Power Generation Using Foot Step Author:v.Jose Ananth Vino,AP,Bharath University ABSTRACT

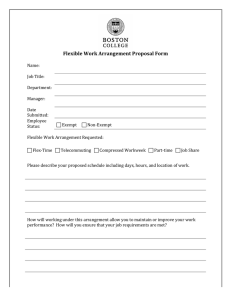

advertisement

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

Power Generation Using Foot Step

Author:v.Jose Ananth Vino,AP,Bharath University

ABSTRACT

In this project we are generating electrical power as non-conventional method by

simply running on the train in the foot step. Non-conventional energy system is very

essential at this time to our nation. Non-conventional energy using foot stepneeds no

fuel input power to generate the output of the electrical power. This project using

simple drive mechanism such as rock and pinion assemble and chain drive mechanism.

For this project the conversion of the force energy in to electrical energy. The

control mechanism carries the rack & pinion, D.C generator, battery and inverter

control. We have discussed the various applications and further extension also. So this

project is implemented to all foot step, the power generation is very high. The initial cost

of this arrangement is high.

INTRODUCTION

Man has needed and used energy at an increasing rate for his sustenance and well

being ever since he came on the earth a few million years ago. Primitive man required

energy primarily in the form of food. He derived this by eating plants or animals, which

he hunted. Subsequently he discovered fire and his energy needs increased as he started

to make use of wood and other bio mass to supply the energy needs for cooking as well

as for keeping himself warm.

With the passage of time, man started to cultivate land for agriculture. He added a new

dimension to the use of energy by domesticating and training animals to work for him.

With further demand for energy, man began to use the wind for sailing ships and

for driving windmills, and the force of falling water to turn water for sailing ships and

for driving windmills, and the force of falling water to turn water wheels. Till this time,

ISSN: 2231-5381

http://www.ijettjournal.org

Page 33

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

it would not be wrong to say that the sun was supplying all the energy needs of man

either directly or indirectly and that man was using only renewable sources of energy.

NEED FOR NON-CONVENTIONAL ENERGY

Fuel deposit in the will soon deplete by the end of 2020Fuel scarcity will

be maximum. Country like India may not have the chance to use petroleum

products. Keeping this dangerous situation in mind we tried to make use of nonpollutant natural resource of petrol energy.

The creation of new source of perennial environmentally acceptable, low

cost electrical energy as a replacement for energy from rapidly depleting

resources of fossil fuels is the fundamental need for the survival of mankind. We

have only about 25 years of oil reserves and 75 – 100 years of coal reserves.

Resort to measure beginning of coal in thermal electric stations to serve the

population would result in global elementic change inleading to worldwide

drought and decertification.

The buzzards of nuclear electric-stations are only to will. Now electric

power beamed directly by micro-wave for orbiting satellite. Solar power stations

(s.p.s) provide a cost-effective solution even though work on solar photo voltaic

and solar thermo electric energy sources has been extensively pursued by many

countries. Earth based solar stations suffer certain basic limitations.

It is not possible to consider such systems and meeting continuous

uninterrupted concentrated base load electric power requirements.Energy plays an

important role in the material, social and cultural life of man kind. The energy

needs are increasing day by day. This is the result of population growth and

increase in the standard of living which is directly proportional to energy

consumption.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 34

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

As we know that mankind will be never lacking in energy. Today, it is

liquid fluid, tomorrow it may be uranium with an element of risk. Risk exists

where ever there is human activity and production of energy. Just as the supply

of fossil fuel is finite thus there will be the supply of uranium. Perhaps, uranium

would be exhausted quickly if it is used on a large scale.

It is therefore, harnessing the gigantic inexhaustible solar energy source

reduces the dependence on fossil fuels. For the environmental concerned, the

solar energy harnessing system offers advantages in that, it emits no pollutants in

to the atmosphere as they are with the combustion of fossil fuels. Thus, as a long

term option solar energy system can be considered as an alternate to all the finite

fuel system. Therefore, there is no energy shortage today nor will there be in the

near future.

The lifting of water for drinking or irrigation purposes is of great

importance in widely distributed villages with little or no rural electrification and

where underground water is available. Solar energy is converted to mechanical

energy to drive small water pumps it would be of great help to the rural

inhibitions.

