―Pre engineered Toilet Block

advertisement

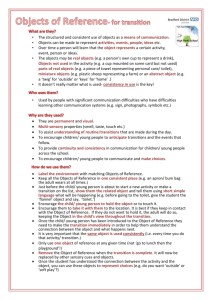

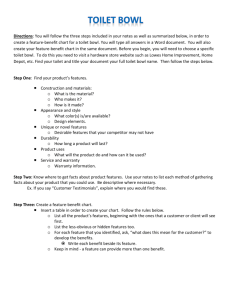

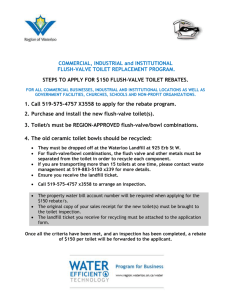

International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 ―Pre-engineered Toilet Block Design for Village Housing” Neha Patel1, Shraddha Sharma2 1 P.G. Scholar, 2 Asso.Prof. Civil Engineering Department, BIT, DURG, INDIA Abstract— Engineers are always looking for ways to increase the speed and efficiency of construction projects. Here we look at an economical design and construction of a toilet block for village houses. In China one company is using pre-fabricated components to build a 30 storey building in less than three weeks. These components are built off-site and then pieced together like flat pack furniture to create the finished building. Systems such as air conditioning, electrical wiring and the water supply are built into the components in advance of assembly. With migration into Chinese cities at extremely high levels it is necessary for engineers to think outside of the box to develop innovative housing solutions such as this one. First broadcast on 'Supersized Earth' on BBC1 in November 2012. In India toilet block for village housing is on top priority because village women have to go to open fields. shuttering of entire floor is ready. Designed reinforcement is erected on the made up plinth and it is then enclosed with shuttering plates. Provisions of openings for doors and windows are made in the shuttering of walls. The slab shuttering is designed with flow pipes so that the concrete slurry poured at slab level runs through entire farm work for walls and slab. Another video we found on internet depicts about use of discarded mineral water bottles. Inspired by above instances we decided to review the existing construction techniques and building materials and come out with most viable design of a toilet block to overcome village women problems. In the quest of economical and multipurpose solution of the problem conventional techniques and pre-engineered techniques have been analysed. Finally pre-engineered technique with modern construction materials resulted in most feasible solution. The present paper therefore invites young budding engineers to take up pre-engineered toilet block making as start-up unit to begin their career as entrepreneurs. The report will help them in arranging bank finance to begin the enterprise. A recent survey of owners of structures identified the following five best features: 1. Ease of erection 2. Solid construction and strength 3. 100% usable space with no floor or ceiling obstructions 4. Sleek contemporary appearance 5. Easy interior to finish or insulate Pre-engineered structures satisfy all the above requirements. In Pre-engineered design a unique combination of materials make construction simple and trouble free. The buildings are designed and erected by people without previous construction experience. In such constructions, more work is done at the manufacturing centre and less work on site. In such construction the building is up in just few days- not weeks, months or years. Pre-Engineered steel building (PEB) or Metal building systems with steel roofing are gaining popularity very fast for the following advantages. Though the concept is quite old with proven technology in advanced countries, the concept is still considered almost new in Indian context therefore proposed village toilet block is designed as pre-engineered construction concept. A. Main Design features of Pre-engineered Toilet Keywords—Toilet design, Septic tank, Biogas digester, Preengineered design INTRODUCTION Mr. Narendra Modi, newly elected prime-minister of India, in his 1st formal address to public form red fort, on Independence Day celebration, expressed his deep concern about village women problem. Even after 68 years of independence the village women have to go to toilet in open fields. Therefore they have to restrain their body for natural calls till early morning or late evening when darkness is there. The issue has received focus of many engineers and architects to take up the challenge to design an affordable and economical design so that every village house can be provided with toilet facility. While surfing on internet for selecting suitable building materials and construction technology we found a video on multi-storied building construction technique adopted in developed countries. The entire construction of superstructure of the building above a made up plinth is cast in-situ by R.C.C. Modular design of uniform shuttering plates for walls, columns, beams and slab are first designed and made ready before the construction is started. The walls and slab are made of R.C.C. therefore the casting is done only when the ISSN: 2231-5381 Pre-Engineered Construction Technology Block Following points have been kept in view to arrive at a suitable design of the toilet block: 1. The design must be simple and all component parts of the toilet block may be transported to the customer‘s site easily and assembled within few days. 2. The septic tank design is modified over the conventional type of requirement. It is adopted as portable biogas digester http://www.ijettjournal.org Page 20 International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 having facility to use human excreta as well as animal waste to produce gas to bring saving in cooking fuel used by villagers. 