the elimination of gearbox, in order to significantly contribute for an overall optimal system, which eventually is consistent with the volumetric needs of ferrite-based magnets, as discussed in the next section. IV. W IND G ENERATOR P ERFORMANCE C ONSIDERATIONS An electrical generator used for a wind turbine system has efficiency imposed by three main issues, as shown in Fig. 4: 1) stator losses; 2) converter losses; and 3) gearbox losses. Stator losses are considered in this paper by the proper design of the machine for the right operating range; the converter losses are given by the proper design of the power electronic circuits (ON-state conduction losses of transistors and diodes, plus their frequency-proportional switching losses, are not considered in this paper, because they must be approached in a specific power electronic topology that best fits the final design). The third main factor responsible for a noticeable power loss is the use of a gearbox, as shown in Fig. 4 for a typical wind turbine system. It can be considered that mechanical viscous losses due to a gearbox are proportional to the operating speed, as indicated by Pgear = Pgear,rated η ηrated (2) where Pgear,rated is the loss in the gearbox at rated speed (on the order of 3% of the rated power), η is the rotor speed (in revolutions per minute), and ηrated is the rated rotor speed (in revolutions per minute). Losses in the gearbox dominate the efficiency in most wind turbine systems, and simple calculations show that a significant annual power dissipation in the generator system is due to the gearbox. From the full energy available in the wind, just part of it can be extracted for energy generation, quantified by the power coefficient Cp . The power coefficient is the relationship of the possible power extraction and the total amount of power contained in the wind. The turbine mechanical power can be given by Pt = (Cp ρAV 3 ) 2 (in kg · m/s). (3) 1810 IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 48, NO. 6, NOVEMBER/DECEMBER 2012 The air density ρ can be corrected by the gas law ρ = P/RT ) for every pressure and temperature of the place with the following expression: ρ = 1.2929 273 P T 760 (4) where P is the atmospheric pressure (in millimeters of mercury) and T is the Kelvin absolute temperature. At normal conditions (T = 296 K and P = 760 mmHg), the value of ρ is 1.192 kg/m3 , and at T = 288 K (15 ◦ C) and P = 760 mmHg, it is 1.225 kg/m3 . One can consider the temperature decrease of approximately 1 ◦ C for every 150 m. The influence of humidity can be neglected. If just the altitude h (in meters) is known (10 000 ft = 3048 m), the air density can be estimated by the two first terms of a series expansion like ρ = ρ0 e −( 0.297 3048 h ) ≈ 1.225 − 1.194 × 10−4 h. (5) Thus, the turbine torque is given by Tt = ρARV 2 CT Pt = ω 2 (6) where the torque coefficient is defined as CT = Cp /λ. If S = 1 m2 and ρ = 1.2929 kg/m3 , the maximum potential of wind can be obtained from the aforementioned equation (without taking into account the aerodynamic losses in the rotor, the wind speed variations in several points of the blade sweeping area, the rotor type, and so on) as calculated by P = 0.5926 × 0.6464 × V 3 = 0.3831 V 3 A (7) where PA is the wind power per swept area (in watts per square meter) and V is the wind speed (in meters per second). For a constant and steady wind speed of 6 m/s, the available shaft turbine power is 260 W. However, wind is never steady nor constant, and such instantaneous power calculation is not useful for sizing and economic studies. The random nature of wind must be considered, and statistical analysis must be performed. Assume, for instance, that a wind turbine site, with strong winds, with periods of low wind and some really good average speed can be defined as a Rayleigh probability density function. Equation (8) shows the calculation of the average cubic wind speed under Rayleigh conditions, and the shape factor (k) is related to the average cubic wind speed as (9) ∞ 3 ∞ 3 (v )avg = v h(v)dv = 0 3 √ = k3 π 4 2 k = √ vavg π v 2 2v v · 2 exp − dv k k 3 0 Fig. 5. Typical Rayleigh wind probability density function for low wind speed as found in inland and rural areas. That is, under Rayleigh wind speed probability distribution