Research Journal of Applied Sciences, Engineering and Technology 2(8): 749-756,... ISSN: 2040-7467 © M axwell Scientific Organization, 2010

advertisement

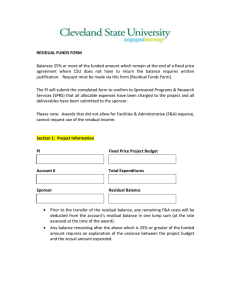

Research Journal of Applied Sciences, Engineering and Technology 2(8): 749-756, 2010 ISSN: 2040-7467 © M axwell Scientific Organization, 2010 Submitted date: October 16, 2010 Accepted date: November 05, 2010 Published date: December 10, 2010 Study of Residual Stress Tensors in High-Speed Milled Specimens of Aluminium Alloys Using a Method of Indent Pairs 1 C.A . Mammana, 1 F.V. Díaz, 2 A.P.M. Guidobono and 3 R.E. Bolm aro Departamento de Ingeniería Electrom ecánica - Departamento de Ingeniería Industrial, Facultad Regional Rafaela, Universidad Tecnológica Nacional, Bvd Roca 989, 2300 Rafaela, Argentina 2 División Metrología D imensional, Centro Reg ional Rosario (INT I) Ocampo y Esm eralda, 2000 Rosario, Argentina 3 Instituto de Física Rosario (CO NIC ET - UN R) B vd 27 de Febrero 210 bis, 2000 Rosario, Argentina 1 Abstract: From data obtained using a method of indent pairs it was possible to analyse different residual stress states generated in high-speed milled specimens of AA 6082-T6 and AA 7075-T6 aluminium alloys. The present method integrates a special device of indentation into a universal measuring machine, allowing the introduction of elongated indents to significantly reduce the absolute error of measurement. Diverse protoc ols for operations of high-speed face milling allow us to compare residual stress tensors inherent to climb and conventional cutting zones. Through an exha ustive analysis of the Mohr’s circles correspo nding to those zones, a relationship was detected, which expre sses the sensitivity of both alloys to develop surface residual stresses. Key words: Aluminium alloys, climb cutting, conventional cutting, high speed milling, process parameters, residual stresses INTRODUCTION Machining is a manufacturing process that plays an important role in the econo my of almost every country. The costs of diverse types of machining can be reduced increasing the volume of chips cut per unit of time (Trent, 1991). The fast development of machines and tool materials has allowed to augment the values of principal processing parameters, converting the conventional machining in to H ig h-S peed M achinin g (H SM ) (King, 1985; Sch ulz, 1996). Although each HSM operation presents a series of technological challenges due to the great speed of some the components, significant benefits can be obtained by this type of machining such as reduced operation time, longer service time of tools and higher productivity. On the other hand, residual stresses generated at the surface of a high-speed m achined part can considerably affect its useful life (Mantle and Aspinw all, 2001; W ithers, 20 07). During the last decad es, differe nt exp erimental techniques have been deve loped and g reatly impro ved in order to determine with high accuracy the residual stresses generated in the processing of engineering materials (Rowlands, 1987; Lu, 1996; Withers and Bhadeshia, 2001). In the case of machining, two approaches have been w idely used: X-ray diffraction technique (Fuh and W u, 1995; M `Saoubi et al., 1999; Hua et al., 2005) and the hole-drilling method (B ouzid Saï et al., 2001; Capello, 2005). However, in recent years different techniques based on instrumented indentation have been used in order to study different issues of residual stresses in machining. Warren et al. (2005) used nanoindentation to perform a study that focused on understanding the basic relationships between mechanical behaviour, residual stress, and m icrostructure of the machined subsurface. Then, Wyatt and Berry (2006) developed a method o f inden t pairs in order to perform different studies of residual stresses in high-speed milled componen ts. More recently, Díaz et al. (2010) studied the influence of mechanical and thermal mechanisms on the residual stress generation in high-speed machined specimens of different aluminium alloys using an impro ved method of inden t pairs. In this study, this method of ind ent pairs is used to carry out a detailed and accurate evaluation of residual stress tensors inherent to climb and conventional cutting. For this purpose, different tests of high-speed face milling were carried out in specimens of AA 6082-T6 and AA 7075-T6 aluminium