Research Journal of Applied Sciences, Engineering and Technology 4(13): 1980-1991,... ISSN: 2040-7467

advertisement

Research Journal of Applied Sciences, Engineering and Technology 4(13): 1980-1991, 2012

ISSN: 2040-7467

© Maxwell Scientific Organization, 2012

Submitted: March 13, 2012

Accepted: March 22, 2012

Published: July 01, 2012

Development of Electronic Control Unit For Body Control System of Pure

Electric Vehicle

1

Li Hongqiang, 1Miao Changyun, 2Yang Haijing, 1Meng Yongqiang,

3

Chen Hong and 1Liu Fangshu

1

School of Electronics and Information Engineering, Tianjin Polytechnic University, Tianjin

300387, China

2

Library, Tianjin University of Technology, Tianjin 300384, China

3

China Automotive Technology and Research Center, Tianjin 300162, China

Abstract: This study concerns the design of Electronic Control Units (ECUs) for the Body Control System

(BCS) of Pure Electric Vehicle (PEV). The main research contents are divided into two parts: its CANopen

application layer protocol and the model based design of fault detection for anti-pinch window. Firstly, the

structure of the BCS and the function of each ECU were analyzed. Then according to the communication needs

among the ECUs, the CANopen protocol for each ECU was designed. It contained the design of Network

Management, Process Data Objects and Service Data Objects. A CANopen network simulation platform was

designed by CANoe software and its components CANoe.CANopen. According to the analysis of anti-pinch

window model system, the algorithm based on H-/H4 fault detection observer estimation is proposed. Apart

from the previous methods, the pinch torque rate is considered as a fault under the pinched condition to generate

a residual. A residual is zero in normal, but it will deviate from the constant when sensing the pinched

condition. Co-simulation model of CANopen protocol and the anti-pinch model based on CANoe-MATLAB

and the bench test are design to verify the designed ECUs. The test results show that the bus load rate is 3.49%

and the results of detection time are respectively 0.18 and 0.185s, which show the CANopen protocol and the

anti-pinch algorithm are proper to the BCS of PEV.

Key words: Anti-pinch window, CANoe-Matlab, CANopen, electronic control units, pure electric vehicle

INTRODUCTION

Due to the fast evolution of semiconductor

technology, there are more and more Electronic Control

Units (ECUs) used in automobiles. ECUs are the core

components in automobiles system. They act in some

aspects such as the engine, bodywork, chassis control and

have communication function.

By now, researchers have done a lot of complex and

detailed study about automotive ECUs and made many

valuable results. Kyung-Bae et al. (2004) introduced auto

efficiency function test equipment for the smart airbag

ECU and write the test program by LabView. Hiroyuki

et al. (2006) discusses a lightweight compact CVT unit

newly developed by Daihatsu and an Electronic Control

Unit (ECU) developed jointly between Daihatsu and

Fujitsu Ten. Takashima and Kita (2008) proposed the

development process of the hybrid vehicle and electric

vehicle’s ECU. Sun and Zhang (2011) introduced the

design of ECU for automotive acceleration slip regulation

system based on Freescale S 12 MCU.

These literatures are most about gasoline and diesel

and the studies of ECUs are also for the automotive

engine and vehicle braking, stability and direction. The

research about the design of Pure Electric Vehicle (PEV)

door windows ECU is not too much.

Compared with the traditional design of automotive

ECU, the design of application layer protocol for ECUs is

more important in PEV system. There are two main

application layer protocols: J1939 and CANopen. Now

J1939 protocol has been used in the design of the

automotive driving force control system (Wu et al., 2009).

CANopen standard has been implemented in the in onvehicle network of the hybrid electric vehicle and the

design scheme of a CANopen slave stack for power train

controller in hybrid electric vehicle (Xu and Dong, 2010).

