Current Research Journal of Biological Sciences 4(4): 350-354, 2012 ISSN: 2041-0778

advertisement

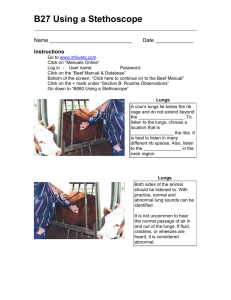

Current Research Journal of Biological Sciences 4(4): 350-354, 2012 ISSN: 2041-0778 © Maxwell Scientific Organization, 2012 Submitted: September 02, 2011 Accepted: October 07, 2011 Published: July 10, 2012 Effects of Zataria multiflora extract as Rumen Modifiers Using in vitro Gas Production Technique Mohammad Salamat Azar, Ramin Salamat Doust-Nober, Naser Maheri Sis, Habib Aghdam Shahryar and Yahya Asadi Department of Animal Science, Shabestar Branch, Islamic Azad University, Shabestar, Iran Abstract: This experiment was to determine effects of tow doses (0 and 0.15 mL/30 mL buffered rumen fluid) of Zataria multiflora extract on Soybean Meal (SBM) degradability were studied by in vitro gas producing techniques. Gas production test with mixtures of filtered rumen liquid of three taleshi native male cattle rumen in times of 2, 4, 6, 8, 12, 24, 48, 72 and 96 were performed. The gas volumes for soybean meal in different incubation times were higher than that of Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid). Chemical composition for dry matter, crude protein and Non-Fibrous Carbohydrate were 94.07, 40 and 29.36%, respectively. The results showed that gas volume at 48 h incubation (for 200 mg dry samples), were 62.12 and 38.01 mL/200 mg DM for soybean meal (control) and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid), respectively. the gas production from soluble fraction (a), the gas production from insoluble fraction (b), rate constant of gas production during incubation (c) and the potential gas production (a + b) contents of soybean meal (control) were 4.42 (mL/200 mg DM), 67.1 (mL/200 mg DM), 0.113 (mL/h) and 71.52 (mL/200 mg DM), respectively, the gas production from soluble fraction (a), the gas production from insoluble fraction (b), rate constant of gas production during incubation (c) and the potential gas production (a + b) contents for Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) were 3.52 (mL/200 mg DM), 45.54 (mL/200 mg DM), 0.07 (mL/h) and 49.06 (mL/200 mg DM), respectively. Gas volume at 72 h incubation (for 200 mg dry samples), of soybean meal and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) were 62.91 and 41.62, respectively. Gas volume at 96 h incubation (for 200 mg dry samples), of soybean meal and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) were 63.72 and 42.82, respectively. Keywords: Gas production technique, insoluble fraction, soluble fraction, soybean meal, taleshi native male cattle, Zataria multiflora extract, animal, respectively. However, this symbiotic relationship has energy losses of methane (CH4) and protein losses of ammonia Nitrogen (N) inefficiencies (Van Nevel and Demeyer, 1988; Calsamiglia et al., 2007). Methane produced during anaerobic fermentation in the rumen represents a 2 to 12% of gross energy loss to the host animal and contributes to emissions of greenhouse gases into the environment (Moss, 1993; Bunthoeun, 2007). The public concern over the routine use of antibiotics and growth promoters in livestock production has increased recently because of the risk of the antibiotic residues presence in milk and meat and its effect on human health. These led to its prohibition in the European Union in 2006 in animal feeding. Accordingly, there is greater interest in using plants and plant extracts as alternatives to feed antibiotics to manipulate ruminal fermentation, improve feed efficiency and animal productivity. Many plants produce secondary metabolites such as phenolic compounds, essential oils and sarsaponins (Calsamiglia et al., 2006, 2007; Sallam et al., 2009) that affect was microbial activity (Sallam et al., 2009). The purposes of this study were to evaluate effects of Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) on gas INTRODUCTION Several methods such as in vivo, in situ and in vitro techniques have been used in order to