Value Addition of Computer Work Station Value Engineering Concept

advertisement

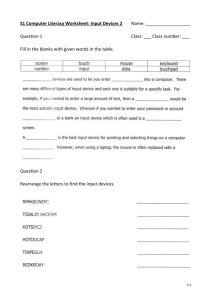

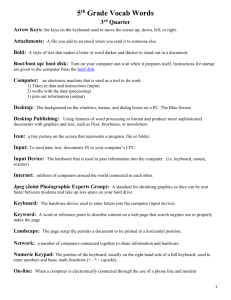

International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 Value Addition of Computer Work Station Manufactured in Furniture Industry by using Value Engineering Concept #1 Dr. S.P. Kallurkar, #2Mr. M. A. Chougule #3Dr. P.N. Nemade #1 Principal, AET’s Atharva College of Engineering, Charkop Naka, Malad (West) Mumbai. #2 Principal, A.G. Patil Polytechnic Institute, Vijapur Road, Solapur (Maharashtra),India. #3 Professor, AET’s Atharva College of Engineering, Charkop Naka, Malad (West) Mumbai. ABSTRACT - Value Engineering is used to design the product that will represent the optimum value to the manufacturer and customer. Value Engineering is a systematic methodology for continuous improvement of products, process etc. The basic fundamental of Value Engineering can be implemented in any product to optimize its value for customer satisfaction by keeping same cost or by increasing the product cost to some extent with value addition. A computer work station manufactured in a furniture industry is taken for optimization of its value in which the product is designed by using value engineering concept. Existing computer work station consists of table top, base top (middle), base top (lower) base top (side), keyboard base, keyboard side strip, keyboard stopper, steel frame, slider, keyboard guide strip with rexin and stud. This product is modified with value addition by reducing length of keyboard and by adding one drawer with lock and key and removing the base top (lower), there by which some required material can be stored in the drawer safely. This drawer can be manufactured from waste cut pieces of board. Also the length of keyboard is reduced thereby which the cost is also reduced. Key words: Value Engineering, Value addition, Computer Work Station, Product Improvement, Furniture Industry. 1. INTRODUCTION Fundamentally, Value Engineering (VE) is a systematic process to improve the value of a product. VE began in the industrial sector in the 1940s and 50s, in the context of product design. Its beginnings are usually attributed to Lawrence Miles, who pioneered its use at General Electric in 1947. Since then, VE methods and applications have expanded significantly and have been applied in a wide variety of environments, from building construction to health care. Similar processes appear under analyzing the function and the cost of the object, the core is to analyze the function. ISSN: 2231-5381 several different names, including Value Analysis and Value Management. The Society of American Value Engineers International, or SAVE, uses the broad term “Value Methodology,” defined as “the systematic application of recognized techniques which identify the functions of the product or service, establish the worth of those functions, and provide the necessary functions to meet the required performance at the lowest overall cost.” A few descriptions of VE concepts are necessary to understand what is considered to be part of VE. First, the product under consideration: this product may be virtually anything; some examples are manufactured objects, buildings, management plans, and road segments. SAVE states that the Value Methodology, or what we shall call VE, “can beneficially be applied to virtually all areas of human endeavor,” “wherever cost and/or performance improvement is desired.” In the construction industry, VE is usually applied to individual projects at various points in their development, particularly between the design and construction phases. Next, it is important to understand what constitutes the value of the product, since “the main objective of VE is to improve value.” Several approaches have been proposed to define and measure “value.” Value Engineering is a directive significance way to the improvement of the products’ cost and function, and there are some disadvantages of the computer work station. Though there are researches on the improvement of the computer work station, we put emphasis on the aesthetic and design parameters. Through evaluating the improving program, we can see that the computer work station improved based on the Value Engineering can solve the disadvantage of material used, lacking of different sized material and design of product with value addition which also reduces the cost. Value Engineering is a technical and economic method which studies