CANopen standard is used in the distributed bus

controlling of the hybrid power vehicle, which ensured

the communication of CAN equipments from different

companies (LivinÛ et al., 2009). J1939 protocol is main

used in heavy vehicles. It is facilitating to decompose but

its scalability is poor. In contrast, CANopen is a

Corresponding Author: Li Hongqiang, School of Electronics and Information Engineering, Tianjin Polytechnic University, Tianjin

300387, China, Tel.: +86-83955390

1980

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

LFD_ECU

CC_ECU

RFD_ECU

CAN BUS

RBD_ECU

L BD_E CU

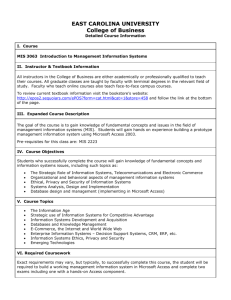

Fig. 1: The topological structure of BCS

CAN

I/O

Communication

Object Dictionary

Application

NMT Objects

PDOs

SDOs

Special Function

Objects

Data Types

Communication

Objects

Application

Objects

Application

Program

Device Profile

Fig. 2: The model of CAN open device

completely open protocol and has a high degree of

flexibility. So we choose CANopen as the application

layer protocol in the PEV.

This study designed the door and window ECUs for

PEV’s Body Control System (BCS). We developed the

CANopen protocol for the body control network and

proposed the model based design of fault detection for

anti-pinch window. By CANoe software and its plug-in

CANoe-Matlab interface, we achieved co-simulation of

the CANopen protocol and the anti-pinch model. Then by

the actual bench test, we further verify the designed

ECUs.

THE STRUCTURE AND CANOPEN

PROTOCOL OF THE BCS

PEV’s BCS consists of five ECUs: central control

ECU (CC_ECU), left front door ECU (LFD_ECU), right

front door ECU (RFD_ECU), left back door ECU

(LBD_ECU) and right back door ECU (RBD_ECU). The

objects of each ECU mainly include vehicle window and

door lock, while front door ECUs also controls the review

mirror. The topological structure of BCS is shown in

Fig. 1. In the remainder of this section, the function of

each ECU is analyzed. CC_ECU is the core of the BCS,

which mainly analyzes the information from other ECUs

and manages the function of those ECUs. In the working

process of the system, LFD_ECU sends the detected

keying information to CC_ECU. Based on the messages,

CC_ECU sends the control signal to the corresponding

ECU and the function is implemented there.

LFD_ECU is the most complicated one, which

integrates almost all the control keys including door lock

control key, control keys of eight windows and review

mirror control key. Through CAN bus, it sends control

command and state information to CC_ECU and receives

the control instruction from CC_ECU. The control objects

of the RFD_ECU mainly contain window motor and lock

motor of that door and the motor of the right review

mirror. RFD_ECU receives control signal from CC_ECU

and sends the local state information. RFD_ECU can also

send lock control instructions.

Compared with front door ECUs input switching

signal of both back door ECUs is simpler, which have

only one key for window controlling. The controlled

objects include lock motor and window motor of the door.

The back door ECUs only receive instruction from

CC_ECU and send the state information.

The model of CANopen device: As it is shown in Fig. 2,

A CANopen device can be divided into three parts:

communication interface, object dictionary and

application program (Kong et al., 2007). The

communication interface defines four types of

communication objects: Network Management Object

(NMT), Service Data Object (SDO), Process Data Object

1981

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

Table 1: The Node-ID of each ECU in BCS

ECU

CC

LFD

RFD

Node_ID

0x01

0x0a

0x0b

LBD

0x0c

RBD

0x0d

(PDO) and Special Function Objects including

Synchronization (SYNC), Time Stamp and Emergency. It

provides services to transmit and to receive these

communication objects over the CAN bus. The Object

Dictionary (OD) describes all data types, communication

objects and application objects used in this device. It is

the interface to the application software. The OD is an

ordered grouping of objects; each object is addressed

using a 16-bit index and 8-bit sub index. The application

program provides the internal control functionality as well

as the interface to the process hardware interfaces.

A CANopen device has to support a number of the

network management services and needs a minimum of

one SDO. Each CANopen device that produces or

consumes process data should have at least one PDO. All

other communication objects are optional. The following

will introduce the design of each ECU’s communication

objects and object dictionary in BCS of PEV based on

CANopen device model.

The design of NMT:

NMT service: The CANopen network management is

node-oriented and follows a master/slave structure. It

requires one device in the network, which fulfills the

function of the NMT Master. The other nodes are NMT

Slaves. We choose CC_ECU to act as the master node,

other nodes act as the slave node. NMT Master is defined

in the entry 1F80h-1F9Fh in OD. So we define the

corresponding content in CC_ECU’s OD. The Node-ID

arrangement is as shown in Table 1.

