Research Journal of Applied Sciences, Engineering and Technology 4(16): 2682-2694,... ISSN: 2040-7467

advertisement

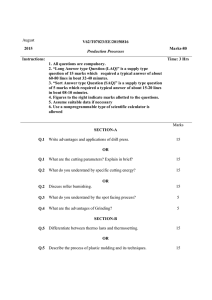

Research Journal of Applied Sciences, Engineering and Technology 4(16): 2682-2694, 2012 ISSN: 2040-7467 © Maxwell Scientific Organization, 2012 Submitted: March 15, 2012 Accepted: April 13, 2012 Published: August 15, 2012 Investigation on the Effect of Roller Burnishing Process on the Surface Quality and Microhardness of Cu-Zn-Al Sma Alloys S.M.A. Al-Qawabah Mechanical Engineering Department, Tafila Technical University, Amman 11942, P.O. Box 13720, Jordan Abstract: Burnishing is a plastic deformation process that can be used to finish surfaces by plastic deformation of surface irregularities. The burnishing is chipless machining which can be used to improve the surface roughness and surface hardness on any metal work piece. The purpose of the research was to demonstrate the roller burnishing process on Cu-Zn-AL to enhance the mechanical properties of Cu-Zn-Al shape memory alloy and improve surface quality and surface microhardness. The experiments were carried on Cn-Zn-Al SMA using CNC turning machine with various spindle rotations, feed rates and depth of penetration, where a roller burnishing tool was designed and manufactured to be used in this investigation. It was found that the surface roughness and microhardness on various Cu-Zn-Al SMA were improved by high spindle speed, The best results were attained at 212 N burnishing force, 50 mm/min feed rate and 1120 rpm. Keywords: Burnishing process, microhardness, shape memory alloys, surface quality INTRODUCTION 1200 Stress (MPa) 1000 800 600 400 Austenite Martensit 200 0 0 5 10 Strain (%) 15 20 Fig. 1: Mechanical behavior of SMA alloy for austenitic and martensitic structure www.tiniaerospace.com Heat flow (mJ/s) Shape Memory Alloys (SMAs) refer to a group of materials which have the ability to return to a predetermined shape when heated. The shape memory effect is caused by a temperature dependent crystal structure. When an SMA is below its phase transformation temperature, it possesses low yield strength as shown in Fig. 1. While in this state, the material can be deformed into other shapes with relatively little force. The new shape is retained provided the material is kept below its transformation temperature. When heated above this temperature, the material reverts to its parent structure known as Austenite causing it to return to its original shape (Phase Transformation figure). This phenomenon can be harnessed to provide a unique and powerful actuator. The most widely used shape memory material is an alloy of Nickel and Titanium called Nitinol. This particular alloy has excellent electrical and mechanical properties, long fatigue life and high corrosion resistance. Martensite phase can be obtained after the Cu-Zn-Al-MnNi SMA is quenched to ambient temperature and it begins to transform into parent phase upon heating to above the initial temperature of reverse martensitic transformation. This process is reversible during heating and cooling in the transformation range. The DSC curve upon heating from martensite phase to parent phase is shown in Fig. 2. The principle of mechanical surface treatments is based on the elastic-plastic cold-working in the nearsurface region. After the mechanical surface treatments, the surface layers are work-hardened and residual compressive stresses are induced. Hence, the surface provides a higher resistance to fatigue crack initiation and/or propagation (Zhang and Lindemann, 2005). In 283 313 343 373 Temperature (K) 403 Fig. 2: DSC curve upon heating from martensite phase to parent phase (Yu-Jun et al., 2000) order to properly design a burnishing process, several controlling parameters have to be considered, namely, burnishing speed, feed rate, force (or pressure) and ball size, number of burnishing passes, workpiece material, 2682 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 ball material and lubricant (Loh et al., 1989). This process transforms tensile residual stress induced in the near surface by machining into compressive residual stresses, giving