Research Journal of Applied Sciences, Engineering and Technology 3(10): 1209-1213,... ISSN: 2040-7467

advertisement

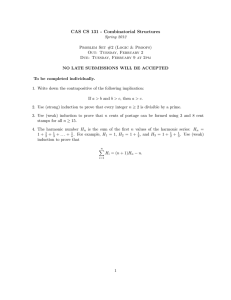

Research Journal of Applied Sciences, Engineering and Technology 3(10): 1209-1213, 2011 ISSN: 2040-7467 © Maxwell Scientific Organization, 2011 Submitted: July 19, 2011 Accepted: September 17, 2011 Published: October 20, 2011 Employing Finite Element Method to Analyze Performance of Three-Phase Squirrel Cage Induction Motor under Voltage Harmonics 1 1 Ali Ebadi, 2Mohammad Mirzaie and 2Sayyed Asghar Gholamian Young Researchers Club, Qaemshahr Branch, Islamic Azad University, Qaemshahr, Iran 2 Department of Electrical and Computer Engineering, Babol University of Technology, Babol, Iran Abstract: Due to various techno-economic advantages associated with induction motors, they are widely used in industrial, commercial and residential applications. also, most of them are connected to electric power distribution system directly, thus they will be affected by voltage quality problems, drastically. One of the important voltage quality problems in power systems is voltage harmonics. Therefore, it is very important to study performance of the motors under nonsinusoidal voltages. This paper presents employing TwoDimensional Finite Element Method to analyze performance of a three-phase squirrel cage induction motor under voltage harmonics. Key words: FEM, induction motor, loss evaluation, torque, voltage harmonic C INTRODUCTION Three-phase induction motor is one of the most widely used equipments in industrial, commercial and residential applications for energy conversion purposes. Based on U.S. Department of energy documents, industrial motors consume seventy percent of electricity, and particularly induction motors consists eighty percent of the loads in a typical industry (Souto et al., 2000). These motors are designed and built to work under balanced sinusoidal voltage supply, however, they are exposed to no ideal voltage conditions in practical applications. For example, most of them are connected to electric power distribution system directly while for various reasons there are harmonics in the power system voltages in most cases. Harmonic Pollution in power system is generally caused by non linear loads. The sources of harmonics in power system can be broadly classified as follows (Souto et al., 2000; Hegazy and salama, 1994; Alcaraz et al., 2006; Duarte and Kagan, 2010): C C Harmonic originated at high voltages by supply authorities such as HVDC systems, Static Var compensation system and, Wind and solar power converters with interconnection. Harmonics originated at medium voltages by large industrial loads like traction equipment, variable speed drives, thyristor controlled drives, induction heaters, arc furnaces, arc welding, capacitor bank and electronic energy controllers. Harmonic originated at low voltages by consumer end like single phase loadings, uninterrupted power supplier, semiconducting devices, Solid state devices, domestic appliances and accessories using electric devices, electronic fluorescent chokes and electronic fan regulator/light dimmers. Presence of voltage harmonics has significant effects on performance of three-phase induction motors. The inXuence of voltage harmonics on the efficiency (Oraee and Emanuel, 2000), temperature rise of machines as a most effective parameter that decreases the age of insulation (Oraee and Filizadeh, 2001) and life reduction due to temperature rise (Brancato, 1992), are some contributions in this area. This article attempts to study performance of a threephase squirrel cage induction motor under balanced nonsinusoidal voltages using finite element method simulation. For this purpose a 2.2 kW, 380V induction motor has been simulated in Maxwell 12.1 and effects of numbers of the voltage harmonics (harmonics 5th, 7th and 11th) on the performance of the simulated machine have been investigated. Simulation of induction motor by using 2D fem: In this section, procedure of induction motor simulation using FEM has been introduced briefly. Analysis model: Figure 1 and Table 1 show the meshed quarter cross section of the analyzed motor and its brief specifications (Ebadi et al., 2011). Corresponding Author: Ali Ebadi, Young Researchers Club, Qaemshahr Branch, Islamic Azad University, Qaemshahr, Iran. Tel.: 0098-9113535718 1209 Res. J. Appl. Sci. Eng. Technol., 3(10): 1209-1213, 2011 WR = I 2 R = σE 2 . ∆ s. L (3) r r ∆ × A= B (4) r ∇×E= r ∂B ∂t = −∇ × r ∂A ∂t (5) In which, B, E, F and )s.L are magnetic flux density, Electric field intensity, the rotor bar conductivity and an element volume in the conductor bars. Calculation of core loss: According to traditional ac machine