Design for Test of Digital Systems TDDC33 Erik Larsson Department of Computer Science

advertisement

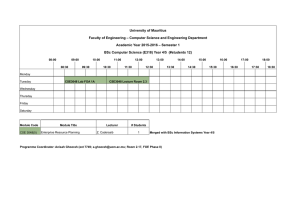

Design for Test of Digital Systems TDDC33 Erik Larsson Department of Computer Science 1 Invited lectures Lecture 7 Invited Talk by Dr. Ingemar Söderquist, SAAB, September 28 at 13-15 Lecture 8 Invited Talk by Dr. Thomas Granlund, SAAB, October 05 at 13-15 2 Course Outline Introduction; Manufacturing, Wafer sort, Final test, Board and System Test, Defects, and Faults Test generation; combinational and sequential test generation Design-for-Test techniques; test point insertion, scan, enhanced scan Test data compression, Built-In Self-Test; Logic BIST and memory BIST System Chip Test; test architectures, test planning, test scheduling, and power constraints System Test and Boundary Scan 3 Making fault free electronic products ok? ok? ok? Test specification ok? ok? Test Preparation Production Test In-Field Test 4 Printed Circuit Board (PCB) IC IC Core Logic IC Core Logic IC Core Logic Core Logic PCB 5 Probing for Test 6 Bed-of-Nails Top view Side view PCB IC IC IC No testing IC Core Logic IC Core Logic Bed of nails IC Core Logic Core Logic PCB IC IC PCB Testing Bed of nails 7 Test Objectives Given a Printed Circuit Board (PCB) composed of a set of components (ICs) where each component is tested good. The main objectives are to ensure that all components are: correct (the desired ICs are selected) mounted correctly at the right place on the board and ensuring that interconnections are functioning according to specification Problems that may occur: A component does not contain logic A component is not placed where it should be, A component is at its place but turned wrongly, A component is correct but the interconnection is not correct, for example due to bad soldering. 8 Comparing SOC Test and Board Test SOC Test Board Test Cores are not tested prior to chip fabrication All components (chips) are tested prior board fabrication Focus on both core test (internal test) and connection test (external test) Main focus on test of interconnections (external test) 9 IEEE 1500 Core Test Standard Goals Define test interface between core and SOC Core isolation Plug-and-play protocols Scope Standardize core isolation protocols and test modes TAM design Type of test to be applied Test scheduling 10 IEEE 1500 Wrapper Test stimuli W B R W B R Test responses Core Functional data W B R W B R WBY Test control+ test stimuli wrapper WIR Functional data Test control+ test responses WIP 11 WPP (optional) Test Wrapper WPC WPO WPI WSP: Wrapper Serial Port WSI: Wrapper Serial Input WSC: Wrapper Serial Control WSO: Wrapper Serial Output WPP: Wrapper Parallel Port WPI: Wrapper Parallel Input WPC: Wrapper Parallel Control WPO: Wrapper Parallel Output Core WSI wrapper WSO WSC WSP (mandatory) Interface between module and the rest of the chip; makes it possible access core and isolate core from rest of the system. Test modes Normal: Functional mode InTest: test of module itself ExTest: test of interconnection to other core IEEE 1500 Standard for Embedded Core Test 13 Test Wrapper: Modes WFO WFI WSI W B R FO Core FO FI FI W B R WFO Normal mode WFI Normal mode W B R FO Core FO FI Test enable Test enable WBY WBY WSO WIR wrapper WSI wrapper WSC UDL UDL WSI W B R FI FI Normal mode WSO WIR W B R W B R UDL UDL FO Core FO FI FI Test enable Test enable WBY WBY WIR Normal mode WSC FO Core FO wrapper FI W B R WSO WSI wrapper WIR W B R WSO 15 WSC WSC Boundary Scan (IEEE std. 1149.1) The Joint European Test Action Group (JETAG), formed in mid-80, became Joint Test Action Group (JTAG) in 1988 and formed the IEEE std 1149.1. The standard consists of: Test Access Port (TAP) TAP Controller (TAPC), Instruction Register (IR), and Data Registers (DR) 19 Boundary Scan BSC BSC BSC Core logic BSC Core logic BSC BSC BSC BSC Bypass TDI TDO Instruction Register TMS TCK TAP Controller TRST 20 20 IEEE Std. 1149.1 and IEEE Std. 1500 (User-defined WPP = WPI+WPO+WPC) BSC BSC BSC W B R BSC Core logic BSC BSC BSC BSC Bypass FO FI FI WFO W B R FO FO FI FI TDO TAP Controller W B R WFO WFI Test enable Instruction Register TMS TCK W B R Core WFI TDI FO WBY WSI wrapper WIR WSO TRST WSC: WRCK, WRST, SelectWR, ShiftWR, CaptureWR, UpdateWR 21 Boundary Scan Boundary Scan cell Core Logic Core Logic IC IC TAP TAP TAP IC TAP IC Core Logic Core Logic Boundary Scan chain TDI TCK TMS TRST TDO PCB 22 Boundary Scan Cell (BSC) SO MODE IN ShiftDR 0 1 MUX D FF Q D FF MUX OUT Q 1 0 SI ClockDR UpdateDR SO IN BSC CTO OUT SI CFI WBC CFO CTI Std. 1149 Std. 1500 23 Boundary Scan BSC BSC BSC BSC Core logic BSC BSC BSC BSC Internal Registers TDI Bypass TDO Miscellaneous Registers Instruction Register TMS TCK TAP Controller TRST 24 Boundary Scan Bypass Register Boundary Scan Register TDO TDI T P Design Specific Data Registers ShiftDR A TAP Controller TMS TCK TRST Device ID Register ClockDR TDI: Test Data In UpdateDR Reset Data Registers (DR) ClockIR ShiftIR Instruction Decode UpdateIR Instruction Register (IR) TDO: Test DataOut TMS: Test Mode Select TCK: Test Clock Optional registers and signals are shown in dotted lines 25 TMS and TCK are used to control the behavior of the TAP. TAP Controller TMS Control of data registers Control of instruction register Test-Logic-Reset 1 Run-Test/Idle 0 1 0 1 1 Select-DR-Scan 1 Select-IR-Scan 0 Capture-DR 1 0 Shift-IR 0 Shift-DR 1 0 Exit1-DR 0 1 1 Update-DR 1 1 0 Pause-IR 1 0 Exit2-DR 0 1 Exit1-IR Pause-DR 1 0 0 Capture-IR Exit2-IR 1 Update-IR 0 1 0 26 Instructions Mandatory Bypass; used to bypassing an IC Extest; tests interconnection between ICs Sample/Preload; used to sample (snapshot) and preload boundary scan during operation Optional Intest Runbist Clamp Idcode Usercode Highz 27 Boundary Scan Description Language (BSDL) BSDL is a subset of VHDL that describes how JTAG (IEEE 1149.1) is implemented in a particular device. For a device to be JTAG compliant, it must have an associated BSDL file. Use BSDL file to work out how to access a device in the JTAG chain. BSDL files contain the following elements: Entity Description: Statements naming the device. Generic Parameter: A value such as a package type. Port Description: Describes the pins on the device. Use Statements: References external definitions. Pin Mapping(s): Maps logical signals in the device to physical pins. Scan Port Identification: Defines the pins to access the JTAG capabilities (TDI, TDO, etc - the Test Access Port). Instruction Register Description: Signals to access JTAG device modes. Register Access Description: Which register is placed between TDI and TDO for each JTAG instruction. Boundary Register Description: List of the boundary scan cells and their functionality. 