several improvements to mechanical properties (Luo et al., 2005). Stresses in most of the metal forming processes, such as cold heading, riveting etc., are compressive in nature. Upset test at room temperature gives a representative behavior during metal forming (Avitzur, 1977; Schey et al., 1982; Altan and Bonlger, 1973). Previously published works indicated that burnished surfaces have many advantages over ground surfaces (El-Tayeb et al., 2006; Hassan, 1997; Hassan and Al-Bsharat, 1996; El-Tayeb, 1994; El-Tayeb and Ghobrial, 1993). In this investigation the Cu-Zn-Al SMA alloy was used due to its cheapness and its availability, however the effect of burnishing process on the surface quality and microhardness of Cu-Zn-Al SMA alloy will be studied. MATERIALS, EQUIPMENT AND EXPERIMENTAL PROCEDURES Materials: Mixing of three powder materials namely; pure copper, pure Zinc and pure aluminum in approperate percentages are normally used to prepare the Cu-Zn-Al SMA. Its chemical composition by weight is shown in Table 1. Preparation Cu-Zn-Al shape memory alloy: The CuZn-Al SMA was prepared by melting the precalculated amount of high purity copper powder at 1250ºC, then the pre-calculated amounts of pure Al and pure Zn were Table 1:Chemical composition by weight of Cu-Zn-Al shape memory alloy Material Cu Zn Al wt.% 70% 26% 4% added to the melt in a graphite crucible. The melt was steered for 2 min then poured to solidify in steel mold and cooled in air. The Cu-Zn-Al shape memory alloy was synthesized in the form of 14 mm diameter and 70 mm length cylindrical rods using melting and casting technique. Recommended procedure to produce the Cu-Zn-Al shape memory alloy (www.tiniaerospace.com): To produce the shape memory alloy the following procedures as reported in (www.tiniaerospace.com) was adopted in the following sequence. C C C Heating the cast (Cu-Zn-Al) to 820ºC for 10 min Quenching the cast material by oil at 120ºC for 5 min Cooling the cast in water at room temperature Equipment: A set of equipment was used in this investigation; that are available in Tafila Technical University: C C C C Surface roughness tester (kosaka surfcorder SE3500). CNC lathe machine (Boxford). Digital microhardness tester (model HWDM-3). The burnishing tool shown in Fig. 3. The burnishing process: It can be seen from Fig. 3 the mechanism of burnishing process, it can be used as a tool on lathe machine that burnish the surfaces of cylindrical parts. The tool inclined 45º. Design and manufacturing of burnishing tool: Burnishing tool design: The Pro-Engineer wildfire 2 was used in this investigation to determine the stresses, deformation and strain for burnishing tool. The tool made from D3 steel that hardened and tempered. Fig. 3: Roller burnishing process 2683 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 Head design: A three burnishing forces were taken based on previous study of Al-Qawabah namely 20, 92.5 and 212 N which cover the range of the tool. The free body diagram of forces and boundary conditions of the head are shown in Fig. 4. After the running of pro-engineer program stress, strain and deformation distribution at F = 20 N are analyzed as shown in Fig. 5, 6 and 7 respectively. The maximum stress according to von-mesis criterion is 5.8*10G1 MPa and the maximum strain is 1.8*10G6 mm/mm where the maximum displacement is 8*10!6 mm. After the running of Pro-Engineer program stress, strain, and displacement at F = 92.5 N are shown in Fig. 8, 9 and 10. The maximum stress according to vonmesis criterion is 2.16 MPa and the maximum strain is 6*10G6 mm/mm where the maximum displacement is 7.3*10G5 mm. Fig. 4: The head of burnishing tool Fig. 5: Stress distribution according to von mesis criterion at 20 N Fig. 6: Strain distribution (mm/mm) 2684 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 Fig. 7: Displacement in mm Fig. 8: Stress distribution according to von mesis criterion at 92.5 N Fig. 9: Strain distribution (mm/mm) at 92.5 N After the running of Pro-Engineer program stress, strain and displacement distribution at F = 212 N are shown in Fig. 11, 12 and 13. The maximum stress according to von-mesis criterion is 