CONCRETE STRUCTURE DESIGN USING MIXED-INTEGER NONLINEAR PROGRAMMING WITH COMPLEMENTARITY CONSTRAINTS

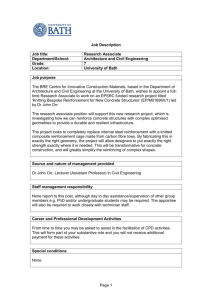

advertisement