28 Mapping component data to the BScan Chain ”Manual” composition of the scan data arrays – Knowledge of position in the overall chain is required TDI data TDO data Component data for one or more DR registers 29 BYPASS BSC BSC BSC BSC Core logic TDI BSC BSC BSC BSC Bypass TDO Instruction Register TMS TCK TAP Controller TRST 30 EXTEST Shift-DR (IC1) TDI Core Logic Core Logic IC IC TAP TAP To be tested TCK TMS TRST TDO TAP TAP IC IC Core Logic Core Logic PCB 31 EXTEST TDI Core Logic Core Logic IC IC TAP Update-DR (IC1) TAP To be tested TCK TMS TRST TDO TAP TAP IC IC Core Logic Core Logic Capture (IC2) PCB 32 EXTEST TDI Core Logic Core Logic IC IC TAP TAP To be tested TCK TMS TRST TDO TAP TAP IC IC Core Logic Core Logic Shift-DR (IC2) PCB 33 Scan and MBIST support with Boundary Scan Scan_out Scan_en Logic BIST controller BIST decoder Scan decoder Memory Compressor Bist_sel Mbist Bist_so Scan_in Scan path Int_scan Decoder TDI TCK TMS Instruction register TAP Controller MUX TDO 34 Making fault free electronic products ok? ok? ok? Test specification ok? ok? Test Preparation Production Test In-Field Test 35 Introduction Backplane 36 Ring Architecture with Shared TMS IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic PCB PCB TDI TCK TMS TRST TDO IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic PCB PCB 37 Ring Architecture with Separate TMS IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic PCB TDI TCK TMS1 TMS2 TMS3 TMS4 TRST TDO PCB IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic PCB PCB 38 Star Architecture TDI TCK TMS TDO IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic PCB PCB TDI TCK TMS TDO TDI TCK TMS TDO TDI TCK TMS TDO IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic PCB PCB 39 Multi-drop Architecture Bus master IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic PCB PCB Multi-Drop Device Multi-Drop Device TDI TCK TMS TDO Multi-Drop Device Multi-Drop Device IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic IC Core Logic PCB PCB 40 IEEE 1149 Standard Family Number Main objectives Status 1149.1 Testing of digital chips and interconnects between chips Std. 1149.1-1990 Std. 1149.1a-1993 Std. 1149.1b-1994 (BSDL) Std. 1149.1-2001 1149.2 Extended digital serial interface Discontinued 1149.3 Direct access testability interface Discontinued 1149.4 Mixed-signal test bus Std. 1149.4-1999 1149.5 Standard module test and maintenance (MTM) bus Std. 1149.5-1995 (not endorsed by IEEE since 2003) 1149.6 High-speed network interface protocol Std. 1149.6-2003 1149.7 Reduced-Pin and EnhancedFunctionality Test Access Port Std.1149.7-2009 41 IJTAG P1687 IJTAG P1687 Statement of Scope: This standard will develop a methodology for access to embedded test and debug features, (but not the features themselves) via the IEEE 1149.1 Test Access Port (TAP) and additional signals that may be required. The elements of the methodology include a description language for the characteristics of the features and for communication with the features, and requirements for interfacing to the features 42 Interface and scan-path 43 Farrokh Ghani Zadegan, Urban Ingelsson, Gunnar Carlsson and Erik Larsson, “Test Time Analysis for IEEE P1687”, IEEE 19th Asian Test Symposium(ATS2010), Shanghai, China, Dec. 2010 Analysis of IEEE P1687 network The control data for the SIB is transported on the same wire as test data Control data is transferred to the status register when the JTAG state machine does ”apply and capture” “CUC” : Apply Capture Update Cycle : 5 clock cycles in the FSM 44 The infrastructure 45 Analysis: Hierarchical architecture Concurrent test schedule 46 Analysis: Hierarchical architecture Concurrent test schedule 47 Analysis: Hierarchical architecture Concurrent test schedule 48 Analysis: Hierarchical architecture Concurrent test schedule 49 Analysis: Hierarchical architecture Concurrent test schedule 50 Analysis: Hierarchical architecture Concurrent test schedule 51 Making fault free electronic