Research Journal of Environmental and Earth Sciences 3(5): 608-613, 2011

advertisement

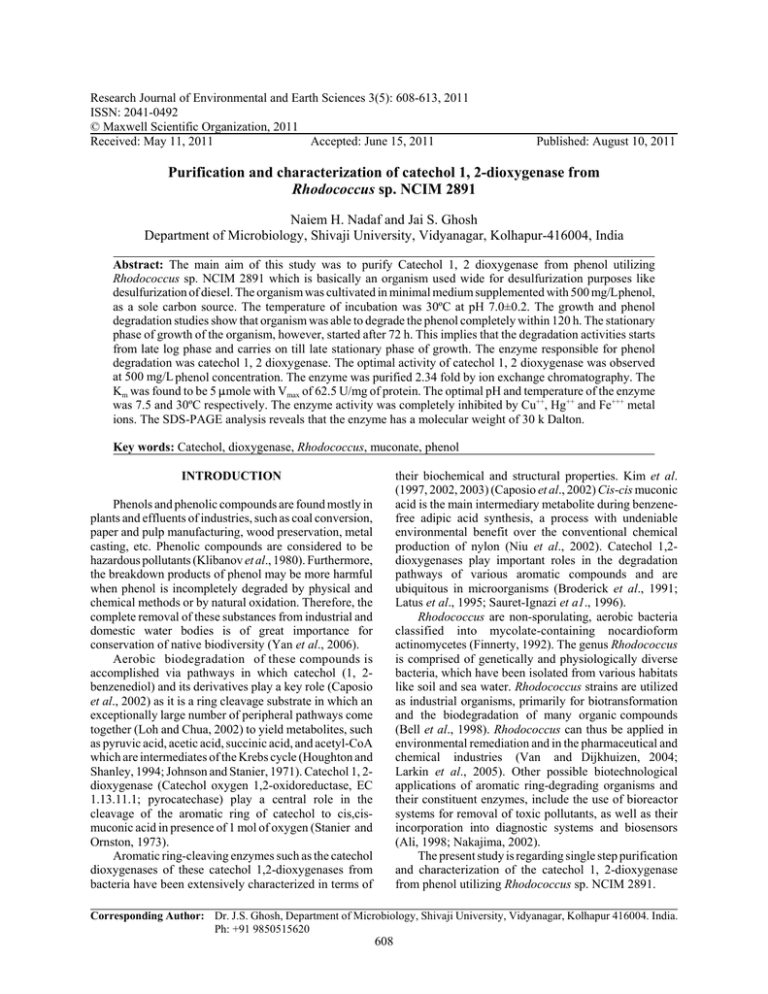

Research Journal of Environmental and Earth Sciences 3(5): 608-613, 2011 ISSN: 2041-0492 © Maxwell Scientific Organization, 2011 Received: May 11, 2011 Accepted: June 15, 2011 Published: August 10, 2011 Purification and characterization of catechol 1, 2-dioxygenase from Rhodococcus sp. NCIM 2891 Naiem H. Nadaf and Jai S. Ghosh Department of Microbiology, Shivaji University, Vidyanagar, Kolhapur-416004, India Abstract: The main aim of this study was to purify Catechol 1, 2 dioxygenase from phenol utilizing Rhodococcus sp. NCIM 2891 which is basically an organism used wide for desulfurization purposes like desulfurization of diesel. The organism was cultivated in minimal medium supplemented with 500 mg/L phenol, as a sole carbon source. The temperature of incubation was 30ºC at pH 7.0±0.2. The growth and phenol degradation studies show that organism was able to degrade the phenol completely within 120 h. The stationary phase of growth of the organism, however, started after 72 h. This implies that the degradation activities starts from late log phase and carries on till late stationary phase of growth. The enzyme responsible for phenol degradation was catechol 1, 2 dioxygenase. The optimal activity of catechol 1, 2 dioxygenase was observed at 500 mg/L phenol concentration. The enzyme was purified 2.34 fold by ion exchange chromatography. The Km was found to be 5 :mole with Vmax of 62.5 U/mg of protein. The optimal pH and temperature of the enzyme was 7.5 and 30ºC respectively. The enzyme activity was completely inhibited by Cu++, Hg++ and Fe+++ metal ions. The SDS-PAGE analysis reveals that the enzyme has a molecular weight of 30 k Dalton. Key words: Catechol, dioxygenase, Rhodococcus, muconate, phenol their biochemical and structural properties. Kim et al. (1997, 2002, 2003) (Caposio et al., 2002) Cis-cis muconic acid is the main intermediary metabolite during benzenefree adipic acid synthesis, a process with undeniable environmental benefit over the conventional chemical production of nylon (Niu et al., 2002). Catechol 1,2dioxygenases play important roles in the degradation pathways of various aromatic compounds and are ubiquitous in microorganisms (Broderick et al., 1991; Latus et al., 1995; Sauret-Ignazi et a1., 1996). Rhodococcus are non-sporulating, aerobic bacteria classified into mycolate-containing nocardioform actinomycetes (Finnerty, 1992). The genus Rhodococcus is comprised of genetically and physiologically diverse bacteria, which have been isolated from various habitats like soil and sea water. Rhodococcus strains are utilized as industrial organisms, primarily for biotransformation and the biodegradation of many organic compounds (Bell et al., 1998). Rhodococcus can thus be applied in environmental remediation and in the pharmaceutical and chemical industries (Van and Dijkhuizen, 2004; Larkin et al., 2005). Other possible biotechnological applications of aromatic ring-degrading organisms and their constituent enzymes, include the use of bioreactor