function, the average power extracted by the turbine shaft is 1.91 multiplied by the instantaneous power calculated by (7). As an example, a Rayleigh distribution function with a cubic average of 6 m/s, as shown in Fig. 5, gives 496 W for a 1-mradius blade, and of course, a larger diameter turbine is required for the machine described in this paper. Since power raises with the cubic growth of wind speed and the square of turbine radius, it is expected that, for low-windspeed Rayleigh site conditions (on the order of 8-m/s average cubic wind speed), a turbine with a radius on the order of 3 m will be needed for the generator described in this paper. The turbine mechanical design is not the scope of this paper and is left for future research and development. Therefore, the main design motivation of this paper is the elimination of the gearbox device [15]–[17]. While, for large wind turbines, a good gearbox system can be employed, any highly efficient gearbox is not usually employed in small wind turbines, for economics reasons, and in such applications, the gearbox expects higher losses than indicated in the literature, because those small turbines must have a very competitive low price. V. FSM D ESIGN The design of an electrical machine is often considered from a given point defined by the maximum torque. In a first approximation, one can consider that the external volume (or the weight) of the machine is influenced by the maximum torque for the considered application, which could be obtained by the wind turbine. Equation (3) shows that the Pturbine and their power coefficient Cp (function of the tip-speed ratio λ) can be considered. The tip-speed ratio λ is defined as λ= (8) (9) and the relationship of the average cubic wind speed with the average speed becomes 3 2vavg 3√ 6 3 √ (v )avg = π = (vavg )3 ∼ = 1.91(vavg )3 . (10) 4 π π Ωr v (11) where Ω is the generator rotational speed and r is the radius of the blade. Maximizing the Cp coefficient depends on the operating conditions. Therefore, in order to obtain a turbine power rated for 5 kW, the radius of the blade and the rotational speed (Ωb ) can be derived accordingly. As an example of the design, considering an optimal blade tip-speed ratio of three, a 1-m blade is obtained for a wind speed of 6 m/s, and a rotational speed of OJEDA et al.: DESIGN OF A FLUX-SWITCHING ELECTRICAL GENERATOR FOR WIND TURBINE SYSTEMS Fig. 6. 1811 Power envelope of the turbine; f (v) function. 30 rad/s is considered as the minimum speed. Then, for a 5-kW generator, the maximum torque (Tmax ) might be computed based on the rated angular speed, so for the maximum speed (vmax ), the power is limited to the maximum power (Pmax ) shown in Fig. 6. The machine chosen for this application is a permanentmagnet FSM [17] here defined as a flux-switching electric generator (FSEG). This machine has many improvements when compared to other permanent-magnet machines, such as the use of a passive rotor and improved heat transfer. It has a torque density similar to that of classical permanent-magnet machines [18] and is used for applications such as aircraft systems [19] and electric vehicles [20]. The FSEG is described by the numbers of stator teeth (Ns ) and rotor teeth (Nr ). The electrical frequency (fs ) is determined by fs = 1 Nr Ω. 2π Fig. 7. Optimization geometry. (12) For a low-speed generator (around 30 rad/s), the number of rotor teeth has to be important in order to obtain a satisfying electrical frequency; consequently, only generators with a high number of rotor teeth have been selected. The structure choice is given by a compromise between the couple (Ns and Nr ), torque, torque ripple, and copper losses. The increase of Nr affects directly the torque and also the iron losses. The torque ripple is determined by Nr and Ns [7]. This paper shows two structures preoptimized (i.e., chosen to obtain a good compromise between electromagnetic torque, torque ripple, and copper losses): 1) a flux-switching generator with 120 stator teeth and 100 rotor teeth and 2) a flux-switching generator with 120 stator teeth and 140 rotor teeth. For both machines (FSEG 120/100 and FSEG 120/140), the permanent-magnet thickness is defined (3 mm), and the magnetic flux density can be selected from 0.4 T (ferrite), 