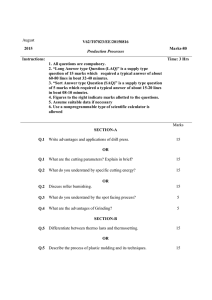

International Journal of Application or Innovation in Engineering & Management... Web Site: www.ijaiem.org Email: Volume 4, Issue 5, May 2015

advertisement

International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 5, May 2015 ISSN 2319 - 4847 Analytical and Experimental Investigation of Contribution of Burnished Parameters on Roughness and Micro Hardness of AA6351 1 Arvind Ghodake, Prof. Bhamre V.G.2 , Prof. Londhe B.C.3 1 Department of Mechanical Engg. SND COE & RC YEOLA 2 Department of Mechanical Engg. SND COE & RC YEOLA 3 Department of Mechanical Engg. SND COE & RC YEOLA ABSTRACT Burnishing is a surface enhancement process in which plastic deformation of surface induces compressive residual stresses. It is a cold working chip less process in which material is pressed against burnishing force or pressure. By imparting compressive stresses in the surface layer, the tensile range on the component surface was reduced. From the literature it is viewed that several methods are available for inducing compressive residual stresses on component surface layer to improve mechanical properties of metal and alloys. Ball burnishing is one of the method for surface enhancement and with the effective burnishing parameter the surface finish and micro hardness of the metals or alloys gets improved. The test will carried out for AA6351 alloy material, 0.10 % Cu, 0.4-1.0% Mn , 0.6 % Fe , 0.4-1.2 % Mg, 0.6-1.3 % Si and reminder is Al. The material having mechanical properties as T.S. =150-160Mpa.This AA6351 alloy is widely used in aerospace industry as well as marine industry. In this work attention is given toward a design such a tool which is suitable for burnishing operation of conventional lathe machine. The ball burnishing tool is manufactured with hard steel ball. The experimental work has been carried out considering suitable burnishing parameters as feed (mm/rev), speed (rpm), depth of penetration (mm) and number of tool passes. Keeping rest parameters constant. The kerosene is used as coolant. In this work ball burnishing process will carried out on specimens as per experimental matrix with burnishing input parameters as feed, speed, depth and number of tool passes on conventional lathe machine. After experimentation the results will be obtained for surface roughness and micro hardness for each specimen. From the experimental results as per experimental matrix the ANOVA and regression analysis will carried out to find out contribution of burnishing parameter for surface roughness and improvement in micro hardness properties of AA6351 alloy. Then the microscopic examination will be done to analysis the effect on microstructure of AA6351. The maximum contribution of burnishing parameter will be investigated for further burnishing operation which will give best mechanical properties for alloys. Keywords: Burnishing, Design of Experiments, Micro hardness, Surface Roughness. I. INTRODUCTION In the present scenario of manufacturing good surface finish and dimensional accuracy plays an important role. A good surface finish is essential in many applications, e.g. in the moulds and dies, bioengineering, semiconductor and optical industries. In the injection molding process, the surfaces finish required is Ra= 0.1μm or less. Surface finish is important not only as an indication of expert workmanship, but it has effects on the life and function of the component. Finishing processes such as grinding, polishing, lapping and honing are commonly employed to improve surface finish. Burnishing is a cold working process in which plastic deformation occurs by applying a pressure through a ball or roller on metallic surfaces. It is a finishing and strengthening process. Improvements in surface finish, surface hardness, wear resistance, fatigue resistance, yield and tensile strength and corrosion resistance can be achieved by the application of this process. It also improves exterior quality of surface. 1.1 Importance of the Problem The main importance of this work is getting required surface quality and improvement in the properties of materials. 