systems for removal of toxic pollutants, as well as their incorporation into diagnostic systems and biosensors (Ali, 1998; Nakajima, 2002). The present study is regarding single step purification and characterization of the catechol 1, 2-dioxygenase from phenol utilizing Rhodococcus sp. NCIM 2891. INTRODUCTION Phenols and phenolic compounds are found mostly in plants and effluents of industries, such as coal conversion, paper and pulp manufacturing, wood preservation, metal casting, etc. Phenolic compounds are considered to be hazardous pollutants (Klibanov et al., 1980). Furthermore, the breakdown products of phenol may be more harmful when phenol is incompletely degraded by physical and chemical methods or by natural oxidation. Therefore, the complete removal of these substances from industrial and domestic water bodies is of great importance for conservation of native biodiversity (Yan et al., 2006). Aerobic biodegradation of these compounds is accomplished via pathways in which catechol (1, 2benzenediol) and its derivatives play a key role (Caposio et al., 2002) as it is a ring cleavage substrate in which an exceptionally large number of peripheral pathways come together (Loh and Chua, 2002) to yield metabolites, such as pyruvic acid, acetic acid, succinic acid, and acetyl-CoA which are intermediates of the Krebs cycle (Houghton and Shanley, 1994; Johnson and Stanier, 1971). Catechol 1, 2dioxygenase (Catechol oxygen 1,2-oxidoreductase, EC 1.13.11.1; pyrocatechase) play a central role in the cleavage of the aromatic ring of catechol to cis,cismuconic acid in presence of 1 mol of oxygen (Stanier and Ornston, 1973). Aromatic ring-cleaving enzymes such as the catechol dioxygenases of these catechol 1,2-dioxygenases from bacteria have been extensively characterized in terms of Corresponding Author: Dr. J.S. Ghosh, Department of Microbiology, Shivaji University, Vidyanagar, Kolhapur 416004. India. Ph: +91 9850515620 608 Res. J. Environ. Earth Sci., 3(5): 608-613, 2011 Enzyme assay: Catechol 1, 2 dioxygenase activity was assayed spectrophotometrically using a Hitachi U-2800 spectrophotometer. The standard assay of enzyme activity was performed by making an assay mixture containing 5 :L of Catechol 1, 2 dioxygenase, 20 :L of 10 mM Catechol as a substrate and final volume adjusted to1 mL with 50 mM sodium phosphate buffer (pH 7.0). The enzyme activity was monitored by measuring the formation of cis, cis-muconic acid at 260 nm (, = 16.8 mM). One unit (U) of the enzyme activity was defined as the amount of the enzyme required to catalyze the formation of 1 µ mol of product per min at 25°C. MATERIALS AND METHODS The study was conducted between June 2010 and September 2011. The work was carried out at the Department of Microbiology, Shivaji University, Kolhapur, India. Microorganism: Rhodococcus sp. NCIM 2891 was obtained from NCIM, (National Collection of Industrial Microorganisms) India. The culture was repeatedly transferred grown and maintained on YEM (Yeast Extract Mannitol) agar containing 10 g mannitol, 4 g CaCO3, 0.5 g K2HPO4, 0.4 g Yeast Extract, 0.2 g MgSO4, 0.1 g NaCL l-1 pH 7.0 at 4ºC during