Research Journal of Applied Sciences, Engineering and Technology 2(5): 487-491,... ISSN: 2040-7467 © M axwell Scientific Organization, 2010

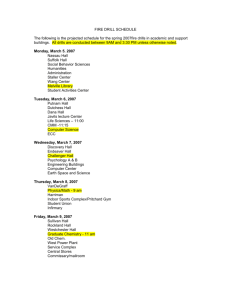

advertisement

Research Journal of Applied Sciences, Engineering and Technology 2(5): 487-491, 2010 ISSN: 2040-7467 © M axwell Scientific Organization, 2010 Submitted Date: May 27, 2010 Accepted Date: June 15, 2010 Published Date: August 01, 2010 Performance Study of Cryogenically Treated HSS Drills in Drillilg Gray Cast Iron Using Orthogonal Array Technique 1 1 B.R . Ram ji, 2 H.N . Narasimha M urthy, 2 M. Krishna and 2 M.J. Raghu Departm ent of Manufacturing Engineering, BM S College of Engin eering, Bangalore, India 2 Departm ent of Mechanical Engineering, RV College o f Engineering, Bangalore, India Abstract: The objective of this research was to study the performance of cryogenically treated HSS drills for drilling gray cast iron. Drilling experiments were conducted with cutting speeds: 560, 710, 900, 1120 rpm, feeds: 0.05, 0.08, 0.12, 0.19 mm/rev and a constant drill diameter: 8 mm. The cry ogenic treatment cycle consisted of coo ling the test sam ples from roo m tem peratu re to cryogenic tem peratu re of -17 8.9ºC in 3 h, soaking at cryogenic temperature for 24 h and w armin g to roo m tem peratu re in about 5 h. The thrust force and torque were measured using drill tool dynamometer. The surface roughness (Ra, Rz, Rq and R t) of the drilled specimens were measured using talysurf. The experimental lay-out was designed using Taguchi’s Orthogonal Array technique. S ignal-to-Noise Ratio analysis was performed to identify the effect of the parameters on the response variables. The treated drills we re foun d sup erior to the non -treated in all the test conditions in terms of lesser thrust force, torque and also superior surface roughness of the specimens. The tool wear was studied u sin g SEM . Key w ords: Cryogenic, drilling, gray CI, surface roughness, Taguchi INTRODUCTION The challen ge of m odern ma chinin g indu stries is mainly focused on achieving high quality in terms of work-piece dimensional accuracy, surface finish and less tool wear. The harde r the material, the more difficult it is to machine. Cast iron has been used in large quantities for years because of desirable properties as good castability, good ma china bility and low cost. A wide variety of gray cast iron is used in industries for various applications. M achin ability of C ast Iron is affected by the amount of carbon. The tool lives may increase significantly after being sub mitted to subze ro temperatures. Cryogenic treatment involves the soaking of cutting tools at very low temperatures, -184ºC or below. The results can be surprisingly good depending upon the application. Reports of 92-817% increases in tool lives after they are treated at -196ºC are found (Paulin, 1993). The tool steels submitted to conventional heat treatment presented only a small amount of retained austenite, but those submitted to cryogenic treatment showed better wear perfo rman ce du ring m achin ing. This is due to a new mechanism besides the transformation of the retained austenite into martensite. The new mechanism is time and temperature dependent during the long hours of dwelling in cryogenic treatment. The carbide particles smaller in sizes are found after the treatment, which w ould c ontribu te to the wear resistance of the tools (Gruman Aircraft Engineering, 1965; Barron, 1974; A hmed , 2004). Chatterjiee (1992) reported the cryogenically treated high speed drills yielded higher tool life compared than that of with untreated ones, for different cutting speeds and for different work materials. Firouzdor et al. (2008) reported the influence of deep cryogenic treatment on wear resistance and tool life of M2HSS drills in high-speed dry drilling of carbon steels. The researchers observed 77 and 126% im proveme nt in cryogenic treated and cryogenic and temper treated drill lives, respectively. The improvement in wear resistance of the drills was mainly attributed to the resistance of cryogenically treated drills against diffusion wear mechanism, due to the formation of fine and homogeneous carbide particles