Raghavendran D. Nagarj

advertisement

AN ABSTRACT OF THE THESIS OF

Raghavendran D. Nagarj

for the degree of Master of Science in Industrial Engineering

presented on 8 December, 2003.

Title: Linking Equations for the Analysis of a Serial Automated Workstation System.

Abstract

Redacted for privacy

David S. Kim

In this research, an analytical model for analyzing a production line consisting of a series

of automated workstations with infinite buffers is developed. Automated workstations are

assumed to have deterministic processing times, and independent exponentially

distributed operating time between failures and repair times. The analytical model starts

with existing results from a Markov chain model of two automated workstations in series,

where analytical expressions are developed for the average number of jobs in the second

workstation and its queue. This research focuses on the development of a set of linking

equations that can be used to analyze larger systems using a two workstation

decomposition approach. These linking equations utilize probabilities computed in the

two-workstation Markov chain model to compute workstation parameters for a single

workstation such that the first two moments of the inter-departure process from the twoworkstation system and the single workstation are the same. Simulations of a number of

different 3-workstation and 10-workstation systems were carried out employing a range

of workstation utilizations and processing time coefficients of variation. The results from

these simulations were compared with those calculated with the analytical model and

various two-parameter GJ/G/l approximations and linking equations present in the

literature. The analytical model resulted in an average absolute percentage difference of

less than 5% in the systems studied, and performed much better than general twoparameter GIG/i approximations. The analytical model was also robust in ranking the

queues in the order of the average number ofjobs present in the queues.

Linking Equations for the Analysis of a Serial Automated Workstation System

by

Raghavendran D. Nagarajan

A THESIS

submitted to

Oregon State University

in partial fulfillment of

the requirements for the

degree of

Master of Science

Presented December 8, 2003

Commencement June 2004

Master of Science thesis of Raghavendran D. Nagarajan

presented on December 8, 2003.

Redacted for privacy

Major Professor, representing Industrial and Manufacturing Engineering

Redacted for privacy

Head of Industrial and Manufacturing Engineering

Redacted for privacy

Dean of the Graduate School

I understand that my thesis will become part of the permanent collection of Oregon State

University libraries. My signature below authorizes release of my thesis to any reader

upon request.

Redacted for privacy

Raghavendran D. Nagarajan, Author

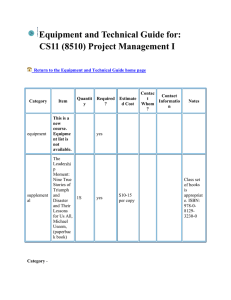

TABLE OF CONTENTS

Pige

Introduction

2

3

1

1.1

General objectives and motivation

1

1.2

System Description

1

1.3

General Approach

2

1.4

Organization of the document

3

Literature Review

2.1

GJIG/1 Approximations

4

2.2

Departure Process Approximations

8

2.3

Serial Automated Systems with Finite Buffers

9

Analytical Model

3.1

11

Finding Markov Chain Failure and Repair Probabilities

3.1.1

3.1.2

3.1.3

4

4

First moment of the processing time

Second moment of the processing time

Failure and repair probabilities for a WS

13

14

14

16

3.2

Distribution of inter-departure times from WS 2

18

3.3

Information from the Markov chain model

27

Evaluation of Methodology

30

4.1

Simulation of 3-workstation systems

31

4.2

Simulation of 10-workstation systems

35

TABLE OF CONTENTS (CONTiNUED...)

5

6

Results

5.1

Results for 3-workstation systems

39

5.2

Results for 10-workstation systems

46

5.3

Ranking workstations

49

Conclusion

50

Bibliography

51

Appendices

54

Appendix A Markov chain model for two automated workstations in series

55

Appendix B

Input data for simulation of 3-workstation system

68

Appendix C

Input data for simulation of 10-workstation system

80

Appendix D

First two moments of the inter-departure time distribution

87

LIST OF FIGURES

Figure

Page

1

The two-workstation decomposition approach

11

2

Results for the 3_WSCV1L system

39

3

Results for the 3_WSCV2L system

40

4

Results for the 3_WSCV3_L system

41

S

Results for the 3_WS_CV4_L system

41

6

Results for the 3_WS_CV5_L system

42

7

Results for the 3_WS_CV1H system

42

8

Results for the 3_WS_CV2_H system

43

9

Results for the 3WSCV3_H system

43

10

Results for the 3_WS_CV4H system

44

11

Results for the 3WS_CV5_H system

44

12

Results for the 3_WS_Dis system

45

13

Results for the 3WS_Sim system

45

14

Results for the 1OWS_CV1 system

46

15

Results for the 1 0_WS_CV2 system

46

16

Results for the 1 0_WSCV3 system

47

17

Results for the 10_WSCV4 system

47

18

Results for the 1 0_WS_CV5 system

48

19

Results for the 10_WS_CVO5 system

48

LIST OF TABLES

Table

The different factors and the levels for the simulations

31

2

Description of the different 3-workstation systems simulated

34

3

Additional 3-workstation systems simulated

35

4

Description of the different 10-workstation systems simulated

36

5

List of all the different theoretical models

37

6

Number of cases of incorrect workstation ranks

for 10-workstation systems

49

LIST OF APPENDIX FIGURES

Figure

Al

State transition diagram for the Markov chain model

58

A2

Macrostate Markov chain model

59

A3

Finding the microstate Markov chain transition probabilities

61

LIST OF APPENDIX TABLES

Table

Page

Bi

Input Data for the 3_WS CV1_L system

69

B2

Input Data for the 3_WS_CV2_L system

70

B3

Input Data for the 3_WS_CV3_L system

71

B4

Input Data for the 3_WS_CV4_L system

72

B5

Input Data for the 3_WS_CV5_L system

73

B6

Input Data for the 3_WS_CV1_H system

74

B7

Input Data for the 3WSCV2_H system

75

B8

Input Data for the 3_WS_CV3_H system

76

B9

Input Data for the 3_WS_CV4_H system

77

BlO

Input Data for the 3_WS_CV5_H system

78

Bi 1

Input Data for the 3_WS_Dis system

79

B12

Input Data for the 3_WS_Sim system

79

Cl

Input Data for the 1OWS_CV1 system

81

C2

Input Data for the 10_WS_CV2 system

82

C3

Input Data for the 10_WS_CV3 system

83

C4

Input Data for the 10_WS_CV4 system

84

C5

Input Data for the IQWS_CV5 system

85

C6

Input Data for the 1 0_WS_CVO5 system

86

Notation

Expected value of a random variable

Var[.]

Variance of a random variable

WS

WorkStation

f

Failure probability of a WS

r

Repair probability of a WS

f,

Failure probability of WS i, = 1, 2, 3...

Repair probability of WS i, i = 1, 2, 3...

N

Number of workstations in series in a system being considered

MTBF

Mean Time Between Failure for WS i

MTTR

Mean Time To Repair for WS i.

