Heat Losses in the Smith College Steam Tunnel EVS 300 Project

advertisement

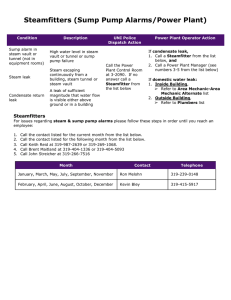

Heat Losses in the Smith College Steam Tunnel EVS 300 Project Joyce Cheung ‘09 Submitted to: Prof. L. David Smith Environmental Science & Policy Seminar Smith College 8 May 2009 1 Abstract The Smith College Steam Tunnel transports steam generated in the Physical Plant to student houses and academic buildings on campus for heating purposes. However, heat is lost in this process because the existing pipe insulation is not 100% efficient. Therefore, this project aims to (1) estimate the amount of heat that is lost when steam is transported from the Smith College Physical Plant to other buildings on campus, (2) determine the percentage decrease in heat loss when insulation is added, and (3) discern whether a heat exchanger unit is feasible. After a site study of the steam tunnel, it was estimate that approximately 20W of power is released per foot of insulated steam pipe. This heat loss can be diminished by adding insulation, but can also be used to heat buildings such as the Lyman Plant House & Conservatory. Mineral fiber was rendered as a more efficient insulator and if the steam pipes were retrofitted with 1.5 in of this material on top of the existing asbestos insulation, energy savings can amount to $294,000 per year. In terms of installing a heat exchanger to heat the plant house, there is insufficient space for this unit because the heat exchanger requires a cross sectional area of 170ft2, yet the basement of Lyman is only has the available space of 45ft2. However, both options should still be taken into consideration as a long‐term investment for Smith College to decrease steam production. 2 Acknowledgements I sincerely express my gratitude to all who have me along this project. Specifically, I recognize Rob Nicholson, the conservatory manager at the Botanic Garden Lyman Plant House, for proposing this project. I would like to thank Todd Holland, the energy manager for the Five Colleges, Inc., for his time and contribution to my heat loss analysis. I want to acknowledge Denise McKay, an assistant professor of engineering, who had guided me in my heat exchanger calculations; Fran Raymond, the chief engineer at the Facilities Management, for providing the map of the steam tunnels; and L. David Smith, the director of the Environmental Science & Policy Program at Smith College, for giving me the foundation to initiate this project. You have provided me with invaluable information, and I truly appreciate your help. Sincerely, Joyce Cheung 3 Table of Contents I. Introduction ..................................................................................................................... 5 II. Methodology................................................................................................................... 9 III. Results.......................................................................................................................... 11 IV. Discussion .................................................................................................................... 17 V. Literature Cited............................................................................................................. 19 VI. Appendices .................................................................................................................. 20 Appendix A: Map of the Smith College Steam Tunnel......................................... 20 Appendix B: Calculations for Sizing Heat Exchanger ........................................... 21 Appendix C: Site Survey – Thermal Images.......................................................... 24 Appendix D: Cost Estimate for Adding Insulation................................................ 