on how to achieve the necessary function with the lowest cost. The main idea of Value Engineering is to enhance the value of the object through 2. ABC Analysis in the Furniture Industry Every manufacturing firm requires allocation of raw materials consumption, labor, and overhead expenses http://www.ijettjournal.org Page 2846 International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 to processed goods in order to determine the final manufacturing costs. In most industries, manufacturing costs range from 60 to 70 percent of the final sale price. Therefore, the need for effective cost allocation systems is vital to control manufacturing costs. In manufacturing firms such as the furniture industries, raw materials and labor might be assigned directly to a product, process, or activity. However, some overhead or indirect costs require the establishment of distributing or cost driving bases to allocate them to final goods. This publication was developed based on concerns from furniture producers that more training in cost accounting methods should be available for practitioners. The paper discusses the basics of cost accounting and explains the strengths and weaknesses of two cost accounting techniques — the direct method and the activity-based costing (ABC) method — using simple examples and applications in the furniture industry. Figure 1 ABC Analysis A class items which represent about 10-15% of the total parts count but account for 70% of the total product cost B Class items which represent the next 20% of the total parts count and the next 20% of the total product costs (for a total of 90% C Class items which represent 70% of the total items, but only about 10% of the total cost. 3. Classification of Product Cost Cost can be classified depending on the financial format used for reporting. For manufacturing companies, cost is usually reported based on product cost. Under this reporting format, the cost needs to be broken out into direct materials, direct labor, and overhead/indirect costs. Direct materials costs are directly linked to a product, activity, or process and sometimes are the largest portion of the total costs. Direct materials can be raw materials or subassemblies as well. Direct labor cost refers to all employees that worked in the manufacturing of a product; they can be allocated by activity, product, or process as well. Collecting direct labor cost information ISSN: 2231-5381 might require intensive use of information technologies, and these costs are a major driver for business strategy in value-added wood products industries such as the furniture industry, which is very labor intensive. All other manufacturing costs that cannot be classified or traced back to the product, activity, or process are considered “indirect costs” or “overhead”; these might include labor, materials, or supplies. Because overhead costs cannot be directly allocated to a product, activity, or process, a cost driver is needed to allocate the cost into a “cost pool.” A cost pool is a collection of indirect costs assigned to a cost object (machine hours, units produced, etc.). Some examples of indirect costs/overhead in a wood products industry include glue, paint, sandpaper, tooling, electricity, hardware, insurance, water, administrative salaries, and energy. 4. Computer Work Stations Figure 2 Computer Work Station (Existing) Model No.: CWS-1002 Figure 3 Computer Work Station (Proposed) Model No.: CWS-1009 5. Value Engineering Analysis of the Computer Work Station http://www.ijettjournal.org Page 2847 International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 1. Distribution of cost The Existing computer work station consists of table top, base top (middle), base top (lower) base top (side), keyboard base, keyboard side strip, keyboard stopper, steel frame, slider, keyboard guide strip with rexin and stud. Existing computer work station is modified by reducing length of keyboard and by adding one drawer with lock and key and removing the base top (lower). There by which some material can be stored in the drawer safely. This drawer can be manufactured from waste cut pieces of board. Also the length of the keyboard is reduced thereby which the cost is also reduced. According to the principle of classification, if cumulative proportion of total costs of the component is between 60%-70%, the component is classified as the A classification, if it is between 15%-20%, the component is classified as the B classification, and if it is near 10%, the component is classified as the C classification. 