Research Journal of Applied Sciences, Engineering and Technology 3(5): 369-376,... ISSN: 2040-7467 © Maxwell Scientific Organization, 2011

advertisement

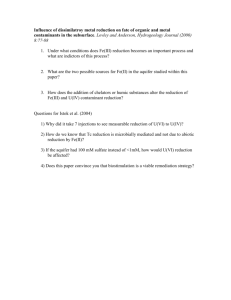

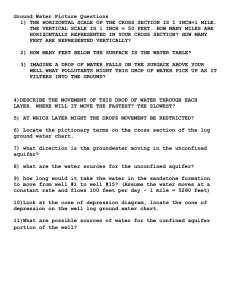

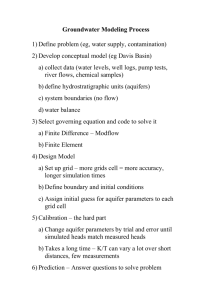

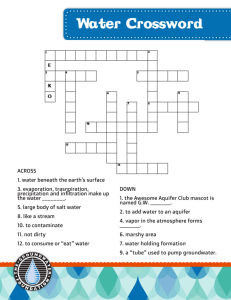

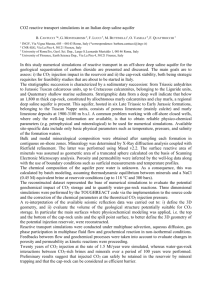

Research Journal of Applied Sciences, Engineering and Technology 3(5): 369-376, 2011 ISSN: 2040-7467 © Maxwell Scientific Organization, 2011 Received: September 03, 2010 Accepted: December 25, 2010 Published: May 25, 2011 Theoretical Analysis of Gravity-controlled Waterfloods 1 1 T.N. Ofei and 2R. Amorin Department of Petroleum Engineering, African University of Science and Technology, Abuja, Nigeria 2 University of Mines and Technology, Tarkwa, Ghana Abstract: Gravity waterflooding (also known as “dumpflooding”) is a process in which water flows from a high pressure aquifer zone to a low pressure oil-producing zone using natural gravity. The water flows through a well connecting the two zones, enhancing the oil sweep into a producing well. This process is economically attractive due to the absence of injection surface facilities and injection fluid costs. This research quantifies the rate of fluid transfer from a high pressure aquifer zone to a low pressure oil producing zone. Detailed theoretical equations are derived to evaluate the rate of water injection from an aquifer into an oil reservoir with a gas cap by dumpflooding. Two cases considered are: (1) A finite aquifer injecting into a finite oil reservoir with a gas cap, and (2) An infinite aquifer injecting into a finite oil reservoir with a gas cap. A single-well model has also been built using an Excel spreadsheet to solve the ordinary differential equations using the bisection iterative technique. Key words: Aquifer, dumpflooding, finite, gas cap, infinite, reservoir difficulties with flood front control, water breakthrough, conformance management, and the inability to quantify the crossflow rate in each well (Rawding et al., 2008). This study suggests a solution to one of the flaws in dumpflooding: the inability to quantify the rate of fluid transfer from a high pressure aquifer zone to a low pressure oil producing zone. This finding was significant because it presents detailed theoretical equations for evaluating the rate of water injection from an aquifer into an oil reservoir with gas cap. Davies (1972), demonstrated that the rate at which fluid transfers from one zone to another is a constant value if the reservoir static pressure in both zones is maintained and presented as: INTRODUCTION The technique of injecting water into an oil producing reservoir for either pressure maintenance or secondary recovery is a well-established process. However, a method is required to replace the voidage created by the volume of oil extracted from the reservoir and to reduce and reverse the declining pressure and increase oil recovery (Rawding et al., 2008). The water sources available for injection purposes are: produced water, sea water, aquifer water, and fresh water and economics associated with the injection project usually dictate which source should be used. Usually the source of water depends on the quality and quantity of water available (Davies, 1972). Probably the cheapest method of injecting water into an oil