Rare Earth Elements Au Cu SnO

advertisement

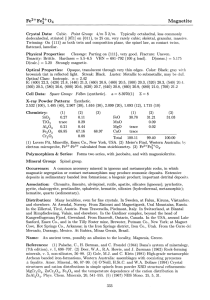

SOIL AND SOLID NON-FUEL MINERAL RESOURCES Au Cu How are solid non-fuel mineral resources formed and concentrated? SnO2 • Internal Processes (magma generation, hot water circulation, pressure & heat) – Magmatic deposits – Hydrothermal deposits – Metamorphism Gabbro Rare Earth Elements • External Processes (weathering, erosion, transport and deposition Marble Slate The Rare Earth Elements “REE” by wind and water; evaporation) – Sedimentary deposits: wind, water, placers – Evaporites – Secondary Enrichment Web Link The 17 Rare Earth Elements http://en.wikipedia.org/wiki/Rare_earth _element Ru Ruthenuim Rh Rodium Pd Palladium Os Osmium Ir Iridium Pt Platinum Se Selinium 1 Bastnäsite: a fluorocarbonate mineral (Ce,La,Y)CO3F Monazite: a phosphate mineral, 4 different types monazite‐Ce (Ce, La, Pr, Nd, Th, Y)PO4 monazite‐La (La, Ce, Nd, Pr)PO4 monazite‐Nd (Nd, La, Ce, Pr)PO4 monazite‐Sm (Sm, Gd, Ce, Th)PO4 Wide Variety of uses: medical (MRI), military, missiles, clean energy technology, catalytic converters, magnets, hybrid car batteries. Consumer Products: cell phones, computer hard drives, monitors, power tools, sun glasses, wine bottles, fluorescent light bulbs, TVs, automobiles, SUV’s 2 • Also used in Cell Phones Until the mid 1980’s, US led the world in REE production; has ~13% of world reserves. China has ~48% of world reserves, but supplies ~97% of the world’s needs. Russia, Canada and Australia also have large deposits. 3 Over 3 Square miles In 2015, global industry forecast is to consume 185,000 tons of rare earth’s Mountain Pass Rare Earth Mine in Mountain Pass California, Mojave Desert. Environmental Concerns Closed in 2002, re‐opened in August 2012 • Need to excavate a lot of earth / dig huge holes / takes a lot of energy + a lots of solid waste rock. • Some elements associated with the REE are radioactive such as Uranium and Thorium. They end up in slurry pools and can enter groundwater. • Toxic acids and chemicals are required during the refining process, often end up in slurry pools and can enter groundwater. • Baotou, a city in China where ~80% of REE are mined produces ~10 million tons of wastewater/year. • Birth defects and Leukemia have been linked to rare earth refinery in Malaysia and China • In 2008, ~1/3 of REE in China were mined illegally by heavy polluting, violent criminal gangs. Web Link: The Only American Mine for Rare Earth Metals http://www.theatlantic.com/technology/archive/2012/02/a-visit-to-the-onlyamerican-mine-for-rare-earth-metals/253372/ 4 How are solid non-fuel mineral resources formed and concentrated? Most of the world’s major metal deposits occur at past or present plate boundaries. Surface processes also play an important role in concentrating nonmetallic minerals and rocks. • Internal Processes (magma generation, hot water circulation, The Lynas Plant in Malaysia is the world's largest processing facility of rare earths. Metamorphism pressure & heat) – Magmatic deposits – Hydrothermal deposits – Metamorphism • External Processes (weathering, erosion, transport and deposition by wind and water; evaporation) – Sedimentary deposits – Evaporites – Water / Placer deposits – Secondary Enrichment How are solid non-fuel mineral resources formed and concentrated? Most of the world’s major metal deposits occur at past or present plate boundaries. Surface processes also play an important role in concentrating nonmetallic minerals and rocks. • Internal Processes (magma generation, hot water circulation, pressure & heat) – Magmatic deposits – Hydrothermal deposits – Metamorphism • External Processes (weathering, erosion, transport and deposition by wind and water; evaporation) – Sedimentary deposits: wind, water, placers – Evaporites – Secondary Enrichment 5 Sand Mining in Monterey Bay has been occurring since 1906, ~150,000 – 250,000 cubic yards/yr, with no regulation until 1960s. 3 companies for ~80 years, only one is left. Sedimentary Deposits: Sand and gravel accumulate in river A connection between mining and shoreline erosion was determined in the mid 1980s, but still 1 company mines ~200,000 cubic yards each year. water filtration, glass production….. channels and bars, coastal offshore bars, sand dunes, beaches and glacial outwash plains. After deposition sediments lithify by compaction and cementation. Materials used for: road beds, cement production, bricks, tiles, abrasives, Sand Mining in Monterey Bay http://coastalcare.org/2014/09/monterey-bay-california-beach-sand-mining-from-a-nationalmarine-sanctuary-by-gary-griggs/ (web link) “Point Bars” Placer Deposits Read this slide over very carefully. 