Kansas State University Steam and Condensate Master Plan Manhattan, Kansas

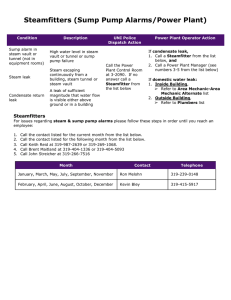

advertisement