1.2 Scope of the work The surface and subsurface nature of materials is usually characterized by an tensile residual stresses which is most prominent effect on the fatigue life of the component, burnishing is the process which can provide deep, stable , surface compression process for improved surface integrity characteristics and fatigue life of the component. The mechanical properties of surface of material can be improved by this operation. The present work focuses on surface roughness and Micro hardness of AA6351 aluminum alloy using full factorial design and it analyzed using ANOVA Method. After analysis the effect various burnishing parameters of ball burnishing which effect the surface roughness and Micro hardness of AA6351 Aluminum alloy , the percentage contribution of parameters is being evaluated. The ball burnishing process can be applied for any material with desired Volume 4, Issue 5, May 2015 Page 42 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 5, May 2015 ISSN 2319 - 4847 burnishing parameters which can satisfactorily gives surface quality and service life. This work can be helpful for deciding input process parameters for carry out surface enhancement and improvement in surface properties of any material under specified operating conditions. It can give significant process cycle time advantage, lowering the capital investment cost. II. BALL BURNISHING TOOL DESIGN For designing of ball burnishing tool different parts are designed and finally all parts are assembled for making model of ball burnishing tool. The assembled model for ball burnishing tool is as shown in figure 1. Figure 1: Assembly model of ball burnishing tool 2.1 Work Material The experimental work is carried out to investigate the effect of process parameter of ball burnishing on surface roughness, hardness and fatigue life of AA6351 alloy work material. This is most widely used alloy in wide variety of general applications in small scale industry as well as large industries. The main focus of selection of this material is the alternative for steel which has maximum chances of corrosion and having high density. The aluminum alloy is widely used in aerospace and space shuttle with high quality and good service life. The composition and mechanical properties of work material are given in Table 1 and Table 2 respectively. Table 1: Composition of work material Element Cu Mg Mn Si Fe Al 0.10 0.4-1.2 0.4-1.0 0.6-1.3 0.6 Reminder Weight ,% Density, g/cc 2.6-2.8 Table 2: Mechanical properties of work material Tensile Yield Modulus Hardness, Strength, Strength, Elasticity HB Mpa Mpa GPa 250 150 95 70-80 of , Poisson’s ratio 0.033 Figure 2 shows the work piece material . Figure 2: Work piece Figure 3 shows Experiment setup on PL lathe machine. Volume 4, Issue 5, May 2015 Page 43 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 5, May 2015 ISSN 2319 - 4847 Figure3: Experiment setup on PL lathe machine 2.2 Process parameter selection The input parameters and their levels are shown in Table 3 Depth, speed, feed rate and number of passes is taken as a burnishing input parameters. For each factor two levels are chosen one is low level and another is high level. Table 3: Burnishing input parameters and levels Factors / Levels Code Low(-) High(+) Feed Rate (mm/Rev) A 0.04 0.051 Speed (rpm) B 850 950 Depth of Penetration(mm) C 0.50 0.75 No. of tool passes D 1 2 III. PERFORMING THE EXPERIMENT Form the full factorial design for 24 factorial the total numbers of experiments performed are 16. 24 factorial = 2× 2 × 2 × 2 = 16 total experiments Based on this design the actual parameters are tabulated as shown in Table 4 Table 4: 16 runs for experiment Actual Values Coded values RUN A B C D A B C D 1 0.04 850 0.50 1 -1 -1 -1 -1 2 0.04 850 0.50 2 -1 -1 -1 1 3 0.051 850 0.50 1 -1 -1 1 -1 4 0.051 850 0.50 2 -1 -1 1 1 5 0.04 950 0.50 1 -1 1 -1 -1 6 0.04 950 0.50 2 -1 1 -1 1 7 0.051 950 0.50 1 -1 1 1 -1 8 0.051 950 0.50 2 -1 1 1 1 9 0.04 850 0.75 1 1 -1 -1 -1 10 0.04 850 0.75 2 1 -1 -1 1 11 0.051 850 0.75 1 1 -1 1 -1 12 0.051 850 0.75 2 1 -1 1 1 13 0.04 950 0.75 1 1 1 -1 -1 14 0.04 950 0.75 2 1 1 -1 1 15 0.051 950 0.75 1 1 1 1 -1 Volume 4, Issue 5, May 2015 Page 44 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 5, May 2015 16 0.051 950 0.75 2 1 1 1 ISSN 2319 - 4847 1 3.1 ANOVA (Analysis of Variance) The purpose of the experimentation should be to reduce and control variation of process; subsequently decisions must be made concerning