Current Research Journal of Biological Sciences 3(3): 246-253, 2011 ISSN: 2041-0778

advertisement

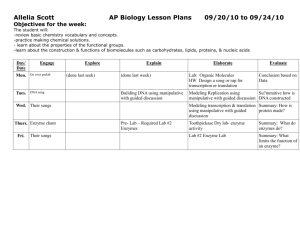

Current Research Journal of Biological Sciences 3(3): 246-253, 2011 ISSN: 2041-0778 © Maxwell Scientific Organization, 2011 Received: March 24, 2011 Accepted: April 20, 2011 Published: May 05, 2011 Production, Purification and Characterization of Tannase from Rhodococcus NCIM 2891 Naiem H. Nadaf and Jai S. Ghosh Department of Microbiology, Shivaji University, Vidyanagar, Kolhapur 416004, India Abstract: The study was done with the objective of tannic acid degradation by tannase from the Rhodococcus NCIM 2891 which is actually a desulfurizing bacteria. Rhodococcus NCIM 2891cultivated in medium containing 0.1% Tannic acid, produced tannase which showed maximum activity after 24 h. The enzyme was purified by DEAE cellulose ion exchange chromatography and was shown to be dimeric in nature it has two subunits as Tannase I and Tannase II, having specific activities of 0.23 U/mg of protein and 0.295 U/mg of protein, respectively. Both the enzyme showed optimum activity at pH 6 and 30ºC. The Km of both enzymes was 0.034 and 0.040 mM respectively and Vmax of both enzymes were found to be 40 and 45 U/mL, respectively. SDS-PAGE analysis of purified proteins fraction revealed that their molecular weights are 60 and 62 kDa. Tannase I was completely inhibited by 10 mM Hg2+, Cu2+, Fe3+, Co2+ and Tannase I and II both was completely inhibited by1 mM Hg2+ alone. The DNA damage- protecting activity of tannic acid and product obtained after tannic acid hydrolysis was assessed bringing about the DNA damage with H2O2 + UV exposure in absence of the hydrolyzed products of tannic acid. The experiment was carried out by using agarose gel electrophoresis to analyze DNA damage in presence of H2O2 + UV. However, there was no damage of DNA by H2O2 + UV exposure in presence of the hydrolysis products. Key words: Gallic acid, NCIM 2891, pollutants, Rhodococcus, tannase, tannin Tannin acyl hydrolase (EC 3.1.1.20), commonly called tannase, is an enzyme that hydrolyzes the ester bonds of tannic acid, to produce gallic acid and glucose and galloyl esters (Belur and Mugeraya, 2011). Besides gallic acid production, the enzyme is extensively used in the preparation of instant tea, wine, beer, and coffeeflavored soft drinks and also as additive for detanniffication of food (Lekha and Lonsane, 1997). In addition, it is also used as a sensitive analytical probe for determining the structure of naturally occurring gallic acid ester (Haslam and Stangroom, 1996). Although tannase is present in the plants, animals and microorganisms, it is mainly produced by the microorganisms (Ayed and Hamdi, 2002). Filamentous fungi of the genus Aspergillus, have been widely used for tannase production (Banerjee et al., 2001; Beniwal and Chhokar 2010). Members of the genus Rhodococcus occur widely, and are aerobic, non-sporulating bacteria, with a high GC content. These organisms are of environmental and biotechnological importance because of their broad catabolic diversity and array of unique enzymatic capabilities (Bell et al., 1998) and their exceptional ability INTRODUCTION Tannins are naturally occurring water-soluble polyphenols which are often considered as recalcitrant, that commonly exist in wastewater from forestry, paper and leather industries and cause many problems associated with environmental pollution (Yagu et al., 2000). These are widespread in the plant kingdom, occurring mostly in leaves, fruits, bark and wood and are often considered nutritionally undesirable (Chung et al., 1998; Murugan and Saleh, 2010). Tannins inhibit growth of various microorganisms, by precipitating many enzymes and (Field and Lettinga, 1992a). Several conventional physiochemical techniques are available for tannin-containing wastewater treatment (Svitelska et al., 2004). However, the major drawbacks of these processes are high cost, tendency to form secondary