37 4 I. Introduction Smith College employs a steam heating system in order to generate and provide heat to buildings on campus. However, a question heretofore unasked is whether the entire stream of steam is actually delivered to the specified destinations ‐ how much heat is lost to the atmosphere as the steam is transferred from the Physical Plant to an academic building? The more heat that is dissipated during this process, the more steam the cogeneration plant would need to produce in order to meet the demands of the campus. Therefore, Todd Holland, the energy manager for the Five Colleges, Inc. was interested to see how heat loss can be diminished by adding insulation. In addition, since this thermal energy can be put into good use, Robert Nicholson from the Lyman Plant House & Conservatory wanted to determine whether heat exchangers can be installed to use the heat from the steam tunnel to warm the greenhouse. Thus, the main purpose of this project was to (1) estimate the amount of heat that is lost when steam is transported from the Smith College Physical Plant to other buildings on campus, (2) determine the percentage decrease in heat loss when insulation is added, and (3) discern whether a heat exchanger unit is feasible. The Steam Tunnel The Smith College Steam Tunnel was built in 1946. This tunnel houses the steam pipes needed to transport the steam generated in the Physical Plant to heat student houses and academic buildings on campus. The steam tunnel has two valve chambers: Valve Chamber A extends from the Physical Plant to the Lyman Plant House & Conservatory; Valve Chamber B extends to John M. Greene Hall (Appendix A). This steam tunnel is located approximately 4ft below grade and has a total length of approximately 3500ft. 5 Insulation & Heat Loss The pipes in the steam tunnel are insulated with 2” of asbestos covered by a canvas jacket. However, a large amount of heat still escapes from these pipes and simply dissipates upward out of the tunnel through the ground. For instance, oftentimes during the winter we see patches of grass amidst snow on Tyler Lawn and College Lane (Fig. 1). These areas with melted snow actually correspond to the path of the steam tunnel illustrated in Appendix A. Thus, the heat is escaping from the steam tunnels and warming the ground, which melts the snow. Figure 1: Melted snow on Tyler Lawn As suggested by Todd Holland, this project will investigate the impact of adding an additional layer of asbestos to the steam pipes. By decreasing the amount of heat dissipation, the cogeneration plant would not need to produce as much steam. The Lyman Plant House & Conservatory The steam tunnel runs under the Lyman Plant house, and there is an entryway in the basement of the plant house. The Lyman Plant House & Conservatory at Smith College consists of 11 distinct houses, each maintained at different environmental conditions (e.g. temperature, humidity) in order to sustain the growth of various plant species. The glass roofs allow solar radiation to be transmitted into the conservatory, where it is difficult for the radiation to pass back out (Fig. 2). This allows the 6 greenhouse to retain solar energy for heating purposes. Conversely, greenhouses become very cold at night, because they lose heat from the building surface via exterior radiation and eventually become almost as cold as the outside temperature. However, the interior temperature must remain fairly constant regardless of the outside temperature, and therefore more energy must be used to heat up the greenhouse during nighttime and especially during winters. Figure 2: Lyman Plant House & Conservatory Since most of the steam is generated during the winters anyway to heat the buildings, the heat dissipating from the steam pipes can be used to maintain the temperatures within the greenhouse. This option to capture the escaping heat and bring it into the plant house was recommended by the conservatory manager, Robert Nicholson. The advantage of using this waste heat is that the greenhouse would not demand as much heat to be generated from the Physical Plant during the winter. In order to use this waste heat from the steam tunnel, I would need to consider a heat exchanger. Although there is no friable asbestos in the tunnels, Richard Korzeniowski, the health and safety coordinator, suggested that the best way to ensure the air is clean would be to use a heat transfer unit to capture the heat from the tunnel. Therefore, this project will also address whether a heat exchanger is feasible. 