0.8 T (bonded NdFeB), and 1.2 T (sintered NdFeB). Then, geometry parameters for all structures are defined in Fig. 7. αic is the thickness of the iron path, βr is the half thickness of a rotor tooth, rext is the external radius, and rag is the airgap radius. These parameters are bounded in a limited range of variations so as to guarantee a structure possible to be built mechanically. Each structure is optimized by a parametric procedure where the torque by active length and the torque ripple are computed with a finite-element (FE) simulation. The optimization procedure is shown in Fig. 8. The optimization procedure is based on a random parametric optimization. Parameters (Lactive , rext , rag , βr , and αic ) are Fig. 8. Optimization scheme function. selected according to a stochastic law (bounded by a minimum and a maximum value), and a FE simulation is achieved. From the computation of the required torque (which is the main criterion), machines minimizing mass and losses are selected. Correlations between parameters and output criteria are achieved in order to select the three best machines that satisfied the required torque and minimized the mass and losses. The three best machines have been compared (one with ferrite, another with bonded NdFeB, and a third one with sintered NdFeB). The active length Lactive is calculated from the required torque and from the torque by active length simulated by 2-D FE analysis. The copper loss (Pc ) is computed by Pc (vmin ) = σc J 2 Vc (vmin ) (13) where σc is the copper resistivity, J is the current density (in this case, equal to 5 A/mm2 ), and Vc is the copper volume which depends on the minimum wind velocity (vmin ). The maximal torque is obtained for the minimum wind speed and, thus, produces the maximal copper loss. For greater values of rotational speed, copper loss can decrease or remain constant according to the control strategy. Thus, in this study, the copper loss is considered constant. The iron loss (Pi ) is computed by Pi (Bs , fs , vmin , v) = k(Bs , v)Mt (vmin , v) (14) 1812 IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 48, NO. 6, NOVEMBER/DECEMBER 2012 Fig. 9. Copper and iron losses versus wind velocity. Fig. 11. Thermal simulation for 1.8 kW of copper losses. Fig. 10. Three-dimensional view of the FSEG 120/100 with ferrite magnet. where k is an iron loss coefficient [21] determined by iron flux density (Bs ) and the operating frequency (which is determined by the wind velocity) and Mi is the iron mass which depends on the minimum and actual wind velocity. Copper and iron losses are shown in Fig. 9. The final geometry with a ferrite magnet is shown in Fig. 10. A. Thermal Aspect and Demagnetization Issues The thermal design is very important for this application [21] because the generator will be enclosed in a nacelle, and consequently, the cooling capability is strongly constrained. The generator will be used in a very long duration cycle (many hours per day), and the temperature rise must be carefully limited. For a ferrite-magnet-based generator (the worst case in terms of copper losses), a thermal simulation using a FE software is achieved with the maximal copper losses (1.8 kW corresponding to a vmin equal to 5 m/s), as shown in Fig. 11. It is possible to observe that the maximal temperature is kept below the 155◦ C level (corresponding to the insulation class F) and lower than the Curie points of ferrite (300◦ C) and NdFeB (310 ◦ C–400 ◦ C). The demagnetization issue is challenging for designers of permanent-magnet motors [23]. The demagnetization field on the permanent magnet can depolarize the magnetic moments and, then, cancel the remanent magnetization. In order to avoid this issue, the demagnetization field is computed on the permanent magnet by the FE method and is shown in Fig. 12. In both cases, the demagnetization field is smaller than the permanent-magnet coercive field (−250 kA/m for the ferrite magnet and −900 kA/m for sintered NdFeB). Moreover, the permanent magnets are located on the stator; therefore, Fig. 12. Demagnetization field on a permanent magnet for a ferrite and a sintered NdFeB configuration. improved characteristics against demagnetization are possible [24]. B. Permanent Magnets and Power Range In order to deal with the interaction