P

Total time spent by ajob in a WS (processing time)

S,

Processing rate of WS i when it is up

u,

Utilization of WS i

u

Utilization of any workstation

Coefficient of Variation (CV) of processing times of workstation i

Ca,

Coefficient of Variation (CV) of inter-arrival times to workstation i

Cd

Coefficient of Variation (CV) of inter-departure times from workstation i

0a2

Variance of inter-arrival times to a workstation

0e2

Variance of service time ofajob on a workstation

Arrival rate ofjobs to a workstation

p

Service rate ofjobs at a workstation

W

Expected waiting time of ajob in a queue

Linking Equations for the Analysis of a Serial Automated Workstation System

1. INTRODUCTION

1.1 General Objectives and Motivation

Queuing models have applications in the perfonnance evaluation of a variety of systems

like communication networks, call centers and production lines. The focus of this

research is directed towards a specific type of queuing system. This system is a series of

workstations in which the work times of the individual servers (or workstations) can be

assumed to be equal and deterministic. The significant randomness in the behavior of

such machines comes from the random downtimes (time between workstation failures)

and random repair times, both of which are normally assumed to be independent and

exponentially distributed.

In the past, researchers have used this queuing system to

model the behavior of a series of automated workstations. The objective of this research

is to develop an analytical model to analyze a system consisting of an arbitrary number of

automated workstations in series. The use of two-moment GJIG/1 approximations, which

seems to be a simple and a popular analytical approach for the analysis of such systems,

results in potentially large errors for system performance measures (e.g., the average

number of jobs in the system), especially when the coefficient of variation of processing

times exceeds 1.5 (Hopp and Spearman, 1995). This provides the motivation for deriving

an accurate, analytical method for analyzing such systems. A description of the exact

system which has been studied in this research is given below.

1.2 System Description

The system studied here is a production line consisting of a series of automated

workstations, numbered from 1 through N. The buffer size between workstations is

assumed to be infinite and the first workstation (WS 1) is assumed to have an unlimited

supply of jobs. The workstations process a single job at a time and are assumed to have

2

deterministic, unit work times. The time between failure and the time to repair for each of

the workstations are assumed to be independent and exponentially distributed. The

performance measure of interest is the average number ofjobs in each workstation and its

input queue. Knowing this and applying Little's Law the total time a job spends in each

workstation and its input queue can be found.

1.3 General Approach

The general approach used in this research is to model the continuous time, discrete event

system described as a discrete time system. In prior research (Kim (2003)) a Markov

chain model of a 2-workstation system has been developed, and analytical results for the

average number of jobs in the second workstation and its queue have been derived (see

Appendix A). This research uses the two-workstation Markov chain model as a building

block to analyze systems containing more than two workstations. The general approach is

to use a two-workstation decomposition approach, which involves analysis of the system

workstation by workstation, and the approximate representation of the system feeding an

input buffer as a single "aggregate" workstation. The main challenge in successfully

using such an approach is estimating the departure process from a workstation which is

occasionally starved. The analysis in this research begins by utilizing the stationary

probabilities from the two-workstation Markov chain model to derive the probability

distribution of the inter-departure times from the second workstation. The probability

distribution of inter-departure times enables us to calculate the first two moments of the

inter-departure times. This, in turn leads to a two-moment 2-workstation decomposition

approach. The equations derived for the mean and variance of the workstation interdeparture times are referred to as "linking equations". The linking equations derived in

this research enable the calculation of the parameters of the aggregate workstation

described above.

1.4 Organization of document

The rest of this document is organized in as follows. In chapter 2, a review of the

literature describing approaches used in the analysis of systems similar to the one

described here is given. In chapter 3, the linking equations that enable the calculation of

parameters for an aggregate workstation are derived. In chapter 4, the methodology used

in evaluating the performance of the analytical model using discrete event simulation is

described. In chapter 5, the results of the simulations carried out on a number of

automated workstation systems are presented. A comparison of the results obtained from

the analytical model presented in this research with some of those given in the literature

is also presented in this chapter.

4

2. LITERATURE REVIEW

The most common analytical approach for the analysis of a series of automated

workstations with infinite buffer capacities has been GJIGI1 queuing approximations used

in conjunction with approximate models for workstation output departure processes

(Whiff (1983), Hopp and Spearman (1995)). A GIIG/1 queue has a general distribution

for independent times between arrivals to a workstation, generally distributed service

times, and serves a single customer (job) at a time. This literature review is organized

into three main sections. The first section is a review of GJIG/1 queuing approximations.

The second section is a review of approximations of the departure process from an

automated workstation. For the most part the focus in these first two sections is on twomoment approximations. The third section reviews research directed towards analyzing a

series of automated workstations with finite buffers.

2.1 GIIG/1 Approximations

A review of some of the methods present in the literature to analyze a GJJG/1 queue is

given here. Because of the general nature and simplicity of the approximations that will

be reviewed they are applicable to any single server queuing system, and are very easy to

use. This simplicity and generality also leads to the expectation that they will not be

good approximations for certain types of queuing systems, like the one being tested in

this research.

Lindley (1952), in one of the earliest works carried out in this area, derived a recursive

integral equation for the distribution of the waiting times of jobs in a GIIG/1 system. As

pointed out by Lindley (1952) and subsequent researchers, the integral equations yield

analytically tractable solutions for very few cases. Since then, researchers have focused

on developing approximate methods for finding the average number of jobs in a GJJG/l

queue.

There have been efforts to arrive at approximate methods by describing the number of

jobs in the system as a diffusion process. A diffusion approximation refers to the concept

of using the diffusion process (a continuous time, continuous state Markov process) to

model the discrete queuing process. Thereupon, the probability distribution of the number

of jobs in the system is usually arrived at by solving a system of differential equations.

Heyman (1975) derived a diffusion approximation for the distribution of the waiting

times by first deriving a diffusion approximation for the MIMI1 queue and using a similar

heuristic for a GJJG/1 queue. Kobayashi (1974) derived a diffusion equation for the

waiting time distribution, under the assumption that the difference in the number of jobs

in the system has a normal distribution. Reiser and Kobayashi (1974) give a method to

extend a diffusion approximation for the GIIG/1 queue to simple queuing networks.

Through empirical investigation, these researchers have also shown that the accuracy of

the diffusion approximation improves as the server utilization goes to unity. However,

Shanthikumar and Buzacott (1980), as part of their research on the comparison of the

various GIIG/l approximations, list some more diffusion approximations for the analysis

of the GJJG/1 queue. They carried out numerical comparisons between these GJJG/1

approximations and conclude that "heuristic approximations" perform better than

diffusion approximations.

In this context a heuristic approximation is one where the researchers have used existing

results for some special cases of the GTIG/1 system (e.g., MIGI1, MIM/1), combined with

their own intuition, conjecture and empirical studies to arrive at bounds for the GJIG/1

case. A substantial amount of research has been directed at obtaining GJJG/1

approximations. A majority of these are two-moment approximations that express the

average number of jobs in the system as a function of mean and variance of the interarrival and service time distributions.

Kingman (1976) derived an upper-bound for the expected wait time for a job in the

GJIGI1 queue. It has been shown that this upper bound can be used to obtain an

approximation for the expected wait time by multiplying the bound by a factor, which

LØJ

makes the resulting expression exact for the MIG/1 queue (Marchal 1976). The expected

waiting time in a GTIG/1 queue, given by Marchal (1976) is,

w

1+A2o

2(1u)

As shown by Marchal (1978) and also Medhi (1991), the upper bound for the average

waiting time derived by Kingman (1976) can also be modified by adjusting it by a factor

to arrive at,

w"

(u)(Ca2+Ce2')('1

1u)

2

)Li

which is the same as the approximation used in Hopp and Spearman (1995).