theory, iron loss in watts per kilogram can be calculated in each element by using Eq. (6) and therefore total iron loss obtained from the summation of iron losses in the all elements. Fig. 1: Meshed model of the IM Table 1: Technical data of three-phase induction motor Item Value Item Rated voltage (V) 380 Stator outer diameter (cm) Output power (W) 2200 Rotor outer diameter (cm) Frequency (Hz) 50 Core length (cm) Rated current (A) 5.3 Air gap (cm) Pole number 4 Stator lamination type Rated speed (rpm) 1410 Rotor lamination type Connection Y Turns no. in stator coil Value 15 9 9 0.03 M530-50A M530-50A 44 Time-stepping 2D FEM: At this study, time-stepping FEM is used for the analysis of the magnetic field. For the time-stepping FEM, time step should be fixed and the input voltage should be defined at each time step. The governing equation for two-dimensional (2-D) FE analysis is given by (Lee et al., 2004): ∂ ∂x ( µ1 ∂∂Ax ) + ∂∂y ( µ1 ∂∂Ay ) =σ dA dt − Jo dI a dt + dϕ a dt 2 m (6) where, Ph and Pc are respectively, hysteresis loss component and eddy current component, both in watts per kilogram. Bm and f are the peak value of the flux density and the frequency, respectively. Kh, Ke and " are constants provided by the manufacture. Simulation setting: In order to realize the variations of the load, a torque with the following equation has been considered as the load: ⎛ T ⎞ TLOAD = ⎜ FL 2 ⎟ × ω 2 ⎝ ω rated ⎠ (1) where, µ is the permeability, A is the component of magnetic vector potential, F is the conductivity of the materials, and J0 is the exciting current density of the stator winding. The voltage equation per each phase is: Va = I a Ra + Le Pc = Ph + Pe = Kh f B αm+ Ke f 2 B (7) In Eq. (7), TFL is full load torque, T, Trated are speed and rated speed of the machine, respectively. Transient solver with step time equal to 10G4s has been used in simulations and quarter cross section of motor is meshed with 9688 of triangles. Simulation of each cycle (0.02 s) consumed 236.3 sec of time by using 3GHz core 2 Duo CPU and 2 Giga Byte of DDR2 Ram. (2) RESULTS AND DISCUSSION where, Va, Ia, Ra, Ka and Le are the input voltage, the current, the resistance, the flux linkage of each phase and the end-coil inductance, respectively. It should be noted, Le is calculated by using RMxprt toolbox in Maxwell 12.1. Calculation of copper loss: The stator winding and the conductor bar losses are calculated using FEM. The conductor bar loss (WR) can be Calculated as follows (Lee et al., 2004): In this section, rated sinusoidal voltage and three major harmonics namely, 5th, 7th and 11th harmonics with THD equal to 10% are applied on the simulated machine and its performance is analyzed under mentioned conditions. Note that, According to the standards the magnitude of the harmonics should be less than 3% of the main frequency magnitude and in this study worse condition is considered. As mentioned above, all simulations are performed by Maxwell V. 12.1 and results are processed in MATLAB/Simulink environment. 1210 Res. J. Appl. Sci. Eng. Technol., 3(10): 1209-1213, 2011 10.00 8.00 6.00 4.00 2.00 0.00 -2.00 -4.00 -6.00 -8.00 -10.00 500 510 520 530 540 550 560 470 580 590 600 Time (ms) Stator Copper loss increment Rotor Copper loss increment 4.0 i a (A) 3.0 (%) 2.5 1.5 0.5 0 5th Harmonic 4 (%) (A) 6 2 0 10 25 15 20 Harmonic order 30 35 7th Harmonic 11th Harmonic Fig. 6: Copper losses under voltage harmonic conditions 8 5 2.0 1.0 Fig. 2: The phase a steady state current under 5th voltage harmonic 0 Total Copper loss increment 3.5 40 Fig. 3: The phase a current in frequency domain under 5th voltage harmonic 1.30 1.25 1.20 1.15 1.10 1.05 1.00 0.95 0.90 0.85 0.80 Core loss increment 5th Harmonic 7th Harmonic 11th Harmonic Current THD Fig. 7: Core loss under voltage harmonic conditions 12 10 (%) 8 6 (%) 4 2 0 5th Harmonic 7th Harmonic 11th Harmonic Sinusoidal Fig. 4: Current THD in sinusoidal voltage and harmonic condition 2192 Output power 2188 Watt Efficiency 5th Harmonic 7th Harmonic 11th Harmonic Sinusoidal Fig. 8: Efficiency under sinusoidal voltage and harmonic condition 2190 2186 2184 2182 2180 5th Harmonic 81.10 81.05 81.00 80.95 80.90 80.85 80.80 80.75 80.70 80.65 80.60 7th Harmonic 11th Harmonic Sinusoidal Fig. 5: Output power under sinusoidal voltage and harmonic condition Current: The stator currents in harmonic conditions are distorted and involve harmonics. For example, Fig. 2 shows the steady state current of phase a under 5th harmonic which is not sinusoidal significantly. this current in frequency domain has been shown in Fig. 3. According to this figure the current involves other harmonics addition to main harmonic. Note that, 5th current harmonics is resulted in the presence of 