The Future of Manufacturing Opportunities to drive economic growth

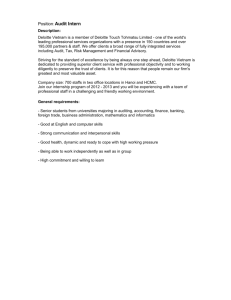

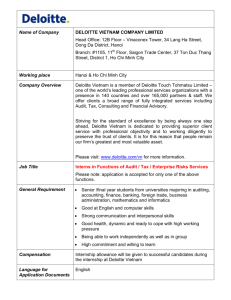

advertisement