Daley (1977) derived an upper bound, which is also cited in Wolff (1988). Whitt (1984),

derived a factor, which when multiplied with the upper bound derived by Daley (1977),

resulted in an approximation for the expected wait time that is exact for the M/G/1 case.

This approximation is given below.

(1 + Ce2)

*

4o + o

(1 u)o]

2(1u)

[(21u)l]+Ce2

Kramer and Lagenbach-Belz (1976) derive what is called the "refinement

function" g() for different ranges of Ca2. The approximation for the average waiting time

is of the following form,

w

"

where,

=1_122i-,

1u)

)u)

2

(1_Ca2)21f

3u

exp[-2(1u)

Ca2+Ce2J

C2

<1

exp[(1_u)(Ca2_1)lfC2l

Ca2 +4Ce2

j

Sakasegawa (1977) derived a heuristic 2-parameter approximation for the average queue

length in a GJJGIs queue, given below:

Ca2 +Ce2

Lq

1u

2

For s

1 the above expression is same as the GJJG/1 approximation given by Marchal

(1978).

In the Queueing Network Analyzer (QNA) described by Whitt (1983), a combination of

GJJG/1 approximations given by Kramer and Lagenbach-Belz (1976) and Sakasegawa

(1977) is used. The QNA uses the former for Ca2 <1 and the latter approximation

for Ca2

1, resulting in,

w"

1u)

2

)u)

where,

g=

u) (1 Ca2

Iexpr_ 2(1

L

L1forCa2

3u

1

2

Ca2+Ce2

]

for Ca2 <1

2.2 Departure Process Approximations

Exact formulae for calculating the Cd2 value for a workstation (where Cd2 is the

squared coefficient of variation of inter-departure times from a workstation) are available

in only some special cases. For instance, in the case of the M/M/1 queue, the time

between departures is exponentially distributed. For the cases where the arrival time and

service time distributions follow a general distribution, the coefficient of variation of

inter-departures, Cd2 can only be estimated.

For a system consisting of a series of workstations the mean inter-arrival time and mean

inter-departure time of all workstations is the same if the utilization of all workstations is

strictly less than one (except for the first workstation which is assumed to have an infinite

supply of jobs). Also, the arrival process to a workstation is the departure process from

the prior workstation (with the exception of the first workstation). Therefore, the Ca2

value for a workstation other than workstation 1, is the Cd2 of the prior (upstream)

workstation. There have been several different approximations developed for Cd2, for a

workstation that does not have an infinite supply of work. These approximations are two-

moment approximations that utilize the squared coefficient of variation, and average

inter-departure times from prior workstations. Hopp and Spearman (1995) have proposed

a simple method for calculating Cd2 as a weighted ratio of

Ca2

and Ce2. The expression

for calculating Cd2 being,

Cd2 = u2Ce2 +(lu2)Ca2.

Buzacott and Shanthikumar (1993) have derived approximations for Cd2 using the

decreasing mean residual life (DMRL) property of the inter-arrival distribution. The

approximations are as given below:

Cd2 =(1u2)

ICa2 +u2Ce2

Cd2 =1u2 +u2Ce2 +(Ca2

1+u2Ce2

}+u2Ce2 and

l){(lu)(2u)+uCe(lu)}

2u + uCe2

These researchers point out that these approximations for Cd2 would work well only

ifCa2

1. Similarly, according to Whitt (1993), there may be serious errors in the

estimated values for the average number in system if Ca2 takes up values as high as 15 or

more.

Justification for the use of moment approximations in general is provided in Whitt

(1982), where an examination of the approximation of the superposition of point

processes by renewal processes is conducted. It is then suggested that distributions

matching moments of the superposed processes can be used to represent the renewal

distribution. These methods can, however, be used to fit a distribution only when the

moments to be matched satisfy a set of conditions derived in the research.

2.3 Serial Automated Systems With Finite Buffers

In contrast to a series of automated workstations with infinite buffer capacity, there has

been much more research directed towards analyzing a series of workstations with finite

buffers. In these systems the presence of finite buffers reduces throughput by causing

blocking of workstations.

A review of some of the studies that have focused on the analysis of serial production

lines involving automated workstations is given below. Altiok (1982) presented a method

to analyze a serial production line with blocking in which the workstations had Poisson

distributed arrival and departure processes and exponential processing times. Buzacott

(1966) analyzed an "automatic transfer line" with the aim of finding out the relationship

10

between capacity of buffers and the efficiency of the production line. Gershwin (1987)

analyzed the automated production line system with finite buffers and presented an

iterative method to evaluate approximate throughput and queue lengths. The method used

in this study was to analyze a serial line as a sequence of 2-workstation lines. This

process was iteratively applied to the whole line. Gershwin (1993) also presented a

method to calculate the variance of the output of a tandem production system.

Most of prior methods are numerical and thus require specially coded software to

implement. In contrast the objective of this research is to build an analytical model for

analyzing a production line consisting of a series of automated workstations with infinite

buffers.

11

3. ANALYTICAL MODEL

The approach taken in this research to develop an analytical method for analyzing an

arbitrary number of automated workstations in series uses a two-workstation Markov

chain model as a building block. The Markov Chain Model, given in Appendix A,

provides an analytical expression for the average number of jobs in Workstation 2 (WS

2). This model is a discrete time approximation of the continuous time system of two

workstations in series. Due to the discrete nature of the model, the workstation

parameters required are the failure probability, f and repair probability, r in place of the

mean time between failures (MTBF) and mean time to repair (MTTR). As found in Kim

(2003), the failure probabilityf, is defined as the probability that a workstation will move

into a down state at the end of the time cycle, if it had been up and processing ajob at the

start of the time cycle. Similarly the repair probability, r is the probability that a

workstation would be repaired at the end of the time cycle if it was in the down state at

the start of the time cycle. Assume for now that we have a method to calculate the failure

and repair probabilities from a workstation's MTBF and MTTR. The approach used for

analytically calculating the average number of jobs in downstream workstations is called

two-workstation decomposition and is outlined below.

Figure 1. The two-workstation decomposition approach.

12

Two-workstation Decomposition Approach

1.

First apply the Markov chain model to the first two workstations of a production

system. Use a set of "linking equations" to calculate parameters of a single

"aggregate" workstation (failure and repair probabilities) such that the first two

moments of the departure process (inter-departure time process) from this

aggregate workstation equals the first two moments of the departure process from

the second workstation. In other words, using the linking equations, WS 1 and

WS 2 can be now replaced by a single "aggregate

workstation", that mimics the

output process from WS 2 (Figure 1).

2. The parameters for the aggregate-workstation and the parameters for WS 3 can

now be used in the Markov chain model to calculate the average number of jobs

inWS3.

3. This process is then repeated for subsequent workstations assuming the aggregate

workstation is now the first workstation in the system.

