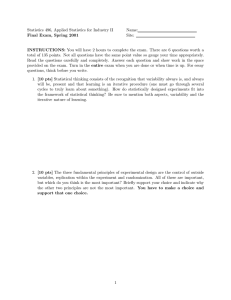

PREDICTIVE MACHINABILITY MODEL OF HARDENED STEEL MATERIAL IN TURNING OPERATION BY RESPONSE

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 10, October 2013 ISSN 2319 - 4847

PREDICTIVE MACHINABILITY MODEL OF

HARDENED STEEL MATERIAL IN

TURNING OPERATION BY RESPONSE

SURFACE REGRESSION METHOD

Manu Ravuri

1

, Akbar Basha.S

2

, Sharmas Vali.S

3

1,2,3 Assistant Professor, Department of Mechanical Engineering,

Madanapalle Institute of Technology and Science, Madanapalle.

Chittor Dst., Andhra Pradesh, India

Abstract

In this paper Design of Experiments for turning the austenitic AISI 302 material for prediction of Tool life, surface Roughness and cutting force are taken in to consideration as output parameters for these experiments. Process parameters (cutting speed, feed rate, depth of cut and tool nose radius) are used as inputs for indentifying the machinability of the material. Response

Surface Regression method is used for prediction of machinability of the material by using this experimental data.

Key Words: AISI 302, Surface Roughness, Design of Experiments (DOE).

1. Introduction

Predicting process of machinability models and determining the optimum values of process parameters in manufacturing systems have been areas of interest for researchers and manufacturing engineers. Machinability database systems are essential for selecting optimum process parameters during the process planning stage which represents an important component in Computer Integrated Manufacturing (CIM) [1]. Most of these researchers have used the generalized empirical equations systems that utilize expanded Taylor tool life equations to determine proper machining conditions based on three criteria: minimum production cost, maximum production rate or maximum profit rate per item. These criteria have been considered in both constrained and unconstrained problems of machining economics. Tool life, surface roughness and cutting forces have an effect on cost, time, design features and quality of manufacturing operations. In addition, these machinability models are very critical constraints for process parameters selection in process planning systems. Therefore, accurate representation of these three important factors in empirical models is very important. These models cannot be predicted without experimental work on specific material using specific conditions.

A considerable amount of studies have investigated the general effects of process parameters (cutting speed, feed rate, depth of cut, etc.) on process functions (tool life, cutting force and surface roughness) [1,3]. Most of these models are based on RA, very few papers used CNN [4–9].

2. Experimental Setup

The obtained machinability models are compared against each other using the relative error analysis, descriptive statistics and hypothesis testing. Four machining parameters were considered (cutting speed (v, m/min), feed rate (f, mm/r), depth of cut (d, mm) and tool nose radius (r, mm)). considered four machining parameters (cutting speed (v, m/min), feed rate

(f, mm/r), depth of cut (d, mm) and tool nose radius (r, mm)). The considered outputs are tool life (T, min), cutting force

(Fc, N) and surface finish (Ra, _m). The four process parameters were considered at three levels ( −1, 0 and 1) as shown in Table 1. The experiments are conducted based on Box and Dehnken design. This design is rotatable and consists of blocks in an orthogonal arrangement. This inputs and responses are illustrated in Table 2.

Table - 1: Factors and levels of the experiment for model constructions

Factors

Level level (-1) level (0) level (1)