6 Evaporites: (Salts: halite, gypsum, borates) water evaporates from shallow inland seas or lakes in warm arid climates. Materials used in: making glass, ceramics, metals, preservatives, cleaning agents, water softeners…….. How are solid non-fuel mineral resources formed and concentrated? Most of the world’s major metal deposits occur at past or present plate boundaries. Surface processes also play an important role in concentrating nonmetallic minerals and rocks. • Internal Processes (magma generation, hot water circulation, pressure & heat) – Magmatic deposits – Hydrothermal deposits – Metamorphism • External Processes (weathering, erosion, transport and deposition by wind and water; evaporation) – Sedimentary deposits: wind, water, placers – Evaporites – Secondary Enrichment How are mineral resources found? Understand the geologic/plate tectonic history of an area Make Maps: rock formations, faults, structure Drill, extract and analyze rock/sediment samples Aerial photos and satellite images, reveals outcrops and types of rock types Seismic & gravitational surveys give info about buried rock layers Chemical analysis of water and plants to detect minerals leached into water and absorbed by plants Remote sensing: (detect /analyze wave transmitted energy) reveals outcrops and types of rock Secondary Enrichment Measure radiation, magnetism to detect radioactive metals, iron and other 7 How are Mineral Resources Extracted? Bingham Copper Mine, Utah >4km wide, 1.2 km deep, >6 billion tons of rock mined since 1906 Surface Mining machines strip away millions of tons of “Overburden” (rock/earth covering ore) and pile it up as waste material sometimes called “Spoil” 1) Open-pit mining: commonly used surface mining technique; used for mining most major metal deposits, also sand, gravel and stone. The Palabora open pit in NE South Africa. The hard rock allows the pit walls to be cut much steeper than is normal in open-pit Copper mining. More Surface Mining 2) Hydraulic Mining: wash away overburden on hillsides; mine uplifted placer deposits. In CA huge volumes of sediment washed into SF-San Joaquin delta harming navigation and agriculture, ~ 1850’s – 1890’s. 3) Dredging: used on underwater mineral deposits; gold mining of CA riverbed sediments until 1960s; leaves great piles of spoil alongside channels called spoil banks/dredge fields. ~13 billion cubic yards of sediment have been washed away from the Sierra Nevada 8 Smelting or “Extractive Metallurgy” How are ores processed? • Remove undesired parts of ore (gangue) is the practice of extracting metal from ore, purifying it, and recycling it Separation of ore from gangue Melting metal • Smelting extracts metals from other elements • Pure metal is then converted to desired product by manufacturing companies Drawbacks? Results in air, water, soil pollution; solid and liquid hazardous wastes; safety and health hazards Metal ore Start Here: Surface Mining Recycling Conversion to product Discarding of product Scattered in environment Why do we mine? Concerns? Environmental degradation from mining and processing, depletion time, economic depletion, exhaustion, import dependence, high cost Supply and Consumption of Mineral Resources • Economic Depletion – Costs more to find, extract, transport and process mineral than deposit is worth. – Options: 1) recycle or reuse existing supplies, 2)waste less, 3) use less, 4) find substitute, 5) do without. • Depletion Time: – time it takes to use up 80% of reserves of a mineral at a given rate of use. • US currently imports ~50% of its most important non-fuel minerals. – Used faster than they can be produced here – Foreign ores are higher grade and can be extracted cheaper than US reserves 9 A Mine, use, throw away; no new discoveries; rising prices Production B Present Recycle; increase reserves by improved mining technology, higher prices, and new discoveries Recycle, reuse, reduce consumption; increase reserves by improved mining technology, higher prices, and new discoveries C Depletion time A Depletion time B Depletion time C Time Mineral and Soil Resources • Greatest concern about mining solid non-fuel mineral resources is environmental degradation caused by extracting, processing and manufacturing. • Soil is a renewable resource if sound, sustainable agricultural practices are used. When soil is depleted of its nutrients or topsoil erodes faster than it is replenished, soil becomes a nonrenewable resource. • As resources become depleted • Soil loss seriously compromises and lower grade ores are our ability to grow food necessary mined, environmental to feed an expanding human degradation increases. population. 10