The rest of this chapter is organized in the following manner. A method to convert the

MTBF and MTTR values of a WS, into the failure and repair probability f and r is

described in section 3.1. This then sets the stage for the application of the Markov chain

model (Appendix A) for the first two workstations. Section 3.2 describes the derivation

of the probability distribution for the inter-departure time from WS 2. One of the terms

involved in this probability distribution isP, the probability that a job leaves WS 2

empty, which is the "information" calculated from the Markov chain model. The

calculation of this term is described in section 3.3.

13

3.1 Finding Markov Chain Failure and Repair Probabilities

In the two-workstation decomposition method described, a basic component of the

method is to combine two adjacent workstations into one aggregate workstation. The end

result of this is that it facilitates the use of the Markov chain model (Appendix A) on two

new workstations, namely, the aggregate workstation and the workstation downstream of

the aggregate workstation. However, before applying the Markov chain model and the

two-workstation decomposition method, all of the continuous time workstation

parameters (MTBF, MTTR) must be translated into Markov chain model parameters

(failure and repair probabilities). This is described in this section, where the objective is

to find expressions for Markov chain parameters for a workstation a function of the

workstations MTBF and MTTR, such that the mean and variance of the time a job spends

in a workstation is the same in continuous and discrete time.

The approach used is to derive expressions for the mean and variance of time that a job

spends in a workstation (processing time) in a discrete model with given failure and

repair probabilities. These expressions can then be equated to known expressions for the

mean and variance of time that a job spends in the workstation, which are functions of the

MTBF and MTTR. The failure and repair probabilities can then be expressed as functions

of workstation MTBF and MTTR.

Let, P = the total time spent by a job in a workstation. It may be observed that P is the

sum of the unit processing time and random downtime of the workstation, if any.

The quantities E[PJ, E[P2] and Var[PJ for an automated workstation (in discrete time)

having parameters f and r are derived as shown below.

14

3.1.1 First Moment of the processing time

By conditioning on whether the workstation was up or down when the job enters the

workstation we have,

E[P] = E[P I =1] * P(I =1) + E[P 1

0] *

P(I = 0) , where,

I = 1 if a failure occurred when a job just moves into the workstation

=0 otherwise.

E[P] =

f*

+ 1)(1

r)' r + 1 * (1f)

where, k is the time to repair the workstation and hence k

k

(1)

1, 2. . co. We know that

0 when a failure has, indeed occurred.

Evaluating (1)

(2)

3.1.2 Second Moment of the processing time

Conditioning once again on the indicator variable I, which was defined previously,

E[P2] = E[P2

I 11* P(I = 1) + E{P2 I = 01* P(I = 0)

I

E[P2]=f*(k+1)2(1_r)lr+(1)2 *(1_f)

Evaluating the right hand side of the above equation,

r2 +f(2+r)

r2

Var[P]

E[P2]

(E[P])2

(3)

15

Using (2) and (3) above, the following variance of the time spent by a job in a

workstation having f and r as parameters, is calculated.

Var[P]

f(2

r

f)

(4)

The above expression can also be arrived at using the method given below:

Var[PJ = E1[Var(P I)] + Var1[E(P I)] (Ross, 1988),

I

I

(5)

where, I is as defined previously.

Since the random variable Y I = 1 is a geometric random variable with the parameter r,

Var(PII=1)=

1r

r

(6a)

2

If the workstation is up, the variance of the processing time is 0, because of deterministic

unit processing times for the workstations.

Var(PII=0)=O,

(6b)

Using (6a) and (6b),

E1[Var(P

Similarly,

J)]

f*

(1

r) + O*(1_f)

r

f(1

r2

r)

(7)

16

EJ[E(P I

I)]

(1+

+ (1f)

(8a)

* f + (1f) * (1)

EZ{E(P I 1)2] = (1

f+2fr+r2

(8b)

r2

Using (8a) and (8b),

f+2fr+r2

Var[E(PII)]=

_1i+L2

(9)

r)

r2

Using (7) and (9),

Var{P]

j(2

,which is the same as (4), given above.

3.1.3 Failure and repair probabilities for a WS

The mean and variance of the time spent by a job in a workstation (in continuous time)

can be expressed as a function of the workstation's MTBF and MTTR. For the system,

being considered here, it is assumed that MTBF and MTTR for the workstations are

independent and exponentially distributed.

E[P]

(MTBF + MTTR1

MTBF

)S

17

In the automated workstation being considered in this study, the processing times all the

workstations are assumed to be equal and deterministic, and hence without loss of

generality, S = 1.

Hence,

E[P]

MTBF + MTTR

MTBF

(10)

The variance of the time spent by a job at a workstation has been derived by Kim and

Alden (1997).

Variance=

(2MTTR2 "(

1

MTBF J1sJ

(11)

Similar to Equation (10), the value of S is equal to 1 in the above equation as well.

The mean and variance of time spent by a job in a workstation can now be calculated.

These two values can be matched with the expressions in f, r of the mean and variance of

time spent in a workstation (Equations (2) and (4)).

Solving the following equations,

MTBF+MTTR

MTBF

r

2MTTR2f(2rf)

MTBF

ç

gives

2MTTR

MTBF+MTTR+2*MTBF*MTTR

18

(12)

2MTBF

r=

MTBF + MTTR +2 * MTBF * MTTR

Thus, the parameters f and

r

of a workstation can be calculated from the MTBF and

MTTR of the workstations. This is done so that the parametersf and r can then be used in

the Markov chain model, described in Appendix A, to calculate the average number of

jobs in the system.

3.2 Distribution of inter-departure times from WS 2 in the two-workstation Markov

chain model

Consider two workstations in series operating in discrete time with failure probability

and repair probability r, for workstation i (i

departure times from WS

2

1,

2).

f,

The mean and variance of the inter-

can be calculated if the underlying probability distribution of

the inter-departure times is known. Since the Markov chain model is discrete, this

distribution will be a discrete probability distribution.

Let, k = time between departure of jobs from WS

2.

It can be seen that

k is

a positive-

valued discrete random variable.

Let,

E:

the event a job leaves WS

F:

the event ajob leaves WS 2 in a failed state; P(F) =

2

empty; P(E) =

Since events E and F only occur when a job is leaving a workstation, the status of the

workstations just before the occurrence of E is that WS 1 is down, and WS

2

is up, and

19

for F, WS 2 is up. Given that WS 2 is up, its probability of failure is independent of the

contents of its input buffer. Hence the following holds true.

P(EnF) P(E)*P(F)

The probability of the event E, P is calculated using the Markov Chain model as shown

in the next section.

To derive the probability distribution of the inter-departures, we condition on specific job

inter-departure times from WS 2.

k=l

The inter-departure time of jobs can be 1, only when the events Ec and Fc occurred at

the departure of the

th

job. In other words, WS 2 should not be down and non-empty

after the departure of the nth job.

Hence,

P(k

=1)=(1_Pe)(1f2)

k=2

Let I = 1, if WS 2 is empty but has not failed after the departure of the nth job,

= 2, if WS 2 has failed but is not empty after the departure of the nt job,

= 3, if WS 2 has failed and is also empty after the departure of the ntI job,

=4, if WS 2 has not failed and is not empty.

