Document 12917232

advertisement

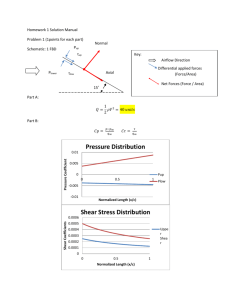

International Journal of Engineering Trends and Technology (IJETT) – Volume 32 Number 2- February 2016 Simulating Drag and Lift Coefficient Variation of the MI VAWT1 airfoil with Angle of Attack at Low Reynolds Number Krishpersad Manohar#1, Rikhi Ramkissoon#2, 1 Senior Lecturer, Mechanical and Manufacturing Department, The University of the West Indies, St. Augustine, Trinidad and Tobago. 2 Ph.D. Candidate, Mechanical and Manufacturing Department, The University of the West Indies, St. Augustine, Trinidad and Tobago. Abstract — Due to the complexity of shear layer development over an airfoil surface, measurements of time-resolved fluctuating surface pressure within the separated flow region are difficulty. Modelling the flow characteristics with computer generated simulations is an alternative for overcoming this difficulty. The DesignFoil simulation served as a tool in analysing the flow regime across the MIVAWT1 airfoil. The results showed that the point at which transition from laminar to turbulent flow occurred moved progressively up towards the leading edge as the angle of attack increased from 0o to 15o. Also, within this range the change in drag coefficient was small and the lift coefficient increased linearly up to 10o and then started decreasing. The results are consistent with published work. Keywords — Lift Coefficient, drag coefficient, airfoil, DesignFoil, vertical axis wind turbine. I. INTRODUCTION (SIZE 10 & BOLD) From as early as 5000 B.C wind energy was used to enhance humankind energy demands. For centuries wind turbines has served as a practical way to capture and convert the kinetic energy of the wind to mechanical and in more recent times directly to electrical energy [1]. Today, wind-powered generators operate in every size range, from small turbines for battery charging at isolated locations to large, near-gigawatt-size offshore wind farms that provide electricity to national electric transmission systems [2]. The straight bladed Darrieus vertical axis wind turbine (VAWT) is very attractive for its low cost and simple design [3]. Selection of airfoil was one of the most critical factors in achieving better aerodynamic performance. Airfoil selection is also affected by the optimum dimensions of a fixed-pitch straight-bladed Darrieus type vertical axis wind turbine (SB-VAWT), along with solidity, radial arm parasitic drag and aspect ratio. Airfoil related design changes also has the potential for increasing the cost effectiveness of SB-VAWTs. This is one of the ISSN: 2231-5381 simplest type of wind turbines and has good potential for diversified urban and rural applications. It has been shown by Islam etal. [4] that conventionally-used old NACA 4-digit symmetric airfoils were not suitable for smaller capacity SBVAWT. Rather, it would be advantageous to utilize a high-lift and low-drag asymmetric thick airfoil suitable for low speed operation typically encountered by SB-VAWT. In this regard a special purpose airfoil called the MI-VAWT1 airfoil was designed by Islam etal. from the University of Windsor, Windsor, Ontario, Canada in 2007 [4, 5]. II. THE MI-VAWT 1 AIRFOIL To improve the performance of the straightbladed vertical axis wind turbine (SB-VAWT), sensitivity analyses were conducted with different geometric features to understand their effects on performance of SB-VAWT. Subsequently, a special purpose airfoil named ―MI-VAWT1‖ was designed by utilizing computer simulations [4, 5]. A schematic of the MI-VAWT1 airfoil is shown in Figure 1. Figure 1. MI-VAWT airfoil [4] The performance of the MI-VAWT1 was superior when compared with that of NACA 0015 and LS-0417 at different Reynolds numbers [4. 