Node guarding: Another feature of CANopen networks

is node guarding. Node guarding enables the network

manager to determine whether a node is still alive on the

network and also to determine the nodes operating state.It

is periodically performed by the NMT Master which

transmits a CAN remote frame to a NMT Slave. The

NMT Slave then responds by sending its operating state

in a single byte back to the NMT Master. Optionally, a

NMT Slave may also guard the NMT Master by timing

the interval between successive life and guard remote

frames. If the interval is too great or a lifeguard remote

frame is not received within a certain preset time frame,

the NMT Slave knows that the NMT Master is dead. The

objects at index 100Ch and 100Dh define the guard time

and the life time factor. The value of guard time is 300 ms

and the value of life time is 500 ms in this study.

The design of PDO: PDO is used to transfer real-time

data. It is transferred from one (and only one) producer to

one or more consumers. PDO transfer is limited to 1 to 8

bytes. The data content of a PDO is defined through its

CAN identifier only and its content is assumed known to

sender as well as receivers. PDO includes TPDO and

RPDO. TPDO is used to transmit message and RPDO is

used to receive message. The message can be

transmitted/received when both RPDO ID and TPDO ID

is set to the same.

In the BCS, all nodes transmit high-speed and realtime data through PDO. According to the preceding

analyze, CC_ECU contains 4 TPDOs and 7 RPDOs. 4

TPDOs were used to send the control commands to other

four ECUs. It includes: window control commands, door

lock control commands. The left front and right front door

ECUs commands include rearview mirror control

commands. 4 RPDOs are used to receive the remaining

four ECUs status information, including: window state,

lock state, the window motor current, motor current door

locks, window controls automatic/electric, fault code, etc.

The left front and right front door ECUs also includes

rear-view mirror state; 2 RPDOs are used to receive the

door lock command and key control commands from

LFD_ECU. RPDO is used to receive the door 1 lock

commands from RFD_ECU. LFD_ECU contains 3

TPDOs and 1 RPDO. 3 TPDOs are used to send key

control commands, status information and door lock

control command. 1 RPDO is used to receive the control

Fig. 3: The PDO transmission relationship

1982

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

TPDO1 Application Object

Index Sub-Index

Data

7000h

01h

WindowUp

7000h

02h

WindowDown

…

…

…

Communication Parameter 1800h

01h

COB-ID

18ah

02h

transmission type

ffh

03h

04h

05h

TPDO1

Inhibit time

reserved

Event timer

18ah

Mapping Parameter 1A00h

00h

0fh

01h

70000101h

02h

70000201h

…

…

-

WindowUp

WindowDown

…

Fig. 4: The diagram of TPDO1 of LFD_ECU

commands from CC_ECU. RFD_ECU contains 2 TPDOs

and 1 RPDO. 2 TPDOs are used to send Door lock

command and the status information. 1 RPDO is used to

receive the control commands from CC_ECU. The back

doors ECUs contain 1 TPDO to send status information,

1 RPDO to receive control commands from CC_ECU.

The transmission relationship between each ECU is

shown in Fig. 3.

Each PDO is described by 2 objects in the Object

Dictionary: PDO Communication Parameter and PDO

Mapping Parameter. We use TPDO1 of LFD_ECU as an

example to illustrate the description of PDO.

As shown in Fig. 4, communication parameter of

TPDO1 is 1800 h, in which sub-index 01 h indicates

communication object identifier (COB-ID) of TPDO1

consisting of 180 h and Node_ID, where Node_ID is the

Node_ID of front-left ECU. 02 h defines the transmission

type of PDO, whose content FFh indicates asynchronous

based on event trigger. 03 and 04 h define prohibition

time and timing time respectively, which both are set to

the default value. The mapping parameter of TPDO1 is

1A00h where its application object list is contained. The

content 70000101 h of its sub-index 01 h indicates its 1st

application object is stored at main index 7000 h and subindex 01 h, which is the raising instruction of front-left

window. The last two bytes indicate the data structure, i.e.

01 h for 1 bit structure, 08 h for 8 bit structure, 10 h for 16

bits structure and 20 h for 32 bits structure. Based on the

same principle, all the rest control instructions are mapped

to the mapping parameters of TPDO1.