evaluate the nutritive value of feedstuffs (Maheri-Sis et al., 2008). The in vitro gas production technique has proved to be a potentially useful technique for feed evaluation (Menke and Steingass, 1988; Getachew et al., 2004; Maheri-Sis et al., 2008), as it is capable of measuring rate and extent of nutrient degradation. In addition, in vitro gas production technique provide less expensive, easy to determine (Getachew et al., 2004; Maheri-Sis et al., 2008) and suitable for use in developing countries (Chumpawadee et al., 2005; Maheri-Sis et al., 2007; Maheri-Sis et al., 2008). This method also predicts feed intake, digestibility, microbial nitrogen supply and amount of short chain fatty acids, carbon dioxides and metabolizable energy of feed for ruminants (Babayemi, 2007; Maheri-Sis et al., 2008). Ruminants establish a symbiotic relationship with rumen microorganisms by which the animal provides nutrients and optimal environmental conditions for the fermentation of feeds and microorganisms degrade fiber and synthesize microbial protein as an energy and protein supply for the Corresponding Author: Mohammad Salamat Azar, Department of Animal Science, Shabestar Branch, Islamic Azad University, Shabestar, Iran 350 Curr. Res. J. Biol. Sci., 4(4): 350-354, 2012 volume (mL/200 mg DM) and estimated parameters of soybean meal at different incubation times using in vitro gas production technique. daily with a diet containing alfalfa hay (60%) and concentrate (40%). The samples were incubated in the rumen fluid in calibrated glass syringes following the procedures of (Menke and Steingass, 1988; Menke et al., 1979) as follows. 200 mg dry weight of the sample was weighed in triplicate into calibrated glass syringes of 100 mL in the absence and presence of Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid). The syringes were pre-warmed at 39ºC before injecting 30 mL rumen fluid-buffer mixture into each syringe followed by incubation in a water bath at 39ºC. The syringes were gently shaken 30 min after the start of incubation and every hour for the first 10 h of incubation. Gas production was measured as the volume of gas in the calibrated syringes and was recorded before incubation 2, 4, 6, 8, 12, 24, 48, 72 and 96 h after incubation. All samples were incubated in triplicate with three syringes containing only rumen fluid-buffer mixture (blank). The net gas productions for soybean meal samples were determined by subtracting the volume of gas produced in the blanks. Cumulative gas production data were fitted to the model of Ørskov and McDonald (1979): MATERIALS AND METHODS Chemical analysis: Dry Matter (DM) was determined by drying the samples at 105ºC overnight and ash by igniting the samples in muffle furnace at 525ºC for 8 h and Nitrogen (N) content was measured by the Kjeldahl method (AOAC, 1990). Crude protein (CP) was calculated as N×6.25 (Van Soest et al., 1991). NonFibrous Carbohydrate (NFC) is calculated using the equation of (NRC, 2001), NFC = 100 (NDF + CP + EE + Ash). All chemical analyses were carried out in triplicate. Zataria multiflora samples: During summer season Zataria multiflora samples were collected from different parts of Isfahan province. Next, there were drying for one week and homogeneous mixture were papered for nutritive chemical analyzes. For determination of (Zataria multiflora extract) effects, we added Zataria multiflora extract with dose Zataria multiflora extract (0, 0.15 mL: 200 mg sample) into gas test syringes. All samples were then ground in a laboratory mill through a 1 mm screen. P = a+b (1-eGct) where, P is the gas production at time t, a gas production from soluble fraction (mL/200 mg DM), b the gas production from insoluble fraction (mL/200 mg DM), c the gas production rate constant (mL/h), a+b the potential gas production (mL/200 mg DM) and t is the incubation time (h). Procedure of Zataria multiflora extract preparation: The Zataria multiflora extract were prepared according to (Patra et al., 2006; Sallam et al., 2009) with some