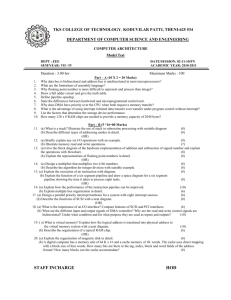

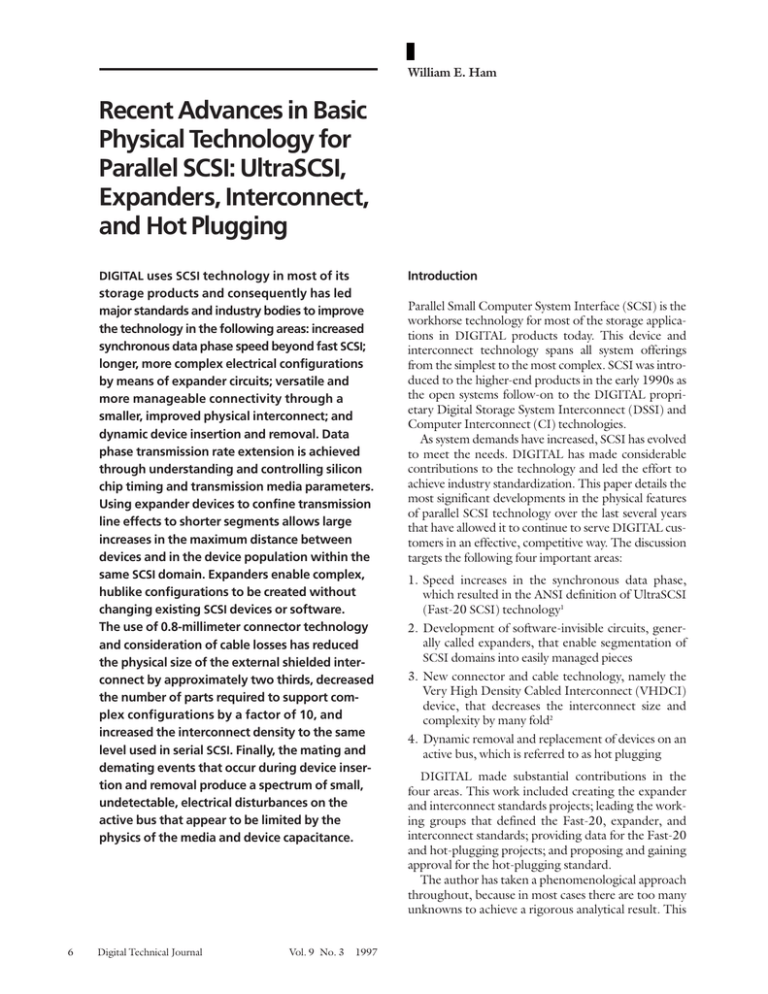

Recent Advances in Basic Physical Technology for Parallel SCSI: UltraSCSI, Expanders, Interconnect,

advertisement