Enclosure 4A - Project Summary Form

advertisement

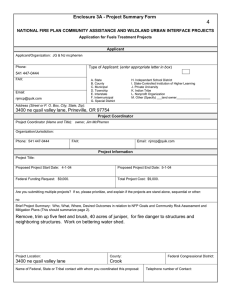

Enclosure 4A - Project Summary Form NATIONAL FIRE PLAN COMMUNITY ASSISTANCE AND WILDLAND URBAN INTERFACE PROJECTS Application for Fuels Utilization and Marketing Projects Applicant Applicant/Organization: NWPA-NORTWEST WOOD PRODUCTS ASSOCIATION Phone: FAX: 541-388-8421 541-389-8572 Address (Street or P. O. Box, City, State, Zip): 18900 Riverwoods Drive, Bend, OR. 97702 Email: Dennisb@empnet.com Project Coordinator Project Coordinator (Name and Title): Dennis G. Brock Executive Director Organization/Jurisdiction: 503-C Non-Profit Trade Association Pacific NW Phone: FAX: 541-388-8421 5431-389-8572 Email: Dennisb@empnet.com Project Information Project Title: Instillation of Dry Kilns Project Start: June 1, 2002 Project End: June 30, 2003 Federal Funding Request: $99,090 Total Project Funding: $ 198,180 Are you submitting multiple projects? If so, please explain and prioritize: NO—Two projects combined into 1 Brief Project Description: A Dry-Kiln instillation project is being submitted to the National Fire Plan to stimulate utilization,on-site research and cost-effective methods to process Non-Traditional wood fiber such as Juniper, LLP, White Fir and small diameter Ponderosa Pine currently being removed from National Forest lands. In Central Oregon the large dryers located in Prineville and John Day used to process traditional large volumes of 180,000 bf set empty. Large capacity dryers are not currently suited for small diameter wood or the currently underutilized wood species that are targeted to be removed. Small capacity drying systems are totally non-existent in the multi-fiber production infrastructure. This proposal addresses the challenges created by the absence of local small volume drying capacities by dramatically reducing added processing costs, reducing added drying costs and reducing added transportation costs to dryers located in the Willamette Valley. Project Location: Bend OR & Fossil OR County: Wheeler/Deschutes Congressional District: Not sure? If the applicant is an unincorporated area, define the geographic area being represented: 503-C Non Profit Trade Association doing business in the Pacific NW. Enclosure 4B (Page 1 of 3) - Project Narrative Description Applications for funding must include a narrative response that describes the proposal. Please do not submit responses longer than one page, single space, 12-pitch font. Describe project including, but not limited to: project location Address these project implementation items as anticipated outcomes applicable: measures and reporting partners project income project time frames specify types of activities and equipment used amount or extent of actions (acres, number of homes, etc) environmental, cultural and historical resource requirements Placement of currently non-existent small capacity “Dry-Kiln” wood fiber drying to assist in the development of a local infrastructure designed to utilize non-traditional and underutilized wood species. Proposed site locations shall be centered in close proximity to the fiber source to significantly reduce fiber costs. Sites selected are Burnt River Juniper located in Fossil and Morelock Wood Products located in Bend. Dryers will process fiber coming off of National Forest, BLM, State lands and private lands located in the counties of Cook, Lake, Jefferson, Deschutes, Wheeler, Grant, Klamath and Harney. The Dry-Kilns will be placed for the use and accessible to local producers producing or is in need of drying services. Dryers will be under the control of each site manager: Tim Coe in Fossil and Scott Morelock in Bend. Anticipated users include Morelock Wood Products, Tim Coe, Wright Bros. Construction, Davenburg Ranch and independent fallers and suppliers of primary fibers. It is estimated that each dryer will generate 15 to 20 jobs in the manufacturing centers. Expected outcomes are to assist the USFS in it’s efforts to find higher economic value for the fiber targeted to be removed from the 880,000 acres in Central OR. over the next twenty years. Project will assist in reducing hazardous fuels, restore forest sustainability, improve and restore wildlife habitat as well as watershed restoration. Additional expected outcomes include: reduction of material processing costs, reduced drying costs, and reduced transportation costs. All of these outcomes will improve market share and improve competitiveness on the open global market. We are expecting the project to start as soon as funding can be arranged, no later than June1, 2002 and ending June 30, 