3.85 MPa and the maximum strain is 1.28*10G5 mm/mm where the maximum displacement is 1.15*10G4 mm. 2685 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 Fig. 10: Displacement in mm at 92.5 N Fig. 11: Stress distribution according to von mesis criterion at 212 N Fig. 12: Strain distribution (mm/mm) at 212 N 2686 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 Fig. 13: Displacement in mm at 212 N Fig. 14: Free boundary diagram of tool holder Fig. 15: Stress distribution according to von mesis criterion at 20 N Holder design: The free body diagram of forces and boundary conditions of the tool holder are shown in Fig. 14. After the running of pro-engineer program stress, strain, and deformation distribution at F = 20 N are analyzed as shown in Fig. 15, 16 and 17, respectively. The maximum stress according to von-mesis criterion is 9*10G1 MPa and the maximum strain is 4.83*10!4 mm/mm where the maximum displacement is 3.57*10!1 mm. 2687 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 Fig. 16: Strain distribution (mm/mm) at 20 N Fig. 17: Displacement in mm at 20 N Fig. 18: Stress distribution according to von mesis criterion at 92.5 N 2688 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 Fig. 19: Strain distribution (mm/mm) at 92.5 N Fig. 20: Displacement in mm at 92.5 N Fig. 21: Stress distribution according to von mesis criterion at 212 N 2689 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 Fig. 22: Strain distribution (mm/mm) at 212 N Fig. 23: Displacement in mm at 212 N (a) (b) Fig. 24: (a) Burnishing tool, (b) Lathe and burnishing tool 2690 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 Table 2: Burnishing force calibration of the tool Load (N) Indicator reading X0.01 mm 20 2 40 3 92.5 8 159.5 14 212 19 259 23 279 25 After the running of pro-engineer program stress, strain and deformation distribution at F = 92.5 N are analyzed as shown in Fig. 18, 19 and 20, respectively. The maximum stress according to von-mesis criterion is 345 MPa and the maximum strain is 1.73*10G3 mm/mm where the maximum displacement is 1.43 mm. After the running of pro-engineer program stress, strain and deformation distribution at F = 212 N are analyzed as shown in Fig. 21, 22 and 23, respectively. The maximum stress according to von-mesis criterion is 580 MPa and the maximum strain is 2.68*10G3 mm/mm where the maximum displacement is 2.13 mm. A roller burnishing tool was manufactured; the schematic photo of the burnishing tool and the burnishing process are shown in Fig. 24. The burnishing force calibration is shown in Table 2. RESULTS AND DISCUSSION In this section, the effect of the roller burnishing process on the microhardness and surface quality of CuZn-Al shape memory alloy was presented and discussed. Where the machined Specimens were burnished on a CNC lathe machine and the Condition of Machine (feed,burnishing force and rotational speed) shown In Table 3 and the specimens with its parts showed in Fig. 25. Fig. 25: Designation of test specimens Effect of burnishing force on the surface roughness for Cu-Zn-Al SMA: Five specimens each specimen has 3 regional areas by which the burnishing conditions applied as shown in Table 3. The investigations were applied at different conditions then the optimum condition is determined. Effect of burnishing force on the surface roughness for the specimen 1 of Cu-Zn-Al SMA at (N = 470 r.p.m, F = 50 mm/min): It can be seen from Fig. 26 that the surface roughness enhanced after burnishing process, the best enhancing is 81.3% after applying 212 N burnishing forces, this enhancement attributed to surface plastic deformation which translate the tensile residual stresses to compressive one. Effect of burnishing force on the surface roughness for specimen 2 of Cu-Zn-Al SMA at (N = 1120 r.p.m, F = 50 mm/min): It can be seen from Fig. 27 that there is a slight improvement in the surface quality after increasing the burnishing speed to N = 1120 rpm. Where the best enhancement was 59.5% achieved at 212 N burnishing force. Table 3: Data of surface roughness and microhardness of SMA NO. of work pies No. of level Feed mm/min Speed (r.p.m) 1 A 50 470 B 50 470 C 50 470 2 