The design of SDO: With SDO the access to entries of a

device object dictionary is provided. One SDO uses two

CAN Data Frames with different identifiers, because the

communication is confirmed. The owner of the accessed

object dictionary is the server of the SDO. A device may

support more than one SDO. One supported SDO is

mandatory and the default case. In this system CC_ECU

is Client and other ECUs are Servers. SDOs are described

by the communication parameter. The default ServerSDO is defined in the entry 1200h-12FFh and Client-SDO

is specified in the entry 1280h-12FFh in OD. The

communication process of CC_ECU accessing LFD_ECU

object dictionary by SDO is depicted in Fig. 5. CC_ECU

is as client and LFD_ECU is as server. Based on its

requirement, CC_ECU generates SDO request message

and sends it onto CAN bus. SDO request message

contains ID and data. ID, defined by main index 1280 h

and sub-index 01 h of its object dictionary, consists of 600

h and Node_ID, where Node_ID is the Node_ID of the

server to be accessed, namely front-left ECU. Data of

SDO request message is used to indicate the requested

task of SDO. On receiving this SDO request, LFD_ECU

analyzes the message and completes the requested task of

CC_ECU SDO, after which the implementation result of

the SDO request is packaged and sent onto the bus.

Finally, one SDO response message is returned to

CC_ECU. Similarly, SDO response message contains ID

and data, where ID is defined by main index 1200 h and

sub-index 02 h of its object dictionary. ID consists of 580

h and Node_ID, where Node_ID is the Node_ID of

server, namely front-left ECU. Data of SDO response

message is used to indicate the implementation result of

SDO request.

The design of SYNC: SYNC is used to synchronize tasks

network-wide. Time Stamp provides application devices

a common time frame reference. Emergency is triggered

by the occurrence of a device internal error. This system

use default value.

The simulation of CANopen protocol: We use CANoe

and its components CANoe.CANopen developed by

Germany Vector Informatik to design the BCS CANopen

network simulation platform. CANoe is a comprehensive

software tool for the development, testing and analysis of

1983

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

Index

CC _ECU

Object Dictionary of CC_ECU

Description

Sub-Index

1280h

01h

1280h

02h

…

…

SDO Request

60ah

58ah

Data

COB-ID Client->Server 60ah

COB-ID Server- >Client 58ah

…

…

data1

data2

SDO R esponse

LFD_ECU

Object Dictionary of LFD_ECU

Index Sub -Index

Data

Description

1200h

01h COB -ID Client->Server 60ah

1200h

02h COB -ID Server->Client 58ah

xxxxh

xxh

---xxh

…

…

---…

Fig. 5: The SDO communication between CC_ECU and LFD_ECU

Analysis this control

requirements and

communication needs

of the system

Use can eds software to

create the EDS file for

each node

Run por can open software

to create the door control

system can open network

Use CAPL language to

build functional

modeling of real nodes

Run can oe

software to generate

the simulation model

Use panel Editor to

de singn display

interface

Complete the de singof

the can open network

Fig. 6: The flow chart of CAN open network design

entire ECU networks and individual ECUs. Its

components contain: ProCANopen, CANeds, Panel Editor

and CAPL Browser. ProCANopen is used to plan and

configures the CANopen networks. CANeds is used to

create and check EDS files (Electronic Data Sheet). Panel

Editor is used for designing of control panels. CAPL

Browser is used to edit the Communication Access

Programming Language (CAPL) program. The flow of

the CANopen network design is shown in Fig. 6.

Object dictionary is necessary for every ECU in the

CANopen network. The Electronic Data Sheet (EDS) is

the standard storage mode for object dictionary. CANeds

software is used to establish EDS file for each ECU. The

main contents of EDS file are: the define of PDO

communication parameter and mapping parameter, SDO

parameter and the data.

ProCANopen is used to configure each ECU’s OD.

As it is shown in Fig. 7, Firstly, body control CANopen

1984

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

G roup:

EDS

CC _EC U

ID 1

G roup:

EDS

E DS

LFD_EC U

ID 10

EDS

R FD_E CU

ID 11

L BD_EC U

ID 12

E DS

R BD_EC U

ID 13

Fig. 7: The configuration of CAN open network

ECU

ECU

ECU

RBD_ECU

RFD_ECU

CC_ECU

Prog

Prog

Prog

Bus

CANopen

CAN 1

ECU

ECU

LBD_ECU

LFD_ECU

Prog

Prog

Fig. 8: The configuration of simulation nodes

network is designed. Secondly, EDS file generated by

the CANeds is imported into each node. Finally the nodes

object dictionary is configure. The main contents are: the

Configuration of NMT, Lifeguarding, PDO relationship

and SDO Properties. Then the files needed for simulation

can be generated automatically during the generation

process.