2. Analyzing of function The basic function of the computer work station is to hold the all parts computer system, and the secondary function is easy to handle, durable and with a beautiful appearance. Through analysis of function of each component, we define the function of table top is to support the computer, base top (middle) is to support the printer and UPS, base top (side) is to support the CPU, keyboard base is to support keyboard, keyboard side strip is to hold slider, keyboard stopper is to restrict extra movement, steel frame is to hold top, the function of slider is to hold keyboard, keyboard guide strip with rexin is to provide comfort, drawer is to hold the material and stud is to support weight and leveling. The function definition of computer work station’ component is shown in table no.2. 3. Functional evaluation 3.1 Defining the functional coefficient (1) Defining functional importance coefficient: Calculating the importance coefficient using absolute evaluation method which asks 6 operators to grade for each function. Sum up the grade of each function given by the 6 operators, and then calculate the importance coefficient using the total grade of each function given by the 6 operators to divide by the total grade of the computer work station. The grade given by operators and the result of calculating the functional importance coefficient are just like table no.1 shown. From the result, we can see that functional importance coefficient of support the computer is 31.17%, functional importance coefficient of easy to handle is 21.16%, functional importance coefficient of durable is 23%, functional importance coefficient of beautiful appearance is 15% and Fictional importance coefficient of hold other material is 9.16% (2) Calculating the functional evaluation coefficient of key components. Asks 6 operators to grade for each function of each component, the total grade of each function is 100, which is shown in table no.1. Then calculate the functional coefficient of each component shown in table no.3 by ISSN: 2231-5381 multiplying functional importance coefficient which is shown in table no.1 and the functional proportion coefficient which is shown in table no.2. From the result we can see that functional evaluation coefficient of Steel Frame, Table Top, Drawer with Lock & Key, Keyboard base, Base Top (Middle), Base Top (Side), Keyboard side strip, Slider, Stud, Keyboard guide strip with rexin, Keyboard stopper is 0.2901, 0.2476, 0.1358, 0.0763, 0.03538, 0.05518, 0.0075, 0.0653, 0.0453, 0.0225 and 0.018. 3.2 Defining the cost coefficient Calculating the cost coefficient of the 11 key components according to their current cost, the result is shown in table no.6. From the result we can see that the cost coefficient of Steel Frame, Table Top, Drawer with Lock & Key, Keyboard base, Base Top (Middle), Base Top (Side), Keyboard side strip, Slider, Stud, Keyboard guide strip with rexin, Keyboard stopper is 0.3961, 0.1927, 0.1784, 0.0499, 0.0535, 0.0364, 0.0356, 0.0356, 0.0085, 0.0071 and 0.0057. 3.3 Calculating the value coefficient The 11 key components’ value coefficient can be calculated according to functional evaluation coefficient table (table no.5) and cost coefficient table (table no.6), which as table 5.15 shown, in order to determine the target of improvement. The value coefficient of Steel Frame, Table Top, Drawer with Lock & Key, Keyboard base, Base Top (Middle), Base Top (Side), Keyboard side strip, Slider, Stud, Keyboard guide strip with rexin, Keyboard stopper is 0.7323, 1.2848, 0.7612, 1.5290, 0.6613, 1.5159, 0.2106, 1.8342, 5.3294, 3.1690 and 3.1578. So the order of the components to be improved is keyboard side strip, base top (middle),steel frame, Drawer with lock and key, table top, base top (side), keyboard base, slider, keyboard stopper, keyboard guide strip with rexin and finally stud, 3.4 Result of value Analysis According to the value coefficient of the 11 key components shown in table no.7, we can come to a conclusion: (1) Drawer with lock and key, Keyboard side strip, Steel frame, and Base top (middle) are the main components need to be improved, for their value coefficients are less than 1, which means the function are too less or the cost are too much. (2) Table top, Keyboard base, base top (side) and slider need not to be improved for their value coefficients are close to 1 which means the function and the cost are nearly the same. (3) The