Cutting Speed (v) m/min

25

60

144

Feed (f) mm/rev

0.1

0.25

0.7

Depth of Cut (d) mm

0.25

0.5

1.6

Nose Radius (r) mm

0.4

0.8

1.6

Volume 2, Issue 10, October 2013 Page 330

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 10, October 2013

3. Results

ISSN 2319 - 4847

Table - 2: Design of experiment and Experimental data for model constructions

Exp. no. v f d r T Fc Ra

10

11

12

13

7

8

9

14

15

16

17

4

5

6

1

2

3

1

-1

1

0

0

0

-1

0

0

0

-1

1

0

0

-1

1

-1

0

0

0

-1

0

0

0

1

-1

1

0

1

0

0

-1

-1

1

-1

1

1

0

-1

1

-1

0

0

0

0

0

-1

1

0

0

0

0

0

0

-1

1

1

0

-1

1

1

-1

0

-1

-1

0

0

0

25.67

4.68

14

3

13.5

9.7

15.2

11.2

19

4.1

20.6

3.2

17.83

12.8

13.16

10.6

13

500

400

1520

1450

400

1050

520

1200

700

540

760

650

500

1800

750

2650

400

1.35

1.35

4.5

3.75

2.35

1.8

1.6

1.1

0.8

13.8

14.7

4.5

4

1.35

1.3

15.6

1.8

18

19

20

21

22

23

24

1

-1

1

0

0

0

0

0

0

0

-1

1

-1

1

0

0

0

-1

-1

1

1

-1

1

1

0

0

0

0

6.2

15.4

7.1

27.3

3.63

17.5

3.2

1440

520

1550

450

350

1360

1150

29.6

0.6

11

4.8

3

3.1

2.6

25

26

0

0

0

0

0

0

0

0

10.6

11.7

700

480

3

3.2

27 0 0 0 0 8.1 620 2.7

3.1 Response surface method

Response surface methods are used to examine the relationship between one or more response variables and a set of quantitative experimental variables or factors. These methods are often employed after identifying the controllable factors and the objective is to find the factor settings that optimize the response. Designs of this type are usually chosen when there is suspecting curvature in the response surface. It is clear from the literature that the tool life, cutting force and surface finish equations are not linear and they could be predicted using the response surface method. The initial analysis of the output obtained from RSM includes all parameters and their interactions. The models are reduced by eliminating elements which have no significant effect on the responses. The revised RSM analysis is illustrated in Table

3.1.1. Response Surface Regression: Time versus A, B, C

The analysis was done using coded units.

Estimated Regression Coefficients for Time

Term Coef SE Coef T P

Constant

A

B

C

A*A

B*B

C*C

A*B

11.3637

-5.8392

-5.6858

-1.4442

-1.4597

0.7178

1.2278

4.8275

A*C

B*C

-0.625

2.3425

S = 3.573 R-Sq = 81.7% R-Sq(adj) = 72.1%

1.537

1.031

1.031

1.031

1.458

1.458

1.458

1.786

1.786

1.786

7.392

-5.662

-5.513

-1.4

-1.001

0.492

0.842

2.703

-0.35

1.311

0

0

0

0.179

0.331

0.629

0.412

0.015

0.731

0.207

Volume 2, Issue 10, October 2013 Page 331

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 10, October 2013

Analysis of Variance for Time

ISSN 2319 - 4847

Source DF Seq SS Adj SS Adj MS F P

Regression

Linear

Square

Interaction

Residual Error

Lack-of-Fit

9

3

3

3

17

9

971.77

822.12

32.91

116.73

216.97

190.98

971.77

822.12

32.91

116.73

Pure Error 8 25.99

Total 26 1188.73

3.1.2. Response Surface Regression: Fc versus A, B, C

The analysis was done using coded units.

Estimated Regression Coefficients for Fc

216.97

190.98

25.99

Term

Constant

A

B

C

A A

B B

C C

A B

Coef

957.41

229.17

320

267.5

-165.69

140.56

-188.19

287.5

A C 12.5

B C -27.5

S = 501.1 R-Sq = 46.1% R-Sq(adj) = 17.6%

Analysis of Variance for Fc

SE Coef

215.6

144.7

144.7

144.7

204.6

204.6

204.6

250.5

250.5

250.5

Source

Regression

Linear

Square

Interaction

Residual Error

9

3

3

3

17

DF

3652298

2717683

600340

334275

4268420

Seq SS

3652298

2717683

600340

334275

4268420

Lack-of-Fit

Pure Error

9

8

3819420

449000

Total 26 7920719

3.1.3. Response Surface Regression: Ra versus A, B, C

The analysis was done using coded units.

Estimated Regression Coefficients for Ra

3819420

449000

T

4.44

1.584

2.212

1.849

-0.81

0.687

-0.92

1.148

0.05

-0.11

107.974

274.041

10.971

38.91

12.763

21.22

3.248

Adj SS

405811

905894

200113

111425

251084

424380

56125

8.46

21.47

0.86

3.05

6.53

Adj MS

1.62

3.61

0.8

0.44

P

0

0.132

0.041

0.082

0.429

0.501

0.37

0.267

0.961

0.914

7.56

0

0

0.481

0.057

0.007

F

0.188

0.035

0.512

0.725

0.005

Term

Constant

A

B

Coef

5.52963

4.20833

2.1125

SE Coef

2.619

1.757

1.757

T

2.111

2.395

1.202

P

0.05

0.028

0.246

Volume 2, Issue 10, October 2013 Page 332

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 10, October 2013 ISSN 2319 - 4847