3. The materials used in making the toilet walls comprise mild steel rectangular pipe (40 mm x 25 mm in section) frame covered with composite panels or it may be Tata corrugated PVC sheets. Provision for water supply and electrification is made with in composite material (alloy of aluminium and PVC) panel. 4. The floor is precast R.C.C. slab with glazed tiles or vinyl sheet. B. Size of the Toilet & Sanitary fittings The toilet room is planned on area 1.2 m x 2 m x 2.80 m. Fig. (1).The height of the room is kept 2.8 to 3 m. For water supply PVC pipe and fittings are recommended. The toilet seat can be Indian style/western commode type. The room has wash basin with mirror and nahani traps to drain out floor water. The flooring is made of 0.60 m x 0.60 m superior tiles. On one of the walls PVC door 1.2m x 2.1 m with a ventilator 1.2m x 0.45m is proposed. A) For portable toilet room, all walls and roof are assembled on m. s. rectangular pipes frame with composite material PVC panels of Tata corrugated sheets fitted with nut-bolts. The entire assembly can be dismantled and shifted if required. on both sides. Roof is covered with PVC sheets. On one of the cast in situ walls PVC Door with ventilator is provided. C) After the toilet block is made ready, the outlet of toilet pan is connected to biogas digester and wash basin water is sent to open drain or a soak pit. The biogas digester has another inlet also for adding cow-dung slurry to make continuous supply of kitchen gas. C. Benefits of Biogas digester as septic tank 1) The wastes thrown out in houses and the premises including the droppings of birds and dung of animals could be fed into the digester chamber through the other inlet provided. Thus the surroundings are kept clean and tidy for hygienic life of people 2) By making use of the biogas produced from the digester as cooking fuel, the use of other fuels for cooking, purposes can be reduced and thereby gain financial benefit. 3) Waste sludge from digester is used as bio manure for agriculture use of chemical fertilizers can be reduced and the expenses for the manure can be saved. Quality vegetables and grains can be produced by the application of bio manure. Pre-engineered Toilet Block Components Main components are shown in following fig. (2) and (3) Inside View of toilet View of Portable Toilet Block Fig. (2) Toilet Room connected to a biomass digester Fig. (3) Precast toilet floor with seat Design of portable Toilet Block for village houses View of Portable Toilet Block Biogas digester & stove Fig.1. Pre-Engineered Toilet Block B) For conventional type of toilet block construction Cast in situ walls 10 cm thick plastic bottles Fig.(2) are used as bricks laid in 1:4 cement mortar slurry with shuttering of ply board ISSN: 2231-5381 * Fig. (3) Precast R.C.C. Slab with glazed tiles, Nahani trap for grey water out let and Orissa Pan (toilet seat), wash basin etc. http://www.ijettjournal.org Page 21 International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 * Out let of toilet seat is connected to a portable septic tank (Syntex make) 1 m3 capacity. * Angle iron frame – components pre-engineered size made with MS pipe 25 mm x 50 mm covered on both sides by PVC sheets, with nut bolts and screw arrangement for two long and two short wall panels. One of the long wall panels to carry wash basin and PVC pipe and tap connection * The short wall panel carries a door and another one near to toilet seat carries cistern to flush the seat. * Similar to wall panel roof is also made up of MS pipe 25 mm x 50 mm covered on both sides by PVC sheets. * Entire assembly described above is erected on precast floor after it is transported to work site. * Toilet floor is placed on murrum platform, 0.60 to 0.75 m above biomass digester unit to have gravity disposal of toilet waste in the digester. Fig. (2) Sanitary fittingsThe toilet room is planned on area 1.2 m x 2m. Fig. (1). the height of the room is kept 3 m. For water supply PVC pipe and fittings are recommended. The toilet seat can be Indian style/western commode