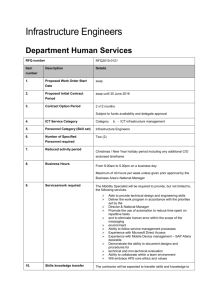

ETSI – TS 103 199 – Life Cycle Assessment of ICT

advertisement

ETSI – TS 103 199 – Life Cycle Assessment of ICT Dr. Anders S.G. Andrae Life Cycle Assessment (LCA) of ICT equipment, networks and services: General methodology and common requirements © 2011 – Proprietary and Information of ETSI Introduction – Problems addressed ISO 14040, ISO 14044 and the ILCD Handbook are recognized as normative LCA knowledge documents for “any” application Based on the ISO standards, numerous LCA results for ICT with different quality and inconsistent result presentations have been provided – EU requirement on improvement Standardization of LCA of ICT IS DEFINATELY NEEDED! ETSI has responded to the gap Work started in 2008-2009 and will finish in 2011 The ETSI standard for ICT LCA is intended to be more specific than ISO 14040/ISO 14044, but less specific than, e.g., Japanese Product Category Rules for, e.g., notebooks 3 © 2011 – Proprietary and Information of ETSI Features of the new ETSI LCA standard Based on ISO 14040, ISO 14044 and the ILCD Handbook Lifetimes – Defined Functional units (f.u.) – Basic f.u. defined System boundaries – Life Cycle Stages and Unit Processes Identified and Classified as Mandatory or Optional -The level of detail is relativelely high good guidance for users Rules for Cut–off if they cannot be avoided Data quality evalution – Qualitative requirements defined for all life cycle stages and unit processes Allocation methods – Specified. E.g., 50/50 allocation prefereed between Raw Matr. Aquisition and Metal recycling. Detailed reporting instructions (diagrams, tables) ...will help, e.g., 3rd party reviewers 4 © 2011 – Proprietary and Information of ETSI General requirements - Life cycle stages 5 • A. Equipment Raw material acquisition which is composed by • Raw material extraction (A1) • Raw material processing (A2) • B. Production which is composed by • ICT Equipment production (B1) • Support Equipment production (B2) 7 categories of Re-occuring Generic • C. Use which is composed by Unit Processes, e.g., • ICT Equipment Use (C1) Transportation, Energy • Support Equipment Use (C2) supply • Operator activities (C3) • Service Provider Activities (C4) • D. Equipment End of Life Treatment • Re–use (D1) • ICT specific EoLT (D2) • Other EoLT (D3) © 2011 – Proprietary and Information of ETSI General requirements - Lifetime Lifetime is (always) critical for the interpretation of the results of (ICT) LCAs Operating lifetime: The duration of the actual use period (consisting of both active and non–active periods) for the first user. Storage time is not included in operating lifetime. Operating lifetime shall always be reported and be based on available information on actual product use. 6 © 2011 – Proprietary and Information of ETSI Goal&Scope Definition - Intro Any ICT Equipment which can be part of a Network delivering voice and/or data lies within the scope of the ETSI LCA standard. 7 © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – Functional Unit The number of users/subscribers supported shall be specified and the traffic profile shall be considered where applicable. MANDATORY BASIC FUNCTIONAL UNITS Annual ICT Equipment use (per one year of ICT Equipment use) or Total ICT Equipment use per lifetime of ICT Equipment. Annual Network use Annual Service use. 8 © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – System Boundaries G1. TRANSPORTS&TRAVEL A: EQUIPMENT RAW MATERIAL ACQUISITION A1. Raw material extraction A2. Raw material processing G2. ELECTRICITY SUPPLY B: PRODUCTION B1. ICT Equipment production B1.1 Parts production B1.2 Assembly B1.3 ICT manufacturer support activities G3. FUEL SUPPLY B2. Support Equipment production B2.1 Support Equipment manufacturing B2.2 Site construction G4. OTHER ENERGY SUPPLY G5. RAW MATERIAL AQUISTION G5.1. Raw material extraction G5.2. Raw material processing G6. END-OF-LIFE TREATMENT G6.1 EHW treatment G6.2 Other waste treatment G7. RAW MATERIAL RECYCLING C: USE C1. ICT Equipment use C2. Support Equipment use C3. Operator activities C4. Service provider activities D: EQUIPMENT END-OF-LIFE TREATMENT D1. Re–use of ICT Equipment D2. ICT specific EoLT D2.1 Disassembly/Dismantling/Shredding D2.2 Recycling