7 Heat Exchangers Heat exchangers are devices that transfer heat from one fluid to another without mixing. As depicted in Fig. 3, the heat from the steam tunnel can enter the heat exchanger and warm up the air. Ultimately, the heat coming out will be cooler and the air coming out will be warmer. Some examples of where heat exchangers are used are in boilers, refrigerators and radiators. Figure 3: Diagram of a heat exchanger In this project, the heat exchanger size would be determined. Because there is a limited amount of space in the basement of Lyman Plant House, the proposed location for a heat exchanger unit is by the door of the entryway to the steam tunnel. The available area is 5’x9’ for the heat exchanger (Fig. 4). Figure 4: Proposed location of heat exchanger unit 8 II. Methodology Site Survey A site survey was conducted in order to obtain the dimensions and existing conditions of the steam tunnel. To observe and quantify the amount of heat loss along the pipes in the steam tunnel, an infrared camera was used to take thermal images, which provided the surface temperatures of the steam pipes. The tunnel and pipe dimensions along with other observations were recorded. Adding Insulation To determine the amount of heat loss from the steam pipes with and without insulation, I used 3E Plus Insulation Thickness Computer Program. This program can calculate heat loss from various pipe insulations, heat loss with multiple insulation layers, and the efficiency of the selected insulation. Therefore, I used this program to calculate the heat loss of an insulated and uninsulated pipe in the steam tunnel. I also set up scenarios to determine the effectiveness of heat loss reduction through adding a layer of mineral fiber or calcium silicate insulation to the existing asbestos layer. Sizing Heat Exchanger Based on the proposed location of the heat exchanger, the device is constrained to have a cross‐ sectional area no greater than 45ft2. Therefore, to see if a heat exchanger is even at all possible, I sized the heat exchanger by analyzing the flow conditions and calculating the thermal resistances on the pipe material Rs, and the inner and outer surfaces of the pipe, Ri and Ro, respectively. This allowed me to determine the overall heat‐transfer coefficient, Uo (Eq. 1). Uo = 1 Ao [Rs + Ri + Ro ] Eq. 1 where Ao is the area of the pipe with the outer diameter (Holman, 2002; Cengel and Boles, 2008). 9 Using Fourier’s law for heat conduction and calculating the log mean temperature difference (LMTD), denoted by ΔTm, the heat exchanger area, A, was determined by A= q . U o ΔTm Eq. 2 The steam in the pipe is assumed to be superheated with a velocity of 50m/s (“Steam Pipes – Sizing,” 2009). The hot air from the steam tunnel would enter a counterflow double‐pipe heat exchanger through a fan and therefore the system would have forced convection with a mass flow rate of 15.3lb/min (Lytron.com, 2009). The air from the steam tunnel is assumed to leave the exchanger at 30°C. The air from the basement would enter the heat exchanger where it is heated from 20°C to 27°C (80°F) for the plant house. These calculations, along with assumptions and analysis, are described in detail and are available in Appendix B. 10 III. Results Site Survey The tunnel consists of three pipes. The first is the main pipe, which is the pipe that transfers the steam from the Physical Plant to other areas on campus. The middle pipe is the backup pipe, which is only used when the main pipe is malfunctioned, under maintenance, or when there is a very high demand for heat. The third pipe is the condensate line, which transports steam that has been cooled down to water back to the Physical Plant (Fig. 5). Main Pipe Backup Condensate Line Figure 5: Pipes in the steam tunnel The tunnel walkway is 5’x7’ and it narrows into a trench that is 32”x54” (Fig. 6). The trench is denoted by the high pressure steam lines illustrated in Appendix A. 11 Figure 6: Trench – 