After importing the generated database to CANoe

software, a simple BCS CANopen network is achieved.

The configuration of nodes is shown in Fig. 8.

But for a real control system, each node has specific

functions. So the CAPL program is used to simulate node

functions in CANoe, such as: window lift, lock switch,

mirror control. The CAPL code is shown as follows:

Simulation nodes LFD_ECU:

on envVar evN10_7004_2

{int a; a = getValue (evN1_7101_2);

putValue (evN10_7001_2, a); // LFD_ECU detects the

control key information and then sends key control PDO

message to the CAN bus.}

Simulation nodes CC_ECU:

on message N10_TPDO0 {int a;

a = getValue (evN1_2101_2);

putValue (evN1_2001_2, a); // Receive command

information and store the command in the object

dictionary.}

Simulation nodes RBD_ECU

on message N1_TPDO0

{int a;

a = getvalue (evN11_7101_2);

SignalWindowDown (a); // window down function is

called putValue (evN13_7001_2, evN13_2101_2); //

change the current state of the RFD_ECU}

In order to make the control panel more intuitive, the

panel editor software included in CANoe is used to edit

the control panel. The designed control panel is shown in

Fig. 9. It contains the control area and the display area.

The control area contains: window, door lock and rear

view mirror control keys. The display area contains: the

display of windows and door locks.

1985

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

Fig. 9: The designed control panel

THE MODELING OF ANTI-PINCH WINDOW

Using (1) and (2), we can obtain the following form:

Recently, special attention has been paid to the antipinch protection and fault diagnosis when the window

lifts (Ma et al., 2008). In this study the pinch torque rate

is seen as a fault which is considered a variable or a

feature deviates from the normal value when the window

is presented by the obstacle. The basic method of the fault

detection is to construct an optimal fault detection

observer which is used to acquire a residual. Through

comparing the residual evaluation value with a threshold,

it is easy to judge whether a fault is in the control system.

Consider the uncertain LTI dynamic system described by

state-space model:

x Ax Bu B f f Bv v Bnn

y Cx Du D f f Dv v Dnn

(1)

where x is the state vector, u is the control input, y is the

measurement vector, v and n are the unknown finite

energy disturbance and the white noise, f is the fault input

vector. A, B, C, D, Bv, Bn, Dv, Dn, Bf, Df are known

matrices with appropriate dimensions.

Generally speaking, a fault detection system consists

of two parts: a residual generator and a residual evaluator.

First we design residual generator based on fault detection

filter as follows:

x ( A LC ) x ( B LD)u Ly

Du

y Cx

r y y

(2)

where are respectively the state and measurement vector,

r is the residual signal, L represents observer gain matrix.

e ( A LC)e ( B f LD f ) f ( Bv LDv )

v ( Bn LDn )n,

r Ce D f D v D n

f

v

n

(3)

Note that the dynamics of the residual signal r

depends on not only v, n and f, but also the state e.

However, r is completely decoupled from the input u. We

can express the (3) in the form of transfer function:

r(s) = Trf(s)f(s)+Trn(s)n(s)+Trv(s)v(s)

(4)

Trv, Trn, Trf are the transfer functions from v, n, f to r

respectively. Here we can describe the fault detection by

the relationship between the input v, n, f and the output r.

The next section we will formulate the fault detection of

anti-pinch window as a mixed H-/H4 estimation problem

and provide an LMI solution to the estimation problem.

Given three scalars $>0, (1>0, (2>0. Observer (1) is

called an H-/H4 fault detection observer if the following

three established:

||Trn(s)||4< (1 Trn= C(sI – A – LC)-1(Bn – LDn)+Dn

(5)

||Trv(s)||4<(2Trv = C(sI – A – LC)-1(Bv – LDv)+Dv

(6)

||Trf(s)||->$Trf = C(SI – A – LC)-1(Bf – LDf)+Df

(7)

while, as we know, condition (5), (6) represent the worsecase criterion for the effect of disturbances on the residual

r, condition (7) stands for the worse-case criterion for the

sensitivity of r to fault. Clearly, these three criteria capture

the most significant features of fault detection observer.