D 50 1120 E 50 1120 F 50 1120 3 G 50 1500 H 50 1500 I 50 1500 4 J 100 470 K 100 470 L 100 470 5 M 100 1120 N 100 1120 O 100 1120 2691 Burnishing force (N) 20 92.5 212 20 92.5 212 20 92.5 212 20 92.5 212 20 92.5 212 Roughness Ra (:m) 0.64 0.71 0.57 2.93 2.86 1.23 2.34 2.68 1.78 1.31 1.58 1.37 2.72 1.27 1.16 Surface hardness (HV) 218 227 230 211 227 262 176 207 233 192 203 211 178 251 268 3.5 Ra_after burnishing Ra_after burnishing Ra_before burnishing Ra_before burnishing 3.04 3.04 3.04 Surface roughness (Ra) ( m) Surface roughness (Ra) (m) Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 3.0 2.5 2.0 1.5 1.0 0.71 0.64 0.57 0.5 3.5 2.0 1.58 1.31 1.37 1.5 1.0 0.5 0 a (20N) a (212N) a (92.5N) Burnishing force (N) J (20N) Fig. 26: Relationship between burnishing force and Ra Ra_after burnishing 2.86 Ra_before burnishing 3.04 3.04 Surface roughness (Ra) (m) Surface roughness (Ra) ( m) 3.04 2.5 2.0 1.5 1.23 1.0 0.5 0 D (20N) E (92.5N) Burnishing force (N) F (212N) 3.5 3.04 3.0 3.04 2.5 2.0 1.27 1.5 1.16 1.0 0.5 0 M (20N) N (92.5N) Burnishing force (N) O (212N) Fig. 30: Relationship between burnishing force and surface roughness Ra Ra_after burnishing Ra_before burnishing 2.79 2.79 2.68 2.79 Hv after burnishing 2.39 Hv before burnishing 2.5 Surface micro hardness (Hv) Surface roughness (Ra) (m) 3.04 2.72 Fig. 27: Relationship between burnishing force and Ra 3.0 L (212N) Ra_after burnishing 3.5 2.93 K (92.5N) Burnishing force (N) Fig. 29: Relationship between burnishing force and surface roughness Ra Ra_before burnishing 3.5 2.79 2.5 0 3.0 2.79 2.79 3.0 1.78 2.0 1.5 1.0 0.5 0 G (20N) H (92.5N) Burnishing force (N) I (212N) 250 230 227 218 200 150 115 115 115 100 50 0 A (20N) Fig. 28: Relationship between burnishing force and surface roughness Ra Effect of burnishing force on the surface roughness for specimen (3) of Cu-Zn-Al SMA at (N = 1500 r.p.m, F = 50 mm/min): It can be seen from Fig. 28 that there is a slight improvement in the surface quality after increasing the burnishing speed to N = 1500 rpm. Where the best B (92.5N) Burnishing force (N) Fig. 31: Relationship between microhardness of SMA C (212N) burnishing force and enhancement was 36.3% achieved at 212 N burnishing force. 2692 Hv after burnishing Hv after burnishing Hv before burnishing Hv before burnishing 300 Surface micro hardness (Hv) Surface micro hardness (Hv) Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 262 250 227 211 200 150 115 115 115 100 300 200 150 268 251 250 178 115 115 115 100 50 50 0 0 M (20N) D (20N) E (92.5N) Burnishing force (N) F (212N) Fig. 32: Relationship between burnishing force and hardness of SMA Surface micro hardness (Hv) Hv before burnishing 300 268 251 200 115 115 115 100 50 0 M (20N) burnishing force and Effect of burnishing force on the surface roughness for the five specimen of Cu-Zn-Al SMA at (N = 1120 r.p.m, F = 100 mm/min): It can be seen from Fig. 30 that there is an improvement in the surface quality at burnishing speed to N = 1120 rpm and after increasing the feed rate to 100 mm/min, Where the best enhancement was 61.8% achieved 212 N burnishing force. 178 150 Fig. 35: Relationship between microhardenss of SMA O (212N) N = 470 rpm and 100 mm/min feed rate, Where the best enhancement was 53% that achieved at 20 N burnishing force. Hv after burnishing 250 N (92.5N) Burnishing force (N) N (92.5N) Burnishing force (N) O (212N) Fig. 33: Relationship between burnishing force and hardness of SMA Hv after burnishing Hv before burnishing Effect of burnishing force on the surface microhardness for Cu-Zn-Al SMA: Effect of burnishing force on the surface microhardness for specimen No. 1 of Cu-Zn-Al SMA at (N = 470 r.p.m, F = 50 mm/min): It can be seen from Fig. 31 that the microhardness enhanced after burnishing process, the best enhancing is 100% after applying 212 N burnishing forces. There is a direct relation between the burnishing force and the microhardness. Surface micro hardness (Hv) 250 211 203 200 Effect of burnishing force on the surface microhardness for specimen No. 2 of Cu-Zn-Al SMA at (N = 1120 r.p.m, F = 50 mm/min): It can be seen from Fig. 32 that the microhardness increased as the burnishing force increase, the maximum is 127% that achieved at 212 N burnishing force. 