5th voltage harmonics and other current harmonics are created due to nonlinear characteristic of the machine and space harmonics. Current THD in various conditions has been shown in Fig. 4. Based 1211 N.m Res. J. Appl. Sci. Eng. Technol., 3(10): 1209-1213, 2011 15.10 15.08 15.06 15.04 15.02 15.00 14.98 14.96 14.94 14.92 14.9 CONCLUSION Average produced torque In this studuy, finite element method has been used to analyze the performance of a three-phase squirrel cage induction motor under voltage harmonics with same THD equal to 10% and following results have been achieved: C 5th Harmonic 7th Harmonic 11th Harmonic Sinusoidal (%) Fig. 9: Average torque under sinusoidal voltage and harmonic condition 1.0 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 C C Produced torque ripple C C The THD is not enough to estimate the induction motor operating performance in the presence of voltage harmonics, but the harmonic content must be considered. The copper and core losses and torque ripple increased under voltage harmonics. This increment is lower at higher order harmonics. Output power and average torque is not affected significantly by considered voltage harmonics. The efficiency is better for higher order of voltage harmonics. However, induction motor has maximum efficiency under sinusoidal voltage. Finite element method as a powerful tool can be used to analyze performance of three-phase induction motor under nonsinusoidal supply. ACKNOWLEDGMENT 5th Harmonic 7th Harmonic 11th Harmonic Sinusoidal Fig. 10: Torque ripple under sinusoidal voltage and harmonic condition upon this figure, current THD decreases with increasing order of voltage harmonics. As expected, current THD in sinusoidal condition is not equal to zero. Power, losses and efficiency: According to Fig. 5, output power is not affected significantly by considered voltage harmonics. While, based on Fig. 6 and 7, the copper losses (including copper loss of the stator and rotor) and the core loss increase under voltage harmonic condition and this increment is lower at higher order harmonics. Note that, discussed figures show losses increment over sinusoidal condition in percent. As expected, based on Fig. 8, the efficiency decreases under harmonic condition and this reduction is higher for lower order of voltage harmonics. Torque: Figure 9 and 10 show average and ripple values of produced torque, respectively. Considering these figures, torque average variations is negligible under voltage harmonics with THD =10% while torque ripple increases significantly and this increment is higher for lower harmonic order. In practical point of view, torque ripple increment means increase of vibration and noises and this is not desirable. The authors would like to thank Mr. Rahmani and Mr. Setareh (R&D Management Office of Motogen Corporation, Tabriz, Iran) for providing data of the studied three-phase induction motor. REFERENCES Alcaraz, R., E.J. Bueno, S. Cobreces, F.J. Rodriguez, F. Espinosa and S. Muyulema, 2006. Power system voltage harmonic identification using kalman filter. 12th International Power Electronics and Motion Control Conference. Aug. 30-Sept. 1, Portoroz, pp: 1283-1288. Brancato, E.L., 1992. Estimating the lifetime expectancies of motors. IEEE Electr. Mag., 8(3): 5-13. Duarte, S.X. and N. Kagan, 2010. A power-quality index to assess the impact of voltage harmonic distortions and unbalance to three-phase induction motors. IEEE T. Power Deliver., 25(3): 1846–1854. Ebadi, A., M. Mirzaie and S.A. Gholamian, 2011. Torque analysis of three-phase induction motor under voltage unbalance using 2D fem. Int. J. Eng. Sci. Technol., 3(2): 871- 876. Hegazy, Y.G. and M.M.A. Salama, 1994. Identifying the relationship between voltage harmonic distortion and the load of harmonic producing devices in distribution networks. Canadian Conference on Electrical and Computer Engineering. Halifax, NS, Canada, Sep. 25-28, pp: 669-672. 1212 Res. J. Appl. Sci. Eng. Technol., 3(10): 1209-1213, 2011 Lee, J.J., Y.K. Kim, H. Nam, K.H. Ha, J.P. Hong and D.H. Hwang, 2004. Loss distribution of three-phase induction motor fed by pulsewidth-modulated inverter. IEEE T. Magn., 40(2): 762-765. Oraee, H. and A.E. Emanuel, 2000. Induction motor useful life and power quality. IEEE Power Engineering Review, 20(1): 47-47. Oraee, H. and S. Filizadeh, 2001. The impact of harmonic orders on insulation aging in electric motors. 36th Universities Power Engineering Conference. Sep. 1214, University of Wales, UK, pp: 21-26. Souto, O., J. Oliveira and L. Neto, 2000. Induction motors thermal behavior and life expectancy under nonideal supply conditions. Ninth International conference on Harmonics and Quality of Power. Orlando, FL., Oct. 1-4, pp: 899-904. 1213