D3. Other EoLT System boundary 9 © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – System Boundaries Classification “Table 1” within your product system Tag A Life cycle stage Unit process Class ICT Equipment Network Service Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Optional Optional Optional Mandatory Mandatory i Mandatory Mandatory Equipment Raw Material Acquisition A1 Raw material extraction A2 Raw material processing B Production B1 ICT equipment production B1.1 Parts production (for further details refer to Annex N1) B1.2 Assembly B1.3 ICT vendor activities B2 Support equipment production B2.1 B2.2 10 © 2011 – Proprietary and Information of ETSI Support Optional (Mandatory if Equipment Support manufacturing* included in the Scope) Site construction Optional Equipment is Goal&Scope Definition – System Boundaries C Use C1 ICT Mandatory Mandatory Mandatory Mandatory Mandatory Optional Mandatory Mandatory Not applicable Optional Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory equipment use C2 Support Optional equipment (Mandatory use Support is if Equipment included in the Scope) C3 Operator activities* C4 Service provider activities D Equipment End of Life Treatment D1 Re–use of ICT Equipment D2 ICT specific EoLT D2.1 Storage/Disassembly/Dismantling/ Shredding D2.2 D3 Recycling Other EoLT 11 © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – Support activities • The term Support activities refers to, e.g., offices • • 12 including ICT use for marketing, sales and R&D, and also to business travel, commuting and service vehicles. Support activities are optional to include but should be included where possible. The extent in which Support activities and other Optional activities are included for different parts of the life cycle shall be clearly described in the study report. © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – Raw Material Acquisition A1. Raw material extraction B. PRODUCTION A2. Raw material processing G7. RAW MATERIAL RECYCLING 13 © 2011 – Proprietary and Information of ETSI System boundary Goal&Scope Definition – Production 14 © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – Use C1. ICT Equipment use D. EoLT C2. Support Equipment Use C3. Operator activities C4. Service provider activities B.PRODUCTION 15 © 2011 – Proprietary and Information of ETSI System boundary Goal&Scope Definition – End-of-Life D1 Re–use of ICT Equipment D2 ICT specific EoLT D2.1 Storage/Disassembly/Dismantling/Shredding D2.2 Recycling D2.2.1 Battery recycling ICT specific metal/mechanical parts/fractions EoLT D2.2.2 PCBA recycling D2.2.3 Cable recycling D2.2.4 Mechanics recycling D2.2.5 Other ICT recycling G7. MATERIAL RECYCLING D3. Other EoLT System boundary C. USE 16 © 2011 – Proprietary and Information of ETSI RAW Goal&Scope Definition – Networks System Boundaries • For the Network under study applicable types of nodes and infrastructure, as well as amounts of these, shall be defined. • Functional Block diagrams (HW and SW) essential for showing study scope • The impact from software development shall be included. • The Network shall be defined in terms of ICT equipment, Support Equipment and infrastructure. • 17 Operator activities (mainly installation, maintenance and de-installation) shall always be included © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – Services System Boundaries • • • In order to calculate the impact of a Service, it is necessary to first assess the Network Most often (i.e., in a multi–service situation) an allocation of an appropriate amount of the Network impact to the Service under study is needed Service software development, Service use of consumables, Service sales and logistics infrastructure, Service associated travels and transports Data centers are key • • Service provider activities • Positive and negative impacts 18 © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – Cut-off rules • Cut–offs shall be avoided as far as possible! • Table 1 constitute a significant share for typical • • • a) b) c) 19 product systems in ICT LCAs The intention is that all Mandatory life cycle stages/unit processes of Table 1 shall be included Model unavailable data based on known data Mandatory to: motivate clearly eventual cut–offs of mandatory