products ok? ok? ok? Test specification ok? ok? Test Preparation Production Test In-Field Test 52 A Fault Management View Network Management NMS displays & correlates alarms I/f: Mun, standard Alarm IRP Sub-network Management OSS • alarm subscriptions • alarm list presentation • standard interfaces • alarm filtering I/f: Mur, Mub Element Management of Network Elements • alarm log RBS • alarm list • alarm correlation within NE 53 Mudassar Majeed, Daniel Ahlström, Urban Ingelsson, Gunnar Carlsson and Erik Larsson, “Efficient embedding of deterministic test data”, IEEE 19th Asian Test Symposium(ATS2010), Shanghai, China, Dec. 2010 Embedded deterministic test Printed Circuit Boards with mounted ICs In-field test (boot-up, regular checks) Detects manufacturing test escapes Detects faults that are due to wear-out, environmental impact etc. In-field diagnosis To determine which IC has the fault Requires on-system test evaluation Key problem: Storing the test data on the system High memory requirements Inflexible in applying different tests The proposed solution An embedded test controller to manipulate test data based on commands With the help of structural information about the system Reduces memory requirements and provides flexibility Supports diagnosis Based on IEEE 1149.1 JTAG 54 Embedded test-specific circuitry 55 IEEE 1149.1 56 Memory requirements 57 Basic idea behind the solution 58 Kim Petérsen, Dimitar Nikolov, Urban Ingelsson, Gunnar Carlsson and Erik Larsson, “An MPSoCs demonstrator for fault injection and fault handling in an IEEE P1687 environment”, IEEE 17th European Test Symposium (ETS 2012), Annecy, France, May 28-June 1, 2012. Demonstrator MPSoC MEMORY MASTER CPU RM IAI IM ACCELERATOR FIPI DSP CPU BLOCK INSTRUMENT FIM MASTER CPU Instrument Access Infrastructure TAP SIB SIB FIF SIB Segment Insertion Bit (SIB) M SIB SIB FIF DSP SIB SIB FIF CPU1 M FIF M SIB FIF M CPU2 SIB FIF M CPU10 M FIF M MASTER CPU Instrument Access Infrastructure TAP Closed SIB FIF SIB Opened SIB M SIB SIB FIF DSP SIB SIB FIF CPU1 M FIF M SIB FIF M CPU2 SIB FIF M CPU10 M FIF M MASTER CPU TAP Fault Indication and Propagation Infrastructure SIB SIB FIF SIB Fault Indication Flag M SIB SIB Masking Bit FIF DSP SIB SIB FIF CPU1 M FIF M SIB FIF M CPU2 SIB FIF M CPU10 M FIF M MASTER CPU TAP RM IM 0 System-Level 0 00 DSP Component Type-Level 00 00 00 Fault injection 11 CPU1 Component-Level 00 00 CPU2 00 00 CPU10 00 0..0 0..0 MASTER CPU TAP RM IM 0 System-Level 0 00 DSP Component Type-Level 00 00 00 Fault injection 11 CPU1 Component-Level 00 00 CPU2 00 00 CPU10 00 1..0 0..0 MASTER CPU TAP RM IM 0 System-Level 0 00 DSP Component Type-Level 00 10 00 Fault injection 11 CPU1 Component-Level 00 00 CPU2 00 00 CPU10 00 1..0 0..0 MASTER CPU Initiate identification TAP RM Fault Detection IM 1 System-Level 0 00 DSP Component Type-Level 00 10 00 Fault injection 11 CPU1 Component-Level 00 00 CPU2 00 00 CPU10 00 1..0 0..0 MASTER CPU Continue identification TAP RM IM 1 System-Level 0 00 DSP Component Type-Level 11 CPU1 Component-Level 00 10 00 00 00 CPU2 00 00 CPU10 00 1..0 0..0 MASTER CPU TAP RM IM Initiate re-execution on Fault source identified CPU 1 and keep monitoring system operation 1 System-Level 0 00 DSP Component Type-Level 11 CPU1 Component-Level 00 10 00 00 00 CPU2 00 00 CPU10 00 1..0 0..0 MASTER CPU TAP RM IM 0 System-Level 0 00 System has recovered from a 00 00 DSP 00 soft fault Component Type-Level 00 CPU1 Component-Level 00 00 CPU2 00 00 CPU10 00 0..0 0..0 Design for Test of Digital Systems TDDC33 Erik Larsson Department of Computer Science 70