between the permanent magnet and the power range in order to maximize the captured energy, the operating wind velocity range (vmin and vmax ) optimized for a function (Fig. 6) that uses a weighted mean energy (W ) is considered for the three designed machines, as proposed by 20m s f (v)η(v)ω2 (v)dv W = vlim 20m (15) s vlim ω2 (v)dv where ω2 is the Rayleigh distribution of the wind with two parameters and η is the generator efficiency calculated by η(v) = P (v) − Pc (v) − Pi (v) . P (v) (16) The efficiency was computed in Fig. 13 for a ferrite magnet configuration and in Fig. 14 for a sintered NdFeB magnet solution. OJEDA et al.: DESIGN OF A FLUX-SWITCHING ELECTRICAL GENERATOR FOR WIND TURBINE SYSTEMS 1813 Fig. 13. Efficiency as function of vmin and vmax for ferrite magnet (maximum value of 77%). Fig. 15. Weighted mean energy for ferrite magnet (maximum value of 1700 Wh for vmin = 6 m/s and vmax = 12 m/s). Fig. 14. Efficiency as function of vmin and vmax for sintered NdFeB magnet (maximum value of 83%). The efficiency is limited by the copper loss for low wind velocity (vmin ) and constrained by the iron loss for high wind velocity (vmax ). Thus, the product f (v)η(v)ω2 (v) determines the energy efficiency of the system. Consequently, the system has to be designed for f (v) for the turbine and for η(v) for the generator for a typical wind statistical distribution [for a geographic region ω2 (v)]. Figs. 15–17 show the weighted mean energy represented for the three machines considering an inland Rayleigh wind distribution typical in France. The energy capacity is limited by both copper and iron losses, and the wind distribution emphasizes wind speed range where it is maximized. As shown in these figures, there is an optimal range for maximum captured energy. Depending on the selection of the permanent magnet and on the typical wind distribution, the optimal range is different. One can notice that the machine with ferrite magnets has to be oversized in order to satisfy the specifications, and consequently, the losses are more significant than for a NdFeB magnet selection. Thus, the optimal range for the ferrite magnet is smaller and the captured energy is decreased, and a comparison has been made, as shown in both Figs. 18 and 19. Fig. 16. Weighted mean energy for bonded NdFeB magnet (maximum value of 2100 Wh for vmin = 5 m/s and vmax = 12 m/s). Fig. 17. Weighted mean energy for sintered NdFeB magnet (maximum value of 2300 Wh for vmin = 5 m/s and vmax = 13 m/s). 1814 IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 48, NO. 6, NOVEMBER/DECEMBER 2012 TABLE I C OMPARISON OF M ASS AND E NERGY C OST FOR THE D ESIGNED M ACHINES Fig. 18. Captured energy for a large operating range. TABLE II C OMPARISON OF C HOSEN O PTIMAL D ESIGN V ERSUS A C ERTAIN M ACHINE IN THE L ITERATURE Fig. 19. Captured energy for a small operating range. Both Figs. 18 and 19 show the energy captured area (power extracted by the turbine). This area is bounded by the maximum power from the turbine (Pmax ) and the system losses; such area can be calculated by vdesign Eca (vmin , vmax ) = (P (v)−Pc (v)−Pi (v)) dv vmin vdesign Eca (vmin , vmax ) = (P (v)−Pc (v)−Pi (v)) dv. (17) vmin The turbine power [P (v)] is given by Fig. 6. Copper and iron losses are given by (13) and (14), respectively. The wind velocity and vdesign define where P (v) equals the sum of losses (no captured energy). Fig. 18 shows that a large power range (corresponding to a small value of vmin ) leads to an overdesigned generator with correspondent higher losses. Thus, the energy captured is positive only for few values of wind speed. Despite a larger power range, the energy captured area is smaller. In Fig. 19, the power range is small and vmin is high, and for this configuration, the energy captured area is higher than that of the previous case. Consequently, maximizing the power range area is not recommended for a wind turbine generator design. Therefore, the methodology proposed in this paper shows the required compromise between acceptable losses and the turbine power range. Table I shows the optimization results for the designed three machines. The level of flux density is lower for a ferrite magnet machine. Therefore, the total mass is increased so as to obtain the same