In our project we use solar photo voltaic cells for pumping water. The

photo voltaic modules convert sunlight direct to electricity which is used to run a

dc motor pump for bailing of water. It consists of solar photo voltaic modules,

power conditioner to protect storage batteries from over charging during non-sun

shine and a dc water pump.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 35

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

FOOT STEP ARRANGEMENT

This is made up of mild steel. The complete set up is fixed in this model FOOT

STEP. The two L-shapes frame is fixed in the above two ends of the track. Bellow this lshapes window, the actual power generation arrangement is constructed. This L-shapes

window pushes the rack when the time of train wheelmoving on these arrangement.

BLOCK DIAGRAM

FOOTSTEP

ARRANGEMENT

RACK & PINION AND

CHAIN SPROCKET

ARRANGEMENT

DC

GENERATOR

BATTERY

INVERTER

LIGHT

LOAD

FIG-1

DESIGN AND DRAWINGS

3.1 DESIGN OF PINION

From PSG design data book (page no.7.18)

dmin> (0.59/ σcmax) х [[Mt]/((1/E1)+(1/E2)) 2](1/3

(1)

Where,

σcmax = maximum contact compressive stress N/m2

E1, E2 = Young’s modulus N/m2

Mt = Torque N-m

E1 = E2 = 1.1х106 N/m2

Calculation of σcmax

σcmax= HB х CB х Kcl

(2)

Where,

HB

= Brinell hardness number

ISSN: 2231-5381

http://www.ijettjournal.org

Page 36

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

Kcl

CB

= coefficient depends on hardness

Kcl

= life factor

= {[1 x 107]/N} 1/6

(3)

N

= 60 x n x T

Where

n

= rpm

N

= life in no. Of cycles

T

= life in hours.

= 8000 hours.

From P.S.G design data book (page no.2.4),

CB =

20

HB =

200

Substituting the values of N, n, T in the equation [3],

The value of kcl is obtained as 1.139.

Kcl = 1.139.

Substituting the values in equation [2]

σcmax

=

=

20 x 200 x 1.1309

4520 x105N/m2

Calculation of Mt

Mt = 97420 x (Kw/n).

(4)

For power calculation

m ω2 r

Centrifugal force, fc=

M =

W

=

(5)

7kg

=

mxg

2Πn/60

R =

1m

Substituting the values of m, ω, r in equation [4]

fc

=

7.56 N.

Downward force, fd

ISSN: 2231-5381

=

mxg

http://www.ijettjournal.org

Page 37

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

=

7 x 9.81

=

68.6N.

Centrifugal force, f

=

=

68.6 + 7.56

=

76.17N

fc + fd

Torque

=

fxr

=

=

76.17 x 1

76.2Nm.

Power

=

=

Torque x angular velocity.

=

76.2 x 1.05

79.7

Substituting the value of kw and n in equation in [3],

Mt

= 776.7

[Mt]

= 1.4 x Mt

= 1.4 x 776.7

= 1087.1 N-m

Substituting the values of σcmax, [Mt], E1,E2

in equation [1],

The minimum diameter of the pinion is calculated to be 78.7mm.

We have taken the standard diameter of pinion as 75mm.

3.1.1 SPECIFICATION OF PINION

Material

: cast-iron

Outside diameter

: 75mm

Circular pitch

: 4.7mm

Tooth depth

: 3.375mm

Module

: 1.5mm

Pressure angle

: 21

Pitch circle diameter

: 72mm

Addendum

: 1.5mm

ISSN: 2231-5381

http://www.ijettjournal.org

Page 38

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

Dedendum

: 1.875mm

Circular tooth Thickness

: 2.355mm

Fillet radius

: 0.45mm

Clearance

: 0.375mm

3.2 DESIGN OF RACK

Pitch circle diameter of the gear is

= 72mm

Circumference of the gear is

= pitch circle diameter

= 72

= 226mm

The dimension is for 360 rotations

For 180rotations the rack length is 113 mm

3.2.1 SPECIFICATION OF RACK

Material

: cast iron

Module

: 1.5mm

Cross-section

:7525mm

Teeth on the rack is adjusted for 113mm

3.3 OUTPUT POWER CALCULATION

Let us consider,

The mass of a body

=

60 Kg (Approximately)

Height of speed brake

=

10 cm

∴Work done

=

Force x Distance

Force

=

Weight of the Body

=

60 Kg x 9.81

=

588.6 N

=

Height of the speed brake

=

10 cm

Here,

Distance traveled by the body

ISSN: 2231-5381

http://www.ijettjournal.org

Page 39

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

∴Output power

=

0.10 m

=

Work done/Sec

=

(588.6 x 0.10)/60

=

0.98 Watts

(For One pushing force)

However, this much power produced, it cannot be tapped fully. From the above

purpose we have select to generate electricity by permanent magnet type D.C generator

and store it by 12V lead-acid battery cell.