5]. The Cpnet values of MI-VAWT1 were higher and the CQnet–λ curves showed superior performance [5]. III. FLOW CHARACTERISTICS DATA To optimize the use of airfoil in low speed applications such as wind turbines, flow characteristics data is a prerequisite. Static surface pressure data, usually in the form of a pressure coefficient distribution, is utilized to estimate locations of flow separation, transition, and reattachment [6, 7, 8]. Lift coefficients are also http://www.ijettjournal.org Page 102 International Journal of Engineering Trends and Technology (IJETT) – Volume 32 Number 2- February 2016 obtained from the pressure coefficient distributions [6, 9]. Time-resolved surface pressure fluctuation measurements can be used for airfoils operating at low Reynolds numbers as the utility of for characterizing the separated flow region. However, due to the complexity of separated shear layer development, studies employing measurements of fluctuating surface pressure in the separated flow region on an airfoil surface at low Reynolds numbers are limited [10, 11]. Modelling the flow characteristics with computer generated simulations is an alternative for overcoming this difficulty. IV. DESIGNFOIL SIMULATION Numerical predictions were done for the MIVAWT1 airfoil the using DesignFoil software which was based on the Hess-Smith panel method [12]. Figures 1 to 4 show the DesignFoil simulation at 0 o, 5o, 10o and 15o angle of attack and the respective values for the lift coefficient and the boundary layer transition at a Reynolds number of 332000. Fig. 2 DesignFoil Simulation at Reynolds number of 332000 and Angle of Attack 5o. The simulation in Figure 2 gave a lift coefficient of 0.422 and a drag coefficient of 0.00456. The transition from laminar to turbulent flow started at 12.86 % along the lifting side and turbulent flow started at 15.71 %. On the non-lifting side of the airfoil the transition from laminar to turbulent flow started at 27.14 % and turbulent flow started at 30.00 %. Fig. 1 DesignFoil Simulation at Reynolds number of 332000 and Angle of Attack 0o. The simulation in Figure 1 gave a lift coefficient of -0.215 and a drag coefficient of 0.0043. The transition from laminar to turbulent flow started at 15.71 % along the lift side and turbulent flow started at 18.57 %. On the non-lifting side of the airfoil the transition from laminar to turbulent flow started at 15.71 % and turbulent flow started at 18.57 %. ISSN: 2231-5381 Fig. 3 DesignFoil Simulation at Reynolds number of 332000 and Angle of Attack 10o. The simulation in Figure 3 gave a lift coefficient of 1.053 and a drag coefficient of 0.0101. Both the laminar and turbulent flow started at 12.86 % along the lifting side. On the non-lifting side of the airfoil the transition from laminar to turbulent flow started at 50.00 % and turbulent flow started at 52.86 %. http://www.ijettjournal.org Page 103 International Journal of Engineering Trends and Technology (IJETT) – Volume 32 Number 2- February 2016 Fig. 4 DesignFoil Simulation at Reynolds number of 332000 and Angle of Attack 15o. The simulation in Figure 4 gave a lift coefficient of 1.238 and a drag coefficient of 0.0207. The transition from laminar to turbulent flow started at 10.00 % along the lifting side and turbulent flow started at 12.86 %. On the non-lifting side of the airfoil the transition from laminar to turbulent flow started at 52.86 % and turbulent flow started at 52.86 %. V. RESULTS The DesignFoil simulation was conducted for Reynolds Number ranging from 332000 to 964000. This corresponded to the relatively low wind velocity range of operation for wind turbines. Figure 5 is a plot of lift and drag coefficient variation with angle of attack at a Reynolds number of 332000. Table 1 shows the simulated lift coefficient and drag coefficient variation with Reynolds Number and angle of attack. Fig. 5 Lift and Drag Coefficient Variation with Angle of Attack at Reynolds number 332000 ISSN: 2231-5381 TABLE 1 DESIGNFOIL SIMULATION RESULTS AT DIFFERENT REYNOLDS NUMBER AND ANGLE OF ATTACK Reynolds Angle of Lift Drag Number Attack Coefficient Coefficient 332000 0 -0.215 0.0043 5 0.422 0.0056 10 1.053 0.0101 15 1.238 0.0207 532000 0 -0.215 0.0039 5 0.422 0.0051 10 1.053 0.0095 15 1.245 0.0206 731000 0 -0.215 0.0037 5 0.422 0.0048 10 1.053 0.0092 15 1.251 0.0201 964000 0 -0.215 0.0035 5 0.422 0.0046 10 1.053 0.0089 15 1.259 0.0198 VI. DISCUSSION AND CONCLUSIONS Due to the complexity of separated