2003. Host site managers will monitor drying process and assist in developing drying quality standards, cycle times and other technical data. NWPA will actively monitor weekly progress and file mid-term and final reports. In addition, all data will be placed on the NWPA Web. During the first year of operation there will be no expected project incomes other than drying fees yet to be determined for the use of dryer to cover utilities, labor and maintenance. We have selected the Wood Mizer DK 8400 kiln chamber. Unites are 33’ in length, 13.5’ wide x 7.5’ inside height. Units will rest on a 6” concrete slab. It is estimated each unit will consume 279 cubic feet of gas and 375 kw of electricity per 1,000 bf of material processed. This equates to $48,240 per year of utilities costs. Expected labor costs will be $10,200. Expected material to be processed is 480,000 bf. Combine these costs and cost per 1000 bf is $ 70.17 Current cost averages between $300 to $350 mbf. This is an expected savings of $279 mbf. Response: Enclosure 4B (Page 2 of 3) - Project Evaluation Criteria Applications for funding must include narrative responses that address the following four criteria. Within each criterion, subcriteria are listed in descending order of importance. Limit your responses to the areas provided. 1. Increasing Local Capacity (35 Points) A. How would the proposal improve or lead to the improvement of the local economy in terms of jobs and sustainable economic activity? How many jobs are expected to be created or retained and for how long (please distinguish between essentially year-round and seasonal jobs)? B. Will biomass or forest fuels be utilized; if so, in what manner and how much? C. Which, if any, private businesses will participate? D. To what extent will this project be offered to serve as a model for other communities or businesses? Response: A. The project is expected to create 4 to 5 jobs immediately, required to operate and maintain dryers. However, economic data show between 15 to 20 sustainable jobs can be created for each million BF of fiber processed. These jobs are year round, sustainable jobs at family wages. B. Hazardous forest fuels will be processed when material meets demand and suited for the secondary wood products manufacturing. When dryers are in full operation, we project 480,000 bf of potentially hazardous fuels will be processed each year. C. We expect the private sector to take the lead with this project in that both site managers are owner/operator of manufacturing facilities. NWPA will build upon its Web site for marketing and product exposure as well as utilizing the expertise of NWPA membership in marketing. Posting material on the Wood Exchange list and marketing through NWPA International buyers Guide. D. This pilot project will serve well as a model for other rural communities where drying capacity is a challenge. The model will also showcase the partnerships built between established private business and partnerships built with public agencies. In addition, the project demonstrates how a small capacity dryer can be a business incubator in both small and fairly large rural communities. 2. Reducing fire risk. (30 points) Describe how the proposal promotes reduction of risk in high hazard areas and communities. Describe how the proposed project benefits resources on federal land or adjacent non-federal land, or how it protects the safety of communities. C. To what extent does the project implement or create a cooperative fuels treatment plan or community fire strategy (include evidence of the plan if it already exists)? D. Explain how the proposal (a) leads to, enhances or restores a local fire-adapted ecosystem, and/or (b) mitigates or leads to the mitigation of hazardous fuels conditions. Response: A. B. A. This project provides for the infrastructure to be developed which promotes better utilization of hazardous fuels on federal land, non federal lands and surrounding communities at high risk of wildfires as identified by the ODF. B. Juniper forest in particular have been expanding dramatically throughout Central Oregon in the past century primarily the result of fire from grasslands. This is very evident by Juniper fueled fires on the outskirts of Madras in 2001 and Prineville in 2000. These added fuels create dramatic risks to rural communities. C. Utilization of Juniper in particular will help restore a fire adapted ecosystem and mitigates current hazardous fuel conditions and at the same time help implement a myriad of community fire strengths Enclosure 4B (Page 3 of 3) - Project Evaluation Criteria 3. Increasing