C -0.5583

A A

B B

C C

1.76597

-0.9903

-2.6965

A B

A C

3.55

0.05

B C 0.325

S = 6.086 R-Sq = 39.2% R-Sq(adj) = 7.1%

Analysis of Variance for Ra

1.757

2.485

2.485

2.485

3.043

3.043

3.043

-0.318

0.711

-0.399

-1.085

1.167

0.016

0.107

0.755

0.487

0.695

0.293

0.259

0.987

0.916

Source

Regression

Linear

Square

Interaction

Residual Error

Lack-of-Fit

DF

9

3

3

3

17

9

Seq SS

406.7

269.81

86.05

50.84

629.65

345.77

Adj SS

406.7

269.81

86.05

50.84

629.65

345.77

Adj MS

45.19

89.94

28.68

16.95

37.04

38.42

F

1.22

2.43

0.77

0.46

P

0.345

0.101

0.524

0.715

1.08 0.461

Pure Error 8 283.88 283.88 35.48

Total 26 1036.35

From the above table the empirical models of the tool life, cutting force and surface finish are as follows

Time (t) = 11.36337-5.83917xA – 5.68583 x B – 1.44417 x C – 1.45972 x A2 + 0.717778 X B2+ 1.22778 x C2 +

4.82750 x A x B – 0.625000 x A x C + 2.34250 x B x C

Cutting Force (Fc) = 957.407 229.167 A+320.000 B+267.500 C-165.694 A2+140.556 B2-188.194 C2 +287.500

A B+12.5000 A C-27.5000 B C

Surface Roughness (Ra) = 5.52963+4.20833 A+2.11250 B -0.558333 C+1.76597A2 -0.990278 B2-2.69653

C2+3.55000 A B+ 0.0500000 A C+0.325000 B C

4. Conclusion

In this paper, empirical data for prediction of machinability model (tool life, cutting force and surface roughness) have been developed based on response surface methodology. The developed machinability model can be utilized to formulate an optimization model for the machining economic problem to determine the optimal values of process parameters for the selected material.

References

[1] I. Coudhury, M. El-Baradie, Machinability assessment of inconel 718 by factorial design of experiment coupled with response surface methodology, J. Mater. Process. Technol. 95 (1999) 30–39.

[2] K. Taraman, Utilization of design of experiments for reduced cost and added reliability, SME (1981).

[3] L. Ozler,A. Ozel, Theoretical and experimental determination of tool life in hot machining of austenitic manganese steel, Int. J. Mach. Tool Manufact. 41 (2001) 163–172.

[4] U. Zuperl, F. Cus, B. Mursec, T. Ploj, A hybrid analytical-neural network approach to the determination of optimal cutting conditions, J. Mater. Process. Technol. 175 (2004) 82–90.

[5] S. Wong, A. Hamouda, Machinability data representation with artificial neural network, J. Mater. Process. Technol.

138 (2003) 538–544.

[6] N. Tosum, L. Ozler, A study of tool life in hot machining using artificial neural networks and regression analysis method, J. Mater. Process.Technol. 124 (2002) 99–104.

[7] C. Feng, X.Wang, Digitizing uncertainty modeling for reverse engineering applications: regression vs. neural networks, J. Intell. Manufact. 13 (2002) 189–199.

[8] T. Ozel,Y. Karpat, Predictive modelling of surface roughness and tool wear in hard turning using regression and neural networks, Int. J. Mach. Tool Manufact. 45 (2005) 467–479.

[9] W. Chien, C. Chou, The predictive model for machinability of 304 stainless steel, J. Mater. Process. Technol. 118

(2001) 441–447.

Volume 2, Issue 10, October 2013 Page 333

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 10, October 2013 ISSN 2319 - 4847

AUTHORS

Manu Ravuri received the B.Tech in Mechanical Engineering from Dr. Paul Raj Engineering Collage,

Bhadarachalam in year 2008, and received Masters Degree in Manufacturing Engineering form National

Institute of Technology Karanataka, Surathkal in the year 2012, he is staying in Madanapalle and working as

Assistant Professor in Department of Mechanical Engineering at Madanapalle Institute of Technology &

Science, Madanapalle. Have many International and National Journals and attended many conferences and workshops, editorial board Reviewer for International Journal of Technology Enhancements and Emerging Engineering Research

(IJTEEE).

Sharmas vali.S received the B.Tech in Mechanical Engineering from MITS, Madanapalle in year 2007, and received Masters Degree in R&AC form JNTUA, Anatapur in the year 2011, he staying in Madanapalle and working as Assistant Professor in Department of Mechanical Engineering at Madanapalle Institute of

Technology & Science, Madanapalle. Have many International and National Journals and attended many conferences and workshops.

Akbar Basha.S received the B.Tech in Mechanical Engineering from JNTUH, Hyderarabad in year 2008, and received Masters Degree in Product Design form JNTUA, Anatapur in the year 2012, he is working as Assistant

Professor in Department of Mechanical Engineering at Madanapalle Institute of Technology & Science,

Madanapalle. Have many International and National Journals and attended many conferences and workshops.