study. Effect of pH and temperature: The effect of pH and temperature was checked after incubation of the purified enzyme at different pH and temperature for 30 min (Tsai and Li, 2007). The effect of pH on enzyme activity was studied at pH ranging from 4.0 to 10.0, using citratephosphate buffer (pH 3.0-5.0), sodium- phosphate buffer (pH 6.0- 8.0), glycine- NaOH buffer (pH 9.0-10.0). The effect of temperature on enzyme activity was studied between temperatures 10 to 90ºC. Growth of bacteria and phenol degradation: Rhodococcus sp. NCIM 2891 was grown in flask containing 3.0 g Na2NO3, 1.0 g K2HPO4, 0.5 g MgSO4, 0.5 g KCL, 0.01 g FeSO4, 0.5 g yeast extract and 0.5 g phenol l-1 pH 7.0 at static condition. The growth of microorganism was routinely assessed through turbidity measurement as absorbance at 530 nm and residual phenol concentrations remaining in broth were assayed routinely by a colorimetric method using 4aminoantipyrine and potassium ferricyanide (Ettinger et al., 1951). The growth of Rhodococcus sp. NCIM 2891 and the residual phenol concentration were monitored at regular time intervals of 24 h. Effect of metal ions: To study the effect of metal ions on enzyme activity, enzyme was pre-incubated in 50 mM sodium phosphate buffer having pH 7.0 in presence of metal ions like Ca2+, Hg2+, Fe3+, Co2+, Mg2+, Cu2+ using their respective water soluble salts in different concentrations ranging from 1 and 10 mM concentration. The residual enzyme activity was subsequently measured by standard assay (Tsai and Li, 2007). Enzyme extraction and purification: After 72 h of incubation the cells were harvested for the enzyme extraction. The harvested cells were washed twice with 30 mL of 50 mM sodium phosphate buffer (pH = 7.0) and resuspended in the same buffer (pH = 7.0) and then homogenized by sonication with vibra model VC.130PB sonicator at 50 amplitude for 5 min. Sonicated sample was centrifuged for 30 min at 8000×g at 4ºC. After centrifugation to remove cell debris, the supernatant was subjected for DEAE - Cellulose chromatography. The column was eluted with 50 fractions of a linear gradient of NaCl with concentration of 0.1 to 0.5 M in 50 mM sodium phosphate buffer (pH 7.0) at a flow rate of 0.5 mL/min. The protein concentration of eluted fractions was analyzed by taking absorbance at 280 nm. The fractions having protein were tested for Catechol 1, 2 dioxygenase activities. Protein estimation: Protein estimation was done by the Lowry method using Bovine Serum Albumin as a standard (Lowry et al., 1951). Enzyme kinetics: The Km and Vmax of the catechol 1,2dioxygenase was determined by Lineweaver-Burk plots of reciprocal reaction velocities versus reciprocal substrate concentrations. Reactions were performed in 50 mM sodium phosphate buffer pH 7.0, with various concentrations of substrate (10 mM catechol varying between 1 to 50 :L. and enzyme activity was monitored by methods mentioned before. RESULTS SDS/PAGE analysis of enzyme: The molecular weights of enzyme were determined by the SDS/PAGE (Laemmli, 1970). The analysis of molecular weight of purified enzyme were carried out by using protein