alloys. It must be noted that through face milling o perations it is possible to ge nerate machined regions corresponding to climb and conventional cutting (Trent, 1991). The above-mentioned tests were performed Corresponding Author: F.V. Díaz, Departamento de Ingeniería Electromecánica - Departamento de Ingeniería Industrial, Facultad Regional Rafaela, Universidad Tecnológica Nacional, Bvd Roca 989, 2300 Rafaela, Argentina. Tel: + 54 3492 432710; Fax: + 54 3492 422880 749 Res. J. Appl. Sci. Eng. Technol., 2(8): 749-756, 2010 Table 1: Chemical compositions and mechanical properties of the evaluated alloys Alloy Ch emical co mpo sition (w t %) --------------------------------------------------------------------------------Mg Si Mn Fe Cr Zn Cu Al 6082-T6 0.91 0.87 0.58 0.5 0.22 0.2 0.16 balance 7075-T6 2.52 0.2 0.16 0.32 0.17 5.6 1.72 balance Tab le 2: To ol geo metry Ra ke a ngle ( (<) 45 an d pro cess pa rameters Cle aran ce an gle " (<) 7 En tranc e an gle P (<) 45 Mechanical properties --------------------------------------------------------------------------F u (Mpa) F y0.2 (Mpa) A (% ) HV 0.5 340 310 11 108 564 506 11 186 Cutting speed V (m/min ) 1000 in a numerically controlled vertical milling machine. The depth of cut was varied in order to evaluate its effects on stress tensors. Different Mohr’s circles (Gere, 2001) corresponding to the climb and conventional cutting zones were drafted in order to evaluate ex haustively these effects in both zones. Finally, this evaluation allowed us to identify a relation ship between the sensitivities of both alloys to develop residual stresses. Fee d rate f (mm /rev) 0.2 Depth of cut d (mm ) 1.00 – 1.25 which have good machinability (curled or easily broken chips and g ood to excellent finish). AA 6082-T6 is a relatively new alloy, which is used in structural applications in the marine and transportation industries as we ll as for precision machined parts in the automotive industry. On the other hand, AA 7075-T6 is a structural alloy widely used for aircraft, aerospace and defence applications due to its high mechanical resistance/weight ratio. Table 1 shows both the chemical compositions and mechanical properties of these alloys. The specimen shape and dimensions are shown in Fig. 1. Before the machining tests, the specimens were annealed to remove residual stresses generated during the manufacturing operations. The temperature and time corresponding to the distension procedure were 573 K and 80 min, respectively. The milling tests were performed with a face mill of 63 m m in diameter. Five tungsten carbide inserts (Palbit SEH T 1204 AF FN-A L SM 10) we re incorporated to the face mill. These inserts were specially designed for using with different types of aluminium alloys. In Table 2, both the insert geometry and high-speed parame ters selected for this work are detailed. The tests of high-speed face milling were performed in a numerically controlled vertical milling mach ine (Clever C MM-100). Figure 2 shows an upper view of the specimen-cutting tool system. As it can be seen, the processed surface can be divided in two zones corresponding to climb and conventional cu tting. Using the present method of indent pairs it is possible to evaluate the residual stress state at any point of the milled surface. Taking into account the above mentioned study (Díaz et al., 2010 ), two representative points were selected. Figure 3 shows these points, w hich are located at the barycentres of the climb and conventional cutting zones. The elongated indents were introduced at the corners of two adjacent squares. The coordinates of these inden ts were m easured b efore and after a distension treatment, within a temperature range of 20±0.2ºC, using a measuring machine GSIP MU -314. Finally, the distension treatment was performed at a temperature of 573 K during 80 m in. MATERIALS AND METHODS This study was carried out in the year 2009 at the Departamen to de Ingeniería Electromecánica and the Departam ento de Ingeniería Industrial, Facultad Regional Rafaela, U niversidad T ecno lógica Naciona l. Experimental work: The m ethod of inde nt pairs consists in determ ining the change in indent spacing, w hich is produced when the specimen is subjected to a distension procedure (Wyatt and Berry, 2006). First, the indent coordinates are measured before and after the distension using a Univ ersal M easu rin g M achin