192 150 115 115 115 100 50 Fig. 34: Relationship between burnishing force and hardness of SMA Effect of burnishing force on the surface microhardness for specimen No. 3 of Cu-Zn-Al SMA at (N = 1500 r.p.m, F = 50 mm/min): It can be seen from Fig. 33 that the microhardness increased as the burnishing force increase, the maximum is 133% that achieved at 212 N burnishing forces. Effect of burnishing force on the surface roughness for specimen 4 of Cu-Zn-Al SMA at (N = 470 r.p.m, F = 100 mm/min): It can be seen from Fig. 29 that there is an improvement in the surface quality at burnishing speed to Effect of burnishing force on the surface micro roughness for specimen No. 4 of Cu-Zn-Al SMA at (N = 470 r.p.m, F = 100 mm/min): It can be seen from Fig. 34 that the microhardness increased as the burnishing 0 J (20N) K (92.5N) Burnishing force (N) L (212N) 2693 Res. J. Appl. Sci. Eng. Technol., 4(16): 2682-2694, 2012 force and the feed rate increased, the maximum is 83.4% that achieved at 212 N burnishing force. Effect of burnishing force on the surface microhardness for specimen No. 5 of Cu-Zn-Al SMA at (N = 1120 r.p.m, F = 100 mm/min): It can be seen from Fig. 35 that the microhardness increase as the burnishing force increase, the maximum enhancement in the hardness was 133.3% that attained at 212 N burnishing force. CONCLUSION Form this study the following can be concluded: C C The surface quality is enhanced after burnishing process where the maximum enhancement is 81.3% that attained after applying 212 N burnishing force at 470 rpm and 50 mm/min feed rate. The surface microhardness is enhanced after burnishing process where the maximum enhancement is 133.3 that achieved after applying 212 N burnishing force at 1120 rpm and 100 mm/min feed rate. ACKNOWLEDGMENT This study has been supported by Tafila Technical University which is acknowledged. Author also would like to thank Eng. Tayseer Al-madani, Eng. Abd asalam Al-smadee, Eng. Hanee Al-Rawshdeh and Eng. Ayman Al-sharadedeh for their help in laboratory works. REFERENCES Avitzur, B., 1977. Metal Forming: Processes and Analysis. TMH Edn., Tata Mc Graw-Hill, New Delhi. Altan, T. and F.W. Bonlger, 1973. Flow stress of metals and its applications in metal forming analysis. J. Eng. Ind., 95: 1009-1019. El-Tayeb, N.S.M., 1994. Frictional behaviour of burnished copper surfaces underdry contact conditions. Eng. Res. Bull. (HU, Cairo), 1: 171-184. El-Tayeb, N.S.M. and M.I. Ghobrial, 1993. The mechanical wear behavior of burnishing surfaces in: Proceedings of the 4th International Conference on Production Engineering and Design for Development, Cairo, pp: 198-209. El-Tayeb, N.S.M., K.O. Low and P.V. Brevern, 2006. Enhancement of Surface Quality and Tribological Properties during Ball Burnishing Process in: Proceedings of the COMAST, GKH Press, Melaka, Malaysia, ISBN: 983-42051-1-2, pp: 335-340. Hassan, A.M., 1997. An investigation into the surface characteristics of burnished cast Al-Cu alloys. Int. J. Mach. Tools Manuf., 37(6): 813-821. Hassan, A.M. and A.S. Al-Bsharat, 1996. Influence of burnishing process on surface roughness, hardness and microstructure of some non-ferrous metals. Wear, 199(1): 1-8. Loh, N.H., S.C. Tam and S. Miyazawa, 1989. A study of the effect of ball-burnishing parameters on surface roughness using factorial design. J. Mech. Work Technol., 18: 53-56. Luo, H.Y., J.Y. Liu, L.J. Wang and Q.P. Zhong, 2005. Investigation of the burnishing process with PCD tool on non-ferrous metals. Int. J. Adv. Manuf. Technol., 25: 454-459. Schey, J.A., T.R. Venner and S.L. Takomana, 1982. The effect of friction on pressure in upsetting at low diameter to height ratios. J. Mech. Work. Technol., 6: 23-33. Yu-Jun, B., G. Gui-Li, B. Xiu-Fang, S. Dong-Sheng and W. Shou-Ren, 2000. Influence of initial heating temperature on the reverse martensitic transformation of Cu–Zn–Al–Mn–Ni alloy. Mater. Sci. Eng. A., 284: 25-28. Zhang, P. and J. Lindemann, 2005. Effect of roller burnishing on the high cycle fatigue performance of the high-strength wrought magnesium alloy AZ80. Scripta Mater., 52: 1011-1015. 2694