molecular weight markers that are phosphorylase b (97.4 kDa), Bovine Serum albumin (66 kDa), ovalbumin (43 kDa), carbonic anhydrase (29 kDa), trypsin inhibitor (20.1 kDa), and lactabumin (14.3 kDa). Growth of bacteria and phenol degradation: It was observed that the Rhodococcus sp. NCIM 2891 was able to grow on phenol as a sole source of carbon. The maximum phenol degradation was observed after 72 h. i.e., in log phase. The residual phenol concentration was 240 mg/L at 92 h, that is nearly half of initial phenol concentration (500 mg/L). In Fig. 1 it was observed that there was complete degradation of phenol within 120 h. 609 Res. J. Environ. Earth Sci., 3(5): 608-613, 2011 Fig. 1: Growth of Rhodococcus NCIM 2891 and residual phenol concentration. Residual phenol concentration (•) and growth of Rhodococcus NCIM 2891(#) Results obtained are mean values±SD, n = 5 Fig. 2: Elution profile of catechol 1, 2 dioxygenase from DEAE-cellulose column chromatography. Fractions from the DEAEcellulose anion exchange chromatography (#) and fractions showing catechol 1, 2 dioxygenase activity (•) Table 1:Purification of catechol 1, 2 dioxygenase Results obtained are mean values±SD, n = 5 Volume (mL) Protein (mg) Specific activity (U/mg) Crude Extract 20 2240±3.77 0.78±0.0262 Ion. exchange 15 510±1.55 1.83±0.06 chromatography Yield (%) 100 45 Purification fold 1 2.34 The SDS-PAGE analysis reveals that the purified enzyme has near about 30 KD molecular weight as shown in (Fig. 3). Purification of catechol 1, 2 dioxygenase: A single-step protocol was used to purify catechol 1, 2 dioxygenase. The purified catechol 1, 2 dioxygenase was obtained from 8 g of wet cell mass the purification profiles is given in (Fig. 2) and the activity of purified catechol 1, 2 dioxygenases at different stages of purification is given in Table 1. Enzyme stability: Effect of temperature and pH on Catechol 1, 2 dioxygenase: The optimal temperature and pH of 610 Recidual enzyme activity (%) Res. J. Environ. Earth Sci., 3(5): 608-613, 2011 120 100 80 60 40 20 0 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 pH Fig. 5: Effect of pH on catechol 1, 2 dioxygenase activity. Residual catechol 1, 2 dioxygenase activity of purified catechol 1, 2 dioxygenase (#) Results obtained are mean values±SD, n = 5 Residual activity (%) 120 Fig. 3: SDS-PAGE of purified catechol 1, 2-dioxygenase (C) crude sample (P) purified sample by ion exchange chromatography from Rhodococcus NCIM 2891 Size of the standard markers is at left. Markers (M): phosphorylase b (97.4 kDa), Bovine Serum albumin (66 kDa), ovalbumin (43kDa), carbonic anhydrase (29 kDa), trypsin inhibitor (20.1 kDa) and lactabumin (14.3 kDa) 100 80 60 40 20 0 None Cu 2+ Ca 2+ Mg2+ Hg2+ Heavy matel Co2+ Fe3+ Fig. 6: Effect of heavy metals on 1, 2 dioxygenase with 1mM and 10 Mm Concentration Results obtained are mean values±SD, n = 5 120 100 160 80 140 60 120 40 100 20 1/v Relative activity (%) 1 mM 10 mM 0 0 10 20 30 40 50 60 70 80 90 100 80 60 Temprature °C 40 Fig. 4: Effect of temperature on catechol 1, 2 dioxygenase activity. Residual catechol 1, 2 dioxygenase activity of purified catechol 1, 