According to bounded real lemma the optimization

problem consists of formula (5), (6) and (7) can be

expressed by the following LMI matrices inequality:

1986

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

Table 2: The parameters of window motor

Variable

Parameter

armature resistance

Rm

Lm

armature inductance

Ke

back electromotive

force coefficient

Kt

torque coefficient

Tn

electromechanical

time constant

J

moment inertia

Vc

supply voltage

Values

0.85

0.649

0.1204

v•s/rad

s

0.1204

9.3×10G3

kg•m2

v

1.5 86×10G4

12

A T P PA C T C LC C T LT

PBv LDv C T Dv T

PBv LDv C T Dv

0

12 I DvT Dv

A T P PA C T C LC C T LT

PBn LDn C T Dn T

PBn LDn C T Dn

0

22 I DnT Dn

A T P PA C T C LC C T LT

T

C T D f LD f PB f

C T D f LD f PB f

0

2 I D Tf D f

A T P PA C T LT LC

T

PB f LD f

.

893109

0 ,

B f

0

Units

S

mH

v•s/rad

PB f LD f

0

0

893109

.

0

0

, B

893109

.

0

B

C = [1 0 0], D = [0], n

,

0

1

Bv 1

0

Using the LMI toolbox in MATLAB, the

performance indices are: (1min = 0.0145, (2min = 0.05, $max

= 1.4883, the observer gain is: L = [183.5130-11.29700.1825]T. Then the robust fault diagnosis system model of

anti-pinch window with the observer gain can be built as

shown in Fig. 10.

SIMULATION AND RESULTS

The parameters of the DC can be get by

experiments which given in Table 2. The matrices of the

model can be designed as follow:

107.530 6305170

0

.

A

0

0

1

0

0

0

Dn = [0.05], Dv = [0], Df = [1]

The co-simulation of CANopen protocol and antipinch algorithms: In the development of ECU, the

simulation evaluation of the design results is to determine

whether the development agreement meets the design

requirements. CANoe is a professional tool for ECU

development, testing and analysis, which supports the

entire system of development process from requirements

analysis to system implementation. Meanwhile,

MATLAB/Simulink often used by researchers has a

strong ability to build complex functional model,

however, it is not perfect to the bus network system

simulation. Considering the two aspects, Vector

Informatik introduces CANoe-Matlab interface in order to

achieve a co-simulation with Matlab and CANoe, (Lin

and Zhang, 2008; Duan et al., 2010; Li et al., 2009).

CANoe-MATLAB interface can be operated in two

different modes: one is offline mode, the other is

Hardware-In-the-Loop (HIL) mode. The whole system

simulation process is based on HIL mode as shown in

Fig. 11. In HIL mode, CANoe runs as

MATLAB/Simulink subsidiary mode. When the time

starts running simulink model, CANoe will automatically

open the bus monitor and display bus message value and

signal value.

Fig. 10: Simulink model of anti-pinch window

1987

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

Simul ati on node

L FD_ECU

M ATL AB/Simul ink

CANo e

CANoe/

MATLAB

interface

C ANope n

net wo rk

Moto r

Con tro l

a lgo rith m

Lef t rear view mir ro r Ri ght r ear view mir ror

Door Lo ck

CANcaseXL USB2 .0

In terf ace car d

Contro l switch

CAN Bus

Fig. 11: The co-simulation of CAN open protocol and anti-pinch window

Vec tor CANoe.ISO11783.LIN.MOST .Fle xRay.J 1587.IP- car_sim.cf g*

File Vie w Star t Mode Configur ation Window He lp

LFD_ECU sends ke y

contr ol c ommand

Chn Dir

Name

Tra ce

Time

2.656544

1

Tx

303.37...

1

Tx

303.38...

1

Tx

303.51...

1

Tx

303.11...