reservoir is gravity waterflooding, or dumpflooding, and the two terms will be used interchangeably in this study. Dumpflooding refers to the process of allowing a water-bearing reservoir of high pressure potential to feed into an oil reservoir of lower pressure potential by placing the two zones in communication through a casing string thereby, providing reservoir pressure support and enhancing oil sweep into a producing well (Davies, 1972; Quttainah and Al-Hunaif, 2001; Rawding et al., 2008). This process is often preferred for cost reasons over conventional waterflooding given the absence of injection surface facilities and injection fluid costs. However, there are also challenges with monitoring the dumpflood wells and controlling the reservoir pressure. These include ⎡1 1 ⎤ I w = ⎢ + + ∆ Pfr ⎥ = Pew − Peo I J ⎣ ⎦ (All terms defined in nomenclature) Quttainah and Al-Hunaif (2001) analysed the applicability of long term effects of dumpflood operation to enhance sweep and maintain reservoir pressure. A dumpflood pilot project was initiated from Umm Gudair reservoir to prove the viability of and quantify sweep benefits of water injection from a source aquifer into a recipient oil reservoir (injected zone). Their study recorded that the dumpflood pilot project can be expanded as a full-field injection to pressure support the falling Corresponding Author: T.N. Ofei, Department of Petroleum Engineering, African University of Science and Technology, Abuja, Nigeria 369 Res. J. Appl. Sci. Eng. Technol., 3(5): 369-376, 2011 reservoir pressure and proved an excellent way to analyse the impact of water injection on the recipient reservoir. Rawding et al. (2008) described the philosophy and design of an intelligent well installation in a water dumpflood well in West Kuwait. They reported on the application of intelligent well completion for controlled dumpflood where water from the Zubair aquifer formation flows to the Minagish Oolite oil formation. The authors referred to the article by Quttainah and Al-Hunaif, (2001) who first tried well dumpflood pilot project in the Umm Gudair field and showed that dumpflood can be expanded as a full field water dumpflood injection to pressure support the falling reservoir pressure. In their conclusion, the use of intelligent completion technology and remotely controlled hydraulic Interval Control Valve (ICV) proved reliable and cost effective solution for a controlled dumpflood. Fig. 1: Downward flow mechanism MATERIALS AND METHODS Dumpflood flow mechanisms: The Fig. 1 describes the flow mechanism where the aquifer located above the oil reservoir flows high pressure water by gravity through a communicating well into the oil reservoir thus, displacing the oil ahead of it into the producing well. The upward flow mechanism in Fig. 2 describes an aquifer located below the oil reservoir and injects high pressure water into the oil reservoir. In the case where the aquifer pressure is low, a downhole pump is used to aid the injection (Yao et al., 1999). The equations associated with dumpflooding apply equally to both flow mechanisms in Fig. 1 and 2. In the aquifer zone, the pressure differential (Pew Pww) results in the movement of water which flows into the wellbore at a rate qw. As the water flows down the communicating well between the two zones by gravity, there exists a pressure drop (i.e., Pww - Pwf) due to friction and kinetic energy. The water finally injects into the oil reservoir at a rate Iw and together with the pressure differential (Pwf - Peo), initiates the displacement of oil into the producing well. The objective of the above description is to deduce an equation for the rate of water Iw injecting into the oil reservoir. The following assumptions are considered in the derivation: C C C C C C Fig. 2: Upward flow mechanism C C C The tubing has no change in diameter Frictional pressure loss is constant Aquifer water is compatible with reservoir water The complete derivation is presented in Appendix A; thus, the rate of water injection, Iw into the oil reservoir as adapted from (Davies, 1972) is given as: Iw[1/I + 1/J] = (Pwf - Peo) + (Pew - Pww) (1) Pressure drop in the wellbore: There exists pressure drop due to friction and kinetic energy as water flows through the connecting well (tubing string) from the aquifer zone to the oil reservoir zone. Since tubing string diameter is constant, the pressure drop due to kinetic energy is negligible. The pressure drop due to friction is a function of flow rate and controls the dumpflood rate to a degree, therefore, there is a relationship between frictional pressure drop ()Pfr) and rate of water injection, Iw as presented in Appendix A and given as: All pressures are datum corrected to the oil reservoir datum Single phase (water) flows in the injection well (tubing) The fluid (water) is incompressible No loss of water in the wellbore (qw = Iw = Contant) The injectivity I, and productivity J, indices are constants There is no water influx Iw[1/I + 1/J] = Pew - Peo – ) Pfr 370 (2) Res. J. Appl. Sci. Eng. Technol., 3(5): 369-376, 2011 Material Balance Equation (MBE) for reservoir boundary pressures: It is noticed from Eq. (2) that the RHS has two unknown pressures quantities. Since these pressures Pew and Peo are boundary pressures in the aquifer zone and oil reservoir zone respectively, they can be deduced from material balance equation. The general MBE for an oil reservoir is given by (Dake, 1978; Craft and Hawkins, 1991): ) ) (W inj ) 9500 Dumping rate ,Iw(BWPD) ( ( N p Bo + R p − Rs B g − We B w − Iw vs I at (t = 28 days) − W p Bw = NCT ∆p ( 6500 5500 ⎤ )⎥⎥ + mBoi ∆p ⎦ ⎛ Bg ⎞ ⎜ ⎟ ⎜ B − 1⎟ ⎝ gi ⎠ ( ) ⎧ Bo + R p − R s B g ⎫ ⎛ B ⎞ ⎪ ⎪ Peo = Pio + ⎜ w ⎟ Winj − ⎨ ⎬N p NC ⎝ NCT ⎠ T ⎪⎩ ⎪⎭ I w (t ) = I iw e ⎛ Bw ⎞ = piw − ⎜ ⎟ Winj ⎝ N w CTW ⎠ 45 50 55 ⎛ E⎞ −⎜ ⎟ t ⎝ D⎠ + Fq o E ⎛ E⎞ ⎧ −⎜ ⎟ t ⎫ ⎪ ⎝ D⎠ ⎪ 1 − e ⎨ ⎬ ⎪⎩ ⎪⎭ (9) where initial rate of injection is in the form: (5) I iw ⎧ ⎫ ⎪ ∆Pi − TI 1.79 ⎪ ⎪ ⎪ iw =⎨ ⎬ 1 1 ⎡ ⎤ ⎪ ⎪ + ⎪⎩ ⎢⎣ I J ⎥⎦ ⎪⎭ (10) These are nonlinear equations which can be solved iteratively. All variables are defined in Appendix B. The bisection method, amongst other iterative techniques, is much preferred in solving these nonlinear rate equations due to its guarantee for convergence and less risky, though it is slow to converge (Kaw, 2009). The initial dumping rate can be written as a continuous function in the form: (6) Applying the MBE to the aquifer zone at time, t, where there is no oil (Np=0) gives; Similarly, the boundary pressure in the aquifer zone presented in Appendix B is given as: Winj Bw = N w CTw ( Piw − Pew ) 25 deduced from both flow mechanism and MBE are simplified using Ordinary Differential Equations (ODEs). The final dumpflood rate equation