32”x54”; walkway is 5’x7’ The tunnel has an average temperature of 90°F. The steam traveling in the main pipe is 350°F, whereas the surface of the pipe is nominally at 130°F. The steam main pipe has a 10" nominal diameter and the backup is 8". According to Francis Raymond from the Physical Plant, the steam supply lines are Schedule 40 steel and the condensate line is Schedule 80, which has a thicker wall. Through this site survey, I observed that there were many of surfaces left uninsulated. The gate valve and parts of the condensate line are bare. From the thermal images, these surfaces are as hot as 300°F (Fig. 7). 12 Gate Valve Gate Valve Condensate Line Condensate Line Figure 7: Uninsulated surfaces There was also damaged insulation. For instance, the canvas jacket on the condensate line is ripped and there is a huge the difference in temperatures between the insulated and uninsulated surfaces (Fig. 8). Figure 8: Damaged insulation on condensate line 13 Furthermore, as demonstrated in Fig. 9a and 9b by the supply takeoff pipe and an expansion joint, not only are these pipes not insulated, but they have leaks as well, which heat up the ceiling of the tunnel. Figure 9a: Leak on supply takeoff pipe Figure 9b: Leak on main pipe Additional thermal images are available in Appendix C. Adding Insulation According to 3E Plus, if the pipes are not insulated, 2140BTU/hr/ft or 630W of power is released per feet. As a comparison, this power output is equivalent to ten 60W light bulbs for every foot. With 14 the asbestos insulation, the pipes release 80BTU/hr/ft or 20W/ft, which is analogous to the power output of one 60W light bulb per three feet. The current insulation is 2” of asbestos, and it is already very efficient in terms on insulating the pipes, where it reduces heat loss from 2142BTU/hr/ft to 79BTU/hr/ft (Table 1). Table 1: Current insulation with asbestos I implemented a case study using two commonly used insulation materials – calcium silicate and mineral fiber. The results for adding 1.585in of calcium silicate and mineral fiber to the existing layer of asbestos are compiled in Table 2 and 3, respectively. Table 2: Insulation with asbestos and calcium silicate 15 Table 3: Insulation with asbestos and mineral fiber In both cases, the efficiency levels increase, which means more heat is insulated. However, notice that there is only a change of 1% in efficiency by adding insulation. Sizing Heat Exchanger The thermal resistances for the steel, inner surface and outer surface of the main pipe is 0.0166°C/W, 1.05E‐5°C/W, and 0.2943°C/W, respectively. Thus, the overall heat‐transfer coefficient, calculated using Eq. 1, was 3.75W/(m2∙°C). Based on this heat‐transfer coefficient, the area of the heat exchanger was sized to be 15.7m2 or 150ft2. 16 IV. Discussion The short‐term solution would be to file a work order to fix the leaks and insulate the uninsulated surfaces. Heat losses from leaks will be fixed as part of the annual summer maintenance. However, for the long‐run, I recommend that the college invest on either retrofitting the tunnel and adding more insulation, or installing a heat exchanger to make use of the waste heat. Insulation If we were to retrofit the pipes, all the old insulation would remain in place and the additional layer would be added on top. The difference between insulation materials is their conductivity values. For instance, carbon steel is not a good insulator because it has a thermal conductivity of 54 W/(m°C). Asbestos has a thermal conductivity of 0.2 W/(m°C), and therefore the layer of insulation prevents 96% of heat escaping from the steam pipe to the atmosphere. Table 4: Thermal conductivity values for various materials (“Thermal Conductivity,” 2009) Material Thermal Conductivity [W/(m°C) ] 1. Carbon Steel 54 2. Asbestos 0.2 3. Calcium silicate 0.06 4. Mineral fiber 0.04 From Tables2 and 3, adding mineral fiber has a better efficiency than calcium silicate. This is because mineral fiber has a lower conductivity, as tabulated in Table 4. Thus, if we were to add insulation to the pipes, we will need to choose a material that