2 dioxygenase (#) Results obtained are mean values±SD, n = 5 20 -0.2 0 0.0 0.2 0.4 0.6 1/s Catechol 1, 2 dioxygenase was 30ºC and pH 7.5, respectively. Results are shown in Fig. 4 and 5. Fig. 7: Km of Catechol 1, 2 dioxygenase with Catechol as substrate Effect of metal ions on enzyme activity: The effects of metal ions on the activity of this enzyme were investigated. The results are shown in Fig. 6. The activity of this enzyme towards catechol was minimally affected by Co2+ (20%), and Mg2+ (20%) at concentrations of up to 1 mM, whereas the enzymatic reaction inhibited completely with addition of 1 mM Fe3+, Cu2+, and Hg+2 For 10 mM, used Ca2+, Cu2+, Fe3+ shows 100% inhibition whereas Mg2+ and Co2+ shows inhibition up to (60 %). Enzyme kinetics: Km and Vmax values of catechol 1, 2 dioxygenase are found to be 5 :mole/mL and 62.5 U/mg of protein respectively as shown in Fig. 7. DISCUSSION The study of phenol and other phenolic compound degradation by bacteria, fungi and other microorganisms were screened and it was found that there are number of 611 Res. J. Environ. Earth Sci., 3(5): 608-613, 2011 ACKNOWLEDGMENT bacteria which have exceptional capability of phenol degradation. This organisms include Pesudomonas, Agrobacterium, Burkholderia, Acinetobacter, Ralstonia, Klebsiella, Bacillus, Rhodococcus and Rhizobium (Koutny et al., 2003). In this study the phenol degradation ability of Rhodococcus sp. NCIM 2891 was demonstrated with purification of the four phenol oxidases. The organism was able to use phenol as a sole source of carbon and energy at a concentration of 500 mg/L under specified condition. There are many reports of production of catechol 1, 2 dioxygenase from number of phenol degrading microorganisms like Ralstonia sp., Pseudomonas aeruginosa, Rhodococcus sp. AN-22, R. rhodochrous NCIMB 13259 strains (Wang et al., 2001; Chuan et al., 2006; Mastumura et al., 2004; Chuan et al., 2006; Strachan, 1998) with phenol and different substrate. The strain Acinetobacter sp. was capable of removing 500 mg/L phenol concentration in liquid minimal medium (Wang et al., 2007). This is the first report on the purification and characterization of catechol 1, 2 dioxygenase from Rhodococcus sp. NCIM 2891 with single step purification procedure. Though the enzyme activity of catechol 1, 2 dioxygenase shows similarity with that from Acinetobacter and other Rhodococcus sp., the SDS-PAGE analysis shows that the molecular weight of the catechol 1, 2 dioxygenase from Rhodococcus sp. NCIM 2891 was near about 30 KD which was observed in catechol 1, 2 dioxygenase of Ralstonia sp. Ba-0323 (30 KD) (Wang et al., 2001). The optimal pH of catechol 1, 2 dioxygenase enzyme is comparatively lower with that of Catechol 1, 2 dioxygenase that have been previously isolated from other microorganisms. The enzyme activity remains up to >80% for 30 min between pH range of 7.0-9.0, whereas the stability of enzyme greatly decreased in the pH condition out of this range. The thermal stability of catechol 1, 2 dioxygenase was found to be similar with Pseudomonas aeruginosa (Chuan et al., 2006) enzyme was stable when it was kept at