1 seTx

RFD_ECU

nds

0.556952

Tx

sta te inf 1or mation

Bus Statistics

Busloa d

Busload [ %]

Pe akloa d [%]

Std Data [ fr/s]

Std Data [ tota l]

DLC

2

4

4

5

5

8

0 NMTZe roMsg

18A N10_TPDO0

181

N1_TPDO0

28A N10_TPDO1

18B N11_TPDO0

58A

SSDO_010

CAN 1

3.49

4.06

44

2084

Data

CC_ECU

01 00

se nds contr ol

02 00 00 00

command

02 00 00 00

00 00 00 00

02 0D 00 00

43 00 10 00 95 01 00 00

Message number

Sta tistics

Msg/s

20.0

10.0

0

100

200

300

400

Fig. 12: The observation window of CAN open network

The CANopen network simulation result: The BCS

CANopen network simulation platform is created. We can

use the simulation platform to test and verify the design

CANopen network. The contents of simulation contain:

the realization of the control button functions, PDO

message sending, bus loads and so on.

As Fig. 12 shown, by controlling the right front

window down button, we observed the response of the

corresponding control object. When the system starts, the

four ECUs sends status messages periodically, the control

keys stochastic control. The bus load rate is 3.49%, the

peak the peak load rate is 4.06%. The bus operation is

good.

The anti-pinch algorithm simulation result: With the

Simulink Real-Time Workshop, we can target CANoe

1988

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

Amplitude

1.2

1.0

0.8

Residual

Evaluation

0.6

0.4

0.2

0.0

-0.2

-0.4

0.0

0.5

1.0

1.5

2.0

2.5 3.0

Time (sec)

3.5

4.0

4.5

5.0

Fig. 13: Co-simulation results

and produce a Windows DLL which can be loaded in

CANoe's simulation environment. With this approach it

is possible to test and verify a design with real hardware

in a networked environment. The simulation can be used

as a simulation of the remainder of the bus in a real-time

environment. This mode is recommended, if it is

necessary to run huge models and the remaining bus in

real time. The simulation results are as follows.

Figure 13 shows the residual and the residual

evaluation when the fault occurs, we can see the results

are similar as the MATLAB Simulation results. The

residual changes dramatically under the pinch condition

and the residual evaluation exceed the threshold as the

former results.

The results of bench test: In order to debug the functions

of the ECU, the tests for various factors in part are

required on the real vehicle test. But a large number of

financial and human recourses are consumed using the

real car test. This is why the specialized research

laboratories develop the test platforms and benches for the

test of the ECU which proposed a means of quick test for

the real car test.

Based on the former test of HIL mode, we rig the

ECU of car door and window on the real frame for the

bench test. The networked control functions of the car

door and window are verified effectively, as well as the

anti-pinch algorithm.

The test bench based on the charade model of

TIANJIN FAW XIALI AUTOMOBILE COLTD which

is the prototype of XL PEV. Figure 14 shows a general

view of the test bench.

In order to verify the effectiveness of door and

window control network, CANopen network can access

to communicate with the PC by interface devices. PC

through the interface device can send control commands

to the network and receive the real-time data transmission

status of ECUs. We use VC++ software to design the door

and window control network CANopen protocol

monitoring testing software. The main window is shown

in Fig. 15.

Computer

USB

CC_ECU

Node-ID: 0x01

USB/CAN converter

LBD_ECU

Node-ID: 0x12

LFD_ECU

Node-ID: 0x10

CAN

RBD_ECU

Node-ID: 0x13

RFD_ECU

Node-ID: 0x11

Fig. 14: Architecture of test system

Fig. 15: The monitoring testing software

1989

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

CONCLUSION

1.2

1.0

Obstacle detected

This study mainly introduces the design and

simulation ECUs for PEV BCS. It contains the design of

its application layer protocol-CANopen and anti-pinch

algorithm of windows. We have built the simulation

model of CANopen network by CANoe and the model of

anti-pinch window by Matlab. By CANoe-Matlab

interface we realize the Co-simulation of the CANopen

protocol and the function of anti-pinch. The simulation

results show the observer can detect the fault after it

occurs 0.16s and the bus load rate is 3.49%. Moreover,

the bench test verifies the algorithm can detect the antipinch with the road vibration after it occurs 0.185s. The

results show that the designed ECUs are proper and have

great practical value.