has a lower conductivity value than asbestos. After a cost estimate analysis, the savings for adding mineral fiber amounts to $84/ft/yr or $294,000 per year for the entire length of the steam tunnel. Likewise, adding calcium silicate yields a 17 savings of $212,915 per year. This analysis was conducted using 3E Plus and more information can be found in Appendix D. However, adding insulation has a low marginal benefit, meaning that adding 1.5in of mineral fiber for the entire length of the pipe will only decrease heat loss by 1%. Furthermore, the cost to refurbish these pipes depends from on the contractor, and to insulate the entire length of the steam pipes might result in a long payback period to offset the retrofitting costs. Heat Exchanger Since the heat exchanger needs to have an area of 170ft2, it exceeds the design requirement of 45ft2 due to the limited space in the basement of Lyman Plant House. Therefore, it is not feasible to install the heat exchanger analyzed in this project. However, there are other types of heat exchangers that might be compact enough but also able to provide the heat exchange requirement (to heat air from 20°C to 27°C). Therefore, I recommend the Physical Plant to investigate which types of heat exchangers are able to capture the heat from the steam tunnel and use it to heat Lyman Plant House. Future Implementation & Additional Recommendations This project is worthwhile to continue because either solution, whether it is adding insulation or installing heat exchanger, will diminish energy consumption in terms of generating steam. There are also future applications of the heat exchanger unit if it is successfully sized and implemented in Lyman Plant House. Since the steam tunnel also passes beneath Tyler House, Sabin‐Reed, Neilson Library and Hatfield Hall, a heat exchanger can also be installed to provide heat in these buildings as well. Additionally, in terms of deciding which option is more economically attractive, it would be interesting to compare the costs of adding insulation to the pipes vs. recovering the heat for use in the greenhouse. Furthermore, since most of the steam tunnel lies under driveways, the steam actually helps melt the snow. Therefore, we can decrease the use of road salt in these areas. 18 V. Literature Cited 3E Plus: Insulation Thickness Computer Program. North American Insulation Manufacturers Association. 7 April 2009. <http://www.pipeinsulation.org> Cengel, Y.A. and M.A. Boles. Thermodynamics: An Engineering Approach, 6th Ed. New York: McGraw Hill, 2008. Holland, Todd. Personal interview. 1 April 2009. Holman, J.P. Heat Transfer, 9th Ed. New York: McGraw Hill, 2002. “Integrating a Heat Exchanger into your System: Fan Considerations.” Lytron Total Thermal Solutions. 6 May 2009. <http://www.lytron.com/tools‐technical/notes/heat‐exchangers‐integrating‐fans.aspx> Korzeniowski, Richard. Email correspondence. 7 April 2009. McKay, Denise. Personal interview. 27 April 2009. Raymond, Francis. Personal interview. 22 April 2009. “Steam Pipes – Sizing.” The Engineering Toolbox. 25 April 2009. <http://engineeringtoolbox.com/steam‐ pip‐sizing‐d_105.html> “Thermal Conductivity of Some Common Materials.” The Engineering Toolbox. 25 April 2009. <http://www.engineeringtoolbox.com/thermal‐conductivity‐d_429.html> 19 Appendix A: Map of the Smith College Steam Tunnel 20 Appendix B: Calculations for Sizing Heat Exchanger 21 22 23 Appendix C: Site Survey – Thermal Images Smith Steam Tunnels Valve Chamber A to Lyman Plant House Prepared For: Smith College L. David Smith Trench looking north from Lyman tunnel. IR000162.IS2 4/2/2009 1:15:00 PM Frome left to right: 126.7F = insulated supply main, 106.9F = insulated backup (not active), 149.7F = uninsulated condensate from mech room, 108.3F = insulated condensate main. Main Image Markers Name P0 P1 P2 P3 Temperature 52.6°C 41.6°C 42.4°C 65.4°C 24 Uninsulated consensate line. IR000163.IS2 4/2/2009 1:15:51 PM Just outside Lyman basement. Condensate line is bare. Background is concrete tunnel wall (very warm). Main Image Markers Name Centerpoint P0 Temperature 103.2°C 48.2°C Looking north where tunnel becomes trench at Lyman Plant House. IR000164.IS2 4/2/2009 1:17:28 PM Hot spots are details where condensate lines can be insulated. 