hazardous byproducts, and incomplete degradation. The biological treatment of tannin-containing wastewater is now considered to be a better alternative, though these too have certain limitations (Bhat et al., 1998; Ren, 2004; Field and Lettinga, 1992b). Corresponding Author: Dr. J.S. Ghosh, Assistant Professor, Department of Microbiology, Shivaji University, Vidyanagar, Kolhapur 416004, India. Ph: +91 9850515620 246 Curr. Res. J. Biol. Sci., 3(3): 246-253, 2011 Tannase assay: The reaction mixture consisted of 0.3 mL of tannic acid (0.7% (w/v) in 0.2 M citrate buffer (pH 6.0) and 0.1 mL of the enzyme extract. This was incubated at 30ºC for 20 min. The enzymatic reaction was paralyzed by the addition of 3 mL of bovine serum albumin solution - BSA (1 mg/mL), leading to the precipitation of the remaining tannic acid. This was then centrifuged at 9000×g for 15 min at 4ºC and the residue was dissolved in 2 mL of SDS-triethanolamine, followed by the addition of 1 mL of FeCl3 reagent and holding for 15 min for colour stabilization. The absorbance was measured at 530 nm. One unit of tannase activity was defined as the amount of tannic acid hydrolyzed by 1 mL of enzyme minute of reaction. to degrade hydrophobic natural compounds and xenobiotics. However, there are no reports of tannic acid degradation or production of tannase by Rhodococcus. This investigation focuses about potential uses of Rhodococcus in tannin waste recycling and production of valuable products, applicable for the various industrial processes. MATERIALS AND METHODS The study was conducted between August 2010 and February 2011. The work was carried out at the Department of Microbiology, Shivaji University, Kolhapur, India. Microorganism: Rhodococcus NCIM 2891 was obtained from NCIM (National Collection of Industrial Microorganisms, NCL, Pune, India). The culture was maintained on GYEME ( Glucose Yeast extract Malt extract ) agar having the following composition 1% glucose, 0.3% yeast extract, 0.3% malt extract 0.5% peptone and 1.5 % agar-agar. High performance thin layer chromatography (HPTLC): The gallic acid produced was analyzed by using High performance thin layer chromatography (HPTLC) system (CAMAG, Switzerland). Stationary phase HPTLC silica gel 60 F254 (Merck, Germany), predeveloped with methanol, dried at 120ºC for 20 min, cooled to room temperature, and equilibrated with the relative humidity of the laboratory. The plates were developed using saturated chamber containing developing solvent (butanol: acetic acid: water in 4:1:1 ratio). The chamber was saturated for 20 min prior to plate development. After development the plate was scanned at 280 nm. The results were analyzed by using HPTLC Win CATS 1.4.4.6337 software. Growth of Rhodococcus on tannic acid: The Rhodococcus NCIM 2891 was grown in medium containing 0.3% NaNO3, 0.1% K2HPO4, 0.05% MgSO4, 0.05%KCL, 0.0001% FeSO4, and 0.1% tannic acid. The pH was adjusted to 7.0. Screening of Rhodococcus for the production of tannase: Tannase production by Rhodococcus NCIM 2891 was checked by growing the microorganism on nutrient agar supplemented with 2% tannic acid which was filter sterilized. Addition of tannic acid to nutrient agar plate forms a complex of tannic acid and proteins and after cleavage of this complex, organism produces clear zone around colony. Effect of pH and temperature: The effect of pH and temperature was checked for both the enzymes. The effect of pH on enzyme activity was studied at varying pH range from 4.0 to 10.0, using citrate- buffer (pH 3.0-5.0), sodium- phosphate buffer (pH 6.0-8.0) and glycineNaOH buffer (pH 9.0-10.0). The effect of temperature on enzyme activity was studied between temperatures 10 to 90ºC. In all cases the preincubation of enzyme was carried out for 30 min with respective pH and temperatures and then activity was measured by standard assay as described above. Tannic acid degradation: Enzyme extraction and purification: The enzymes tannase was purified from cell