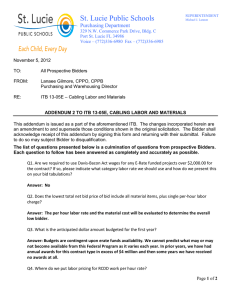

Charlotte Douglas International Airport’s Invitation to Bid for

advertisement