life cycle stages/unit processes from Table 1 describe clearly the cut–off criteria used within a study consider unit processes/flows that have been cut–off for the sensitivity analysis. © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – Data quality requirements • Generic data: Data from any relevant data source • • • 20 which need not be specific for ICT applications and processes. Generic data is always secondary. Specific data: Data emerging from, in this case, ICT specific applications and processes. This data could be either primary or secondary. Primary data: Data collected/estimated/measured by a researcher, specifically for the LCA project; for example, pilot studies or customer or producer surveys. Secondary data: Data that has been collected for another purpose, but can be analyzed again in a subsequent study; for example, LCA estimates by academia, government, or industry organizations. © 2011 – Proprietary and Information of ETSI Goal&Scope Definition – Data quality requirements onTable 1 Tag Life cycle stage Unit process Type of data Equipment A Network Service Equipment Raw Material Acquisition A1 Raw material Generic data Generic data Generic data Generic data Generic data Generic data extraction A2 Raw material processing B Production B1 ICT equipment production B1.1 Parts production (for Specific data Specific data Specific data further details refer to Annex M2) B1.2 Assembly Specific data Specific data Specific data B1.3 ICT vendor activities Specific data Specific data Specific data B2 Support equipment production B2.1 Support Equipment Specific data: manufacturing Amounts etc Specific Specific data:: data:: Amounts etc Amounts etc Generic data: processes Generic data: processes B2.2 Site construction Specific data: Amounts etc Specific Generic data: processes Specific data:: data:: Amounts etc Amounts etc Generic data: processes Generic data: processes 21 © 2011 – Proprietary and Information of ETSI Generic data: processes Goal&Scope Definition – Data quality requirements on Table 1 cont C Use C1 ICT equipment use C2 Specific data Support equipment Specific data use C3 Operator activities C4 D Specific data Specific data data Specific Specific data data Specific Specific data data Service provider Not Specific Specific activities applicable data data Specific data Specific Specific data data Specific Specific data data Specific Specific data data Specific Specific data data Equipment End of Life Treatment D1 Re–use of ICT Equipment D2 ICT specific EoLT D2.1 Specific data Disassembly/Dismantling/ Specific data Shredding D2.2 D3 Recycling Other EoLT Specific data Generic data 22 Specific © 2011 – Proprietary and Information of ETSI Generic data Generic data Life Cycle Inventory – Data collection • The LCA practitioner shall report for which processes transports/energy supplies have been separately and for which they are “hidden”. added • For many products (especially end–user equipment), periods of idling and power off are important to model the usage profile and shall be considered. 23 © 2011 – Proprietary and Information of ETSI Life Cycle Inventory - Allocation rules • Generic processes (G1–G7) shall be allocated as a • • • • • 24 whole to the life cycle stage in which they are used Support activities… Facilities… Transports shall be allocated based on chargeable weight Recycling: The 50/50 method shall be used to allocate use of recycled Raw Material between A1-A2 and D. If used LCI data (e.g., for gold production) do not reveal the scrap% of metal, the 100/0 method is allowed. No metal recycling in EoLT allowed with 100/0. © 2011 – Proprietary and Information of ETSI Life Cycle Inventory – Allocation rules – 50/50 25 © 2011 – Proprietary and Information of ETSI Life Cycle Inventory – Allocation rules – 100/0 26 © 2011 – Proprietary and Information of ETSI Life Cycle Inventory - Allocation rules for Equipment data to Networks • End–user equipment (e.g., PCs, smart phones) which is accessing more than one Network (e.g. 3G, WLAN) shall be allocated to these Networks based on use time • Impact from shared Network resources (e.g., transmission equipment, core nodes and data centers) shall be allocated to an access network based on data traffic 27 © 2011 – Proprietary and