free medium. In first step cell free medium was saturated up to 40% with ammonium sulphate and allowed to precipitate for 6 hrs at 4ºC. This precipitate was discarded and the supernatant was saturated with ammonium sulphate up to 80%, which was kept overnight for residual enzyme precipitation. This precipitate was dissolved in 20 mL of 1 mM citrate buffer (pH = 6.0) and was further purified by DEAE - Cellulose ion exchange column chromatography. The elution was carried out at a flow rate of 0.5 mL/min, using NaCl concentration gradient from 0 to 0.2 M in 50 mM citrate buffer (pH = 6.0). The fractions were analyzed for tannase activities, and later used for SDS-PAGE analysis. Effect of metal ions: To study the effect of metal ions on enzyme activity, enzyme was pre-incubated in citrate buffer (pH 6.0) with metal ions Ca2+, Hg2+, Fe3+, Co2+, Mg2+, Cu2+ using their respective water soluble salts with 1 and 10 mM concentration. The residual enzyme activity was subsequently measured by standard assay as described above. Enzyme kinetics: The Km and Vmax of the Tannase I and II was determined by Lineweaver-Burk plots of reciprocal reaction velocities versus reciprocal substrate 247 Curr. Res. J. Biol. Sci., 3(3): 246-253, 2011 Protein estimation: Protein estimation was done by the Lowry method using bovine serum albumin as standard (Lowry et al., 1951). concentrations. Reactions were performed in citrate buffer (pH 6.0); with various concentrations of substrate 1% tannic acid by the addition of 0.1 to 1 mL. and enzyme activity was monitored under the same conditions that are mentioned above. Statistical analysis: Results obtained were the mean of 5 replications. Analysis of the variants was carried out on all data at p<0.05 using Graph Pad software. (Graph Pad Instat version 3.00, Graph Pad software, San Diego, CA, USA). Protection against DNA damage induced by H2O2 + UV: DNA damage and DNA protecting activities on sample DNA according to protocol of Russo et al. (2000) modified by Skandrani et al. (2009). The test DNA used in experiment was 8 phage DNA (Linear double stranded with 48502 base pairs purchased from Genie, Bangalore India). The 8 phage DNA was oxidized with H2O2 + UV treatment in presence and in absence of product obtained after hydrolysis of tannic acid. The total volume of reaction mixture prepared was17 µL containing 500 ng of 8 phage DNA, 10 µL tannic acid (0.1% w/v) and 10 µL incubated cell free medium (filter sterilized). H2O2 was added to this at a final concentration of 100 mM. The whole system was exposed to UV light (wavelength of 312 nm) at ambient temperature for 5 min. After irradiation, the mixture was incubated at room temperature for 15 min. Untreated 8 phage DNA was used as a control during the run of gel electrophoresis along with UV and H2O2 treated sample of DNA. RESULTS Growth of Rhodococcus NCIM 2891: It was observed that the Rhodococcus NCIM 2891 was able to grow on Tannic acid as a sole source of carbon. The maximum Tannic acid degradation was observed in exponential phase. Screening of Rhodococcus for the production of tannase: The clear zone was observed around the growth of Rhodococcus NCIM 2891 after 48 h of incubation indicates that the microorganism producing tannase enzyme cleave tannic acid protein complex by hydrolyzing tannic acid. Fig. 1: The elution profile of DEAE-Cellulose Ion exchange chromatography of Tannase enzyme. Protein concentration of fractions (•) and activity of tannase enzymes (#)Results obtained are mean values±SD, n = 5 Table 1: Purification profile of tannase enzymes Enzyme Enzyme activity (units) Proteins (mg) Sp activity (Units/mg) Crude 455 3500±0.05* 0.13±0.08* After ammonium 301 1005±0.06* 0.29±0.05* sulfate precipitation After ion exchange chromatography Fraction 1 60 268±0.03* 0.23±0.02* (Tannase - I) Fraction no 2 190 644±0.06* 0.295±0.05* (Tannase - II) Results obtained were the standard error of mean of 5 replications; *: p< 0.05 248 Yield (%) 100 66 Purification