(13)

20

It can be seen that,

P(I =:1)=Pe(1_f2)

P(I=2)=(1P)f2

P(I

)pef2

P(I =4) = (1 i )( f2)

(14)

It can be verified thatP(I =r)=1. We also haveP(k=q,q2I =4)=0, because

if I = 4, then k = 1 is the only possibility.

Using the law of total probability,

P(k=2)=>P(k=2II =p)P(I =p)

(15)

For the case I = 1, for k to be equal to 2, WS 1, must have been repaired by the time

the flth job departs from WS 2. Hence, the 2 time units are just times spent by the (n + 1)th

job in getting processed in WS 1 and WS 2. Hence,

P(k = 21 I =

1)

=

Using a similar argument, it can be seen that,

P(k = 2 I I = 2) =

P(k = 21 'n 3) = rr2

21

Hence, from (14),

P(k

2) = J(1

(1 J)f2r2 +

f2)ij +

(15)

k=3

We use the same indicator variable I,, as defined above. The next step would be to

calculate the values of-

P(k = 3 I

I = m),m = 1,2,3.

For the case I = 1, for k to be equal to

3,

the (n +

1)th

job must have spent

2

time units

in WS 1 and its queue and 1 time unit in getting processed by WS 2. This means that,

after the departure of the n job from WS 2, one time unit was used up in the repair of

WS 1, and

2

time units were used up in the processing of the (n +

l)t1

job on each of the

two workstations. Hence,

P(k=3JI =1)=(1i)r.

For the case I = 2, for

units in WS

2

(16)

to be equal to

k

3,

the (n +

l)t1I

job must have spent two time

without getting processed. This means that at the end of the first time unit

after the departure of the

job, WS

2

must still have been in a failed state. At the end of

the second time unit after the departure of the nth job, WS

2

must have been repaired and

at the end of the third time unit the (n + l)th job must have departed from WS 2. Hence,

(17)

P(k=3II =2)=(1r2)r2.

For the case I =3, for

k

to be equal to

3,

the (n

l)th

job could have spent 2 time units

in WS 1 or in WS 2. We condition on the state of WS 1 after the departure of the ntl job.

22

Let,

J, =0, if WS 1

= 1,

is down when the nth job departs, and

if WS 1 is

up when the nth job departs.

By definition, we have

P(J =0) =1

P(J =1) =

If J, = 1,

then the (n +

1)t1

job must have spent 1 time unit in getting processed in WS 1,

one time unit in WS 2 without getting processed and 1 time unit getting processed in

WS 2. Hence we have the following,

P(k=3II =3,J =1)=(1r2)r2.

Consider the case when k

(18)

= 3, J, = 0

(andI = 3).

WS 1

must necessarily get repaired at

the end of the next time unit (the next time unit after the departure of the nh job) so that

k = 3 is

true. The probability of the occurrence

time unit after the departure

of the

of this

event is rj. At the end

of the

first

nh job, WS 2 may or may not have been repaired.

Let,

K = 1, if, after the departure of the nth job from WS 2, the (n + 1) th job takes 1 time unit

to arrive at WS 2.

= 2, if, after the departure of the nth job from WS 2, the (n + l)th job takes 2 time

units to arrive at WS 2.

= 3,

if, after the departure

of the

nthjob from WS 2, the (n + l)th job takes more than

2 time units to arrive at WS 2.

The distribution for the indicator variable

K

is as follows.

23

P(K =1) =0

P(K =2) =

P(K =3) =1

We therefore have, the following:

P(k=3II=3,J=0,K=2)=r2+(1r2)r2

P(k=3II =3,J =O,K =3)=O

(19)

We now uncondition on the indicator variable, K,, to get the following.

P(k=311,, =3,J,, =O)=r(r +r2(lr2))

(20)

We now uncondition on the indicator variable, J,, (Equations 18 and 19 given above) to

get the following.

P(k=311,, =3)=(1ij){rj(r2 +r7(1r2))}+r1{(1r2)r2}

(21)

Finally, we uncondition on the indicator variable, I,, (Equations 14, 16, 17 and 21 above)

to get the following.

P(k = 3) =

1f2)[(1ij)ij]+(1P,,)f2[(1r2)rj

+Jf2[(1r1){ij( +i(1r2))}+11{(1r2)r2}]

k = c, C

4

We use the same indicator variable I,,, as defined above.

24

For the case when I =1, WS 1 must have not been repaired for c 2 time units after the

departure of the nh job. In addition to this, WS 2 must also have got repaired at the end of

the c

1 time units, so that the (n + l)th job departs after c time units. Therefore, we have

the following equation.

P(k=c,c4JI =1)=(1-r1)2ij

(22)

Similarly, for the case when I,, =1, WS 2 must not have been repaired for c

units and must have got repaired after c

2 time

1 time units, after the departure of the nth job

from WS 2. Therefore we have,

P(k=c,c4JI =2)=(1_r2)c_2r2

(23)

For the case I =3, consider the indicator variable J as defined above. For the case

J, =1 (that is, WS 1 is up when the n1 job departs WS 2), it can be seen that WS 2 must

not have been repaired for c

at the end of c

2 time units and subsequently, it should have got repaired

1 time units. Therefore we have,

P(k=c,c4II =3,J =1)=(1_r2)c_2r2

(24)

For the case I =3 and J =0, consider the indicator variable L, defined as given

below.

= 1, if, after the departure of the nth job from WS 2, the (n + l)th job takes c 2 time

units or less to arrive at WS 2.

= 2, if, after the departure of the nt job from WS 2, the (n + l)th job takes exactly

c

1 time units to arrive at WS 2.

25

= 3, if, after the departure of the nth job from WS 2, the (n + l)th job takes more than

c

1 time units to arrive at WS 2.

The probability distribution for the indicator variable L is given below.

P(L =l)=(1r)r,

P(L

=2)=(1,y31

P(L =3)=(1-iiY2

It can be verified that

P(L = j) =1, holds true.

It can be seen that ifL =1, then WS 2 must have taken c

1 time units to get repaired.

Hence, we have,

P(k=c,c4II =3,J =O,L =1)=(1_r2)c_2r2.

Similarly, if L = 2, then WS 2 must have taken c

1 time units or less to get repaired.

Hence, we have,

P(k=c,c4II =3,J =O,L =2)=(lr2)'r2.

It can be seen that ifL =3, then k cannot equal c. Hence we have,

P(k=c,c4II =3,J =O,L =3)=O.

26

We now uncondition successively on the indicator variables used. We first uncondition

on Ln , to get the following.

cI

C-4

j=I

i=o

"n =O)=(1_ij)c_3, *(1_r2)lr2 +(1r2)2r2 *(1_rj)1r1

P(k=c,c4II

We uncondition on J, andI, successively and in that order, to get the following.

P(k = c, c 4)

=Pe(1f2)[(1 _rj)c_2ri] +(1 P)f2[(1 _r2)r2]

+((lr2)2r2)(1i)} r1{(lr2)2r2}]

The complete probability distribution for the inter-departure times is given below.