which parameters affect the performance of a product or process. ANOVA is the statistical method used to interpret experimental data and make the necessary decisions. The method was developed by Sir Ronald Fisher in the 1930's as a way to interpret the results from agricultural experiments. ANOVA has a lot of mathematical beauty associated with it. ANOVA is a statistically based decision tool for detecting any differences in average performance of groups of item tested. [3] 3.1.1 Statement of the problem The objective of the present work is to investigate the effect of factors that is (A) feed rare (mm/rev), (B) speed (rpm) and (C) depth (mm) and (D) for the burnishing on AA6351 alloy. 3.1.2 Response variable In these investigations “surface roughness and micro hardness” are typically chosen as response variables. The entire experimentation performed on PL lathe machine. 3.1.2.1 Response table for surface roughness A response Table 6 is now created which contains the sum of Ra values for each factor and each level. From Table 5, it is clear that feed rate is taken as factor A and at level L1 and L2 its value in mm/rev taken during experimentation trials. Now the sum for factor A at level L1, this is obtained by adding all values of Ra that have feed rate 0.04 mm/rev. Table 5: Response of surface roughness Actual Values Surface RUN Roughness(Ra)(µm) A B C D 1 0.04 850 0.50 1 0.156 2 0.04 850 0.50 2 0.116 3 0.051 850 0.50 1 0.094 4 0.051 850 0.50 2 0.131 5 0.04 950 0.50 1 0.192 6 0.04 950 0.50 2 0.156 7 0.051 950 0.50 1 0.088 8 0.051 950 0.50 2 0.149 9 0.04 850 0.75 1 0.117 10 0.04 850 0.75 2 0.102 11 0.051 850 0.75 1 0.108 12 0.051 850 0.75 2 0.089 13 0.04 950 0.75 1 0.105 14 0.04 950 0.75 2 0.069 15 0.051 950 0.75 1 0.120 16 0.051 950 0.75 2 0.113 Table 5.6 shows that the sum of Ra values for factor A (feed rate) at level L1 and L2; factor B (speed) at level L1 and L2 ,factor C (depth) at level L1 and L2 and factor D (Number of passes) at level L1 and L2. Table 6: Level total for each factor Factor A (feed rate) B(speed) C (depth) D (passes) 1.013 0.913 1.082 0.980 L1 0.892 0.992 0.823 0.925 L2 1.905 1.905 1.905 1.905 Total 0.121 0.079 0.259 0.055 Difference Volume 4, Issue 5, May 2015 Page 45 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 5, May 2015 Table 7 shows the average factor level for surface roughness. Table 7: Average factor level Factors A (feed rate) B(speed) C (depth) 0.1266 0.1141 0.1352 L1 0.1115 0.1240 0.1828 L2 ISSN 2319 - 4847 D (passes) 0.1225 0.1156 3.1.3ANOVA Table for Surface Roughness The table 8 shows ANOVA Table for surface Roughness. The calculations are done based on following equations wherein the reading for factor A at each level are used to show the calculations. Sum of Squares (SSA) = 2 × [(MA1 – M) 2 + (MA2 – M) 2 (1) Total sum of SS = SSA + SSB + SSC + SSD (2) Factors A (feed rate) B(speed) C (depth) D (passes) Total Table 8: ANOVA Table for surface roughness SS DF MS 2.280 × 10- 4 3 7.6 × 10- 5 9.802 × 10- 5 3 3.26 × 10- 5 -3 8.665× 10 3 2.895 × 10- 3 -5 4.762× 10 3 1.578 × 10- 5 -3 9.039 × 10 12 3.01938× 10- 3 F 4.8162 2.0659 183.46 1 - %P 2.522 1.084 95.862 0.526 - 3.1.4 Response table for micro hardness A response Table 10 is now created which contains the sum of Hv values for each factor and each level. From Table 9, it is clear that feed rate is taken as factor A and at level L1 and L2 its value in mm/rev taken during experimentation trials. Now the sum for factor A at level L1, this is obtained by adding all values of Hv that have feed rate 0.04 mm/rev. Table 9: Response for micro hardness Actual Values RUN Micro Hardness (Hv) A B C D 1 0.04 850 0.50 1 143.3 2 0.04 850 0.50 2 143.2 3 0.051 850 0.50 1 145.8 4 0.051 850 0.50 2 140.7 5 0.04 950 0.50 1 142.3 6 0.04 950 0.50 2 146.6 7 0.051 950 0.50 1 144.8 8 0.051 950 0.50 2 145.9 9 0.04 850 0.75 1 147.6 10 0.04 850 0.75 2 143.9 11 0.051 850 0.75 1 142.4 12 0.051 850 0.75 2 150.1 13 0.04 950 0.75 1 145.7 14 0.04 950 0.75 2 146.6 15 0.051 950 0.75 1 142.3 16 0.051 950 0.75 2 145.5 Table 10 shows that the sum of Ra values for factor A (feed rate) at level L1 and L2; factor B (speed) at level L1 and L2 ,factor C (depth) at level L1 and L2 and factor D (Number of passes) at level L1 and L2. Table 10: Level total for each factor Factor A (feed rate) B(speed) C (depth) D (passes) 1159.2 1157 1151.6 1154.2 L1 Volume 4, Issue 5, May 2015 Page 46 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 5, May 2015 1157.5 1159.7 1164.1 L2 2316.7 2316.7 2316.7 Total 1.7 2.7 12.5 Difference Table 10 shows the average factor level for surface roughness. Table 10: Average factor level Factors A (feed rate) B(speed) C (depth) 144.90 144.625 143.95 L1 144.68 144.962 145.51 L2 ISSN 2319 - 4847 1162.5 2316.7 8.3 D (passes) 144.275 145.312 ANOVA Table for Micro Hardness The table 12 shows ANOVA Table for Micro hardness. The calculations are done based on following equations wherein the reading for factor A at each level are used to show the calculations. Sum of Squares (SSA) = 2 × [(MA1 – M) 2 + (MA2 – M) 2] (3) Total sum of SS = SSA + SSB + SSC + SSD (4) Factors A (feed rate) B(speed) C (depth) D (passes) Total SS 0.0481 0.1135 2.2510 1.0764 3.489 Table 12: ANOVA Table for micro hardness DF MS 3 0.01603 3 0.03780 3 0.75030 3 0.35880 12 1.1629 F 1 2.35 46.80 22.38 - %P 1.3786 3.253 64.517 30.8512 - IV. CONCLUSION Ball burnishing operation is successfully carried out on AA6351 alloy material which implies surface enhancement of the material. The mechanical properties of the selected material gets improved. The following conclusion is made for the successful results. 1. Full factorial design is successful in Surface Roughness and Micro hardness of the AA6351 alloy. In the experiment the independent variables are feed rate, speed, depth of penetration and number of burnishing tool passes while the dependent variables (output variables) are surface roughness (Ra) and Micro hardness respectively. Roughness and hardness experiment on AA6351 alloy is successful by varying burnishing parameters (feed rate, speed, depth and number of passes ) and output variables are Ra and Hv. Based on the extensive experimental investigations, statistical analysis using ANOVA and the regression method the following observations were made: a. Performing ball burnishing operation on AA6351 with burnishing parameters is successful. b. The below table 13 shows percentage contribution of burnishing parameters on Roughness and micro hardness. Table 13: Contribution of Burnishing Parameters on Ra & Hv Response % Contribution of Feed Surface % Contribution of Speed % Contribution of % Contribution of No. Depth of Passes 2.522 1.084 95.8623 0.5238 1.3786 3.253 64.517 30.8512 Roughness Micro hardness 2. After successful experimentation it is concluded that the microstructure of material is dose not changes with these burnishing parameters. 3. The tool designed for ball burnishing process is worked with better efficiency and provides better output response for surface properties. 4. Ball burnishing process reduces surface roughness maximum from 0.4516µm to 0.069µm with higher speed of 950 rpm and 0.75 mm depth of penetration of AA6351 alloy. 5. Ball burnishing process improves micro hardness maximum from 144.9Hv to 150.1Hv with speed of 850 rpm, 0.75 mm depth of penetration and 0.051 mm/rev feed for AA6351 alloy. 6. The kerosene is used as lubricant which dissipate heat during ball burnishing process and provides damage of hard steel ball rotate freely by lubricating action Volume 4, Issue 5, May 2015 Page 47 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 5, May 2015 ISSN 2319 - 4847 REFERENCES [1]. A.S. Maheshwari, U.M. Shirsat, “Optimization of Two ball burnishing process parameters to improve material properties”, S.V. National Institute of Technology, (2011), Surat – 395 007, Gujarat, India, PP-531-535, [2]. U.M. Shirsat, B.B. Ahuja, “Parametric Analysis of combined turning and ball burnishing process”, International journal of engineering and material science, (2004), Vol. 11, PP-391-396. [3]. A.P. Ghodake , A.S. Maheshwari, “Effect of Burnishing Process on Behavior of Engineering Materials”, International Journal of Scientific Research”, e- ISSN:2278-1684, Vol-5, Issue-5, Mar-Apr-2013, PP:09-20. [4]. R.K. Jain, “Engineering Metrology”, Terminology of surface Texture & surface roughness, Khanna Publication, 20th Edition, (2010), PP- 639-646 & 654-655. [5]. V.B. Bhandari, “Design of machine elements, Design of tool parts, Mc Hill publication, Second Edition, (2009), PP-391-398 Volume 4, Issue 5, May 2015 Page 48