fold 1 2.23 13.18 1.76 41.57 2.23 Curr. Res. J. Biol. Sci., 3(3): 246-253, 2011 Purification of Tannase: The purification profile of tannase enzyme is given in Fig. 1 and the activity of extracted tannase at different stages of purification is given in Table 1. It has been noted from Table 1, that the precipitate at 80% saturation of (NH4)2SO4 was giving the best yield of the enzyme. The same yield did not show any improvement after DEAE Cellulose ion-exchange chromatography, except that the 2 fractions seperated (Fig. 1). The specific activities of Tannase I and Tannase II was measured about 0.23 U/mg of protein and 0.295 U/mg of protein using tannic acid as substrate. SDS/PAGE analysis revealed that the two enzymes had molecular weights of 60kDa and 62 kDa respectively as shown in Fig. 2. HPTLC analysis: The HPTLC analysis of incubated broth indicated the production of gallic acid due to hydrolysis of tannic acid by Tannase, as shown in Fig. 3. The Rf value of standard gallic acid was 0.90 where as the product of hydrolysis gave Rf values 0.89 and 0.88. these Rf values linearly equals each other, indicating that tannase produced by the microorganism was able to degraded tannic acid in to its monomer, gallic acid. Fig. 2: SDS-PAGE of purified Tannase I (a) Tannase II (b), from Rhodococcus NCIM 2891 Size of the standard markers is at left. Markers (da) (m): phosphorylase b (97.4 kDa), Bovine Serum albumin (66 kDa), ovalbumin (43 kDa), carbonic anhydrase (29 kDa), trypsin inhibitor (20.1 kDa), and lactabumin (14.3 kDa) d 1000.0 [AU] 800.0 700.0 1000.0 [AU] 600.0 800.0 500.0 700.0 400.0 300.0 600.0 200.0 500.0 400.0 100.0 0.0 50.0 [AU] 40.0 35.0 30.0 25.0 20.0 15.0 300.0 200.0 100.0 0.0 0.20 0.00 0.20 0.40 0.00 10.0 0.00 5.0 [AU] 1.20 0.0 Fig. 3: HPTLC analysis of standard gallic acid and incubated broth after 24 h. and 48 h,(a) standard gallic acid; (b) broth after 24 h. incubation; (c) Broth after 48h. Incubation; (d) 3D peak profile of gallic acid; (e) developed HPTLC plate in that 249 Residual activity of Tannase II (%) Curr. Res. J. Biol. Sci., 3(3): 246-253, 2011 Residual activity (%) 120 100 80 60 40 20 0 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 pH Fig. 4: Effect of pH on enzyme activity tannase I (•) and Tannase II (#).Results obtained are mean values±SD, n=5 160 1 mM 10 mM 140 120 100 80 60 40 20 0 Control Hg Mg Mn Ca Metal ions Cu Fe Co Fig. 7: Effect of heavy metals on Tannase II with 1mM and 10 mM concentration. Results obtained are mean values±SD, n = 5 250 100 80 200 60 40 150 20 0 1/V Recidual activity (%) 120 10 20 30 40 50 60 Temperature °C 70 80 90 100 Residual activity of Tannase I (%) Fig. 5: Effect of Temperature on enzyme activity Tannase I (•) and Tannase II (#).Results obtained are mean values±SD, n = 5 120 50 0 1 mM 10 mM -50 0 50 100 150 200 1/S 100 Fig. 8: Km of Tannase I with Tannic acid as a substrate results obtained are mean values±SD, n = 5 80 60 400 40 350 20 0 Control Hg Mg Mn Ca Metal ions Cu Fe 300 Co 250 1/V Fig. 6: Effect of heavy metals on tannase I with 1mM and 10 mM concentration. Results obtained are mean values±SD, n = 5 200 150 pH and temperature effect: The optimum pH of the Tannase I and Tannase II were 6 whereas temperature optimum for Tannase I and Tannase II were 30ºC as shown in Fig. 4 and 5. 100 50 -50 Effect of heavy metals: The Tannase I showed complete inhibition by Hg+2 in 1mM concentration and by 10 mM Fe3+, Cu2+, Co2+ whereas the activity of tannase was retained 100 %, by 1 mM Cu2+ as shown in Fig. 6. 