modifications. The Zataria multiflora materials were dried at 50ºC and ground in mills to pass a 1 mm sieve and 100 g placed in 1000 mL of methanol solvent. The flasks of all the solvents were stoppered and agitated with a magnetic stirrer for 24 h at room temperature. Then the solutions were centrifuged at 3000 g for 10 min. The residue was re-extracted with 500 mL of methanol for 24 h stirring at room temperature and centrifuged again at 3000 g for 10 min. The Zataria multiflora extract were combined. Distilled water was evaporated from the solution at approximately 65ºC by using a rotaryevaporator (Patra et al., 2006; Sallam et al., 2009). Statistical analysis: Data on apparent gas production parameters were subjected to one-way analysis of variance using the analysis of variation model ANOVA of SAS (2000). Multiple comparison tests used Duncan’s multiple- t-test (1980). Mean differences were considered significant at (p<0.05). Standard errors of means were calculated from the residual mean square in the analysis of variance. All data obtained from three replicates n = 3. RESULTS Treatments and experimental design: The different doses of Zataria multiflora extract were added to the diet sample. Tow doses (0, 0.15 mL/30 mL buffered rumen fluid) of Zataria multiflora extract were investigated as follow: C C Chemical composition: The chemical composition of soybean meal shown was in Table 1. Chemical composition of soybean meal including Dry matter (DM), crude protein CP) and Non-Fibrous (Carbohydrate )NFC) were estimated; 94.07, 40 and 29.36%, respectively. No additive (control); Zataria multiflora extract (0.15/30 mL buffered rumen fluid). In vitro gas production: Gas production volumes (mL/200 mg DM) at differents incubation times of soybean meal and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) shown were in Fig. 1. In vitro gas production: Fermentation of soybean meal samples were carried out with rumen fluid was obtained from three fistulated Taleshi native male cattle fed twice 351 Curr. Res. J. Biol. Sci., 4(4): 350-354, 2012 70 Gas volumes (mL/200mg DM) contents for Zataria multiflora extract (0.15/30 mL buffered rumen fluid) were 3.52 (mL/200 mg DM), 45.54 (mL/200 mg DM), 0.07 (mL/h) and 49.06 (mL/200 mg DM). No additive (control) Zataria multiflora extract dose 0.15 60 50 DISCUSSION 40 30 In vivo, in situ and in vitro methods have been used to evaluate the nutritive value of feedstuffs (Maheri-Sis et al., 2011). The in vitro gas production technique has proven to be a potentially useful technique to evaluate the nutritive value of feedstuffs, since it gives an estimate of the potential rate and extent of nutrient fermentation in the rumen. However, this technique is measuring gas produced by the fermentation of energy containing components in feeds and not only that of protein (MirzaeiAghsaghali and Maheri-Sis, 2008a; Mirzaei-Aghsaghali et al., 2008; Maheri-Sis et al., 2007, 2008). Gas volume at 24 h incubation (for 200 mg dry samples), soluble fraction (a), insoluble but fermentable fraction (b), potential gas production (a + b) and rate constant of gas production (c) of sunflower meal were 42.40, 3.607, 49.32, 52.92 mL/200 mg DM and 0.135 mL/h, for Zataria multiflora water extract (0.15 mL/30 mL buffered rumen fluid) 41.41, 3.921, 49.08, 53.004 and 0.135 while for Zataria multiflora water extract (0.3 mL/30 mL buffered rumen fluid) were 40.52, 4.655, 48.66, 53.321 mL/200 mg DM and 0.134 mL/h, respectively (Salamat azar et al., 2011). Gas volume at 48 h incubation (for 200 mg dry samples), of sunflower meal, Zataria multiflora water extract (0.15 and 0.3 mL/30 mL buffered rumen fluid) were 44.99, 44.49 and 43.27 (mL/200 mg DM), respectively. Gas volume at 72 h incubation (for 200 mg dry samples), of sunflower meal, Zataria multiflora water extract (0.15 and 0.3 mL/30 mL buffered rumen fluid) were 45.75, 45.23 and 44.25, respectively (Salamat Azar et al., 2011). These results are in agreement with the findings of (Salamat Azar et al., 