coefficients of Keyboard stopper, keyboard guide strip with rexin and stud are more than 1, which means the cost is already lower compared with function that has already met the needs. And in this condition, Base top (Side), slider, keyboard guide strip with rexin and stud are not the target of value analysis, we may neglect the analysis of them. http://www.ijettjournal.org Page 2848 International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 Table-1 ABC Analysis of the Computer Work Station Name of Component Proportion of the Total No. Qty. Steel Frame 1 Table Top Drawer with Lock & Key Keyboard base 1 1 Base Top (Middle) 5.26% 5.26% Current Cost in Rs. Proportion Cumulative of Total Cost Proportion of in Rs. Total Cost in Rs. Classification 555 39.61 39.61 A 270 19.27 58.88 A 250 17.84 76.72 A 5.26% 70 4.99 81.71 A 1 5.26% 75 5.35 87.06 B Base Top (Side) 1 5.26% 51 3.65 90.71 B Keyboard side strip 3 15.79% 50 3.57 94.28 C Slider 4 21.05% 50 3.57 97.85 B Stud 4 21.05% 12 0.86 98.71 C Keyboard guide strip with rexin 1 5.26% 10 0.72 99.43 C Keyboard stopper 1 5.26% 8 0.57 100 C Total 19 100% 1401 100 5.26% 1 Graph 1 ABC Analysis of the Computer work station (Proposed) Table-2 Function Definition of Computer Work Station Components Name of Part (Component) Steel Frame Function Definition Table Top Support Computer Drawer with Lock & Key Hold Material Keyboard base Support Keyboard ISSN: 2231-5381 Hold Top http://www.ijettjournal.org Page 2849 International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 Base Top (Middle) Support Printer Base Top (Side) Support CPU Keyboard side strip Hold Slider Slider Hold Key Board Stud Support Weight Keyboard guide strip with rexin Provide Comfort Keyboard stopper Restrict Extra movement Table-3 Calculation of the Functional Coefficient of Furniture Components Function of Computer work station Support the Computer A 30 Expert Rating B C D 32 25 35 28 40 General Comment Score 191 E F Functional Importance Coefficient 31.66% Easy to handle 25 20 20 20 33 20 127 21.16% Durable 30 23 25 20 20 20 138 23% Beautiful Appearance 10 15 15 20 15 15 90 15% Hold other Material 05 10 15 05 15 05 55 9.16% 100 100 100 100 100 100 600 100 Total Table-4 Functional Distribution of key Components of Computer Work Station Functional Items Name of Component Support the Easy to Beautiful Computer handle Durable Appearance Hold other Material Steel Frame 35 25 30 20 30 Table Top 30 20 25 20 25 Drawer with Lock & Key 05 10 20 20 25 Keyboard base 10 10 05 05 05 Base Top (Middle) 05 00 00 10 05 Base Top (Side) 10 00 05 05 05 Keyboard side strip 00 00 00 05 00 Slider 00 20 10 0 00 Stud Keyboard guide strip with rexin 05 00 05 05 05 00 05 05 00 05 Keyboard stopper 00 05 00 05 00 100 100 100 100 100 Total ISSN: 2231-5381 http://www.ijettjournal.org Page 2850 International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 Graph 2 Functional Distribution of key Components Table-5 Functional Evaluation Coefficient of key Components of Computer Work Station Functional Items Name of Component Steel Frame Table Top Drawer with Lock & Key Keyboard base Base Top (Middle) Base Top (Side) Keyboard side strip Slider Stud Support the Computer 0.1108 0.0949 Easy to handle 0.0529 0.0423 Durable Beautiful Appearance 0.069 0.03 Hold other Material 0.0274 0.03 0.0229 0.0575 Functional Evaluation Coefficient 0.2901 0.2476 0.0229 0.0158 0.02116 0.046 0.03 0.0316 0.02116 0.0115 0.0075 0.00458 0.0763 0.015 0.00458 0.03538 0.0075 0.00458 0.05518 0.0075 0 0.0075 0.0158 0.0316 0 0 0 0 0 0.0423 0 0.0115 0 0.023 0 0.1358 0 0 0.0653 0.0158 0.0105 0.0115 0.0075 Keyboard guide strip with rexin 0 0.0105 0 0.0075 0.00458 0.0225 Keyboard stopper 0 0.0105 0 0.0075 0 0.018 0.3163 0.21132 0.23 0.15 0.09152 1 Total ISSN: 2231-5381 http://www.ijettjournal.org 0.0453 Page 2851 International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 Graph 3 Functional Evaluation Coefficient of key Components Table-6 Cost Coefficient of Furniture Components Name of Component Cost in Rs. Cost Coefficient Steel Frame 555.00 0.3961 Table Top 270.00 0.1927 Drawer with Lock & Key 250.00 0.1784 Keyboard base 70.00 0.0499 Base Top (Middle) 75.00 0.0535 Base Top (Side) 51.00 0.0364 Keyboard side strip 50.00 0.0356 Slider 50.00 0.0356 Stud 12.00 0.0085 Keyboard guide strip with rexin 10.00 0.0071 Keyboard stopper 08.00 0.0057 1401.00 1 Total ISSN: 2231-5381 http://www.ijettjournal.org Page 2852 International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 Graph 4 