25 Insulated steam main. IR000165.IS2 4/2/2009 1:18:02 PM Surface temp of canvas jacket is uniform 120‐130F, roof of concrete tunnel is >100F. Main Image Markers Name Centerpoint P0 Temperature 49.8°C 40.2°C Expansion joint. IR000166.IS2 4/2/2009 1:20:45 PM Insulation temps here are warmer, may be location of live steam leak at this joint. Main Image Markers Name Centerpoint P0 P1 Temperature 179.3°C 57.7°C 59.8°C 26 Expansion joint in condensate line. IR000167.IS2 4/2/2009 1:21:41 PM Exposed flanges at expansion joint, note that temp is much lower than supply. Flexible, removable jacket over joint itself (102.3F). Main Image Markers Name Centerpoint P0 P1 Temperature 65.2°C 41.8°C 39.1°C Steam trap. IR000168.IS2 4/2/2009 1:23:17 PM Operational, right side is 125psig steam (~350F), left side is condensate (227.7F). Trap allows liquid condensate to pass, keeps steam and pressure contained upstream. See http://www.armstronginternational.com/files /common/allproductscatalog/cg‐09.pdf Main Image Markers Name Centerpoint P0 P1 Temperature 168.0°C 108.7°C 173.6°C 27 Uninsulated hanger detail. IR000169.IS2 4/2/2009 1:24:53 PM Missing insulation at pipe rack. Main Image Markers Name Centerpoint P0 Temperature 166.5°C 55.1°C Uninsulated bonnet on backup valve. IR000170.IS2 4/2/2009 1:26:01 PM Connection to backup main at Sabin‐Reed (?). Note that valve and backup line are rather warm here, is there a leaky valve back‐ pressuring the line? Main Image Markers Name Centerpoint P0 Temperature 112.6°C 50.0°C 28 Unisulated bonnet. IR000171.IS2 4/2/2009 1:26:32 PM Large gate valve at supply for Sabin‐Reed (?). Note that background temperature of concrete tunnel is very warm, same is insulation surface temperature. Main Image Markers Name Centerpoint P0 Temperature 170.5°C 63.2°C Expansion joint w/ leak. IR000172.IS2 4/2/2009 1:27:39 PM Can exposed flanges at expansion joints be covered w/ additional jackets? Note that live setam leak has made this section of tunnel very warm, concrete ceiling is >200F. Main Image Markers Name Centerpoint P0 P1 Temperature 174.7°C 65.5°C 94.3°C 29 Expansion joint and steam trap. IR000173.IS2 4/2/2009 1:28:46 PM Exposed flanges at expansion joint (jacket?) and operational steam trap. Main Image Markers Name Centerpoint P0 P1 P2 P3 Temperature 177.3°C 142.0°C 178.6°C 66.3°C 57.6°C Steam trap off high‐pressure main. IR000174.IS2 4/2/2009 1:28:58 PM Trap is operational. Main Image Markers Name Centerpoint P0 P1 P2 Temperature 123.4°C 175.9°C 177.6°C 80.1°C 30 Stub‐out w/ pinhole leak at Sabin‐Reed. IR000176.IS2 4/2/2009 1:30:24 PM Uninsulated stub has leak w/ visible plume at old supply takeoff. Main Image Markers Name Centerpoint Hot P0 Temperature 161.9°C 182.9°C 58.8°C Ball joint (?) at offset in tunnel. IR000177.IS2 4/2/2009 1:31:30 PM Companion to other joint at offset, just north of 90‐degree bend. Note warm (253.6F) insulation on bottom of pipe just aft, is insulation wet and/or compromised here? Can a jacket be applied over flanges? Main Image Markers Name Centerpoint P0 P1 P2 Temperature 147.1°C 123.1°C 51.0°C 53.6°C 31 Ball joint (?) at jog in tunnel. IR000178.IS2 4/2/2009 1:32:00 PM Ball joint or reducer in steam main has audible steam leak. Silver paint gives false temperature readings; all exposed metal is ~350F. Main Image Markers Name Hot P0 P1 Temperature 177.6°C 48.2°C 48.5°C Expansion joint on main. IR000179.IS2 4/2/2009 1:33:24 PM Flanges are uninsulated. Canvas‐covered pipe insulation before flanges, fabric‐coated fiberglass jacket aft, covering expansion joint. Main Image Markers Name Centerpoint P0 P1 Temperature 166.9°C 51.2°C 53.3°C 32 Uninsulated flanges at expansion joint. IR000180.IS2 4/2/2009 1:35:49 PM Main Image Markers Name Centerpoint Temperature 176.4°C Steam main, insulated surface. IR000181.IS2 4/2/2009 1:37:17 PM Uniform temperature of uncompromised canvas wrap over good insulation. Additional insulation could lower temperature