0 0 50 1/S 100 150 200 Fig. 9: Km of Tannase II with Tannic acid as a substrate Results obtained are mean values±SD, n = 5 250 Curr. Res. J. Biol. Sci., 3(3): 246-253, 2011 a b c Monika et al. (2007) reported the production of two extracellular tannase but cold adapted from Verticillum sp. 9 each consisting of approximately 40 and 60 kDa sub units Rhodococcus NCIM 2891 also produces two enzyme namely Tannase I and Tannase II having approximately molecular weight around 60 and 62 kDa. The other known fungal tannase are multimeric proteins and molecular weight varying from 168 to over 310 kDa (Sabu et al., 2005; Hatamoto et al., 1996). Both tannase were optimally active at pH 6 however the optimum pH was 5-5.5 in case of fungal tannase (Sabu et al., 2005). The optimum temperature of the Tannase I and and II is 30oC which is same as reported for the Bacillus licheniformis KBR 6 (Mondal and Patil, 2000) as compared many reports regarding temperature variability among tannase produced by different type of fungi (Sabu et al. 2005). The Km of Tannase I and II are 0.034mM and 0.040 mM which is very low as compared to the Km value for a similar enzyme produced by Cryphonectria parasitica, using tannic acid as substrate, have been found to be 0.94 mM (Farias et al., 1994). The Km values for tannases from Selenomonas ruminantium and Cryphonectria parasatica using methyl gallate as substrate have been found to be 1.6 mM (Skene and Brooker, 1995) and 7.49 mM (Farias et al., 1994). The Km values for tannic acid of tannases produced by other fungi ranged from 0.20 to 1.03 mM (Mukherjee and Banerjee 2006; Sharma et al., 1999; Sabu et al., 2005). The enzyme was completely inhibited by Hg2+, Cu2+, 2+ Fe , Co2+ ions the effect of metal ions are similar to those reported previously but the only difference was that activity of other tannases are increased in presence of Mg2+ (Kar et al., 2003). There are reports which states important application of tannase that is the production of gallic acid and propylgallate, fine-chemicals employed as antioxidants in foods, cosmetics, hair products, adhesives, and lubricant industry (Kar et al., 2002; Yu et al., 2004; Yu and Li, 2006). Min-Jer and Chinshuh, (2008) studied enzymatic modification by tannase which increased the antioxidant activity of green tea. The antioxidant properties of tannic acid degradation, was checked by using DNA damage assay. The oxidative DNA damage induced by tea catechins especially epigallocatechin gallate (EGCG) in presence of metals complexes such as Cu2+ and Fe3+ has been reported to decrease due to EGCG hydrolysis (Furukawa et al., 2003). These are similar with our results but the difference was only that there were no metals complexes. d Fig. 10: Profile of agarose gel electrophoresis lane (a) DNA + H2O2, lane (b) Control DNA, lane (c) DNA+ H2O2+ incubated cell free medium and lane (d) DNA+ H2O2+ Tannic acid The Tannase II showed complete inhibition by Hg+2 at 1 mM concentration and 25% of the activity was inhibited by 1 mM Mn+2, and 10mM Mg2+, Cu2+, Co2+. Tannase I showed increase in activity by 37% above optimum, in presence of 1 mM Cu2+, 10 mM Ca2+, by 25% in presence of Co2+ and up to 12% in presence of Fe3+ (Fig. 7). Enzyme kinetics: The Km of Tannase I is 0.034 mM whereas the Km Tannase II 0.040mM. The Vmax of both enzymes were found to be 40 and 45 U/mL, respectively as shown in (Fig. 8 and 9). Protection against DNA damage induced by H2O2 + UV by obtained product after hydrolysis of tannic acid: Figure 10 shows that the DNA damage was observed in first sample (a) where the DNA was treated with 100 mM H2O2. Sample (b) which was unexposed control, shows no damage of DNA. Sample(c), which was treated with 100 mM H2O2 and 10 :L incubated cell free medium containing gallic acid shows similar band as in control. Sample (d) which had tannic acid, showed some damage of the DNA. DISCUSSION This is a first report of tannase production from Rhodococcus NCIM 2891 where this microorganism produces 2 extracellular tannase namely Tannase I and Tannase II. The study regarding the production of Tannase by other microorganisms reveals that the fungi are predominant tannase producers and extensively studied (Bradoo et al., 1996). Deschamps et al. (1983) reported that the optimum enzyme production by Bacillus pumilus, Bacillus polymyxa, Cornybacterium sp. and Klebsiella pneumoniae in presence of chestnut bark as sole carbon source. The preliminary study to check tannase production from Rhodococcus NCIM 2891 included plate assay. The production of gallic acid during incubation was checked by HPTLC method. 