e (U M M ) and then, the components of the residual stress can be evaluated by classical and/or empirical analysis. It is important to note that if the distension treatment is performed below the recrys tallization temp erature (M ao, 20 03), th e dimensional chan ges at the specimen will be governed only by the elastic relaxation of the lattice. Therefore, the com ponents of the residual stress can be obtained from the strain components using an elastic model (Timoshe nko and G oodier, 1970). In this work, sev eral indents are introduced using an indentator device that is sp ecially integrated to the U M M . Through this integration it is possible to obtain a great accu racy in the optical localization of those indents. It is also possible to introduce elongated indents, from which the uncertainty of specimen repositioning after the distension treatment can be reduced. The maximum abso lute errors corresponding to pyramidal and elongated indent distances were compared in a previous study (Díaz et al., 2010); for a nominal distance of 28 mm, the obtained values were ±1.51 and ±0.26 :m, respectively. This reduction allowed us to substantially diminish the abso lute error of stress components, which in turn enabled to extend the sensitivity of the method below 6% of the yield stress. The experimental work was carried out in specimens of AA 6082-T6 and AA 7075-T6 aluminium alloys, Residual strain and stress determination: For the points A and B in F ig. 3 it is possible to determine norm al strain com ponents in three directions. Two of these, corresponding to the components g x and g y , are orthogonal. The direction of the other com ponent, g 4 5 , 750 Res. J. Appl. Sci. Eng. Technol., 2(8): 749-756, 2010 Fig. 1: Test specimen. The units are in mm and the thickness is 4 mm Fig. 2: Diagram of the face milling operation corresponds to the bisector of the angle formed by the directions inherent in g x and g y . These compo nents of residual strain can be expressed as: Fig. 3: Barycentres of climb and conventional cutting zones Besides, through the compon ents g x , g y and ( xy , it is possible to express the normal and shear com ponents associated to an arbitrary direction (Gere, 200 1): (1) whe re lx and l’x are the mean values of the horizontal sides of the square (Fig. 3), and ly and l’y are the mean values of the vertical sides, for both cases before and after the distension, respectively. In addition, the distances l4 5 and l’4 5 correspond to the diago nal of the mentioned square, also before and after the distension, respectively. Then, the shear strain com ponent ( xy can be obtained from the no rmal com ponen ts using (Ge re, 2001): (3) whe re 2 is the angle formed by the arbitrary direction and the axis y = 0 (Fig. 3). As mentioned above, if the distension procedu re is performed below the recrystallization temperature, the dimensional change of the evaluated surface will be caused by the elastic relaxation o f the lattice. Therefore, if the evaluated surface is considered to be under planestress conditions (Timoshenko and Goodier, 1970), the (2) 751 Res. J. Appl. Sci. Eng. Technol., 2(8): 749-756, 2010 infinitesimal element w hose axes were rotated an angle 2 with respect to the reference ax es (Gere, 20 01). In addition, the different point at each circle relates to the reference direction (2 = 0 in F ig. 3). M ohr’s circles correspon ding to the bary centre of climb cutting zone (point A) are show n in Fig . 4a. It is worth noting that in this zone the Vy component of cutting speed and feed rate have the same directions. By comparing the circles, it is obvio us that the normal stresses in alloy 6082-T6 are lower (more compressive) than those corresponding to alloy 7075-T6. In addition, alloy 6082-T6 shows higher sensitivity when the depth of cut is incre ase d. Figure 4b show s M ohr’s circles corresponding to the baryce ntre of conventional cutting zone (point B). In this zone, the Vy com ponent and feed rate have opposite directions. Altho ugh this circle arrangement is similar to that of point A, all circles associated to point B are slightly shifted to the left, which means that normal stresses are more comp ressive in the region corresponding to conventional cutting. It occurs that this type of cutting is so light at the beginning that each insert slides on the specimen surface until sufficient pressure is built up and