Zero Carbon House Worcester Zero Carbon House: Code for Sustainable Homes:

advertisement

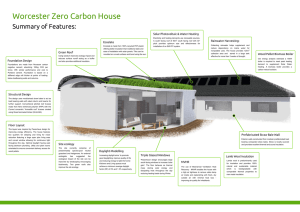

Zero Carbon House Worcester Zero Carbon House: This project is to design a new zero carbon house located near the centre of Worcester. The building is to be largely self-sufficient in terms of its services and energy usage and is to conform to Level 6 of the Code for Sustainable Homes (CSH) Aims & Objectives: The team has been appointed to develop the project from a conceptual design stage to Stage D of RIBA plan of work. This entails producing a detailed tender proposal with careful consideration to specific elements such as: 6 5 4 3 2 1 Structure: Modularised straw bales to act as load bearing walls. Steel Column and Beams Conventional pitched roof trusses - fibre reinforced polymer (FRP). Curved concentric “Armadillo roof” trusses Glued laminated timber (GLULAM). Code for Sustainable Homes: The CSH provides the national standard for assessing the environment performance of the design and construction for new homes. It encourages greater innovation and continuous improvements in sustainable home building practice. The Code is currently not mandatory, but the government has set targets that all new homes must meet a zero carbon standard by 2016 – Code Level 6. The CSH uses a rating system represented by ‘stars’ ranging from one to six . One star is the entry level – above the level of the Building Regulations and six stars is the highest level and mark of quality and indicates a ‘zero carbon home’. The Code measures the environmental impact of a home against nine design Foundations: Foundations made from Novacem carbon negative cement. Cement absorbs 100kg of CO2 per tonne of cement produced. Performance and cost similar to Portland cement. Foundation based on a stiffened edge raft. Thicker at points of loading: below loadbearing walls and columns. Energy / CO2 Water Materials Surface water run-off Floor Plan: Waste Pollution Health and wellbeing Management Ecology Air tightness strategy Exploded View of Structure Waste water treatment management Roof Trusses Mechanical Ventilation Heat Recovery (MVHR) Passive heating and cooling design Foundation and ground floor slab design Loadbearing Walls Solar Photovoltaic & Water Heating MVHR enables houses with a high air tightness to remove stale damp air inside and replenshing with fresh, dry outside air with minimal heat loss. Low embodied energy structure Renewable energy strategy This academic poster describes and illustrates the design characteristics of our proposal, emphasising the architectural, technological and functionality of the home. Warm, moist air from bathrooms and the kitchen are extracted and a heat exchanger (HEX) recovers heat. Outside Heat is transferred to the cold, dry outside air through the HEX and are typically over 85% effective. MVHR removes the need for opening windows and can be reversed to provide cooling. Bedrooms Living Areas Office Bathrooms Kitchen Site ecology: Foundations 50m2 south facing roof with 30° pitch Solar Water heating can supply up to 60% of hot water needs requiring an area of 5m2 4kW PV system requires area of 3m2 Electricity used immediately and remainder is fed back into National Grid for payback Panels are self-cleaning by rainfall Using seedum improves ecology impact Reduce surface runoff acting as a buffer Rainwater harvested for outdoor usage Provides additional thermal insulation HEX Columns and Beams Becoming carbon zero requires meeting all electricity and heating demands using renewable sources. Green Roof Warm, dry air is circulated by the Heat Exchanger through ducting into rooms throughout the house. Key areas of innovation Two quarters for sleeping and living for noise reduction. Open plan living area and curved window allow for a continuous light source throughout the day. Optimal daylight having east facing bedrooms, south facing lounge and west facing dining room. Based on Passivhaus design for improving energy efficiency. Bathrooms and WC's placed adjacent for easy plumbing. Utility and plant rooms orientated to ensure convenient delivery access for wood pellets. Ecoslate The site currently comprise of predominately species-poor neutral grassland and hedgerows. An external ecologists has