which is fully developed in Appendix B can be calculated at any time, t. Thus: (4) The boundary pressure in the oil zone presented in Appendix B is given as: Pew 35 40 Injective index, I 7500 Fig. 3: Effects of J & I on in oil reservoir with gas cap (t = 28 days) when an oil reservoir is with an initial gas cap (i.e., the oil is initially saturated), there is negligible liquid expansion energy. It is assumed that with an initial gas cap, water and pore compressibilities (Cw and Cf) and water influx (We) are negligible (Dake, 1978). The total compressibility in the oil zone reduces to: ∆p 30 8500 20 ⎞ ⎤ ⎡ Boi (1 + m) ⎛ Bg ⎟ ⎜ C w S wc + C f ⎜ B − 1⎟ ⎥ + ⎢ 1 − S ⎝ gi ⎠ ⎥⎦ ⎢⎣ wc ( Bo − Boi ) + ( Rsi − Rs ) B g J = 200 4500 ⎡ ( Bo − Boi ) + ( Rsi − Rs ) B g ⎤ CT = ⎢ ⎥+ ∆p ⎢⎣ ⎥⎦ CT = J = 100 J = 50 (3) )p = initial pressure-current pressure (Pi - P), and ⎡ mB ⎢ oi ⎢⎣ ∆p J = 25 f ( I iw ) = AI iw + TI iw 1.79 − ( Piw − Pio ) (11) (7) The continuous function for the final rate of water injection is given by: (8) f ( I w ) = I w − I iw e RESULTS AND DISCUSSION ⎛ E⎞ −⎜ ⎟ t ⎝ D⎠ − ⎛ E⎞ ⎧ −⎜ ⎟ t ⎫ Fqo ⎪ ⎝ D⎠ ⎪ e 1 − ⎨ ⎬ E ⎪ ⎪ ⎩ ⎭ (12) The above Fig. 3 indicates how the dumping rate from a finite aquifer varies as a function of constant Case 1: Finite aquifer injecting into finite oil reservoir with gas cap: The rate of water injection equations 371 Res. J. Appl. Sci. Eng. Technol., 3(5): 369-376, 2011 Iw vs I at (t = 28 days) Dumping rate ,Iw(BWPD) 11500 J = 25 J = 100 J = 50 J = 200 shown in Fig. E1 to E4 in Appendix E. The ‘solid’ curves record rates from infinite aquifer while ‘dash’ curves record rates from finite aquifer. It can be deduced that for constant productivity index in cases 1 and 2, infinite aquifer injects much water compared to finite aquifer as time increases from 7 to 28 days. 10500 9500 8500 7500 CONCLUSION 6500 C 5500 4500 20 25 35 40 Injective index, I 30 45 50 55 C Fig. 4: Effects of J & I on Iw in Oil Reservoir with Gas Cap (t = 28 days) C productivity indices J for a time period of 28 days. It is evident that an increase in dumping rate is proportional to an increase in constant productivity index. C Case 2: Infinite aquifer injecting into finite oil reservoir with gas cap: The final dumpflood rate equation which is fully developed in Appendix C can be calculated at any time, t. Thus; I w (t ) = I iw e ⎛Y⎞ −⎜ ⎟ t ⎝ X⎠ + Zq o Y ⎛Y⎞ ⎧ −⎜ ⎟ t ⎫ ⎪ ⎝ X⎠ ⎪ ⎨1 − e ⎬ ⎪⎩ ⎪⎭ NOMENCLATURE API symbols are used whenever possible: Symbol Description I Injectivity Index J Productivity Index N Original Oil in Place Original Water in Place Nw Oil Production, Cumulative Np Water Injected, Cumulative Winj Oil Producing Rate qo Water Producing Rate qw from the Aquifer Iw Water Producing Rate BWPD into Oil Reservoir Initial Water Producing Rate Iiw Lower Boundary of the function Iw(L) Upper Boundary of the function Iw(u) Estimated Root of the function Iw(m) n Number of Iterations External Boundary Pressure pe Pe at initial Conditions Boundary Pressure in Water Zone Pew Pew at initial Conditions Boundary Pressure in Oil Zone Peo Peo at initial Conditions Pio Flowing Bottom Hole Pressure Pwf )P Initial Pressure minus Current pressure t Time Total Compressibility (Oil Zone) CT Total Compressibility (Water Zone) CTW Current Oil Formation Bo Volume Factor Bo at Initial Condition Boi Current Gas Formation Bg Volume Factor Bw at Initial Condition