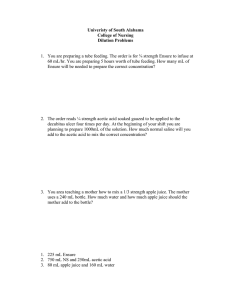

S9. ANALYSIS OF IRON IN FOODS BY AAS PURPOSE

advertisement

S9. ANALYSIS OF IRON IN FOODS BY AAS PURPOSE To analyse a number of food items for their iron content by atomic absorption spectrophotometry, comparing the results from both normal standard calibration graph and standard addition. INTRODUCTION The concentration of unknowns can be determined in AAS by using a Beer’s Law plot, in a similar way to what is done in UV/visible spectrophotometric methods. The plot should be linear. The standards should have the same background/impurity ions present as the sample (matrix matching). In practice, matrix matching may not be possible or it may involve so many different sets of standards for all the different samples you might have to work on that it is too much work to carry out. Because of these reasons, the method of standard addition is often used. In this method, a constant amount of sample is added to a range of standards. The concentration of the unknown is usually found graphically. PROCEDURE I. Preparation of Sample Solutions Curry Powder 1. Weigh accurately about 0.8g of curry powder into a 150 mL beaker and add 50 mL of concentrated HCl via a measuring cylinder 2. Boil gently on a hotplate for 45 minutes. If the volume of the liquid drops below 30 mL, top it up with more concentrated HCl. 3. Remove from the hotplate and allow to cool in the fumehood. 4. Quantitatively transfer the solution via gravity filtration into a 100 mL volumetric flask. Make up to the mark with water Red Wine or Apple Juice 5. De-gas about 100 mL of the red wine or apple juice, by standing it in an ultrasonic bath for 5 minutes. 6. Check the samples of apple juice or wine to ensure that no level of suspended solids is visible. If there is cloudiness in the sample, filter by Millipore filtration. II. Simple Calibration graph 7. Prepare 100 mL of 0, 2.5, 5 and 10 mg/L Fe solution from the supplied 1000mg/L Fe solution. A double-step dilution series will be required. Add 5 mL of 5M HCl to each flask before making up to the mark III. Standard Addition Technique 8. Clean and dry six 100-150 mL beakers. You should have by the end of steps 10-12 (for each sample) separate beakers with 0, 100 and 200 µL of 1000 mg/L Fe solution added to 25 mL of sample solution. 9. Pipette 25 mL aliquots of the wine or juice into three of the beakers 10. Use a micropipette to add 100 µL of 1000mg/L Fe solution to the second beaker containing the wine or apple juice. 11. To the third beaker of wine or apple juice, add 200 µL of 1000mg/L Fe solution 12. Repeat steps 9-11 but using the curry powder solutions 13. Mix the solutions well by swirling 14. Set up and optimise the AAS using the appropriate resonance line. 15. Record the absorbance of each solution, obtaining at least 2 readings for each, and rezeroing the instrument with the blank as required. CALCULATIONS II. Simple Calibration Graph • plot the absorbance vs concentration data from the standards • determine the concentration of Fe in the wine (%w/v) and in the curry powder (%w/w) III. Standard Addition Technique The calculation can be done by plotting the absorbance vs the volume of 1000 mg/L standard added or by plotting the absorbance vs the concentration of Fe added to 25 mL solution. • Extrapolate the graph to show the x-intercept • Calculate the concentration of the solutions from the line-of-best-fit data. • For the curry powder sample, given the original volume of solution, calculate the mass (in mg) of iron in the sample calculate the mg Fe/100g sample by dividing the mg of Fe by the sample mass in g and multiplying by 100. DISCUSSION • compare the methods of standard addition and calibration standards for the samples analysed. • compare this method for iron analysis with the visible absorption method using thiocyanate QUESTIONS 1. Why is the following statement wrong? “By using the standard addition method, all interferences by the matrix in the flame are eliminated.” 2. For the copper content of the following samples, which method (simple calibration graph or standard addition) would you expect to be most accurate? Explain your answer. a) pure copper metal b) a copper salt c) copper ore d) beer S9. RESULTS SHEET Date of analysis I. Preparation of Sample Solution Mass of curry (g) II. Simple Calibration Graph Solution (mg/L) Blank 2.5 5.0 10.0 Curry powder Wine/apple juice Absorbances Ave Absorbance Sample: wine/apple juice Solution Sample Sample + 100 µL Sample + 200 µL Conc Fe Added 0.0 Absorbances Ave Abs Conc Fe Added 0.0 Absorbances Ave Abs Sample: curry powder Solution Sample Sample + 100 µL Sample + 200 µL Have you? Date Signature Completed the instrument log Completed the sample register Completed the standard register Teachers signature