further, is it cost effective? Main Image Markers Name Centerpoint Temperature 45.4°C 33 Operational steam trap. IR000182.IS2 4/2/2009 1:37:54 PM Temperature differential shows trap is operating properly (not blowing by). Note that pipes before and after could be insulated. Main Image Markers Name Centerpoint P0 P1 Temperature 157.2°C 170.3°C 100.2°C Uninsulated bonnet on gate valve in valve chamber. IR000183.IS2 4/2/2009 1:42:52 PM Main Image Markers Name Centerpoint P0 Temperature 179.9°C 54.7°C 34 Uninsulated stub‐out on steam supply main. IR000184.IS2 4/2/2009 1:49:34 PM Main Image Markers Name Centerpoint Temperature 182.8°C Damaged insulation on condensate pipe. IR000185.IS2 4/2/2009 1:50:18 PM Main Image Markers Name Centerpoint P0 Temperature 106.2°C 57.1°C 35 Inverted bucket trap. IR000186.IS2 4/2/2009 1:51:31 PM Trap is operational (cooler at top outlet). Can pipe be instlated upstream of union? Main Image Markers Name Centerpoint P0 Temperature 162.1°C 109.5°C Notes: 36 Appendix D: Cost Estimate for Adding Insulation North American Insulation Mfgs. Assoc. NAIMA 3E Plus 4.0 Smith College 1 Chapin Way, Box 6712 Northampton, MA 01063 917-992-2720 Project Name Project Number System Location Engineer Contact = = = = = = Steam Tunnel Insulation EVS 300 Steam Tunnel Smith College Joyce Cheung 37 North American Insulation Mfgs. Assoc. NAIMA 3E Plus 4.0 Smith College 1 Chapin Way, Box 6712 Northampton, MA 01063 917-992-2720 Fuel Type First Year Price Heating Value Efficiency Annual Fuel Inflation Rate Annual hours of operation = = = = = = Natural Gas 10 $/Mcf 1026 Btu/cuft 75% 3% 4368 hours ECONOMIC DATA Interest Rate or Return on Investment = 8% Effective Income Tax Rate = 35% Physical Plant Depreciation Period = 7 years New Insulation Depreciation Period = 7 years Incremental Equipment Investment Rate = 3.47 $/MMBtu/hr Percent of New Insulation Cost for Annual Insulation Maintenance = 2% Percent of Annual Fuel Bill for Physical Plant Maintenance = 1% Ambient temperature = 90 ?XF Emittance of outer jacketing = 0.9 Canvas Wind speed = 0 mph Emittance of existing surface = 0.8 Reference thickness for payback calculations = 0 inches Insulation material = 850F Mineral Fiber PIPE, Type I, C547-07 38 NAIMA 3E Plus 4.0 Smith College 1 Chapin Way, Box 6712 Northampton, MA 01063 917-992-2720 Surface or Pipe Number 17 Horizontal Cylinder - 0.8 Steel Pipe Size = 10 inches Average Installation Complexity factor =1.15 Insulation costs estimated by FEA method. Labor rate = 38.25 $/hr Productivity factor = 110 Price of 2x2 pipe insulation with jacket = 4.97$/lnft Price of 2 inch block with jacket = 1.71$/sqft Operating Temperature 350?XF Insulation Annualized Payback Heat Thick Cost Cost Period Loss Inches $/ft $/ft Years Btu/hr/ft 1.5 17.96 5.10 0.27 45 2.0 21.66 5.65 0.32 42 2.5 25.55 6.27 0.38 40 3.0 28.91 6.80 0.43 38 4.0 36.11 7.97 0.54 35 Double Layer 3.0 32.70 7.48 0.49 38 4.0 41.56 8.96 0.62 35 5.0 50.67 10.51 0.75 33 6.0 59.58 12.04 0.88 31 Triple Layer 6.0 66.70 13.32 0.99 31 7.0 78.72 15.42 1.17 30 8.0 91.28 17.63 1.35 29 9.0 103.30 19.75 1.52 28 10.0 114.82 21.79 1.69 27 Surf Temp ?XF 98 97 97 96 95 96 95 94 94 94 93 93 93 93 Insulation material = 850F Mineral Fiber PIPE, Type I, C547-07 The Economic Thickness is single layer 1.50 inches. The savings for the economic thickness is 84.02 $/ft/yr. 39 North American Insulation Mfgs. Assoc. NAIMA 3E Plus 4.0 Smith College 1 Chapin Way, Box 6712 Northampton, MA 01063 917-992-2720 Fuel Type First Year Price Heating Value Efficiency Annual Fuel Inflation Rate Annual hours of operation = = = = = = Natural Gas 10 $/Mcf 1026 Btu/cuft 75% 3% 4368 hours ECONOMIC DATA Interest Rate or Return on Investment = 8% Effective Income Tax Rate = 35% Physical Plant Depreciation Period = 7 years New Insulation Depreciation Period = 7 years Incremental Equipment Investment Rate = 3.47 $/MMBtu/hr Percent of New Insulation Cost for Annual Insulation Maintenance = 2% Percent of Annual Fuel Bill for Physical Plant Maintenance = 1% Ambient temperature = 90 ?XF Emittance of outer jacketing = 0.9 Canvas Wind speed = 0 mph