shear layer development over an airfoil surface, measurements of time-resolved fluctuating surface pressure within the separated flow region were less common than those performed with separated flow region forming on simpler geometries. For an airfoil the flow conditions changes the location and extent of the separated flow region. As a consequence, it was difficult to design and instrument an airfoil with an array of pressure transducers to adequately resolve and cover the separated flow region for various flow conditions. The DesignFoil simulation served as a tool in analysing the flow regime across the MI-VAWT1 airfoil. The results shown in Figures 1 to 4 indicated that the point at which transition from laminar to turbulent flow occurred moved progressively up towards the leading edge as the angle of attack increased from 0o to 15o. This result was consistent with published work [12, 13, 14]. Figure 5 shows a plot of lift and drag coefficient variation with angle of attack between 0o to 15o. Within this range the change in drag coefficient was small, however, the lift coefficient increased linearly up to 10o and then started decreasing. The results are consistent with published work that showed a region of conventional linear growth in the lift coefficient with the angle of attack at low angles [14, 15]. The change in lift and drag coefficients with increasing Reynolds over the range simulated was negligible. This can be attributed to the low Reynolds number which is associated with the low wind velocity for wind turbines. http://www.ijettjournal.org Page 104 International Journal of Engineering Trends and Technology (IJETT) – Volume 32 Number 2- February 2016 REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] History of Wind Energy, Wind Energy Foundation, 1501 M Street, NW, Suite 900, Washington, DC 20005, 2016. Timeline: The history of wind power. [Online]. Available: http://www.The guardian. com /environment / 2008 / oct / 17 / wind-power-renewable-energy. R. Ramkissoon., and K. Manohar, ―Increasing the power output of the Darrieus Vertical Axis Wind Turbine,‖ British Journal of Applied Science & Technology, Vol.3, No.1, pp.77-90, 2013. M. D. Islam, S. K. Ting, and A. Fartaj, ―Desirable Airfoil Features for Smaller-Capacity Straight-Bladed VAWT,‖ Wind Engineering, Vol. 31, No.3, pp. 165–196, 2007. M. D. Islam, S. K. Ting, and A. Fartaj, ―Design of a special purpose Airfoil for Smaller-Capacity StraightBladed VAWT,‖ Wind Engineering, Vol. 31, No. 6, pp. 401–424, 2007. I. Tani, ―Low-Speed Flows Involving Bubble Separations,‖ Progress in Aerospace Sciences, Vol. 5, pp. 70–103, 1964. M. M. O'Meara and T. J. Mueller, ―Laminar Separation Bubble Characteristics on an Airfoil at Low Reynolds Numbers,‖ AIAA Journal, Vol. 25, No. 8, PP. 1033-1041. 1987. S. Yarusevych, P. E. Sullivan and J. G. Kawall, ―On Vortex Shedding from an Airfoil in Low-Reynolds- ISSN: 2231-5381 [9] [10] [11] [12] [13] [14] [15] Number Flows,‖ Journal of Fluid Mechanics, Vol. 632, pp. 245-271, 2009. T. Lee and P. Gerontakos, ―Investigation of Flow Over an Oscillating Airfoil,‖ Journal of Fluid Mechanics, Vol. 512, pp. 313-341, 2004. M. Kiya and K. Sasaki. ―Structure of a Turbulent Separation Bubble,‖ Journal of Fluid Mechanics, Vol. 137, pp. 83-113, 1983. N. J. Cherry, R. Hillier and M. E. M. P. Latour, ―Unsteady Measurements in a Separated and Reattaching Flow,‖ Journal of Fluid Mechanics, Vol. 144, pp. 13-46, 1984. T. J. Mueller, ―The Influence of Laminar Separation and Transition on Low Reynolds Number Airfoil Hysteresis,‖ Journal of Aircraft, Vol. 22. No. 9, pp. 763– 770, 1985. D. G. Mabey, ―Analysis and Correlation of Data on Pressure Fluctuations in Separated Flow,‖ Journal of Aircraft, Vol. 9, No. 9, pp. 642–645, 1972. T. J. Mueller, ―The Influence of Laminar Separation and Transition on Low Reynolds Number Airfoil Hysteresis,‖ Journal of Aircraft , Vol. 22, No. 9, pp. 763–770, 1985. W. A. Timmer, ―Two-Dimensional Low-Reynolds Number Wind Tunnel Results for Airfoil NACA 0018,‖ Wind engineering, Vol. 32, No. 6, pp. 525–537, 2008. http://www.ijettjournal.org Page 105