suggested the ecological impact of the site can be improved by: 100% Recycled PET plastic Self-bonding using sun's heat Better insulation compared to traditional slate Lightweight (20kg/m2) Easy to install with solar panels 50 year warranty No maintenance Growing native trees, coppice and hedgerow climbing species Use of turf containing a mix of grass and flower species The provision of three bat boxes and three bird boxes Integrating green roof within the roof design Lamb Wool Insulation Rainwater Harvesting: Derived from lambswool 100% Natural and sustainable material 100% Biodegradable Absorbs 40% of Volume in moisture Retains high U-Value for 50 Years High thermal conductivity Collecting rainwater helps supplement and reduce dependancy on mains water for nonpotable uses. Only 80L of water p/p per day can be used. Rainwater is collected from roof (256m2) Estimated water harvesting per year: 57600L Effective through more than 3 weeks drought Water is stored in a large tank (3600L) Rainwater can be used for: Washing machines, toilets and outdoor uses Daylight Modelling Rainwater Harvesting Green Roof Solar PV & Heating Increasing daylight aims ‘to promote good daylighting and improve quality of life and reducing energy to light the home’ Kitchens and Living spaces must achieve a minimum average daylight factor (DF) of 2% and 1.5% respectively Wood Pellet Biomass Boiler Triple Glazed Windows Preliminary energy analysis estimaed a 15kW boiler is required to meet peak heating demand to supplement Solar Water heating. 'Passivhaus' design encourages large south facing windows to increase 'solar gain'. The floor behaves as thermal mass storing solar energy and dissipating heat throughout the day reducing heating loads during Winter. Daylight modelling has shown our kitchen design to achieve an average of 11.3% Good uniformity and over 80% of the working plane receives direct light from the sky High DF = possible overheating problems in the summer; this is being addressed in our heating and cooling strategy Prefabricated Straw Bale Wall Exterior walls constructed from modular prefabricated load bearing compacted straw bales. Straw is locally sourced and these offers superior properties: Burning Biomas is carbon neutral Wood pellets offer convenience will be stored in silos and fed automatically into boiler. Delivery required 2-3 times per year. The RHI - Renewable Heat Initiative supported by the Government provides extra payback. Used in combination with underfloor heating Thermal losses are reduced using triple glazing with timber/aluminium frame: U = 0.63 W/m²K Wood Box Straw Plaster High thermal insulation: U = 0.13 W/m²K Sound reduction: 50dB Low embodied energy Breathable - reducing damp Prefabrication reduces construction time and damp issues during construction Great fire protection: 2hrs 15Mins Hannah Rowland, Erin Dunn, Ashan Craig, Jonny Martin, Chris Goodwin, Will Jebb, Luke Parry, Emily Huynh Prof. Toby Mottram, Kieran Gosling Background reading: case studies, materials and technologies Initial concepts begun In depth research on: solar PV and water heating, triple glazing, green roofs, ventilation, foundations. Structural considerations: spans, pitch of roof. Week 2 Week 4 Drawing updated Further roof research Loading considerations Roof material decided Heating calculations and consideration Week 6 Week 8 Structural Work Developed Lighting Considered Detailed design calculations begin: Foundations Structures Energy calcuations via SAP Academic poster Week 10 Construction planning and on-site assembly. Final SAP energy calculations February Week 16 April Timeline Week 1 Formation of group Outline of plan for work Week 3 2nd and 3rd iterations of house designs presented. Final floor plan drawing produced. Week 5 Further technologies, energy and materials research. Week 7 Floor plan finalised Roof designs and materials developed Week 9 Solidworks model produced Insulation ideas developed Week 15 Structural Work developed CRM considered Daylight modelling begun January Creation of one overall knowledge document Finalisation of materials and technologies choice March Continuation of detailed design calculations Waste conservation and waste water treatment strategies. May Final tender proposal submission Tender presentation to client