2011). Compounds with phenolic structures, such as thymol, are more effective as antimicrobials in comparison with other nonphenolic secondary plant metabolites because of the presence of a hydroxyl group in the phenolic structure (Helander et al., 1998; Ultee et al., 2002; Calsamiglia et al., 2007). Furthermore, the small molecular weight of thymol allows it to gain access to the cell membrane through the pores of the external wall (Calsamiglia et al., 2007). The strong and widespectrum activity against gram-positive and gram-negative bacteria, the narrow margin of security between an optimal and a toxic dose and the effects reported, which were not always in the desired direction (Castillejos et al., 2006; Calsamiglia et al., 2007), suggest that its antimicrobial activity may be too strong and nonspecific to modulate the fermentation in a complex microbial environment such as the rumen (Calsamiglia et al., 2007). he cumulative volume of gas production 20 10 0 0 20 40 60 80 Incubation times, (h) 100 120 Fig. 1: In vitro gas production volume of soybean meal and Zataria multiflora extract (0.15/30 mL buffered rumen fluid) was different incubation time Table 1: Chemical composition of soybean meal (%) Component Dry Matter (DM) Crude Protein (CP) Non-Fiber Carbohydrate (NFC) % 94.07 40.00 29.36 Gas production volumes (mL/200 mg DM) and estimated parameters at differents incubation times of soybean meal and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) are presented in Table 2 and 3. The gas volumes for soybean meal in different incubation times were higher than that of Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid). Gas volume at 12 h incubation (for 200 mg dry samples), of Soybean Meal (SBM) and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) were 46.24 and 24.34 mL/200 mg DM, respectively. Gas volume at 24 h incubation (for 200 mg dry samples), of Soybean Meal (SBM) and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) were 56.38 and 36.41 (mL/200 mg DM), respectively. Gas volume at 48 h incubation (for 200 mg dry samples), of Soybean Meal (SBM) and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) were 62.12 and 38.01 (mL/200 mg DM), respectively. Gas volume at 72 h incubation (for 200 mg dry samples), of soybean meal and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) were 62.91 and 41.62, respectively. Gas volume at 96 h incubation (for 200 mg dry samples), of soybean meal and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) were 63.72 and 42.82, respectively. the gas production from soluble fraction (a), the gas production from insoluble fraction (b), rate constant of gas production during incubation (c) and the potential gas production (a+b) contents of soybean meal (control) were 4.42 (mL/200 mg DM), 67.1 (mL/200 mg DM), 0.113 (mL/h) and 71.52 (mL/200 mg DM), the gas production from soluble fraction (a), the gas production from insoluble fraction (b), rate constant of gas production during incubation (c) and the potential gas production (a+b) 352 Curr. Res. J. Biol. Sci., 4(4): 350-354, 2012 Table 2:In vitro gas production volumes (mL/200 mg DM) of soybean meal and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) at different incubation times Incubation times --------------------------------------------------------------------------------------------------------------------------------------------------------Treatment 2 4 6 8 12 24 48 72 96 No Additive 9.31 19.96 27.623 7.26 46.24 56.38 62.12 62.91 63.72 ZME 0.15 4.92 7.47 9.04 14.11 24.34 36.41 38.01 41.62 42.82 P Value 0.0001 p<0.001 p<0.001 p<0.001 0.0001 0.0007 0.0004 0.0007 0.0012 SEM 2.428 6.868 10.194 12.723 12.093 18.186 13.428 11.958 11.774 Table 3: The estimated parameters from the gas production were soybean meal and Zataria multiflora extract (0.15 mL/30 mL buffered rumen fluid) Estimated parameters ---------------------------------------------------------------Treatment a b |a|+b c No additive 4.42 67.1 71.52 0.113 ZME 0.15 3.52 45.54 49.06 0.07 P-value 0.0476 0.0012 0.0014 p<0.001 SEM 0.605 12.569 12.693 0.023 a+b : SBM : DM : ZME : The potential gas production (mL/200 mg DM) Soybean meal Dry matter Zataria multiflora extract REFERENCES AOAC, 1990. Official Method of Analysis. 