it begin s to cut. This introduces a small additional increase in local plastic deformation of the machined surface, which does not occur in the case of climb cutting (Trent, 1991). Figure 5 shows the F p component of the normal stress, which corresponds to a principal direction, as a function of the depth of cut for both tested alloys. It shou ld be no ted that the principal directions are those associated to the normal components with the maximum and minim um values (G ere, 2001). In o ur case, F p corresponds to the most compressive component. It can be observed that the different gradients corroborate each alloy has a singular way of changing when the depth of cut is increased. For each alloy, the stress increment does not depe nd on the evaluated barycentre. Moreover, the differences betw een the values correspo nding to these barycentres would no t be dependent neither on the alloy type nor on the value of depth o f cut. Table 3 reports the increm ents of F p due to the variation of depth of cut. It must be noted th at all increments are negative. In addition, the values are similar on both barycentres. From Table 3, it is possible to express a relationship between the increments corresponding to both alloys: residual stress components for the case of a homogeneou s, isotropic and linear-elastic material can be expressed as: (4) whe re k 1 = E / ( 1 - L² ), k 2 = L · k 1 , E is the longitudinal elastic mod ulus, G is the shear elastic modulus and L is the Poisson’s ratio. It is possible to assert that the residual stress state at a point of the ev aluated surface is com pletely defined by the components F x , F y , and J x y . How ever, it could be necessary to evaluate residual stress com ponents associated to other directions. The normal and tangential components in an arbitrary direction 2 can be obtained through (G ere, 2001): (5) It is worth noting that these components show a continuous variation in function of the angle 2. In addition, these can be represented using a graphical format known as Mohr’s circle (Timoshenko and Goo dier, 1970). This graphical representation is very useful because it allows visualizing the relationships between normal and shear com ponents co rrespo nding to different orientations. Moreover, this representation also enables to appreciate c learly the intervals of variation of each com ponent. Furthermore, the errors inherent in residual strain and stress com ponents were obtained fro m the absolute error corresponding to indent distances using the equation of the probable absolute error (Bevington and Robinson, 2002). The values corresponding to these components were ±0.001% and ±0.9 MPa, respectively. RESULTS AND DISCUSSION It is possible to evaluate different Mohr’s circles for each significant point of the studied surfaces in order to clearly comp rehend the different residual stress states generated by H SM . As mentioned above, two representative points situated at the barycentres of the conventional and climb cutting zones were selected (points A and B in Fig. 3). Mohr’s circles corresponding to these points are shown in Fig. 4. It is important to note that orthogonal coordinates at each point represent the values of residual stress components corresponding to an Tab le 3: P rincip al stres s incr eme nts (MP a) Alloy 6082-T6 7075-T6 752 ----------------------------------------------------------Po int A Po int B - 7.23 - 6.82 - 3.32 - 3.36 Res. J. Appl. Sci. Eng. Technol., 2(8): 749-756, 2010 Fig. 4: Mohr’s circles corresponding to the barycentres (a) A and (b) B Fig. 5: Principal stress corresponding to the barycentres A and B 753 Res. J. Appl. Sci. Eng. Technol., 2(8): 749-756, 2010 temperature increm ents. Figure 6 show s the effe cts associated to the principal stress increments. From climb to conventional cutting zone, the principal s t r e s s c ha nge s a re simila r i n b o th a l lo y s because the cutting force increm ents are low (the mechanical effect prevails). On the other hand, when the depth of cut is modified, higher cutting force increm ents m ake p ossible the manifestation of the thermal effect. Finally, it is possible to expect the surface temperature increments, related to the change in depth of cut, responding to a relationship similar to that obtained for p rincipal stress increme nts. CONCLUSION Fig. 6: Effects associated to the principal stress increments The