performance. However, in this case, the captured energy is less than those in the other two cases. The best set of characteristics in terms of mass, captured energy, and, consequently, the mass–energy ratio is reached for the sintered NdFeB (1.2 T) magnet configuration due to the high efficiency of the permanent magnet. However, when cost–energy ratio is computed using cost market data (as for the year 2012) for all components (iron, copper, and permanent magnet), the cost–energy ratio criteria show a different scenario where the ferrite magnet configuration shows the smallest ratio. Although mass is the highest one, the price of the ferrite magnets is about 20 times smaller than the price of NdFeB magnets, showing that the total cost is smaller than that of the NdFeBmagnet-based design. Neodymium is a strategic material, and its price will most probably increase in the future. Thus, it is expected that the cost–energy ratio will further increase in the near future. Although the mass–energy ratio is the smallest for ferrite magnets, it is indeed still a good alternative when compared to rare-earth permanent-magnet options. Table II shows a comparison of the generator with bonded NdFeB magnet and a high-torque generator taken in the literature for similar application [23]. The machine selected in the literature has the same electromagnetic characteristics (torque and speed) and the same type of permanent magnet with the machine designed in this paper and can be used for a fair comparison. The flux-switching electrical generator designed in this paper, which considered the operating range for a typical wind distribution, operates in low speed compatible with the linear wind velocity and turbine radius (eliminating the need of gearbox), and is constructed out of low-cost standard ferrite magnets, is indeed a promising solution for wind turbine applications. OJEDA et al.: DESIGN OF A FLUX-SWITCHING ELECTRICAL GENERATOR FOR WIND TURBINE SYSTEMS 1815 R EFERENCES Fig. 20. Typical power electronic topology. C. Control Strategy For the control point of view, the FSEG is equivalent to an interior permanent-magnet machine. Therefore, previous control methodologies used for this kind of machine [17], [20] can be used in the drive system. Fig. 20 shows a diagram for a power electronic topology [26] of the FSEG for a grid-connected wind turbine, as well as stand-alone dc output without connection to the grid [27]. The authors expect to report in the future the required power-electronic-based control for flux-switching electrical generators. A flux-switching electrical generator can be connected to a small-scale wind turbine with fixed attack angles of the blades. They are connected to either the distribution grid or a dc load through power electronic interfaces. The control must be based on the load flow which acts on the turbine rotation. As the rotor speed changes according to the wind intensity, the speed control of the turbine has to command low speed at low winds and high speed at high winds, so as to follow the maximum power operating point. The maximum power tracking requires a hill-climbing-type controller or maybe a fuzzy-logic-based controller for commanding the speed of the generator [3], [4], but the discussion of these controllers is out of the scope of this paper. VI. C ONCLUSION AND PATH F ORWARD This paper has presented the detailed design and parametric optimization of a flux-switching electrical machine, customized for a wind turbine operating range typical of low-wind-velocity sites. The statistics of wind resources were taken into consideration in order to define the power envelope for the turbine considering copper plus iron losses for three machine designs. Three machines were detailed for configurations with a ferrite magnet and two NdFeB magnets in order to extract the energy potential of each configuration. Although the NdFeB magnet has a greater index energy/mass, regarding the market evolution and the difficulty to obtain rare-earth magnet, the ferrite configuration is a serious alternative for the future. This paper has shown that such a direct-drive flux-switching electrical generator can be very competitive and possibly the best solution for small-scale wind turbines, typically used in rural systems, small farms, and villages. [1] B. J. Chalmers and E. Spooner, “An axial-flux permanent-magnet generator for a gearless wind energy system,” IEEE Trans. Energy Convers., vol. 14, no. 2, pp. 251–257, Jun. 1999. [2] H. Polinder, F. F. A. van der Pijl, G.