15th Edn., Association of Official Analytical Chemists, Washington DC. USA, pp: 66-88. Babayemi, O.J., 2007. In vitro fermentation characteristics and acceptability by West African dwarf goats of some dry season forages. Afr. J. Biotechnol., 6(10): 1260-1265. Blummel, M. and E.R. Ørskov, 1993. Comparison of in vitro gas production and nylon bag degradability of roughages in predicting feed intake in cattle. Anim. Feed Sci. Technol., 40: 109-119. Blummel, M. and K. Becker, 1997. The Degradability characteristics of fifty-four roughages and roughage neutral detergent fibers as described by in vitro gas production and their relationship to voluntary feed intake. Br. J. Nutr., 77: 757-768. Bunthoeun, P.E.N., 2007. Major Chair of Animal Production the United Graduate School of Agricultural Sciences, Iwate University. Obihiro University of Agriculture and Veterinary Medicine. Calsamiglia, S., L. Castillejos and M. Busquet, 2006. Alternatives to Antimicrobial Growth Promoters in Cattle. In: Garnsworthy, P.C. and J. Wiseman, (Eds.), Recent Advances in Animal Nutrition. Nottingham University Press, Nottingham, UK, pp: 129-167. Calsamiglia, S., M. Busquet, P.W. Cardozo, L. Castillejos and A. Ferret, 2007. Invited review: Essential oils as modifiers of rumen microbial fermentation. J. Dairy Sci., 90: 2580-2595. Castillejos, L., S. Calsamiglia and A. Ferret, 2006. Effect of essential oils active compounds on rumen microbial fermentation and nutrient flow in in vitro systems. J. Dairy Sci., 89: 2649-2658. Chumpawadee, S., K. Sommart, T. Vongpralub and V. Pattarajinda, 2005. Nutritional evaluation of non forage high fibrous tropical feeds for ruminant using in vitro gas production technique. Pak. J. Nutr., 4: 298-303. increased with increasing time of incubation. Although there are other models available to describe the kinetics of gas production, the (Ørskov and McDonald, 1979; Mirzaei-Aghsaghali and Maheri-Sis, 2008; MirzaeiAghsaghali et al., 2008; Maheri-Sis et al., 2007, 2008) was chosen because the relationship of its parameters with intake, digestibility and degradation characteristic of forages and concentrate feedstuffs had been documented. Sommart et al. (2000) reported that gas volume is a good parameter from which to predict digestibility, fermentation end product and microbial protein synthesis of the substrate by rumen microbes in the in vitro system (Mirzaei-Aghsaghali and Maheri-Sis, 2008; MirzaeiAghsaghali et al., 2008; Maheri-Sis et al., 2007, 2008). Gas volumes also have shown a close relationship with feed intake (Blummel and Ørskov, 1997) and growth rate in cattle (Blummel and Ørskov, 1993; Mirzaei-Aghsaghali and Maheri-Sis, 2008; Mirzaei-Aghsaghali et al., 2008; Maheri-Sis et al., 2007, 2008). The soluble fraction (a) makes it easily attachable by ruminal microorganisms and leads to much gas production (Blummel and Becker, 1997). The gas volumes at asymptote (b) have the advantage for predict feed intake (Mirzaei-Aghsaghali and Maheri-Sis, 2008a; Mirzaei- Aghsaghali et al., 2011; Maheri-Sis et al., 2007, 2008). This study the gas volumes for soybean meal in different incubation times were higher than that of Zataria multiflora extract (0.15/30 mL buffered rumen fluid). ABBREVIATIONS GP : Gas production technique NFC : Non-Fibrous Carbohydrate (a) : The gas production from soluble fraction (mL/200 mg DM) b : The gas production from insoluble fraction (mL/200 mg DM) c : Rate constant of gas production during incubation (mL/h) 353 Curr. Res. J. Biol. Sci., 4(4): 350-354, 2012 Mirzaei-Aghsaghali, A., N. Maheri-Sis, A. MirzaAghazadeh, H. Mansouri, A.R. Safaei, A. Aghajanzadeh-Golshani and K. Alipoor, 2011. Estimation of the nutritive value of tomato pomace forruminant using in vitro gas production technique., Res. J. Biol. Sci., 10(33): 6251-6256. Moss, A.R., 1993. Methane: Global Warming and Production by Animals. Chalcombe Publications, Kingston, UK. NRC, 2001. Nutrient Requirements of Dairy Cattle. 