Information of ETSI Life Cycle Inventory - Allocation rules for Network data to Services • Data for End–users– and home/CPE equipment: • to be allocated based on active use time of the • • 28 Service Data for transport equipment: • to be allocated based on data traffic The data center(s), where the Service is operated, as well as the Service provider activities shall be allocated based on number of subscriptions and Service users © 2011 – Proprietary and Information of ETSI Life Cycle Impact Assessment The baseline model of 100 years of the IPCC (GWP100) LCIA method is mandatory (shall) as mid–point impact assessment indicator for climate change. For other mid-points Impact Assessment Categories than Climate Change and Ozone Depletion there are several Category indicators developed. If these mid– points are included in the study scope the ILCD Handbook shall be followed as close as possible. Also for best End-point assessment practise the ILCD Handbook for LCIA shall be consulted. 29 © 2011 – Proprietary and Information of ETSI Life Cycle Interpretation - how robust are the results and conclusions? The challenge of the completeness check is to overcome the paradox of evaluating the degree of completeness of the product system when not knowing 100% of it. If two or more ICT Equipment, Networks or Services LCA results do not differ significantly there is a risk of erroneous interpretations. The significance is determined for instance by magnitude in difference, modeling assumptions, and LCA software program calculation algorithm. 30 © 2011 – Proprietary and Information of ETSI Comparative LCA between ICT and business as usual (BAU) systems - reduction potential LCAs with the same goal&scope, system boundaries and functional unit need to be performed for both the ICT Service and the BAU Service it replaces Especially as identical as possible system boundaries for the Raw Material Acquisition and Production Phases. For the BAU Service the associated environmental impacts shall be estimated according to travel and infrastructure first order effects. The first order effects are those directly attributable to the Services. The reduction potential is the second order effect. Rebound effects are outside the scope. 31 © 2011 – Proprietary and Information of ETSI Comparative LCA between ICT and business as usual (BAU) systems - Example Travel 32 Paper usage Buildings PCs Data centers BAU Service 30,000 200 0 0 0 ICT Service 15,000 100 0 200 200 Reduction potential = ICT Service – BAU Service 15,000– 30,000 = – 15,000 tons/year –100 tons/year 0 tons/year +200 tons/year +200 tons/year TOTAL reduction potential –14,700 tons/year © 2011 – Proprietary and Information of ETSI Reporting Common ways of reporting increase transparency and a proper basis for interpretation of results. The following shall be transparently reported and motivated: • • • • 33 Operating lifetime Cut–off Allocations Data sources © 2011 – Proprietary and Information of ETSI Reporting – ICT Equipment kg CO2e / year (20##) Total result: <X kg CO2e/year> Study year: <20##> Operating life time: < # years> Production: Assembly location:< Global average> Transports <Included> Support activities <Included> Use: Use location: < Global average> Transports: <Included> Support activities <Included> Infrastructure: <included/excluded> Raw material acquisition* Production* Use EoLT* This kind of results cannot be compared between studies unless equal assumption and modelling applies, e.g. the resulting values are very sensitive to operating life time assumptions *) The life cycle stage has been divided by life time to produce a yearly figure 34 © 2011 – Proprietary and Information of ETSI Reporting – ICT Equipment 8 kg CO2e / year Other EoLT ICT specific EoLT 7 Support equipment use 6 ICT equipment use 5 Operator activities Transports 4 Site construction 3 Support equipment production ICT vendor activities 2 Assembly 1 ICT equipment parts production 0 -1 Raw materials acquisitions Production Use EoLT Raw materials processing Raw materials extraction This kind of results cannot be compared between studies unless equal assumption and modelling applies, e.g. the resulting values are very sensitive to operating life time assumptions 35 © 2011 – Proprietary and