251 Curr. Res. J. Biol. Sci., 3(3): 246-253, 2011 Bradoo, S., R. Gupta and R.K. Saxena, 1996. Screening of extracellular tannase producing fungi: Development of a rapid and simple plate assay. J. Gen. Appl. Microbiol., 42: 325-329. Chung, K.T., T.Y. Wong, C.I. Wei, Y.W. Huang and Y. Lin, 1998. Tannins and human health: A review. Crit. Rev. Food Sci. Nutr., 38: 421-464, PMID: 9759559. Deschamps, A.M., G. Otuk and J.M. Lebault, 1983. Production of tannase and degradation of chestnut tannins by bacteria. J. Ferment. Technol., 61: 55-59. Farias, G.M., C. Gorbea, J.R. Elkins and G.J. Gpiffin, 1994. Purification, characterization, and substrate relationships of the tannase from Cryphonectria parasitica. Physiol. Mol. Plant Pathol., 44: 51-63. Field, J.A. and G. Lettinga, 1992a. Biodegradation of Tannins. In: Sigel, H. (Ed.), Metal Ions and Biological Systems, Marcel Dekker, New York, 28: 61-97. Field, J.A. and G. Lettinga, 1992b. Toxicity of Tannic Compounds to Microorganisms. In: Hemingway, R.W. and R.E. Laks (Eds.), Plant Polyphenols, Synthesis, Properties, Significance, Plenum Press, New York. Furukawa, A., S. Oikawa, M. Murata, Y. Hiraku and S. Kawanishi, 2003. Epigallocatechin gallate causes oxidative damage to isolated and cellular DNA. Biochem. Pharmacol., 66: 1769-1778. Haslam, E. and J.E. Stangroom, 1996. The esterase and depsidase activities of tannase. Biochem. J., 99: 28-31. Hatamoto, O., T. Watarai, M. Kikuchi, K. Mizusawa and H. Sekine, 1996. Cloning and sequencing of the gene encoding tannase and a structural study of the tannase subunit from Aspergillus oryzae. Gene, 175: 215-221. Doi: 10.1016/0378-1119(96)00153-9 Kar, B., R. Banerjee and B.C. Bhattacharyya, 2002. Optimization of physicochemical parameters for gallic acid production by evolutionary operationfactorial design technique. Process Biochem., 37: 1395-1401. Kar, B., R. Banerjee and B.C. Bhattacharyya, 2003. Effect of additives on the behavioral properties of tannin acyl hydrolase. Process Biochem., 38: 1285-1293. Lekha, P.K. and B.K. Lonsane, 1997. Production and application of tannin acyl hydrolase: State of the art. Adv. Appl. Microbiol., 44: 215-260. Lowry, O.H., N.J. Rosebrough, A.L. Farr and R.J. Randall, 1951. Protein measurement with the with the Folin phenol reagent. J. Biol. Chem., 193: 265-275, PMID: 14907713. CONCLUSION The tannase production by microorganism is extensively studied with respect to the food and pharmaceutical industries. However, it was mostly studied in fungi and in some extent in other microbial species. The results of this investigation clearly indicate that tannase produced by Rhodococcus NCIM 2891 has higher affinity for tannic acid as compared to those produced by other bacterial species. Tannic acid is water soluble metabolite of plant showing antagonistic activity against bacteria and its high concentration in environment can significantly affect the biodiversity. The findings of this study clearly indicates that tannase from Rhodococcus NCIM 2891 can be used as a potent bioremediation tool for industrial waste containing tannins or their derivatives. The antioxidant properties of tannic acid degradation products was another significant, novel finding which could be used to remove tannins from various substances like fodder for sheep and goats and thus improve the health of these animals. ACKNOWLEDGMENT The authors are very grateful to the Department of Microbiology, Shivaji University, Kolhapur, for extending the laboratory facilities to complete the investigation. REFERENCES Ayed, L. and M. Hamdi, 2002. Culture conditions of tannase production by Lactobacillus plantarum. Biotechnol. Lett., 24: 1763-1765. DOI: 10.1023/A:1020696801584 Banerjee, D., K.C. Mondal and B.R. Patil, 2001. Production and characterization of extracellular and intracellular tannase from newly