during cryogenic treatment. Additionally, transformation of retained austenite to martensite played an effective role, i.e. improved hardn ess va lues. C arter (1956), Shaw (1986) and Adler et al. (2006) reported results of tool performance in case of cryogenically treated tools used for drilling, milling, turning, etc. Based on the literature review it was concluded that experimental studies on the effect of cryogenic treatment on drilling gray cast iron has not been reported yet. Finite Element Analysis for the performance of cryo genically treated drills has been very scarcely repo rted. Th us, this research was aimed at studying the performance of Corresponding Author: B.R. Ramji, Department of Manufacturing Engineering, BMS College of Engineering, Bangalore, India Tel: 9844348421 487 Res. J. Appl. Sci. Eng. Technol., 2(5): 487-491, 2010 Table 1: Experimental conditions used for drilling exercises Machine tool Sensitive drilling machine Wo rkpiece Gray Cast Iron (C-3.266 % , M n-0.329%, P0.407, S-0.120, Si-1.806 %) Size N50 X 40 mm Cu tting to ol HSS drills Working tool geo metry Diameter: 8 mm, Flute length: 75 mm , Ov erall length: 117 mm Lip angle: 118°, Helix angle: 20° Drilling parameters Cutting velocity, A: 560, 710, 900, 1120 rpm Feed rate, B: 0.05, 0.08,0.12, 0.19 mm/rev Depth of drilled blind hole: 15 mm Tool co nd ition , C: Cry oge nica lly treated (C T), non-treated (NT) M easu ring in strum ents Talysu rf (SJ-201) for surface roughn ess (Ra, Rz, Rq, Rt) Drill tool dy nam ome ter for m easuring thrust force in Kgf and Torque in Kg-m, Scanning Electron Microscope: JOEL Place of study R V College of Engineering, Bangalore, Ind ia Time of study September 2009 cryogenically treated HSS drills in terms of thrust force, torque and the surface roughness in drilling of gray cast iron expe rimen tally based on Tagu chi’s Orthogonal array technique and FEA. MATERIALS AND METHODS Experimental-drilling studies: The drilling exercises on gray cast iron and the study of the influence of cryo genic treatment of the inserts on the thrust force, torque and the surface roughness of the work piece were undertaken under the experimental conditions presented in Table 1. The experim ents were conducted at RV College of Engineering Bangalore, India during September 2009. The cryogenic treatment involved cooling the inse rts from room temperature to cryogenic temperature (-178.9ºC) in 3 h, soaking at this temperature for 24 h and warming to room temperature in 5 h. Drilling exercises were carried out for each experimental condition to cut 15 mm dep th blind hole in the w ork-piece an d for each experimental condition five holes were drilled. Table 2: Parameters, levels and orthogonal array Factor code Parameter A Cu tting v eloc ity B Feed rate C Tool condition No. of levels considered for study Orth ogo nal A rray c hos en c orres pon ding to fou r para mete rs an d fo ur lev els Design of experiments using taguchi’s orthogonal array technique: The factor level combinations selected for the design of experiments is shown in Table 2. An L'16 OA layou t was selected to satisfy the minimum number of experiments condition. The experimental results are shown in Table 3 and 4. No. of levels 4 4 2 4 L'16 The calculation of the SN for the first experiment in the array above is shown below for the case of a specific target value of the performance characteristic. Signal-to-Noise ratio analysis of the responses: The signal-to-noise ratio analysis based on the responses obtained in the drilling exercises is shown in Table 5, 6 and 7 for thrust force. To determine the effect each variab le has on the output, the signal-to-noise ratio, or the SN number, has been computed for each experiment conducted. (1) Stl = 602 + 59 2 + 60 2 + 62 2 + 61 2 = 18246 Stl = Stl-Sml = 18246-18240.8 = 5.2 (2) (3) Table 3: Experimental lay-out and results for thrust force as response S.No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Cutting speed (rpm) 560 560 560 560 710 710 710 710 900 900 900 900 1120 1120 1120 1120 Feed mm/rev 0.05 0.08 0.12 0.19 0.05 0.08 0.12 0.19 0.05 0.08 0.12 0.19 0.05 0.08 0.12 0.19 T o o l c o nd it io n N T /C T NT CT NT CT CT NT CT NT NT CT