Bgi Current Oil Formation Bw Volume Factor Bw at Initial Condition Bwi Free Gas Rsi Rs at Initial Condition Rsi (13) Where initial rate of injection is in the form; I iw ⎧ ⎫ ⎪ ∆P − TI 1.79 ⎪ ⎪ i ⎪ iw =⎨ ⎬ 1 1 ⎡ ⎤ ⎪ + ⎥ ⎪ ⎢ ⎪⎩ ⎣ I J ⎦ ⎪⎭ (14) The initial dumping rate can be written as a continuous function in the form: f ( I iw ) = AI iw + TI iw 1.79 − ( Piw − Pio ) (15) The continuous function for the final rate of water injection is given by: f ( I w ) = I w − I iw e ⎛Y⎞ −⎜ ⎟ t ⎝ X⎠ − Zq o Y ⎛Y⎞ ⎧ −⎜ ⎟ t ⎫ ⎪ ⎝ X⎠ ⎪ ⎨1 − e ⎬ ⎪⎩ ⎪⎭ Theoretical dumpflood equations have been developed to evaluate the rate of water injection into an oil reservoir with gas cap from an aquifer. A simple Excel spreadsheet model is built to solve the rate equations using Bisection iteration technique. The boundary pressure in the finite aquifer zone depletes much faster compared to the infinite aquifer zone. In both cases, water injection recorded higher rates for infinite aquifer compared to finite aquifer (Fig. E1 to E4 in Appendix E). (16) All variables are defined in Appendix C. In the above Fig. 4, the dumping rate from an infinite aquifer also shows an increase in proportion to the increase in constant productivity indices J. Comparisons of dumping rates from both finite and infinite aquifer are 372 Units BWPD/psi BWPD/psi MMSTB MMBW MMSTB MMBW BOPD BWPD BWPD BWPD BWPD BWPD Dimension less PSIG PSIG PSIG PSIG PSIG PSIG PSIG PSIG DAYS 1/PSI 1/PSI RB/STB RB/STB RB/SCF RB/SCF RB/STB RB/STB SCF/STB SCF/STB Res. J. Appl. Sci. Eng. Technol., 3(5): 369-376, 2011 Rp Swc )Pfr D : d dc dt h Cumulative GOR Connate Water Saturation Friction Pressure Drop Density of Dumping Fluid Viscosity of Dumping Fluid Diameter or Equivalent* diameter of Pipe, Internal Internal Diameter of Casing Internal Diameter of Tubing Distance between Mid-point of Source Zone Producing Interval to Mid-point of Injected Zone Producing Interval SCF/STB FRACTION PSI GM/CC CP INCHES ⎛ B ⎞ Peo = Pio + ⎜ w ⎟ Winj ⎝ NCT ⎠ ( INCHES INCHES FEET d = ( dc − d t ) 2.79 × ( dc + dt ) (B2) Total compressibility in oil zone is reduced to: CT = The equivalent* diameter of the annular space between the casing and tubing is computed using the formula: 4.79 ) ⎡ Bo + R p − Rs Bg ⎤ ⎥Np −⎢ NCT ⎢ ⎥ ⎣ ⎦ Appendix A: Dumpflood flow mechanism: Reference to Fig. 2, the rate of water injection into oil zone, Iw from Darcy is given by: Winj Bw = Nw CTw (Piw - Pew) Pew = Piw - (Bw / Nw CTw) Winj ⎡1 1 ⎤ I w ⎢ + ⎥ + TI w1.79 = ( Piw − Pio ) ⎣I J⎦ (A3) ⎡ 1 1 ⎤ − Bw ⎢ + ⎥Winj ⎣ N w CTw NCT ⎦ ( (A4) (A5) Letting (A6) )Pfr = [518D0.79 :0.207 h / d4.79 × 1000 × 14401.79] qw1.79 = Tqw1.79 (A7) ⎡1 1 ⎤ D=⎢ + ⎥ ⎣I J⎦ ( ) ⎛ Bo + R p − Rs Bg ⎞ ⎟ F =⎜ ⎜ ⎟ NC T ⎝ ⎠ Since qw = Iw Rate of water injection from flow mechanism gives: (A8) ∆Pi = ( Piw − Pio ) Appendix B: Case 1: Finite aquifer injecting into finite oil reservoir with gas cap: Assumptions of oil reservoir with gas cap are, Cw = 0 and Cf = 0, thus MBE in the oil zone at time, t, is deduced as: Winj Bw - Np (Bo + (Rp -Rs) Bg) = NCT (Peo - Pio) ) ⎛ 1 1 ⎞ E = Bw ⎜ + ⎟ ⎝ N w CTw NCT ⎠ For non-Newtonian fluids (Darley and Gray, 1988): Iw [1/I + 1/J] + TIw1.79 = Pew - Peo (B6) ⎡ Bo + R p − R s B g ⎤ ⎥N p +⎢ ⎥ ⎢ NCT ⎦ ⎣ For constant tubing cross-section, pressure drop due to kinetic energy )PKE is negligible. Thus: Iw [1/I + 1/J] = Pew - Peo - )Pfr (B5) Substituting (B2) and (B5) into (A8) and simplifying gives: (A2) Pressure drop in the wellbore is given by: Pww - Pwf = )PKE + )Pfr (B4) Boundary pressure in aquifer zone from gives: Adding equations (A-1) and (A-3) gives: Iw [1/I + 1/J] = (Pwf - Peo) + (Pew - Pww) (B3) (A1) Productivity index J is a measured constant Assuming qw = Iw (no loss of fluid in wellbore) Iw / J = Pew - Pww ⎞ ⎛ Bg ⎜⎜ − 1⎟⎟ ⎝ Bgi ⎠ Likewise, MBE in aquifer zone at time, t, gives: Injectivity index I is a measured constant For aquifer zone, the rate of water flow into the wellbore is given by: qw = J(Pew - Pww) or Iw / J = Pew - Pww ∆p mBoi + ∆p 2 Iw = I(Pwf - Peo) or Iw / I = Pwf - Peo ( Bo − Boi ) + ( Rsi − Rs ) Bg Equation (B6) becomes: DIw + TIw1.79 = )Pi - EWinj + FNp (B1) (B7) For constant frictional pressure drop, i.e., TIw1.79 and differentiating Eq. (B7) with respect to time, t gives: Boundary pressure in oil zone is given as: 373 Res. J. Appl. Sci. Eng. Technol., 3(5): 369-376, 2011 ∂Winj ∂Np ∂I D w +E −F =0 ∂t ∂t ∂t Final dumpflood rate equation gives: [ (B8) Fq − E D t − E D t I w ( t ) = I iw e ( ) + o 1 − e ( ) E But ∂Winj = Iw ∂t Thus: and ∂Np = qo ∂t ∂I D w + EI w − Fqo = 0 ∂t ⎡ ∆P − TI 1.79 ⎤ I iw = ⎢ i 1 1iw ⎥ +J ⎢⎣ ⎥⎦ I ( (B9) (B10) dI w ⎛ E ⎞ Fqo + ⎜ ⎟ Iw = dt ⎝ D ⎠ D (B11) Pew = Piw Iw Let 1 J ] + TI 1.79 w X= [ 1 I + 1 J = ( Piw − Pio ) (C2) ] ( ) 1 NCT ( ) ∆Pi = ( Piw − Pio ) Equation (C2) becomes: (B14) XIw + TIw1.79 = )Pi - YWinj + ZNp Substituting (B14) into (B12) at t = 0 D + ⎛ Bo + R p − Rs Bg ⎞ ⎟ Z=⎜ ⎜ ⎟ NC T ⎝ ⎠ (From A6) (B13) ∆Pi − ∆Pfr D ∆Pi − ∆Pfr 1 I Y = Bw Substituting the above conditions into (A6): K= [ ⎛ B ⎞ ⎡ Bo +( R p − Rs ) Bg ⎤ − ⎜ w ⎟ Winj + ⎢ ⎥Np NCT ⎝ NCT ⎠ ⎣ ⎦ (B12) Iw = Iiw, Pew = Piw and Peo = Pio I iw = (C1) Substituting (B2) and (C1) into (A8) gives: where K, is a constant. At initial condition: DI iw = ∆Pi − ∆Pfr (B18) Appendix C: Case 2: Infinite aquifer injecting into finite oil reservoir with gas cap: For an infinite aquifer, Nw = 4, therefore the boundary pressure (B5) in the aquifer zone reduces to: Solution to this ordinary differential equation (ODE) (B11) with respect to time t, is given as: ⎡1 1 ⎤ I iw ⎢ + ⎥ = Piw − Pio − ∆Pfr ⎣I J⎦ ) These nonlinear equations (B17) and (B18) can be solved by an iterative technique. dI w + EI w = constant dt Fq − E D t I w ( t ) = Ke ( ) + o E (B17) Where initial rate of injection is in the form: If oil production rate qo is a specified constant, then: D ] − Fqo E By similar approach in Appendix B, final dumpflood rate equation gives: [ Zq −Y X t −Y X t I w ( t ) = Iiw e ( ) + o 1 − e ( ) Y (B15) Substituting (B15) into (B12) and simplifying gives: ⎡ ∆ Pi − ∆ Pfr ⎤ − ( E D )t I w (t ) = ⎢ ⎥e D ⎣ ⎦ Fq o ⎡ − E D t 1 − e ( ) ⎤⎥ + ⎢ ⎦ E ⎣ (C3) ] (C4) where initial rate of injection is in the form: ⎡ ∆P − TI 1.79 ⎤ I iw = ⎢ i 1 1iw ⎥ +J ⎢⎣ ⎥⎦ I ( (B16) ) (C5) These nonlinear equations (C4) and (C5) can be solved by an iterative technique. 