P(k=1)=(1I)(1f2)

P(k = 2) =](1f2)ij +(1P)f2r2 +1f2ijr

P(k =3) =I(lJ)[(lij)i]+(lI)f2[(lr2)i]

+]f2[(1ij){ij(r2 +r2(lr2))}+ij{(lr2)r2}]

P(k = c, c 4)

f2)[(1

r)2rJ + (1

Pe)f2[(1 r2)

ci

c-2

r2]

c-4

[(1_r1){((1_r1)r1)(1r2yr2 +((1r2)2r2)(1r1)r1} +

1

j=i

[1{(1r2)

c-2

r2}

]

The above distribution can be used to calculate the mean and the variance of the interdeparture times, if the value of P is known.

The first two moments of the inter-departure times from WS 2 have been calculated and

are as follows.

27

= Mean2

E{k] =1+

Ti

E[k2]=

r +f2(2+r)(2

+-+ f2r2(

1

1)f2(2+ij)

(r+rrr)2

L'ii

J

The details pertaining to these calculations are given in Appendix D.

3.3 Information from the Markov Chain model

Let X be the long term probability of the system of WS 1 and WS

2

being in a state which

can lead to departure ofajob, given that a job, indeed departed.

Let,I = 1, if there is exactly 1 job in WS 2 at the start of cycle,

= 2,

if there are 2 or more jobs in WS

In the Markov chain model (Appendix A),

2

r0

at the start of cycle.

and

of finding zero and one job respectively in the WS

WS

2

r1

2

refer to the long-term probabilities

system (that is the number ofjobs in

and its queue).

It can be seen that,

=1)

= 2) = 1

The notation used in Appendix A for describing the long term probabilities involved with

certain events is given below. ib, is the long term probability of finding WS 1 in state

a, WS 2

in state b, given q jobs in the WS 2 system. The variable

a takes

a value of 1 or 0

depending on whether or not WS 1 is up. Similarly b takes values 1 or 0 depending on

whether or not WS 2 is up.

1, then the long term probability of being in a state which can lead to a departure

If I

of ajob from WS 2, isz1 + ,r. Similarly, whenI = 2, this probability isa

+

,r0.

Using the law of total probability,

X=(1

+

+ (if1 + 7t1)if1

By the definition ofI,

,r1,rI

__=________________

X

(1 ifX1TH2 + r) + (r1 +

The distribution of inter-departures from WS 2 has now been completely defined, from

which the mean and variance of inter-departures can be calculated. As discussed

previously, the next step is to replace WS 1 and WS 2 by a single workstation whose

output process mimics the output process of WS 2. This is done by matching the mean

and variance of inter-departures from both cases.

Thus, if Mean2 and Variance2 denote the mean and variance of inter-departure times from

WS 2, the parameters of the aggregate-workstation, namely, f' and r' are obtained by

solving the equations,

Mean2 =1+

Variance2

which leads to,

f'(2r'f')

29

f

r=

2(1-2Mean2

+Mean)

Mean2 Mean2 +

2(Mean2

Mean

Variance2

1)

Mean2 + Variance2

(16)

30

4. EVALUATION OF METHODOLOGY

Discrete-event simulations of serial automated workstations were carried out to evaluate

the performance of the analytical model. Arena 5.0 (Rockwell Software) was the

simulation tool used to carry out these studies. The simulation results for the average

number of jobs in the workstations and their input queues were compared with that

predicted by the analytical model. The simulation of automated workstation systems was

carried out until 1 million jobs had been processed by all the workstations present in a

particular system. The output from these simulations was the average of the average

number of jobs in system for each of the workstations over 30 replications. In addition,

comparisons between the results given by the analytical model and those given by some

of the GJIG/1 approximations discussed in the literature section are also given.

The following factors were used to create a variety of serial workstation systems for

analysis.

1. Number of automated workstations in the system.

2. Coefficient of variation of the processing time of the workstation.

3. Utilization of the workstations.

Experiments were conducted at different "levels" of each of these factors as shown in the

table below.

31

Table 1. The different factors and the levels for the simulations

Factor

Number of Levels Description of levels

Number of WS, N

2

1. Number of workstations = 3

2. Number of workstations = 10

1. CV between 0 and 1

2. CV between 1 and 2

CV of processing

3. CV between 2 and 3

5

times, Ce

4. CV between

3 and 4

5. CV between

4 and

1.

Utilization, u,

2

5

Utilization between 0.80 and 0.90

2. Utilization between 0.90 and 0.95

4.1 Simulation of 3-workstation systems

The MTBF and MTTR values for these systems were generated randomly. The procedure

is outlined below:

1.

Let the CV of processing times (total time spent by a job in a WS) be between

CV10

and

CV/,jgh

Let the utilization of the workstations be between

and

Uhj.

2. Effective speed Se of a WS may be defined as the product of the actual speed S of

the workstation and the proportion of time the WS is up. Hence, we have,

Se=SI

MTBF

(\MTBF + MTTR

32

It was ensured that all workstations had an effective speed of more than 0.5. In

other words, the MTBF is always greater than the MTTR for any workstation.

3. Very large and very small MTBF and MTTR values (values greater than 10,000

and less than 0.1), if any, were discarded.

4. First, the effective speed of WS 1, Se1, was arrived at, by generating a random

number between 0.5 and

U high

5. Secondly, the CV of processing times on WS 1, Ce1, was arrived at, by generating

a random number between

and

CVh,gh

6. The MTBF and MTTR values for WS 1 can be calculated using the following set

of equations:

cv2

MTBF1=

2(Se1

1)

2

(17)

C2

MTTR1

2(Se1 1)Se1

The following is a description of the procedure used to derive the above set of

equations. By definition, the following equations for

Se1

and Ce12 hold true.

MTBF

MTBF + MTTR

Se

2

Ce1 =

2(MTTRI2/MTBF)

(1/Se)2

Solving for MTBF1 and MTTR1 in the above equations leads to equation set given

in (17).

7.

For subsequent workstations in the system, a similar procedure was adopted,

except for the fact that the speeds of these workstations were random numbers

generated between

and 1. This was done to ensure that the utilization values

U high

33

for the workstation was less than 1 and the speed of the workstation was more

than speed of WS 1.

The following table gives the list of all the experimental sets carried out on systems

having 3 automated workstations.

34

Table 2. Description of the different 3-workstation systems simulated

Label for

Number of

Experiment

workstations systems simulated

3_WS_CV1_L

3

20

3_WS_CV2_L

3

20

Number of

Description of the system

CVs between 0 and 1

u, s between 0.8 and 0.9

CVs between 1 and 2

U

s between 0.8 and 0.9

CVs between 2 and 3

3_WS_CV3_L

3

20

3_WS_CV4_L

3

20

u, s between 0.8 and 0.9

CVs between 3 and 4

CVs between 4 and 5

3

3_WS_CV5_L

u, s between 0.8 and 0.9

20

u, s between 0.8 and 0.9

CVs between 0 and 1

3_WS_CV 1_H

3

20

3_WS_CV2_H

3

20

3_WS_CV3_H

3

s between 0.9 and 0.95

CVs between 1 and 2

u, s between 0.9 and 0.95

CVs between 2 and 3

20

U

s between 0.9 and 0.95

CVs between 3 and 4

3_WS_CV4_H

3

20

U

s between 0.9 and 0.95

CVs between 4 and 5

3_WS_CVS_H

3

20

s between 0.9 and 0.95

In addition to the experimental sets described in the above table, two other 3workstation

systems were also simulated. In the first set of experiments, the second and the third

Ji

workstations were identical. In the second set of experiments, the second and the third

workstations were ensured to have very different Ce values. In other words, the third

workstation would have a Ce between 4 and 5, if the second workstation had a Ce

between 0 and 1, and vice-versa. Five such systems were randomly generated and then

the second and third workstations were inter-changed so that there were a total 10

different 3-workstation systems with the second and third workstations having dissimilar

Ce

values. The following table summarizes the two additional experimental sets of 3-

workstation systems.