type. The room has wash basin with mirror and nahani traps to drain out floor water. The flooring is made of 0.60 m x 0.60 m superior tiles. On one of the walls PVC door 1.2m x 2.1 m with a ventilator 1.2m x 0.45m is proposed. * Until recently application of biogas plants have been confined to rural areas, where villagers have dairy farming as their main business. * The innovation in production and marketing methods of biogas highlighted herein, help in commercialization of preengineered toilets in urban areas also. Thus marketing of portable units open many new possibilities to commission biogas plants in residential colonies in towns and even in metro cities suburb areas. * The production and management of proposed system of biogas plants open many new business opportunities in rural areas to absorb unemployed villagers. Specification for biogas digester to be used with preengineered toilet Capacity (Ltrs.) 1000 2000 3000 4000 5000 No. of Domestic users 3 Height (mm) 1385 1850 1950 2150 2250 Diameter (mm) 1200 1400 1650 1800 2000 Inlet centre (ram tap 115 115 115 115 115 Outlet centre from top 160 160 160 160 160 Thickness of pipe (mm) 100 100 100 100 100 Air Vent diameter (mm) 50 50 50 50 50 Total Septic Volume (M3) 1.00 2.00 3.00 4.00 5.00 6 10 13 16 Chamber Volume (MJ) 0.67 1.34 2.01 2.68 3.35 A) For portable toilet room, all walls and roof are assembled 0.33 0.66 0.99 1.32 1.65 on angle iron frame with PVC panels fitted with nut-bolts. All Filter Volume (M3) components are designed on a hand push cart having 4 wheels. The carriage is 1st sent to the site and assembly of room Bill of Materials – for prototype model components is done there. The wheels are locked at the site. The entire assembly can be dismantled and shifted if required. No Particulars N L B D Qty Remar . os ks B) For Cast in situ walls 10 cm thick plastic bottles are used 3 A Precast cast 1 1 2 0.06 0.14 M as brick laid in 1:4 cement mortar slurry with shuttering of ply flooring . board on both sides. Roof is covered with PVC sheets. On one finished with 2 of the cast in situ walls PVC Door with ventilator is provided. toilet seats and C) After the toilet block is made ready, the outlet of toilet pan vinyl flooring is connected to biogas digester and wash basin water is sent to PVC wall 2 1 3 7.2 M2 open drain or a soak pit. The biogas digester has another inlet 1 Panels covered 2 . 3 12 M2 also for adding cow-dung slurry to make continuous supply of on 25 mm x 50 2 kitchen gas. mm MS pipes 2 Advantages of Using Biogas digester as septic tank 2 P.V.C. Roof 1 2 1 2.4 M2 * It is the cheapest and cleanliest option as a fuel for cooking, Panel covered . lighting, heating etc. It is very clean gas and generate no on 25 mm x 50 2 smoke hence completely Environment Friendly. It is not only mm MS pipes an Eco friendly alternative source of energy, but also a means 3 P.V.C. Septic 1 1 No. to produce Organic manure for enriching our Soil. Tank Rate for Alter* The operating cost of Bio Gas plant is very less. It requires 4 composite native 25 Kg. of Cow dung Slurry for 1 Cu. Mtr. of Bio Gas plant or material for say 5to 6 Kg of Kitchen waste / on dry weight basis. wall panel * It does not generate bad odour ISSN: 2231-5381 http://www.ijettjournal.org Page 22 International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 Abstract of Estimate No . 1 2 3 4 5 No. Particulars Qty Rate Per Floor of the toilet block Seat and cistern and wash basin PVC Panels with MS pipes Portable P.V.C. Septic tank Total Labour cost 25% of above Total Cost 0.1 4 9000 M3 2400 21. 6 1 Amount In Rs. 1260 600 M 5000 No . Credit Points Points scored survey 10 1 Sustainable Site 14 2 Water Efficiency 5 3 3 Energy & Atmosphere 17 7 12960 4 Materials & resources 13 10 5000 5 Indoor Environmental quality 15 10 6 Innovation & design 5 5 7 1/3rd life span Appreciation 12 5 8 CO2 emission & eco-friendly use of energy systems Market appreciation for greenness 13 7 6 5 2400 2 Particulars 16620 4165 20785 Total Estimated Cost say = 0.21 lacs. Initially 4 prototype models must be made 9 *Village toilet construction drawing and Comparative cost estimate with conventional construction materials is given in Appendix-I. The site inspection team would give credit points for greenness factors out of 100 points sub-divided into 9 heads shown in above table. * The buildings are classified for credit points scored GREENNESS FEATURES OF PREREENGINEERED TOILET BLOCK (i) 0 to 5 No green (ii) 6 to 25 points – weak green, (iii) 26 to 45 points - fairly green, (iv) 46 to 70 points - good green and (v) Above 71 points- excellent green The inspection team allocated total credit points = 62 out of 100. Therefore proposed pre-engineered toilet block comes under the category ‗good green‘ CONCLUSION Village toilet block design is in conformity with green building standards to provide living comforts, water efficiency and energy savings. The cost of Pre-engineered toilet is Rs. 22000/- and that of conventional type of same size is Rs. 70000/- Green Building Requirements are: i) Economic Factors, Energy Efficiency & ii) Lighting iii) Water Efficiency, Material Efficiency iv) Energy efficient biogas digester v) The construction cost estimate is Rs. 25,000 and with 15% profit it can be marketed, provided the government does not impose any extra tax. * Pre-Engineered design of toilet block brings – 50% water efficiency by following ways: The design is eco-friendly and cost effective. It brings continuous saving in fuel purposes 1. Use of Wastewater flow 2. Use of waste material to produce domestic fuel 3. Portability – ready to use within 24 hours time of installation Demonstrable benefits exist in construction of village toilet blocks are To stop open field toilet practice of villagers, Need of implementation of Pre-engineered toilet design: 15% in average total water demand, 20% in average total wastewater flow. The greenness of a building is decided on 100 points Measuring Scale i) Green building benefits are apparent ii) Expedited installation and biogas production from waste and easy availability of cow-dung makes the design cost effective and adoptable. iii) Proposed toilet block scores 100% Greenness points on Valuation tally REFERENCES [1] Video on Civil Engineering construction & form works [2] Video on house construction with plastic bottles by Samarpan Foundation [3] B.N. Dutta‖Estimating & costing‖. ISSN: 2231-5381 http://www.ijettjournal.org for cooking Page 23 in International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 Appendix –I Drawing of Conventional Type of Toilet for estimate 10 cm R.C.C. Slab 20 cm wall 3m 20 cm wall P.L. 20 cm wall 0.60 m 10 cm partition wall G.L. 3m 1.2 m Side View of Toilet Block 10 cm P.C.C. 1:5:8 10 cm sand filling P.L. 1.2Detail m m drawing of a conventional toilet 2.4 block 10 cm R.C.C. Slab 20 cm wall 20 cm wall 10 cm partition wall 3m P.L. 1.2 m 10 cm P.C.C. 1:5:8 10 cm sand filling 2.4 m Walls Construction10 by Plastic cm R.C.C. Slab Bottles 20 cm wall 20 cm wall 10 cm partition wall ISSN: 2231-5381 P.L. G.L. http://www.ijettjournal.org 10 cm P.C.C. 1:5:8 10 cm sand filling Page 24 P.L. G.L. International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 Appendix – I: Pre-engineered Toilet Construction Quantity Estimate No. Particulars A Nos. L B D Qty Remark Units Foundation with Septic Tank 1 Excavation in soft soil 1 2.40 1.20 1.20 3.46 M3 2 Sand filling to level the surface 1 2.40 1.20 0.10 0.29 M3 3 P.C.C. (1:5:8) to prepare base 1 2.40 1.20 0.10 0.29 M3 4 Brick Wall 20 cm thick in 1:8 Mortar 1 7.20 0.20 1.00 1.44 M3 (Total centre line length =2(1.4+2.2) 5 Brick Wall 10 cm thick in 1:6 Mortar 1 1.00 1.20 1.00 1.20 M2 6 Plastering the floor: Small tank 1 1.00 1.00 1.00 1.00 M2 Large Compartment 1 1.90 1.00 1.00 1.90 M2 Walls 3 No. short walls 6 1.00 1.00 1.60 9.60 M2 Long walls Inside 2 1.90 1.00 1.60 6.08 M2 Outside walls above ground level 1 7.20 1.00 0.60 4.32 M2 22.90 M2 Sub total 7 1 2.60 1.40 0.10 0.36 M3 Brick Wall 20 cm thick in 1:8 Mortar 1 7.20 0.20 3.00 4.32 M3 Less Door opening 1 1.20 0.20 2.10 0.50 R.C.C. Slab 10 cm thick (1:2:4) B 8 Super-Structure Net Brick work 9 10 3.82 R.C.C. Slab 10 cm thick (1:2:4) 1 2.60 1.40 0.10 0.36 M3 Door lintel 1 1.40 0.20 0.10 0.03 M3 Plastering the walls Inside/outside 2 7.20 1.00 3.00 43.20 M2 Ceiling 1 2.40 1.20 1.00 2.88 M2 46.08 M2 Net Plastering in superstructure 11 Flooring : Glazed tiles on floor 1 1.20 2.00 1.00 2.40 M2 Tiles on walls 0.9 m above floor 1 7.20 1.00 0.90 6.48 M2 8.88 M2 Sub total ISSN: 2231-5381 http://www.ijettjournal.org Page 25 International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 Appendix – I: Abstract of Pre-engineered Toilet Construction Particulars 1 2 QTY Rate Per Amount Rs. Excavation in soft soil 3.46 280 M3 968.80 Sand filling to level the surface 0.29 630 M3 182.70 3 957.00 Remarks 3 P.C.C. (1:5:8) to prepare base 0.29 3300 M 4 Brick Wall 20 cm thick in 1:8 Mortar 5.26 3400 M3 17884.00 5 Brick Wall 10 cm thick in 1:6 Mortar 1.20 425 M2 510.00 Foundation & Super Structure 6 R.C.C. Slab 10 cm thick (1:2:4) 0.75 12400 M3 9300.00 2 Nos M 2 9657.20 M 2 3108.00 7 Plastering 68.98 8 Floor & Wall Tiels 8.88 9 P.V.C. Door complete with fittings 140 350 1 3500.00 Total 46067.70 Sanitary & Electrical fittings 25% 11516.93 Contractors Profit 25% 11516.93 Total Cost 69101.55 Say Rs. 70000.00 Graphical Comparison of Pre-engineered Vs Conventional Toilet w.r.to Cost & Greenness scale ISSN: 2231-5381 http://www.ijettjournal.org Page 26