374 Res. J. Appl. Sci. Eng. Technol., 3(5): 369-376, 2011 [ I w ( u) − I w ( L) ] Appendix D: Solving the rate of water equation using bisection iterative technique: The root of the function is estimated as (Kaw, 2009): Iw (m) = Iw (L) + Iw (u) (D5) The number of iterations, n, of the bisection method needed to determine the root within an error of at most 5×10G8 is given by: The absolute error is estimated as (Kaw, 2009): | Iw (m)new - Iw (m)old | I w ( u) − I w ( L ) (D2) Similarly, the relative percentage error is given as (Kaw, 2009): I w ( m) new − I w ( m) I w ( m) (D4) 2 n +1 2 n +1 (D5) where old new ≤ 5 × 10−8 × 100 ⎡ log⎛⎜ I w ( u ) − I w ( L ) ⎞⎟ + 8 ⎤ 5 ⎠ ⎥ ⎢ ⎝ n≥⎢ ⎥ −1 log( 2) ⎥ ⎢ ⎦ ⎣ (D3) After n steps of iterations, the approximate root is computed with an absolute error of at most (Kaw, 2009): (D6) Appendix E: Case 1 & 2 (t = 7 days) Case 1.J=25 Case 1.J=50 Case 1.J=50 12500 Case 1 & 2 (t = 21 days) Case 1.J=100 Case 1.J=200 Case 1.J=100 Case 1.J=200 13500 12500 11500 Dumping rate ,Iw(BWPD) Dumping rate ,Iw(BWPD) Case 1.J=25 10500 Case 1.J=25 Case 1.J=50 Case 1.J=50 Case 1.J=100 Case 1.J=200 Case 1.J=100 Case 1.J=200 11500 10500 9500 8500 7500 6500 5500 9500 8500 7500 6500 5500 4500 4500 20 25 30 40 35 Injective index, I 45 50 20 55 Fig. E1: Dumping rate comparison: Oil reservoirs with gas cap for Case 1 & 2 (t = 7 days) 13500 25 30 35 40 Injective index, I 45 50 55 Fig. E3: Dumping rate comparison: Oil reservoirs with gas cap for Case 1 & 2 (t = 21 days) Case 1 & 2 (t = 28 days) Case 1 & 2 (t = 14 days) Case 1.J=25 Case 1.J=25 Case 1.J=25 Case 1.J=25 Case 1.J=50 Case 1.J=50 Case 1.J=50 Case 1.J=50 Case 1.J=100 Case 1.J=200 Case 1.J=100 Case 1.J=200 Case 1.J=100 Case 1.J=200 Case 1.J=100 Case 1.J=200 11500 Dumping rate ,Iw(BWPD) 12500 Dumping rate ,Iw(BWPD) Case 1.J=25 10500 11500 10500 9500 8500 7500 6500 5500 9500 8500 7500 6500 5500 4500 4500 20 25 30 35 40 Injective index, I 45 50 20 55 Fig. E2: Dumping rate comparison: Oil reservoirs with gas cap for Case 1 & 2 (t = 14 days) 25 30 35 40 Injective index, I 45 50 55 Fig. E4: Dumping rate comparison: Oil reservoirs with gas cap for Case 1 & 2 (t = 28 days) 375 Res. J. Appl. Sci. Eng. Technol., 3(5): 369-376, 2011 REFERENCES Quttainah, R. and J. Al-Hunaif, 2001. Umm Gudair Dumpflood Pilot Project: The Applicability of Dumpflood to Enhance Sweep and Maintain Reservoir Pressure. paper SPE 68721, presented at the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 17-19 April. Rawding, J., B.S. Al-Matar and M.R. Konopczynski, 2008. Application of intelligent well completion for controlled dumpflood in West Kuwait. Paper SPE 112243, presented at the SPE Intelligent Energy Conference and Exhibition, Armsterdam, The Netherlands, 25-27 February. Yao, C.Y., N.C. Hill and D.A. McVay, 1999. Economic pilot-floods of carbonate reservoirs using a pumpaided reserve dumpflood technique. Paper SPE 52179, presented at the SPE Mid-Continent Operations Symposium, Oklahoma City, Oklahoma, 28-31 March. Craft, B.C. and M.F. Hawkins, 1991. Applied Petroleum Reservoir Engineering. 2nd Edn., Prentice-Hall, Inc., Englewood Cliffs, N.J. 07632, pp: 146-153, 184-186. Dake, L.P., 1978. Fundamentals of reservoir engineering. Elsevier Dev. Petrol. Sci., The Netherlands, 8: 71-79. Davies, C.A., 1972. The theory and practice of monitoring and controlling dumpfloods. paper SPE 3733, presented at the European Spring Meeting of the Society of Petroleum Engineers of AIME, Armsterdam, The Netherlands, 16-18 May. Darley, H.C.H. and G.R. Gray, 1988. Composition and Properties of Drilling and Completion Fluids. Gulf Publishing Company, Houston, TX, 5th Edn., pp: 221-222. Kaw, A., 2009. Bisection Method for Solving Nonlinear Equations. General Engineering. Retrieved from: http://numericalmethods.eng.usf.edu/, (Accessed on: 26 August, 2009). 376