temperature lower than 40ºC.the optimal temperature of catechol 1, 2 dioxygenase was 30ºC. It was observed that the catechol 1, 2 dioxygenase of this organism was sensitive to Fe, Cu, Mg, Co, ions that were also observed in Aniline-Assimilating Bacterium Rhodococcus sp. AN-22 (Mastumura et al., 2004). The Km of this enzyme is 5 :mole/mL with Vmax 62.5 U mg-1of protein. The Km value of enzyme indicates that it has lower affinity for substrate (catechol) that is formed during phenol assimilation in broth. This Km value was found to be parallel with Km of P. aeruginosa (Chuan et al., 2006) and higher than R. rhodochrous NCIMB 13259 strains (Strachan, 1998). The authors are very grateful to the Department of Microbiology, Shivaji University, Kolhapur, for extending the laboratory facilities to complete the investigation. REFERENCES Ali, S., L.R. Fernandez and D.A. Cowan, 1998. Metapathway degradation of phenolics by thermophilic Bacilli. Enzyme Microb. Technol., 23: 462-468. Bell, K.S., J.C. Philp, D.W.J. Aw and N. Christofi, 1998. The genus Rhodococcus. J. Appl. Microbiol., 85: 195-210. Broderick, J.B. and T.V. O’Halloran, 1991. Overproduction, purifcation, and characterization of chlorocatechol dioxygenase, a non-heme iron dioxygenase with broad substrate tolerance. Biochemistry, 30: 7349-7357. Chuan, L.W., L.Y. Su and L.W. San, 2006. Purification and characterization of a novel catechol 1, 2dioxygenase from Pseudomonas aeruginosa with benzoic acid as a carbon source. Process Biochem., 41: 1594-1601. Caposio, P., E. Pessione, G. Giuffrida, A. Conti, S. Landolfo and C. Giumta, 2002. Cloning and characterization of two catechol 1,2-dioxygenases genes from Acinetobacter radioresistens S13. Res. Microbiol., 153: 69-74. Ettinger, M., C. Ruchhoft and R. Lishka, 1951. Sensitive 4-Aminoantipyrine method for phenolic compounds. Anal. Chem., 23(12): 1783-1788. Finnerty, W.R., 1992. The biology and genetics of the genus Rhodococcus. Annu. Rev. Microbiol., 46: 193-218. Houghton, J.E. and M.S. Shanley, 1994. Catabolic potential of Pseudomonads: A regulatory perspective. Dioscorides Press, Portland, pp: 11-32. Johnson, B.F. and R.Y. Stanier, 1971. Dissimilation of aromatic compounds by Alcaligenes eutrophus. J. Bacteriol., 107: 468-475. Kim, S.I., S.H. Leem, J.S. Choi, Y.H. Chung, S. Kim, Y.M. Park, Y.N. Lee and K.S. Ha, 1997. Cloning and characterization of two catA genes in Acinetobacter lwoYi K24. J. Bacteriol., 179: 5226-5231. Kim, S.I., S.J. Kim, M.H. Nam, S. Kim, K.S. Ha, K.H. Oh, J.S. Yoo and Y.M. Park, 2002. Proteome analysis of aniline-induced proteins in Acinetobacter lwoYi K24. Curr. Microbiol., 44: 61-66. Kim, S.I., S.Y. Song, K.W. Kim, E.M. Ho and K.H. Oh, 2003 Proteomic analysis of the benzoate degradation pathway in Acinetobacter sp. KS-1. Res. Microbiol., 154: 697-703. Klibanov, A.M., B.N. Alberti, E.D. Morris and Z.M. Felshin, 1980. Enzymatic removal of toxic phenols and anilines from wastewaters. J. Appl. Biochem., 2: 414. 