-J. de Vilder, and P. J. Tavner, “Comparison of direct-drive and geared generator concepts for wind turbines,” IEEE Trans. Energy Convers., vol. 21, no. 3, pp. 725–733, Sep. 2006. [3] M. G. Simoes, B. K. Bose, and R. J. Spiegel, “Fuzzy logic based intelligent control of a variable speed cage machine wind generation system,” IEEE Trans. Power Electron., vol. 12, no. 1, pp. 87–95, Jan. 1997. [4] M. G. Simoes, B. K. Bose, and R. J. Spiegel, “Design and performance evaluation of a fuzzy-logic-based variable-speed wind generation system,” IEEE Trans. Ind. Appl., vol. 33, no. 4, pp. 956–965, Jul./Aug. 1997. [5] U.S. Dept. Energy, Wind Powering America, Washington, DC. [Online]. Available: http://www.windpoweringamerica.gov/ [6] E. Morgan, M. Lackner, R. Vogel, and L. Baise, “Probability distributions for offshore wind speeds,” Energy Convers. Manage., vol. 52, no. 1, pp. 15–26, Jan. 2011. [7] P. Nielsen, “Offshore wind energy projects, feasibility study guidelines,” in Proc. SEAWIND-Altener Proj.-Feasib. Study Guidelines (EMD), 2003, pp. 1–39. [8] B. Multon, O. Gergaud, H. B. Ahmed, X. Roboam, S. Astier, B. Dakyo, and C. Nichita, “Etat de l’art dans les aerogenerateurs electriques,” in Proc. Extrait du Rapport de Synthese ECRIN, 2002, pp. 1–52. [9] E. Muljadi and C. Butterfield, “Pitch-controlled variable-speed wind turbine generation,” IEEE Trans. Ind. Appl., vol. 37, no. 1, pp. 240–246, Jan./Feb. 2001. [10] M. Pinilla and S. Martinez, “Optimal design of permanent-magnet directdrive generator for wind energy considering the cost uncertainty in raw materials,” Renewable Energy, vol. 41, no. 1, pp. 267–276, May 2012. [11] P. Tavnet, G. Van Bussel, and F. Spinato, “Machine and converter reliabilities in wind turbines,” in Proc. 3rd IET Int. Conf. Power Electron., Mach. Drives, Mar. 2006, pp. 127–130. [12] B. Palle, M. G. Simoes, and F. A. Farret, “Dynamic simulation and analysis of parallel self-excited induction generators for islanded wind farm systems,” IEEE Trans. Ind. Appl., vol. 41, no. 4, pp. 1099–1106, Jul./Aug. 2005. [13] J. R. Cotrell, “A preliminary evaluation of a multiple generator drivetrain configuration for wind turbines,” in Proc. 21st ASME Wind Energy Symp., 2001, pp. 345–352. [14] W. Qiao, X. Yang, and X. Gong, “Wind speed and rotor position sensorless control for direct-drive PMG wind turbines,” IEEE Trans. Ind. Appl., vol. 48, no. 1, pp. 3–11, Jan./Feb. 2012. [15] A. Grauers, “Design of direct-driven permanent-magnet generators for wind turbines,” Ph.D. dissertation, Chalmers Univ. of Technol., Gothenburg, Sweden, 1996. [16] M. Dubois, H. Polinder, and J. Ferreira, “Comparison of generator topologies for direct-drive wind turbines,” in Proc. IEEE Nordic Workshop Power Ind. Electron., 2000, pp. 22–26. [17] E. Hoang, H. B. Ahmed, and J. Lucidarme, “Switching flux permanent magnet polyphased synchronous machines,” in Proc. EPE Conf., 1997, pp. 1–6. [18] W. Hua, Z. Zhu, M. Cheng, Y. Pang, and D. Howe, “Comparison of fluxswitching and doubly-salient permanent magnet brushless machines,” in Proc. ICEMS, 2005, vol. 1, pp. 165–170. [19] Y. Amara, E. Hoang, M. Gabsi, M. Lecrivain, and S. Allano, “Design and comparison of different flux-switch synchronous machines for an aircraft oil breather application,” Eur. Trans. Elect. Power, vol. 15, no. 6, pp. 497– 511, Nov./Dec. 2005. [20] A. Zulu, B. C. Mecrow, and M. Armstrong, “A wound-field threephase flux-switching synchronous motor with all excitation sources on the stator,” IEEE Trans. Ind. Appl., vol. 46, no. 6, pp. 2363–2371, Nov./Dec. 2010. [21] Cogent Electrical Steel, Surahammar, Sweden. [Online]. Available: http:// www.sura.se [22] G. Li, J. Ojeda, E. Hoang, M. Lecrivain, and M. Gabsi, “Comparative studies between classical and mutually coupled switched reluctance motors using thermal-electromagnetic analysis for driving cycles,” IEEE Trans. Magn., vol. 47, no. 4, pp. 839–847, Apr. 2011. [23] S. Ruoho, E. Dlala, and A. Arkkio, “Comparison of demagnetization models for finite-element analysis of permanent-magnet synchronous machines,” IEEE Trans. Magn., vol. 43, no. 11, pp. 3964–3968, Nov. 2007. [24] M. Cheng, K. T. Chau, and C. C. Chan, “Design and analysis of a new doubly salient permanent magnet motor,” IEEE Trans. Magn., vol. 37, no. 4, pp. 3012–3020, Jul. 2001. 