7th Edn., National Research Council, National Academy Press, Washington, DC. Ørskov, E.R. and I. McDonald, 1979. The Estimation of protein degradability in the rumen from incubation measurements weighed according to rate of passage. J. Agric. Sci., 92: 499-503. Patra, A.K., D.N. Kamra and N. Agarwal, 2006. Effect of plant extracts on in vitro methanogenesis, enzyme activities and fermentation of feed in rumen liquor of buffalo. Anim. Feed Sci. Technol., 128: 276-291. Salamat azar, M., R. Salamtdoust nobar, Y. Asadi. M. Kiani Nahand. S. Najafyar. B. Khodaparast and H. Aminipur, 2011. Effect of Zataria multiflora extract on Degradability kinetics, of sunflower meal. J. Am. Sci., 7: 119-122. Sallam, S.M.A., I.C.S. Bueno, P. Brigide, P.B. Godoy, D.M.S.S. Vitti and A.L. Abdalla, 2009. Investigation of potential new opportunities for plant extracts on rumen microbial fermentation in vitro. Nutr. Foraging Ecol. Sheep Goats, 85: 255-260. SAS, 2000. SAS Users Guide. Cary, Statistical Analysis Systems Institute, USA. Sommart, K., D.S. Parker, P. Rowlinson and M. Wanapat, 2000. Fermentation characteristics and microbial protein synthesis in an in vitro system using cassava, rice straw and dried ruzi grass as substrates. AsianAust. J. Anim. Sci., 13: 1084-1093. Ultee, A., M.H.J. Bennik and R. Moezelaar, 2002. The phenolic hydroxyl group of carvacrol is essential for action against the food-borne pathogen Bacillus cereus. Appl. Environ. Microbiol., 68: 1561-1568. Van Nevel, C.J. and D.I. Demeyer, 1988. Manipulation of Rumen Fermentation. Elsevier Applied Science, London, pp: 387-443. Van Soest, P.J., J.B. Robertson and B.A. Lewis, 1991. Methods for dietary neutral detergent fiber and non starch polysaccharides in relation to animal nutrition. J. Dairy Sci., 74: 3583-3597. Getachew, G., P.H. Robinson, E.J. DePeters and S.J. Taylor, 2004. Relation-ships between chemical compositions, dry matter degradation and in vitro gas production of several ruminant feeds. Anim. Feed Sci. Technol., 111: 57-71. Helander, I.M., H. Alakomi, K. Latva-Kala, T. MattilaSandholm, I. Pol, E.J. Smid, L.G.M. Gorris and A. Wright, 1998. Characteritzation of the action of selected essential oil components on gram-negative bacteria. J. Agric. Food Chem., 46: 3590-3595. Maheri-Sis, N., M. Chamani, A.A. Sadeghi, A. MirzaAghazadeh and A.A. Safaei, 2007. Nutritional evaluation of chickpea wastes for ruminants using in vitro gas production technique. J. Anim. Vet. Adv., 6(12): 1453-1457. Maheri-Sis, N., M. Chamani, A.A. Sadeghi, A. MirzaAghazadeh and A. Aghajanzadeh-Golshani, 2008. Nutritional evaluation of kabuli and desi type chickpeas (Cicer arietinum L.) for ruminants using in vitro gas production technique. Afr. J. Biotechnol., 7: 2946-2951. Maheri-Sis, N., M. Eghbali-Vaighan, A. MirzaAghazadeh, A. Ahmadzadeh, A. AghajanzadehGolshani, A. Mirzaei-Aghsaghali and A.A. ShaddelTelli, 2011. Effects of microwave irradiation on ruminal dry matter degradation of tomato pomace. Res. J. Biol. Sci., 3(3): 268-272. Menke, K.H. and H. Steingass, 1988. Estimation of the energetic feed value obtained from chemical analysis and gas production using rumen fluid. Anim. Res. Dev., 28: 7-55. Menke, K.H., L. Raab, A. Salewski, H. Steingass, D. Fritz and W. Schneider, 1979. The estimation of the digestibility and metabolisable energy content of ruminant feedstuffs from the gas production when they are incubated with rumen liquor. J. Agric. Sci., 93: 217-222. Mirzaei-Aghsaghali, A. and N. Maheri-Sis, 2008. Nutritive value of some agro-industrial by-products for ruminants-A review. World J. Zool., 3(2): 40-46. Mirzaei-Aghsaghali, A., N. Maheri-Sis, A. MirzaAghazadeh, A.R. Safaei and A. AghajanzadehGolshani, 2008. Nutritive value of alfalfa varieties for ruminants with emphasis of different measuring methods: A review. Res. J. Biol. Sci., 3(10): 1227-1241. 354