Table 3. Additional 3-workstation systems simulated

Label for

Numberof

Number of

Experiment

workstations

systems simulated

3_WS_Dis

3

10

Descnption of the system

Ce1

between 0 and 5.

Ce3

between 0 and 1 if

Ce2

between 4 and 5, and viceversa.

u, s between 0.8 and 0.95

3WSSim

3

10

Ce1

between 0 and 5.

Ce2

between 0 and 5.

WS 2 and WS 3 identical.

4.2 Simulation of 10-workstation systems

A total of 6 experimental sets having 10-workstations were simulated. In the first set, the

Ce values

of the workstations were allowed take values between 0 and 5. In the five

subsequent sets of experiments, the Ce values of the workstations were allowed to take

values within smaller intervals as summarized in the table below.

Table 4. Description of the different 10-workstation systems simulated

Label for

Numberof

Number of

Experiment

workstations

systems simulated

10_WS_CVO5

10

10

Description of the system

Ce values between 0 and 5.

u.s between 0.8 and 0.95

Ce values between 0 and 1.

1 0_WS_CV 1

10

10

10_WS_CV2

10

10

1 0_WS_CV3

10

10

10_WSCV4

10

10

10_WSCV5

10

10

u, s between 0.8 and 0.95

Ce values between 1 and 2.

u.s between 0.8 and 0.95

Ce values between 2 and 3.

s between 0.8 and 0.95

Ce values between 3 and 4.

s between 0.8 and 0.95

Ce values between 4 and 5.

u,s between 0.8 and 0.95

Thus, there were 18 experimental sets in all

12 of which were systems having 3

workstations and the rest having 10 workstations.

A total of 5 GI!G/1 approximations were compared with the analytical model. In the

analytical model, the linking equations provided the mean and variance of inter-departure

times from workstation i. For the

GJJGI1

approximations, three different methods to

calculate Cd,2 found in the literature were used. Thus, this resulted in a total 15

37

combinations against which the results from the analytical model were compared. The

different combinations are listed in the table given below.

Table 5. List of all the different theoretical models

Label

Calculation for average number in system

Calculation of departure process

Markov chain model

Linking equations

2

Marchal (1976)

Hopp and Spearman (1995)

3

Marchal (1976)

Buzacott and Shantikumar (1993)

4

Marchal (1976)

Buzacott and Shantikumar (1993)

1

Marchal (1978),

5

Hopp and Spearman (1995)

Hopp and Spearman (1995)

Marchal (1978),

6

Hopp and Speannan (1995)

Buzacott and Shantikumar (1993)

Marchal (1978),

7

Hopp and Spearman (1995)

Buzacott and Shantikumar (1993)

8

Daley (1977)

Hopp and Spearman (1995)

9

Daley (1977)

Buzacott and Shantikumar (1993)

10

Daley (1977)

Buzacott and Shantikumar (1993)

11

Kraemer Langenbach-Belz (1976)

Hopp and Spearman (1995)

12

Kraemer

Langenbach-Belz (1976)

Buzacott and Shantikumar (1993)

13

Kraemer Langenbach-Belz (1976)

Buzacott and Shantikumar (1993)

14

Whitt (1983)

Hopp and Spearman (1995)

15

Whitt (1983)

Buzacott and Shantikumar (1993)

16

Whitt (1983)

Buzacott and Shantikumar (1993)

The measure of performance used for the comparison of each of the 16 models listed

above was the absolute percentage errors calculated as shown below.

38

Absolute Percentage Error = IQsim

'sim I

S

where,

Qsjm

'sim

x 100%,

= the average number ofjobs in system from simulation,

= the average number ofjobs in system predicted by a model.

The graphs for the average of the absolute percentage errors in each of the 18

experimental sets are given in the next chapter.

39

5. RESULTS

5.1 Results for 3-workstation systems

For each of the 3-workstation system categories mentioned in Table 2 there were 20

different systems simulated on Arena. As shown in Table 2, there were 20 different 3

workstation systems simulated. From each of those simulations, the average number of

jobs in WS 3 was obtained and the Absolute Percentage Error (APE) was calculated as

shown previously. The following graph shows the average of the 20 APE values obtained

for the average number of jobs in system for WS 3. In the graphs that follow, the x-axis

represents the different models

for instance, model 1 represents the analytical model

that was derived in this research.

3 WS CVI L

Average Errors for average number of Jobs in WS 3 and its queue

0.45

0.4

0.35

0

0.3

0.25

o

0.2

0.15

0.1

0.05

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Index for the model

Figure 2. Results for the 3_WS_CV1_L system.

16

17

16

19

40

In the case of the 3-workstation systems mentioned in Table 3 and the 10-workstation

systems mentioned in Table 4, the number of systems simulated on Arena was 10.

3 WS CV2 L

Average Errors for average number of jobs in WS 3 and its queue

0.45

0.4

0.35

0

0.3

C

0.25

0.2

a

0.15

a

0.1

0.05

1

2

3

4

5

6

7

8

9

10

11

12

13

Index for model

Figure 3. Results for the 3_WS_CV2_L system

14

15

16

41

3 WS CV3 L

Average Errors for average number of jobs in WS 3 and Its queue

0.45

0.4

0.35

0

0.3

C

0.25

0.2

.0

4

a

0.15

a

0.1

0.05

0

2

4

3

5

7

6

8

9

10

11

12

13

14

15

16

Index of model

Figure 4. Results for the 3_WS_CV3_L system

3 WS CV4 L

Average Errors for average number of jobs in WS 3 and Its queue

045

0.4

0.35

0

0.3

0.25

0.2

.0

4

a

0.15

4

0.1

0.05

0

1

2

3

4

5

6

7

8

9

10

11

12

13

Index for model

Figure 5. Results for the 3_WS_CV4_L system

14

15

16

42

3 WS CV5 L

Average Errors for average number of jobs in WS 3 and its queue

0.45

04

0.35

0

0.3

025

a.

a

0.2

.0

a

0.15

0.1

0.05

1

2

4

3

5

6

8

7

9

10

11

12

13

14

15

16

Index for model

Figure 6. Results for the 3_WS_CV5_L system

3 WS CVI H

Average Errors for average number of jobs In WS 3 and Its queue

045

0.4

0.35

0

0.3

C

0.25

02

a 0.15

a

0.1

0.05

0

1

2

3

4

5

6

7

8

9

10

11

12

13

Index of model

Figure 7. Results for the 3_WS_CV1_H

14

15

1

43

3 WS CV2 H

Average Errors for average number of Jobs in WS 3 and its queue

0.45

0.4

035

0

w

0.3

C

S

S

0.25

a-

C

0.2

.0

a

e

0.15

0.1

005

0

I

2

3

4

5

6

7

8

9

10

11

13

12

14

15

16

Index for model

Figure 8. Results for the 3_WS_CV2_H

3 WS CV3 H

Average Errors for average number of Jobs in WS 3 and its queue

0.45

0.4

0.35

0

Ui

& 0.3

C

S

a

0.25

a.