Emittance of existing surface = 0.8 Reference thickness for payback calculations = 0 inches Insulation material = Calcium Silicate BLK+PIPE, Type I, C533-07 40 NAIMA 3E Plus 4.0 Smith College 1 Chapin Way, Box 6712 Northampton, MA 01063 917-992-2720 Surface or Pipe Number 17 Horizontal Cylinder - 0.8 Steel Pipe Size = 10 inches Average Installation Complexity factor =1.15 Insulation costs estimated by FEA method. Labor rate = 38.25 $/hr Productivity factor = 110 Price of 2x2 pipe insulation with jacket = 4.97$/lnft Price of 2 inch block with jacket = 1.71$/sqft Operating Temperature 350?XF Insulation Annualized Payback Heat Thick Cost Cost Period Loss Inches $/ft $/ft Years Btu/hr/ft 1.5 18.55 5.43 0.28 50 2.0 22.75 6.10 0.34 48 2.5 26.20 6.65 0.39 46 3.0 29.40 7.16 0.44 45 4.0 36.55 8.34 0.55 42 Double Layer 3.0 33.10 7.83 0.50 45 4.0 42.80 9.47 0.64 42 5.0 52.66 11.16 0.79 40 6.0 62.56 12.87 0.93 38 Triple Layer 6.0 70.77 14.35 1.05 38 7.0 82.80 16.45 1.23 37 8.0 94.76 18.55 1.40 36 9.0 101.81 19.77 1.50 35 10.0 117.81 22.61 1.74 34 Surf Temp ?XF 99 98 98 97 96 97 96 95 95 95 94 94 93 93 Insulation material = Calcium Silicate BLK+PIPE, Type I, C533-07 The Economic Thickness is single layer 1.50 inches. The savings for the economic thickness is 83.69 $/ft/yr. 41 North American Insulation Mfgs. Assoc. NAIMA 3E Plus 4.0 DISCLAIMER OF WARRANTY No warranties. The software product is provided as is without warranty of any kind. To the maximum extent permitted by applicable law, NAIMA and its members and Company Name Here and NAIMA's suppliers disclaim all warranties, either express or implied, including, but not limited to, implied warranties of merchantability and fitness for a particular purpose and any warranty againstinfringement, with regard to the software product. This limited warranty gives youspecific legal rights. You may have others, which vary from state/jurisdiction to state/jurisdiction. NAIMA's entire liability and your exclusive remedy shall not exceedthe price paid for the software product. No liability for damages. To the maximum extentpermitted by applicable law, in no event shall NAIMA or its suppliers be liable for anydamages whatsoever including, without limitation, damages for loss of business profits, business interruption, loss of business information, or any other pecuniary loss arising out of the use of or inability to use this NAIMA product, even if NAIMA has been advised of the possibility of such damages. Because some states/jurisdictions do not allow the exclusion or limitation of liability for consequential or incidental damages, the above limitation may not apply to you. THE U.S. GOVERNMENT HAS RESTRICTED RIGHTS - If you acquired this product in the United States, this license is governed by the laws of the State of Virginia. Use of the 3E Plus program for an assessment of the economic thickness guidelines for all insulations does not ensure or guarantee compliance with any energy code in your geographic location. Consult local authorities before finalizing your installation plans. The use of the 3E Plus program to calculate heat transfer does not ensure or guarantee specific dollars savings or energy savings. This program was designed for the industrial process, environmental managers and the insulation industry. It is a valuable tool for calculating and selecting the insulation thickness needed to reduce heat transfer, and maintain a safe insulated surface temperature for personnel protection and condensation control. Each insulation and jacket material manufacturer have specific recommendations for the installation of its product. Consult your manufacturer for specific details. All the information printed in this report is based on the given input information. Actual values will vary depending on the actual service conditions. The system of mathematical heat flux equations used in this analysis has been accepted by ASTM as applicable for most systems normally insulated with bulk-type insulations. The thermal performance equations are based on laboratory conditions and may not represent actual conditions of use. 42