Residual

0.8

0.6

0.4

Obstacle appear

0.2

0.0

-0.2

-0.4

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Time (sec)

Fig. 16: Residual of pinch condition

1.2

1.0

Residual

0.8

Obstacle detected

2

1

3 4

ACKNOWLEDGMENT

0.6

0.4

This study is supported by The National High

Technology Research and Development Program of China

(No.2001AA501310) and the Specialized Research Fund

for the Doctoral Program of Higher Education of China

(No. 20101201120001).

Obstacle appear

0.2

0.0

-0.2

-0.4

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Time (sec)

REFERENCES

Fig. 17: Residual of pinch condition with road vibration

Figure 16 shows the pinch condition when the

window lifts. The beeline is the threshold 0.5042 and the

residual exceeds the threshold at 2.88s when the obstacle

prevented the window rising at 2.7s. We can calculate the

detection time is 0.18s. The robust fault detection can

detect the anti-pinch accurately and quickly as the figure

shown.

Based on the actual measurement of Hall signal on

the C-class road which is dirt, gravel, continuous winding

road, 10 degree slope, below the hard ground 20 cm

wading and the two snow-covered roads in China road

grader. The test of anti-pinch window with road vibration

is verified. Figure 17 shows the residual of pinch

condition with road vibration. As the figure shown, the

residual appears some fluctuation which all below the

threshold at the point 1, 2, 3, 4 because of the road

vibration. As the former the pinch condition occurs at 2.7s

and the residual exceeds the threshold at 2.885s. The

detection time is 0.185s. We can see the fluctuation of

residual with the road vibration does not exceed the

threshold, avoiding the error detection. The robust fault

detection for anti-pinch can inhibit the disturbance of road

vibration as the results shown. But this inhibition is within

a certain range because of the threshold.

Kyung-Bae, C., K. Tae-Kook and P. Gwi-Tae, 2004.

Development function test equipment for smart

airbag Electronics Control Unit (ECU). IEEE

International Symposium on Consumer Electronics,

ISCE, United Kingdom, September, pp: 1-3.

Duan, J., H. Deng and Y. Yu, 2010. Co-Simulation of

SBW and FlexRay Bus Based on CANoe-MATLAB.

Proceedings of the 2010 IEEE International

Conference on Automation and Logistics, Hong

Kong and Macau, August, pp: 16-20.

Hiroyuki, H., I. Yutaka and K. Junichi, 2006.

Development of CVT/ECU for Daihatsu Vehicles.

Fujitsu Ten Technical Report., 24(2): 20-25.

Kong, F., H. Zhang and X. Song, 2007. A preliminary

investigation into vehicle control network based on

CANopen Protocol. Automot. Eng., 29(7): 594-596.

Lin, C. and L. Zhang, 2008. Hardware-in-the-loop

simulation and its application in electric vehicle

development. IEEE VPPC, China, September, pp:

3-5.

Li, D., J. Cao and J. Zhang, 2009. Co-simulation of

vehicle CAN bus based on CANoe-MATLAB. J.

Comput. Appl., 6: 57-61.

LivinÛ, G., V. Horga, M. R|Ûoi, M. Albu and G. Chiriac,

2009. Implementing the CANopen Protocol for the

Distributed Control of a Hybrid Electric Vehicle.

EPE Chapter ‘Electric Drives’ Joint Symposium,

France, July 1-3.

1990

Res. J. Appl. Sci. Eng. Technol., 4(13) 1980-1991, 2012

Ma, W., S. Zhang and H. Wang, 2008. The design of antipinch car window using Hall sensor. Automotive

Eng., 35(12): 1256-1260.

Sun, J. and L. Zhang, 2011. ECU design of automotive

ASR systems and Its hardware-in-the-loop simulation

using xPC target. Chinese J. Automot. Eng., 1(1): 7680.

Takashima, H. and T. Kita, 2008. Study on Architecture

of ECU for automobile. T. Jap. Soc. Mech. Eng. Part

C., 74(743): 1758-1764.

Wu, J., Y. Li, J. Li, Y. Li, H. Yu and L. Song, 2009. CAN

bus of automotive driving force control system based

on SAE protocol J1939. J. Jilin Univ. Eng. Technol.

Edn., 39(4): 855-858.

Xu, Z. and S. Dong, 2010. The Design and

Implementation of a CANopen Slave Stack for

Powertrain Controller in Hybrid Electric Vehicle.

2010 International Conference on Intelligent

Computation Technology and Automation, China,

May 11-12.

1991