NT CT CT NT CT NT 488 Thrust force (Kg f) ---------------------------------------------------------------------------------------T1 T2 T3 T4 T5 60 59 60 62 61 59 57 60 62 63 114 114 115 115 116 92 95 93 97 98 55 55 56 58 59 75 77 75 76 78 82 81 80 89 87 173 172 172 170 167 73 73 72 74 75 65 63 57 58 56 126 129 130 127 122 122 123 121 119 120 65 64 66 67 69 90 91 90 92 93 96 95 92 94 92 199 201 206 210 208 Res. J. Appl. Sci. Eng. Technol., 2(5): 487-491, 2010 Table 4: Experimental results for torque and surface roughness as responses Torque (Kg-m) -------------------------------------------------------------------------S.No. T1 T2 T3 T4 T5 1 5.08 5.12 5.11 5.33 5.27 2 5.36 4.78 5.12 4.38 4.98 3 5.77 6.10 5.82 5.63 5.97 4 5.31 4.86 5.14 4.93 5.42 5 5.42 5.19 4.63 5.62 5.89 6 5.58 6.21 5.24 4.91 4.47 7 4.33 5.60 4.20 4.72 4.80 8 6.44 6.31 6.10 5.98 5.82 9 5.96 6.11 6.24 5.87 6.06 10 4.82 5.11 5.15 4.11 4.92 11 6.50 6.53 6.16 6.34 5.40 12 5.91 5.24 5.92 5.88 6.41 13 4.66 4.92 5.57 5.36 4.73 14 6.88 6.11 6.30 6.14 6.23 15 5.35 4.90 5.11 5.32 5.42 16 5.14 5.79 5.23 5.63 5.09 S u rf ac e r ou g hn e ss – Ra ( :m) ------------------------------------------------------------------------------------T1 T2 T3 T4 T5 0.13 0.12 0.13 0.13 0.13 0.11 0.10 0.11 0.09 0.12 0.17 0.17 0.16 0.16 0.17 0.15 0.16 0.15 0.16 0.17 0.11 0.13 0.15 0.16 0.16 0.14 0.15 0.14 0.15 0.15 0.15 0.13 0.13 0.18 0.14 0.29 0.29 0.29 0.29 0.32 0.14 0.13 0.12 0.14 0.14 0.11 0.10 0.11 0.09 0.08 0.22 0.21 0.22 0.23 0.24 0.21 0.18 0.16 0.16 0.18 0.14 0.11 0.11 0.12 0.13 0.18 0.19 0.21 0.21 0.21 0.15 0.14 0.16 0.18 0.21 0.36 0.40 0.43 0.45 0.41 Table 5: SN number for each experiment conducted for thrust force S.No. Speed A Feed B Tool condition C 1 560 -1 0.05-1 NT -1 2 560 -1 0.08-2 CT -2 3 560 -1 0.12-3 NT -3 4 560 -1 0.19-4 CT -4 5 710 -2 0.05-1 CT -2 6 710 -2 0.08-2 NT -1 7 710 -2 0.12-3 CT -4 8 710 -2 0.19-4 NT -3 9 900 -3 0.05-1 NT -3 10 900 -3 0.08-2 CT -4 11 900 -3 0.12-3 NT -1 12 900 -3 0.19-4 CT -2 13 112 0-4 0.05-1 CT -4 14 112 0-4 0.08-2 NT -3 15 112 0-4 0.12-3 CT -2 16 112 0-4 0.19-4 NT -1 Sm1 18 24 0.8 18 12 0.2 65 89 5.2 45 12 5.1 16 01 7.8 29 03 2.2 35 11 2.2 14 58 63 .2 26 93 7.8 17 88 0.2 80 39 1.2 73205 21 91 2.2 41 58 7.2 43 99 2.2 20 97 15 .2 Table 6: Computed average SN values SN A 1 34.17 SN B 1 32.81 SN A 2 32.20 SN B 2 30.95 SN A 3 32.40 SN B 3 33.96 SN A 4 33.72 SN B 4 34.76 )= 1.97 )= 3.81 SN C 1 SN C 2 SN C 3 SN C 4 )= S t1 18246 18143 65898 45151 16031 29039 35175 145886 26943 17943 80430 73215 21927 41594 44005 209802 S e1 5.2 22 .8 2.8 26 13 .2 6.8 62 .8 22 .8 5.2 62 .8 38 .8 10 14 .8 6.8 12 .8 86 .8 V e1 1.3 5.7 0.7 6.5 3.3 1.7 15 .7 5.7 1.3 15 .7 9.7 2.5 3.7 1.7 3.2 21 .7 SN 1 34.48 28.03 42.75 31.42 29.87 35.33 26.50 37.09 36.17 23.56 32.19 37.68 30.73 36.89 34.39 32.86 After computing the SN ratio for each experimen t, the average SN value is calculated for each factor and level as shown in Table 6. Where: 33.72 32.49 38.23 28.05 10.17 (6) Tab le 7: Range and rank for thrust force, torque and surface roughn ess Speed Feed Tool condition Thrust force Ra ng e, ) 1.97 3.81 10.17 Rank 3 2 1 Torque Ra ng e, ) 5.27 1.96 8.28 Rank 2 3 1 Surface rough ness Ra ng e, ) 6.80 5.33 7.04 Rank 2 3 1 Similarly SN B1, SN C1 were computed and ) = SN Amax – SN Amin = 34.17-32.20 = 1.97 (7) Table 7 shows the range R ( ) = high SN - low SN) of the SN compu ted for each parameter for each of the response factors. Larger the R value for a parameter, the larger the effect the variable has o n the process. This is because the same change in signal causes a larger effect on the output variable being measured. It can be seen that the tool condition has the largest effect on the thrust force, torque and surface roughness. Speed has the smallest effect on the thrust force and feed has the smallest effect on the torque and the surface roughness. (4) (5) Similarly SN 2, SN 3, SN 4 … etc. have been computed. 