Cost Coefficient of key Components Table-7 Value Coefficient of Furniture Components Functional Evaluation Coefficient (F) Cost Coefficient (C) Value Coefficient (V)=F/C Steel Frame 0.2901 0.3961 0.7323 3 Table Top 0.2476 0.1927 1.2848 5 Drawer with Lock & Key 0.1358 0.1784 0.7612 4 Keyboard base Name of Component Order of Improvement 0.0763 0.0499 1.5290 7 Base Top (Middle) 0.03538 0.0535 0.6613 2 Base Top (Side) 0.05518 0.0364 1.5159 6 Keyboard side strip 0.0075 0.0356 0.2106 1 Slider 0.0653 0.0356 1.8342 8 Stud 0.0453 0.0085 5.3294 11 Keyboard guide strip with rexin 0.0225 0.0071 3.1690 10 0.018 0.0057 3.1578 9 Keyboard stopper Table-8 Target Cost of Furniture Components Functional Evaluation Component Name of Component Coefficient Cost in Rs. (F) Cost Coefficie nt (C) Value Coefficie nt (V)=F/C Target Cost in Rs. Amount of Cost Reduction Steel Frame 0.2901 555.00 0.3961 0.7323 356.82 +198.18 Table Top 0.2476 270.00 0.1927 1.2848 304.75 -34.75 Drawer with Lock & Key 0.1358 250.00 0.1784 0.7612 167.23 +82.77 Keyboard base 0.0763 70.00 0.0499 1.5290 93.95 -23.95 Base Top (Middle) 0.03538 75.00 0.0535 0.6613 43.69 +31.31 Base Top (Side) 0.05518 51.00 0.0364 1.5159 67.87 -16.87 Keyboard side strip 0.0075 50.00 0.0356 0.2106 9.33 +40.67 Slider 0.0653 50.00 0.0356 1.8342 80.42 -30.42 Stud 0.0453 12.00 0.0085 5.3294 55.72 -43.72 Keyboard guide strip with rexin 0.0225 10.00 0.0071 3.1690 27.68 -17.68 0.018 08.00 0.0057 3.1578 22.54 -14.54 1 1401.00 1 1 1230 171.00 Keyboard stopper Total ISSN: 2231-5381 http://www.ijettjournal.org Page 2853 International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue7- July 2013 Graph 5 Target Cost of Components 6. Conclusion The value engineering analysis suggests that the existing Computer work station can be modified in to proposed computer work station by adding one drawer with lock and key and removing the base top (lower) by which the customer requirements are can be fulfilled. Cost analysis of the existing computer work station (Rs.1194.00) and proposed Computer work station (Rs.1401.00) shows that the cost is increasing by Rs. 207.00 but in the proposed computer work station we have added one drawer which can be manufactured by using waste cut pieces therefore only lock and fitting screws are required which costs Rs. 30.00. Therefore the cost of drawer can be reduced from Rs 250.00 to Rs. 30.00 as it is manufactured from waste cut pieces. Also in the proposed computer work station, the base top (lower) is also removed with reducing the size of the keyboard base in which the material saving is achieved. The total cost of proposed computer work station can be reduced from Rs. 1401.00 to Rs. 1181.00. Comparing this with existing computer work station, we achieved the cost saving of Rs.13.00 with Value addition by adding one drawer with lock and key in the proposed computer work station. 7. References: [1] The Use of Target Cost Techniques to Achieve Market Dominance with New Technology by Renee V. Dorjahn [2] REN Jie, ZHANG, Xiao-hua. (2008). Appliance of Value Engineering on the construction enterprise. Construction Economy, 6:50-51 ISSN: 2231-5381 [3] Value Engineering in Product Renovation Fang-Lin CHAO, Chien-Ming SHIEH and Chi-Chang LAI [4] The ABCs of Cost Allocation in the Wood Products Industry: Applications in the Furniture Industry by Henry Quesada-Pineda, Assistant Professor, Wood Science and Forest Products [5] Lawrence D. (1972). Miles. Techniques of Value Analysis and Engineering, New York, Mcgraw-Hill (Tx), June. [6] Quality Function Deployment, Value Engineering and Target Costing, an Integrated Framework in Design Cost Management: Mathematical Programming Approach F. Jariri_ and S.H. Zegordi [7] Application of VE Methodology To Product Development That Warrants Compliance To Key Certification Requirements - Daniel Arockiam and Raghavendra Rao, Tata Consultancy Services (TCS), India [8] Techniques of Value Analysis and Engineering by Lawrence D. Miles 2nd edition, McGraw Hill Text (1972). [9] Structured Cost Reduction Value Engineering by the Numbers David Meeker F James McWilliams Hewlett-Packard Company. [10 Improving Nickeling Process through Value Engineering Technique by: Chinmay Das [11] An analysis of materials and plant in current use in the furniture industry by T. G. Doyle [12] LI, Zhi-rong, XUE Song, NI Cui-ping (2009). Installation, maintenance and conservation of the headstock gear. Water Conservancy of Jiang Su Province, 12:27-28 http://www.ijettjournal.org Page 2854