1816 IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 48, NO. 6, NOVEMBER/DECEMBER 2012 [25] Alxion Automatique Productique, High Torque Motors, Wind Turbine Generator, Colombes, France. [Online]. Available: http://www.alxion. com/ [26] M. Rolak, R. Kot, M. Malinowski, Z. Goryca, and J. T. Szuster, “Design of small wind turbine with maximum power point tracking algorithm,” in Proc. IEEE Int. Symp. Ind. Electron., 2011, pp. 1023–1028. [27] G. Joos and J. Belanger, “Real-time simulation of a wind turbine generator coupled with a battery supercapacitor energy storage system,” IEEE Trans. Ind. Electron., vol. 57, no. 4, pp. 1137–1145, Apr. 2010. Javier Ojeda was born in Buenos Aires, Argentina, in 1980. He received the Ph.D. degree in electrical engineering from the Ecole Normale Supérieure de Cachan (ENS Cachan), Cachan, France, in 2009. In 2010, he was a Postdoctoral Fellow with Tsinghua University, Beijing, China. Since September 2010, he has been an Assistant Professor with the Systèmes et Applications des Technologies de l’Information et de l’Energie, ENS Cachan– University Paris Sud 11–Centre National de la Recherche Scientifique, UniverSud Paris, Cachan. His main research topics are active damping of switched reluctance machine motors for high-speed applications, machine noise modeling, and fault diagnosis in electrical machines for vehicular applications. Marcelo Godoy Simões received the B.S. and M.S. degrees from the University of São Paulo, São Paulo, Brazil, in 1985 and 1990, respectively, the Ph.D. degree from The University of Tennessee, Knoxville, in 1995, and the D.Sc. degree (Livre-Docência) from the University of São Paulo in 1998. He is currently an Associate Professor with the Department of Electrical Engineering and Computer Science, Colorado School of Mines (CSM), Golden, where he has been establishing research and education activities in the development of intelligent control for high-power electronic applications in renewable and distributed energy systems and is currently the Director of the Center for the Advanced Control of Energy and Power Systems. Since joining CSM, he has been involved in activities related to the control and management of smart grid applications. Dr. Simões was a recipient of the National Science Foundation CAREER award “Intelligent Based Performance Enhancement Control of Micropower Energy Systems” in 2002. He was the Chair for the IEEE Industry Applications Society Industrial Automation and Control Committee and the Vice-Chair for the IEEE Industrial Electronics Society Technical Committee on Smart Grids. Guangjin Li was born in Xiaogan, China, in 1984. He received the Ph.D. degree in electrical engineering from the Ecole Normale Supérieure de Cachan (ENS Cachan), Cachan, France, in 2011. He was a Research Assistant with the Systèmes et Applications des Technologies de l’Information et de l’Energie, ENS Cachan–University Paris Sud 11–Centre National de la Recherche Scientifique, UniverSud Paris. He is currently a Research Associate with the Electrical Machines and Drives Group, The University of Sheffield, Sheffield, U.K. His main research interests include the design and the thermal and faultbased analysis of switched reluctance machines and other permanent-magnet machines. Mohamed Gabsi received the Ph.D. degree in electrical engineering from the University of Paris VI, Paris, France, in 1987, and the Habilitation À Diriger des Recherches from the University of Paris XI, Orsay, France, in 1999. Since 1990, he has been with the Electrical Machine Team, Systèmes d”Energies pour le Transport et l’Environnement, Systèmes et Applications des Technologies de l’Information et de l’Energie, École Normale Supérieure de Cachan–University Paris Sud 11–Centre National de la Recherche Scientifique, UniverSud Paris, Cachan, France, where he is currently a Full Professor and the Director of the Electrical Engineering Department. His research interests include switched reluctance machines, vibrations and acoustic noise, and permanent-magnet machines.