isolated Aspergillus aculeatus DBF 9. J. Basic. Microbiol., 41: 313-318, PMID: 11802541. Bhat, T.K., B. Singh and O.P. Sharma, 1998. Microbial degradation of tannins-a current perspective. Biodegradation, 9: 343-357. DOI: 10.1023/A: 1008397506963 Bell, K.S., J.C. Philp, D.W.J. Aw and N. Christofi, 1998. The genus Rhodococcus. J. Appl. Microbiol., 85: 195-210. DOI: 10.1046/j.1365-2672.1998.00525.x Belur, P.D. and G. Mugeraya, 2011.Microbial production of Tannase: State of art. Res. J. Microbiol., 6(1): 2540. DOI: 10.3923/jm.2011.25.40. Beniwal, V. and V. Chhokar, 2010. Statistical optimization of culture condition for tannase production by Aspergillus awamori MTCC 9299 under submerged fermentation. Asian J. Biotechnol., 2(1): 46-52. 252 Curr. Res. J. Biol. Sci., 3(3): 246-253, 2011 Min-Jer, L. and C. Chinshuh, 2008. Enzymatic modification by tannase increases the antioxidant activity of green tea. Food Res. Int., 41: 130-137. DOI: 10.1016/j.foodres.2007.10.012. Mondal, K.C. and B.R. Patil, 2000. Studies on the extracellular tannase from newly isolated Bacillus licheniformis KBR 6. J. Basic. Microbiol., 40: 223-232, PMID: 10986668 Monika, K.B., K. Karina, K. Halina, K. Monika and T. Marianna, 2007. Purification and characterization of two cold-adapted extracellular tannin acyl hydrolases from an Antarctic strain Verticillium sp. Appl. Microbiol. Biotechnol., 77: 77-89. DOI: 10.1007/s00253-007-1124-4 Mukherjee, G. and R. Banerjee, 2006. Effects of temperature, pH and additives on the activity of tannase produced by a co-culture Rhizopus oryzae and Aspergillus foetidus. World J. Microbiol. Biotechnol., 22: 207-212, DOI: 10.1007/s11274-0059022-3. Murugan, K. and S.A. Al-Sohaibani, 2010. Biocompatible removal of tannin and associated color from tannery effluent using biomass and tannin acyl hydrolase (E.C.3.1.1.20) enzyme of mango industry solid waste isolate Aspergillus candidus MTTC 9628. Res. J. Microbiol., 5(4): 262-271 Ren, S., 2004. Assessing wastewater toxicity to activated sludge: Recent research and developments. Environ. Int., 30: 1151-1164, PMID: 15337358 Russo, A., R. Acquaviva, A. Campisi, V. Sorrenti and C. Di-Giacomo, G. Virgata, M.L. Barcellona and A. Vanella, 2000. Bioflavonoidas antiradicals, antioxidants and DNA cleavage protectors. Cell Biol. Toxicol., 16: 91-98. Sabu, A., G.S. Kiran and A. Pandey, 2005. Purification and characterization of tannin acyl hydrolase from Aspergillus niger ATCC 16620. Food Technol. Biotechnol., 43: 133-138. Sharma, S., T.K. Bhat and R.K. Darwa, 1999. Isolation, purification and properties of tannase from Aspergillus niger van Tieghem. World J. Microbiol. Biotechnol., 15: 673-677. DOI: 10.1023/A: 1008939816281. Skene, I.K. and J.D. Brooker, 1995. Characterization of tannin acylhydrolase activity in the ruminal bacterium selenomonas ruminantium. Anaerobe, 6: 321-327. Skandrani, I., I. Bouhlel, I. Limem, J. Boubaker, W. Bhouri, W. Bhouri, A. Neffati, M.B. Sghaier, S. Kilani, K. Ghedira and L. Ghedira-Chekir, 2009. Moricandida arvensis extract protect against DNA damage, Mutagenesis in bacteria system and scavenge the superoxide anion. Toxicol. in vitro, 23: 166-175. Svitelska, G.V., G.P. Gallios and A.I. Zouboulis, 2004. Sonochemical decomposition of natural polyphenolic compound. Chemosphere, 56: 981-987. Yagu, S., M.C. Terron, T. Gonzalez, E. Zapico, P. Bocchini, G.C. Galletti and A.E. Gonzaiez, 2000. Biotreatment of tanninrich beer-factory, wastewater with white-rot basidiomycete Coriolopsis gallica monitored by pyrolysis/gas chromatography/mass spectrometry. Rapid. Commun. Mass Spectrom., 14: 905-910. Yu, X., Y. Li and D. Wu, 2004. Enzymatic synthesis of gallic acid esters using microencapsulated tannase: effect of organic solvents and enzyme specificity. J. Mol. Catal. B Enzym., 30: 69-73. Yu, X.W. and Y.Q. Li, 2006. Kinetics and thermodynamics of synthesis of propyl gallate by mycelium-bound tannase from Aspergillus niger in organic solvent. J. Mol. Catal. B. Enzym., 40: 44-50. 253