measurement procedure carried out in this work allowed a comp lete evaluation of the residual stress components in representative points of different machined surfaces, which correspond to zones of climb and conventional cutting. This evaluation included the residual stress compo nents associated to arbitrary directions, which made possible to comprehend the complete variation of the normal and shear componen ts. The normal co mpon ents are distributed in reduced ranges around small values, and they are also compressive. On the other hand, the tangential componen t values are concentrated in reduced ran ges around zero . The sensitivity of the present method e nabled to detect a small difference between the residual stresses associated to climb and conventional cutting zone s. This difference would be related to the influence of the relative orientation of the vectors Vy and f on the generation of local plastic strain. Regarding the principal components of residual stress, it was observed that each alloy has a singular way of changing when the depth of cut is increased. In addition, alloy 6082-T6 showed larger susceptibility to be stressed. Th e difference in the susceptibility between both alloys could be quantified by a relationship associated to the stress tensors. This relationship is the same for climb and conventional cutting zone s. Finally, this susceptibility difference would be due to the differenc es in the thermal flow from the cutting primary zone to specimen surface, which is always highe r for the case of alloy 6082-T6. which would qu antify the sensitivity difference to the chan ge in depth of cut when the values corresponding to F p are evaluated. This relationship is similar to (Díaz et al., 2010 ): which was obtained in a previous work , for the stress component perpendicular to the feed direction, when the barycentres of entire surfaces generated by HSM were evaluated. It is important to note that the present relationship corresponds to the stress tensors because the associated direction s are not the sa me fo r both alloys. The difference on sensitivity between both alloys, which is similar in both evaluated regions, could be explained from thermal effects generated in the cutting zone. First, it is possible to expect the the rmal energy in the cutting primary zone to be similar for both alloys because the machin ability difference between them could com pensate the small difference in cutting forces (higher for alloy 7075-T6) (Díaz et al., 2010). It must be noted that alloy 6082-T6 is m ore difficult to machine because the magnesium it contains is essentially tied up w ith silicon to fo rm hard M g2 Si particles (Kamiya and Yakou, 2008). Secondly, the fraction of the energy generated in the cu tting prim ary zo ne that enters in the machined surface will always be higher for alloy 6082T6, which basically responds to the difference on thermal conductivity between both alloys (K 6 0 8 2 /K 7 0 7 5 = 1.3) (Özel and Zeren, 2004). Due to this thermal effect, stresses are always more compressive for alloy 6082-T6. When the depth of cut is increased, the change in cutting forces is similar for both alloys (Díaz et al., 2010). Therefore, the difference between the principal stress inc reme nts would respond to a precise difference between surface ACKNOWLEDGMENT The authors w ish to express their sincere thanks to Eduardo Cravero and Silvio Acosta for their assistance during HSM test pha se. Th is work was supported by the Departam ento de Ingeniería Electromecánica and the Departam ento de Ing eniería Industrial, Facultad Regional Rafaela, U niversidad T ecno lógica Naciona l. 754 Res. J. Appl. Sci. Eng. Technol., 2(8): 749-756, 2010 NOMENCLATURE A d E f G HV0.5 k1, k2 K lx , l’x ly , l’y l4 5 , l’4 5 V Vx Vy " ( ( xy ( x'y' gx g x' gy g45 2 L Fx F x' Fy Fp Fu F y0.2 J xy J x'y' P REFERENCES elongation (% ) depth of cut (mm) longitudinal elastic mo dulus (G Pa) feed rate (mm/rev) transverse elastic modulus (G Pa) Vickers micro-hardn ess (test load: 500 gf) elastic constants thermal con ductivity (w/( mAK )) mean values of the horizontal sides of the square, before and after the stress-relieving, respectively (mm) mean values of the vertica l sides of the squa re, before and after the stress- relieving, respectively (mm) length of the square diag onal, before and after the stress-relieving, respectively (m m) cutting speed (m/min) cutting speed component at the x directio n (m/min) cutting speed comp onent at the y directio n (m/min) clearance angle (deg) rake angle (deg) tangential deformation component tangential deform ation comp onent associated to an angle 2 normal deformation component at the x direction normal deformation component associated to an angle 2 normal deformation component at the y direction normal deformation component associated to an angle 2 = 45° ang le formed by an arbitrary d irection and th e axis y = 0 Poisson’s ratio normal stress component at the x direction (MPa) normal stress co mpo nent associated to a n ang le 2 (MP a) normal stress component at the y direction (MPa) princip al stress comp onent ultimate tensile strength (UTS) (MPa) yield strength (MPa) tangential stress component tangential stress component associated to an angle 2 entrance an gle (deg) variation in the F p com ponent du e to an increase in the d parameter (MPa) variation in the F p component due to the change of the evaluated zone (MPa) variation in the F x component due to an increase in the d parameter (MPa) 755 Bevington, P.R. and D. Robinson, 2002. Data Reduction and Error Analysis for the Physical Sciences. McG raw-Hill, New York. Bouzid Saï, W., N. Ben Salah and J. Lebrun, 2001. Influence of machining by finishing milling on surface characteristics. Int. J. Mach. Tools Manufact., 4: 443-450. Capello, E., 2005. Residual stresses in turning. Part I: Influence of process parameters. J. Mater. Proc. Tech., 160: 221-228. Díaz, F.V., R. Bolmaro, A. Guidobo no an d E. G irini, 2010. Determination of residual stresses in high speed milled aluminium alloys using a method of indent pairs. Exp. Mech., 50: 20 5-215. Fuh, K.H . and C . W u, 1995. A residual stress model for the milling of aluminium alloy (2014-T 6). J. Mater. Proc. Tech., 51: 87-105. Gere, J.M ., 2001 . Mecha nics of Materials. 5th Edn., Brooks/C ole, Pacific Grove, CA . Hua, J., R. Shivpuri, X. Cheng, V. Bed ekar, Y. Matsumoto, F. Hashimoto and T. Watkins, 2005. Effect of feed rate, workpiece hardness and cutting edge on subsu rface residual stress in the hard turning of bearing steel u sing chamfer + hone cutting edge geometry . Mater. Sci. Eng. A., 39 4: 238 -248. Kamiya, M. and T. Yakou, 2008. Role of second-phase particles in chip breakability in aluminium alloys. Int. J. Mach. Tools Manuf., 48: 688-697. King, R.I., 1985. Handbook of High Speed Machining Technology. C hapman and H all, New Y ork. Lu, J., 1996. Handbook of Measurement of Residual Stresses. Fairmont Press Inc., Lilburn, Georgia. Mantle, A.L. and D. Aspinwall, 2001. Surface integrity of a high speed milled gamma titanium aluminide. J. Mater. Proc. Tech., 118: 143-150. Mao, W ., 2003. Recrystallization and Grain Growth. In: Totten, G.E. and D. MacK enzie (Eds.), Handbook of Aluminum, Physical Metallurgy and Processes. New York: Marcel Dekker Inc., 1: 211-258. M`Saoubi, R., J. Outeiro, J. Changeux, J. Lebrun and A. Morão Dias, 1999 . Residual stress an alysis in orthogonal machining of standard and resulfurized AISI 316 steels. J. Mater. Proc. Tech., 96: 225-233. Özel, T. and E. Zeren, 2004. Determination of flow mate rial stress and friction for FEA of machining using orthogonal cutting tests. J. Mater. Proc. Tech., 153: 1019-1025. Row lands, R.E., 1987 . Residual Stresses. In: Kobayashi, A. (Ed.), Handbook on Experimental Mec hanics. Prentice-H all, New Jersey, pp: 768-813. Schulz, H., 1996. High Speed Machining. C arl Hanse r, Munich . Res. J. Appl. Sci. Eng. Technol., 2(8): 749-756, 2010 Timoshenko, S.P. and J. Goodier, 1970. Theory of Elasticity. 3rd Edn., M cGraw-Hill, N ew York. Trent, E.M., 1991. Metal Cutting. Butterworth/ Heinemann, London. W arren, A.W., Y. Guo and M. W eaver, 2005. The influence of machining induced residual stress and phase transformation on the measurement of s u b s u r fa c e m e c h a n i c a l b e h a v i o u r u s i n g nanoindentation. Surf. Coat. Technol., 200: 3459-3467. W ithers, P.J. and H. Bha desh ia, 2001. Residual stress. Part 1 - measu rement techniques. Mater. Sci. Technol., 17: 355-365. W ithers, P.J., 2007. Residual stress and its role in failure. Rep. Prog. Phys., 70: 2211 -2264. W yatt, J.E. and J. Berry, 2006. A new technique for the determination of superficial residual stresses associated with machining and other manufacturing processes. J. Mater. Proc. Tech., 171: 132-140. 756