ASSEMBLY DIAGRAM

ISSN: 2231-5381

http://www.ijettjournal.org

Page 40

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

WORKING PRINCIPLE

The complete diagram of the power generation using FOOT STEP is given

below. L-shapes window is inclined in certain small angle which is used to generate the

power. The pushing power is converted into electrical energy by proper driving

arrangement.

The rack & pinion, spring arrangement is fixed at the FOOT STEP which is

mounded bellow the L-shapes window. The spring is used to return the inclined Lshapes window in same position by releasing the load. The pinion shaft is connected to

the supporter by end bearings as shown in fig. The larger sprocket also coupled with the

pinion shaft, so that it is running the same speed of pinion. The larger sprocket is

coupled to the small cycle sprocket with the help of chain (cycle).

This larger sprocket is used to transfer the rotation force to the smaller sprocket.

The smaller sprocket is running same direction for the forward and reverse direction of

rotational movement of the larger sprocket. This action locks like a cycle pedaling

action.

The fly wheel and gear wheel is also coupled to the smaller sprocket shaft. The

flywheel is used to increase the rpm of the smaller sprocket shaft. The gear wheel is

coupled to the generator shaft with the help of another gear wheel. The generator is used

here, is permanent magnet D.C generator. The generated voltage is 12Volt D.C. This

D.C voltage is stored to the Lead-acid 12 Volt battery. The battery is connected to the

inverter. This inverter is used to convert the 12 Volt D.C to the 230 Volt A.C. This

working principle is already explained the above chapter. This 230 Volt A.C voltage is

used to activate the light, fan and etc.

By increasing the capacity of battery and inverter circuit, the power rating is

increased. This arrangement is fitted in FOOT STEPs; the complete arrangement is kept

inside the floor level except the pushing arrangement.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 41

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

FABRICATED MODEL

FIG-27

CONCLUSION

In concluding the words of our project, since the power generation using foot

step get its energy requirements from the Non-renewable source of energy. There is no

need of power from the mains and there is less pollution in this source of energy. It is

very useful to the places all roads and as well as all kind of foot step which is used to

generate the non conventional energy like electricity.

It is able to extend this project by using same arrangement and construct in the

foot steps/speed breaker so that increase the power production rate by fixing school and

colleges, highways etc.

BIBLIOGRAPHY

RAI. G.D. “NON CONVENTIONAL ENERGY SOURCES”, KHANNA

PUBLISHERS, DELHI.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 42

International Journal of Engineering Trends and Technology (IJETT) – Volume1 Issue2 – May 2011

RAMESH. R, UDAYA KUMAR, K.ANANDAKRISHNAN “RENEWABLE

ENERGY TECHNOLOGIES”, NAROSA PUBLISHING HOUSE, MADRAS.

A.K.SAWHNEY. “A TEXT BOOK OF ELECTRICAL, ELECTRONICS,

INSTRUMENTATION AND MEASUREMENTS”

B.L.THERJA, A.K. THERAJA. “A TEXT BOOK OF ELECTRICAL

TECHNOLOGY”

G.R.NAGPAL. “POWER PLANT ENGINEERING” KHANNA PUBLISHERS,

DELHI.

T.NEJAT VEZIROYGAL , ALTERNATIVE ENERGY SOURCES-III,

HEMISPHERE PUBLISHING CO.,

BARBARA KEILER, ENERGY ALTERNATIVES, LUSCENTR BOOKS.

PRABHU T.J. FUNDAMENTALS OF MACHINES DESIGN,2009

DESIGN DATA, PSG COLLEGE OF TECHNOLOGY,2007

BHANDARI V.B. “DESIGN OF MACHINE ELEMENTS”- TATA MCGRAW

HILL,2007

SHIGLEY

J.E.

AND

MISHEKA

“MECHANICAL

ENGINEERING

DESIGN”MCGRAW HILL,2007

PANDYA AND SHAH “ELEMENTS OF MACHINES DESIGN ”,2000

MAITRA, HANDBOOK OF GEAR DESIGN,TATA MCGRAW HILL,1995

GERE TIMOSHENKO “MECHANICS OF MATERIALS” CBS,1997.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 43