Information of ETSI Reporting – Networks 50 Total result: <X kg CO2e/year> Study year: <20##> kg CO2e / year 40 Operation (electricity) 30 Operation (other energy / fuels) 20 Raw materials acquisition, production and EoLT 10 0 End-user Home equipment equipment 36 © 2011 – Proprietary and Information of ETSI Access network C&C network Operator activities Data transport Data center(s) Service provider(s) Reporting – Networks 50 Total service result: <X kg CO2e/year> Study year: <20##> kg CO2e / year 40 Service (all life cycle stages) 30 20 Specific to the service LCA 10 0 End-user Home equipment equipment 37 © 2011 – Proprietary and Information of ETSI Access network C&C network Operator activities Data transport Data center(s) Service provider(s) Reporting – ICT Equipment, Network and Service Raw materials acquisition and EoLT* GWP [CO2e] Production ODP [CFC-11e] Use ACP [SO2e] POCP [C2H4e] EUP [PO4(3-)e] ... 0% 38 20% © 2011 – Proprietary and Information of ETSI 40% 60% 80% 100% Reporting - Mandatory set of parts for LCA of ICT equipment. Part Mandatory set of Part unit processes Product Important issues Part categories (for each Part flow unit which influence category) B1.1.1 Batteries LCI data Lead batteries Raw Material Piece, Lithium batteries Acquisition, energy Nickel—Cadmium Battery cell assembly, content, batteries Battery module mass Size assembly Coaxial cables Raw Material Fiber cables Acquisition, Power cables Cable final assembly Network/signal cables (one unit process per Connectors part category*) B1.1.3 Connectors Raw Material Electro—mechanics Electric motors Acquisition, Speakers Part final assembly Microphones (one unit process per Camera objectives part category*) B1.1.2 Cables Hard Disc Drives Lighting (lamps) 39 © 2011 – Proprietary and Information of ETSI Piece, mass Piece, mass Length Reporting - Mandatory set of parts for LCA of ICT equipment - ICs B1.1.4 Processors, Front–end: Piece, front–end: good die area [cm2], Yield in Integrated DSPs Special IC back–end: piece package type chip circuits (ICs) ASICs materials Example1: A BGA289 package. Good production Memories production, die area 0.166 cm2. Environmental Load Business Microprocessors Wafer per BGA289 = ELU/good die area in activities Transistors and production, cm2 × 0.166 + ELU/piece BGA package Factory and diodes Chip production type back-end process machinery (“the wafer fab”) Example2: A “stacked chip” package. Back–end: IC Total Good die area 12 cm2. encapsulation Environmental Load (ELU) per “stacked chip” package = ELU/good die area in cm2 × 12 + ELU/piece “stacked chip” package type back-end process Transistors and diodes: Piece, mass 40 © 2011 – Proprietary and Information of ETSI Reporting - Reporting format for included life cycle stages, activities and generic processes Ta Life Unit Include Electricity g cycle proces d stage s (Yes/N Support Transpo Other Motivation/Comm (specific/country/w activitie rt generic ent orld average s activitie activitie include s s d include include (Yes/N d d o) (Yes/N (Yes/N o) o) o) A Equipment Raw Material Acquisition A1 Raw material extractio n A2 Raw material processi ng 41 © 2011 – Proprietary and Information of ETSI mix Reporting - Reporting format for raw materials Total Recycled Content Recycling input input in of total product input* (%) (%) (g,kg, (%) ton) Iron/Steel alloys Aluminum alloys Copper alloys Silver Gold Equipment Raw materials (optional) Raw material 1 Raw material … Raw material n Auxiliary Raw Materials(production materials etc.) (optional) Auxiliary material 1 Auxiliary material … Auxiliary material n Packaging materials(optional) 42 Packaging material 1 Packaging material … Packaging material n © 2011 – Proprietary and Information of ETSI Reference Reporting - Reporting format for Parts production B1.1.1 Batteries B1.1.2 Cables B1.1.3 Electro–mechanics B1.1.4 Integrated circuits (ICs) B1.1.5 Mechanics / materials B1.1.6 Displays B1.1.7 Printed circuit boards (PCBs) B1.1.8 Other PBA components B1.1.9 Packaging materials B1.1.10 Black box modules 43 © 2011 – Proprietary and Information of ETSI Part Part Unit Handling of categories included processes included special issues CONTACT anders.andrae@huawei.com 44 © 2011 – Proprietary Information of ETSI