489 Res. J. Appl. Sci. Eng. Technol., 2(5): 487-491, 2010 lack of matrix strength indicating the absence of carbide particles i.e., martensitic matrix. The treated drills showed (Fig. 1d) micro damages at the chisel edge indicating the presence of carbide particles i.e., martensitic matrix. The cryogenic treatment of HSS drills toughened the tool material and increased its strength, which was also indicated by the increase in hardness. The treated drills showed decreased thrust force and torque and better surface roughness than that obtained by non-treated drills. RESULTS AND DISCUSSION Thrust force and torque are indicators of tool performance. Greater the thrust force and torque, greater is the tool w ear and hen ce low er drill tool life. T he drill tool wear is caused by abrasive, diffusive and adhesive wear mechanisms. The heat generated during drilling also affects drill tool life. At higher speeds and feeds, the thrust force and torque of the drill tool increases for a given depth of hole drilled. Surface finish is an impo rtant index of m achin ability because life and performance of the machined com ponents are influenced by their surface finish, residual stresses and surface defects (Paul et al., 2001). The signal-to-noise ratio analysis indicated that, the cryogenic treatment has the largest effect on the thrust force, torque and surface roug hness. Speed h as the smallest effect on the thrust force and feed has the smallest effect on the torque and surface roughness (R a). CONCLUSION Drilling exercises w ere performed using cryogenically treated and non-treated HSS drills to study the tool performance. Based on the study the following conclusions were drawn: The extents of influence of cutting velocity, feed and the condition of the inserts were examined by conducting drilling exercised based on O rthogona l Array Experimentation technique. Cryogenic treatment resulted in lesser thrust force, torque and y ielded superior surface finish com pared to that of non -treated drills. The response s obtained after drilling were analyzed using signal-to-noise ratio analysis.The tool condition had the largest effect on the Scanning electron microscopy: The scanning electron micrographs of the HSS drills are shown in Fig 1. Figure 1a and c show non treated and treated drills respectively. In this after drilling condition Fig. 1(b), the non-treated drills showed plastic deformation, which was due to the Fig. 1: SEM of HSS drills (a) Non-treated before drilling, (b) Non-treated after drilling showing excessive wear on cutting edge, (c) treated before drilling and (d) treated drill after drilling showing less wear of the cutting edge 490 Res. J. Appl. Sci. Eng. Technol., 2(5): 487-491, 2010 thrust force, torque and surface roughness. Speed had the smallest effect on the thrust force and feed had the smallest effect on the torque and the surface roughness. Based on the resu lts it was conc luded that cryogenic treatment can yield significant improvemen t in both productivity and p roduct quality and henc e ove rall machining economy offsetting the cost of cryogenic cooling. Carter W .A., 1956. Metal Machining, Part VI, Overseas Edition, Cutting Fluids, Machinery Lloyd. Chatterjee, S., 1992. Performance characteristics of cryogenically treated high-speed drills.Int. J. Prod. Res., 32(4): 773-786. Firouzdor, V., E. Nejati and F. Khomamizadeh, 2008. Effect of deep cryogenic treatment on wear resistance and tool life of M 2 HSS drill. J. Mater. Process. Technol., 206(1-3): 46 7-472. Gruman Aircra ft Engineering, 196 5. Cry ogenic coolants speed titanium machining. Machinery, pp: 101-102. Paul, S., N.R. Dhar and A.B. Chattopadhyay, 2001. Beneficial effects of cryogen ic cooling over dry and wet machining on tool wear and surface finish in turning AISI 1060 steel. J. Mater. Process. T ech., 116(1): 44-48. Paulin, P., 1993. Frozen gears. Gear Technol., pp: 26-29. Shaw, M.C., 1986. Metal Cutting Principles. Oxford University Press, Oxford. REFERENCES Adler, D.P., W . W-S. Hii, D.J. M ichalek and J.W . Sutherland, 2006. Examining the role of cutting fluids in machining and efforts to address associated environm ental/health conc erns. M ach. S ci. Technol., 10(1): 23-58. Ahmed, M., 2004. Cryogenic drilling of Kevlar compo site laminated. M.Sc. Thesis, Mechanical Engineering, King Fahd U niversity of Petroleum and M inerals. Barron, F.R., 1974. Yes-C ryogenic Treatments Can Save You M oney! Here's Why. Tappi J., 57(5): 35-40. 491