interagency and intergovernmental coordination. (15 Points) A. To what extent have interested people and communities been provided an opportunity to become informed and involved in this proposal? B. Describe the extent of local support for the project, including any cost-sharing arrangements C. What are the environmental, social and educational benefits of the project? Response: A. NWPA has worked very hard to involve each community in this project. Working with Burnt Ranch Juniper and the city of Fossil in their quest to build an Industrial Park within the township of Fossil. Scott Morelock’s willingness to serve as a host site by providing space for dryer and both Tim Coe and Scott Morelock will be providing “In-Kind Match” on labor and support equipment. B. In-Kind match, land, support equipment and expertise is being supplied by local communities. Oregon Economic and Community Development Department has made a commitment to share in the cost of the project by funding a portion of the unit purchase price. Results and technical data will be posted on NWPA Web and available to anyone looking for information. C. Environmental benefits include improvement of watersheds, reduced fuel loads and range land improvements. Social and educational goals will be improved by providing for community job retention and community sustainability. Education goals will be accomplished through new learned job skills, transfer of technical data and creation of new manufacturing skill levels. 4. Increasing interagency and intergovernmental coordination. (20 Points) A. Explain the level of cooperation, coordination or strategic planning among federal, state, tribal, local government and community organizations in developing this proposal. List the cooperators. B. Describe how this project implements a local intergovernmental strategy or plan, or creates such a plan. Describe the plan if it already exists. Response: A. This project started as a relationship between NWPA, the Oregon Economic and Community Development Department (OECDD) and various Regional Investment Boards. The identified need comes from a series of questionnaires and information obtained during interview process of over 30 different individuals who are directly affected by the challenge of the absence of drying capacity. Specific individuals include NWPA Board of Directors, Darrin Fleener OECDD, Larry Swan USFS, Cindy Glick USFS and Scott Leavengood OSU Wood Products Extension specialist. B. This project brings together the private sector, federal agencies, state agencies and local investment boards who are all committed to or have a common purpose. The project gained strength out of conversations stimulated by the Central Oregon Partnership for Wildfire Risk Reduction (COPWFRR) an advisory council who discusses and implements Central Oregon Intergovernmental Council’s business strategy for Central Oregon. Enclosure 4C - Project Work Form Tasks Time Frame Responsible Party Place purchase order for Drying Units ASAP after funding approved No later than June 1 2002 NWPA/ Dennis Brock Installation of units Pour slab Assemble units Gas & electric hook-up July 2002 NWPA, Wood Mizer Staff Tim Coe, Scott Morelock Test run units Promote Dryer & start drying Documentation of data Establish cycle times Establish quality standards Post results on NWPA Web Draft Mid-Term report Draft Final Report Mid July August NWPA, Wood Mizer Staff Tim Coe, Scott Morelock Project partners August 2002 / June 2003 Project partners December 2002 NWPA Staff July 2003 NWPA Staff Enclosure 4D - Project Budget Cost Category Description Federal Agency Applicant Partner 1 Partner 2 Total In-Kind Personnel $42,400 $20,000 $42,400 $104,800 Subtotal Fringe Benefits $10,000 $10,000 $3,600 $3,600 Subtotal Travel Subtotal Equipment $31,690 $31,600 $63,380 $1,000 $2,500 $24,000 $48,000 Subtotal Supplies $1,000 $500 Subtotal Contractual Subtotal Other Gas & Power Utilities $24,000 Subtotal $99,090 $36,000 $99,090 $234,780 $99,090 $36,000 $99,090 $234,780 Total Costs Project (Program) Income1 1 N/A First year: Program income is the gross revenue generated by a grant or cooperative agreement supported activity during the life of the grant. Program income can be made by recipients from fees charged for conference or workshop attendance, from rental fees earned from renting out real property or equipment acquired with grant or cooperative agreement funds, or from the sale of commodities or items developed under the grant or cooperative agreement. The use of Program Income during the project period may require prior approval by the granting agency.