612 Res. J. Environ. Earth Sci., 3(5): 608-613, 2011 Niu, W., K.M. Draths and J.W. Frost, 2002. Benzene-free synthesis of adipic acid. Biotechnol. Prog., 18: 201-211. Sauret-Ignazi, G., J. Gagnon, C. Beguin, M. Barrelle, J. Markowicz, J. Pelmont, and A. Toussaint, 1996. Characterization of a chromosomally encoded catechol 1,2-dioxygenase (E.C.1.13.11.1) from Alcaligenes eutroohus CH34. Arch. Microbiol., 166: 42-52. Strachan, P.D., A.A. Freer and C.A. Fewson, 1998. Purification and characterization of catechol 1,2dioxygenase from Rhodococcus rhodochrous NCIMB 13259 and cloning and sequencing of its catA gene. Biochem. J., 333: 741-747. Stanier, R.Y. and L.N. Ornston, 1973. The betaketoadipate pathway. Adv. Microb. Physiol., 9: 89-151. Tsai, S.C. and Y.K.V. Li, 2007. Purification and characterization of a catechol 1,2-dioxygenase from a phenol degrading Candida albicans TL3, Arch. Microbiol., 187: 199-206. Van der, G.R. and L. Dijkhuizen, 2004. Harnessing the catabolic diversity of rhodococci for environmental and biotechnological applications. Curr. Opin. Microbiol., 7: 255-261. Wang, C.L., S. Takenaka, S. Murakami and K. Aoki, 2001. Production of catechol from benzoate by the wild strain Ralstonia species Ba-0323 and characterization of its catechol 1,2-dioxygenase. Biosci. Biotechnol. Biochem., 65: 1957-1647. Wang, Y., Y. Tian, B. Han, H.B. Zhao, J.N. Bi and B.L. Cai, 2007, Biodegradation of phenol by free and immobilized Acinetobacter sp. strain PD12, J. Environ. Sci., 19: 222-225. Yan, J., W. Jianping, J. Xiaoqiang, C. Qinggele and H. Zongding, 2006. Mutation of Candida tropicalis by Irradiation with a He-Ne laser to increase its ability to degrade phenol. Am. Soc. Microbiol., pp: 226-231. Koutny, M., J. Ruzicka and J. Chlachula, 2003. Screening for phenol-degrading bacteria in the pristine soils of south Siberia. Appl. Soil Ecol., 23: 79-83. Laemmli, U.K., 1970. Cleavage of structural protein during the assembly of the head of bacteriophage T4. Nature, 227: 682-685. Larkin, M.J., L.A. Kulakov and C.C. Allen, 2005. Biodegradation and Rhodococcus-masters of catabolic versatility. Curr. Opin. Biotechnol., 16: 282-290. Latus, M., H.J. Seitz, J. Eberspächer and F. Lingens, 1995. Purifcation and characterization of hydroxyquinol 1, 2-dioxygenase from Azotobacter sp. strain GP1. Appl. Environ. Microbiol., 61: 2453-2460. Loh, K.C. and S.S. Chua, 2002. Ortho pathway of benzoate degradation in Pseudomonas putida: Induction of meta pathway at high substrate concentrations. Enzyme Microb. Technol., 30: 620-626. Lowry, O.H., N.J. Rosebrough, A.L. Farr and R.J. Randall, 1951. Protein measurement with the with the Folin phenol reagent. J. Biol. Chem., 193: 265-275. Mastumura, E., S. Ooi, S. Murakami, S. Takenaka and K. Aoki, 2004 Constitutive Synthesis, Purification, and Characterization of Catechol 1,2-Dioxygenase from the Aniline-Assimilating Bacterium Rhodococcus sp. AN-22. J. Biosci. Bioeng., 98(2): 71-76. Nakajima, H., T. Ishida, H. Tanaka and K. Horiike, 2002. Accurate measurement of near-micromolar oxygen concentrations in aqueous solutions based on enzymatic extradiol cleavage of 4-chlorocatechol: Applications to improved low-oxygen experimental systems and quantitative assessment of back diffusion of oxygen from the atmosphere. J. Biochem., 131: 523-531. 613