0.2

0.15

0.1

0.05

0

1

2

3

4

5

6

7

8

9

10

11

12

13

index for model

Figure 9. Results for the 3_WS_CV3_H

14

15

1

44

3 WS CV4 H

Average Errors for average number of jobs In WS 3 and its queue

0.45

0.4

0.35

0

0.3

0.25

0.2

.0

0

a

0.15

0.1

0.05

0

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

Index for model

Figure 10. Results for the 3_WS_CV4_H

3 WS CV5 H

Average Errors for average number of jobs In WS 3 and Its queue

0.45

04

0.35

0

0.3

C

0.25

a

0.2

.0

0

0.15

a

0.1

0.05

0

1

2

3

4

5

6

7

8

9

10

11

12

Index for model

Figure 11. Results for the 3_WS_CV 5_H

13

14

15

1

3_WS_Dis

Average Errors for average number of jobs In WS 3 and its queue

o 45

0.4

0.35

2

0.3

0.25

0.2

0.15

0.1

0.05

0

2

3

4

5

6

7

8

9

10

12

11

13

14

15

16

13

14

15

16

Index for model

Figure 12. Results for the 3_WS_Dis

3_WS_Sim

Average Errors for average number of jobs in WS 3 and its queue

0.45

0.4

0.35

0

0.3

025

6

02

a

a

0.15

0.1

0.05

0

2

3

4

5

6

7

8

9

10

11

12

Index for model

Figure 13. Results for the 3_WS_Sim

5.2 Results for 10-workstation systems

lowscv1

Average Errors for Average number of jobs In a WS and Its queue

0.350

0.300

4-1

5-2

3

0.250

w

a

*-5

4-6

8

C

0.200

4-- 7

e

a.

0.150

.0

10

11

5

12

13

0.100

14

* 15

16

0.050

0000

2

3

4

5

8

7

6

9

10

WorkStation

Figure 14. Results for the 1O_WSCV1

1O_WS_CV2

Average Errors for Average number of Jobs In a WS and its queue

0.350

0.300

.-1

4-2

w

S

3

0.250

4

*5

-

0.200

4-- 7

0

a.

S

.0

6

8

C

-.9

10

0.150

11

0

12

--

0.100

13

--.-.

14

15

16

0.050

0.000

1

2

3

4

5

6

7

8

WorkStation

Figure 15. Results for the 1O_WS_CV2

9

10

47

1 OWS_CV3

Average Errors for Average number of jobs in a WS and its queue

0.350

0 300

U-2

w

C

3

0250

4

-a-- 5

--6

C

8

9

0200

4--i

a

a-

a

a

0.150

10

.0

11

C

,'__\\S*.k

/

0 100

0 050

12

13

-*-- 14

5-15

____-

16

0.000

2

3

4

5

6

7

8

9

10

WorkStation

Figure 16. Results for the 1O_WS_CV3 system

1O_WS..CV4

Average Errors for Average numb.r of Jobs In a WS and Its queue

0.350

0300

.-1

U

w

C

* 5

C

8

0200

4-7

C

a-

C

a

a

2

3

_r. 4

0.250

0.150

10

11

C

12

.--..---.,......---,

13

0100

14

-*-- 15

16

0050

0 000

1

2

4

3

5

6

7

8

9

WorkStation

Figure

17.

Results for the 1 OWS_CV4 system

iC

1O_WS_CV5

Average Errors for Average number of jobs in a WS and Its queue

0.350

0.300

.-1

5-2

3

0.250

4

Mi

5-5

a

C

8

0.200

'--.7

a

a.

a

0

0.150

10

ii

.0

a

12

I!

13

0.100

14

15

16

0 050

A AflA

12345678950

WorkStation

Figure 18. Results for the 1 O_WS_CV5 system

1O_WS_CVO5

Average Errors for Average number of jobs in a WS and Its queue

0.700

0.600

.-1

5

2

3

p0.500

4

UI

5-5

a

--6

8

C

+7

0.400

a

aa

a

--9

0.300

10

.0

11

a

12

13

0.200

14

-

15

16

0100

0.000

2

3

4

5

6

7

8

WorkStation

Figure 19. Results for the 1O_WS_CVO5 system

9

10

49

5.3 Ranking workstations

For 10-workstation systems, the workstations were ranked on the basis of the average

number of jobs in the workstations and its queue, as given by the simulation. In other

words, the workstation with the highest value for the average number of jobs was given a

rank of 1. This ranking of workstations was carried out for workstations 3 through 10.

Such a ranking was also done for the predicted values given by the theoretical model and

each of the 15

GJJGI1

departure process combinations. The number of times, a

workstation was wrongly ranked by a model was counted. The results for this count are

given in Table 5. For example, it can be seen from the table that, in case of the

1 OWSCV 1 system, the theoretical model gave a wrong workstation rank in 18 cases

out of a total of 80 cases, whereas the K-L-Belz 1 combination gave a wrong workstation

rank in 45 cases.

Table 6. Number of cases of incorrect workstation ranks for 10-workstation systems

Model

Index

10 WS CV1

10 WS CV2

10 WS CV3

10 WS CV4

10 WS CV5

10- WS- CVO5

1

18

7

8

6

0

14

2

41

31

18

24

21

27

3

44

39

28

36

28

32

4

44

39

28

33

28

32

5

44

27

14

18

15

23

6

43

31

25

28

24

26

7

43

30

25

28

24

26

8

41

31

18

24

19

27

9

44

39

28

35

26

32

10

44

39

28

33

26

32

11

45

26

12

18

12

20

12

44

29

25

26

24

21

13

44

29

23

26

24

21

14

45

27

14

18

15

23

15

44

31

25

28

24

26

16

44

30

25

28

24

26

6. CONCLUSION

The analytical model developed in this research results in a model for analyzing a series

of automated workstations that clearly outperforms other existing analytical approaches

(Two-moment GIL/Gil approximations). In most cases tested, the various GJIG/l

approximations examined in this research resulted in higher average absolute percentage

differences (compared to simulation results) for the average number ofjobs in the system.

For the analytical model, the typical average difference was less than 5%. In addition, the

model seems to perform well for systems where the coefficient of variation of processing

times was greater than 4.0. Among the GTIGI1 approximations used, the ones given by

Kraemer and Lagenbach-Belz (1976) and Whitt (1973) seem to give better results than

the rest. The analytical model presented here, also gave fewer errors in the ranking of

queues than the GIIG/1 approximations. The implications of this study are two-fold. First,

it has been shown that there exists an accurate analytical approximation for calculating

the average number of jobs in the workstation and its queue for systems discussed in the

study. Secondly, the analytical model does give consistently better results than other

approximate methods studied.

51

Bibliography

Altiok, T., 1982, "Approximate analysis of exponential tandem queues with blocking",

European Journal of Operations Research, Volume 11, 390 398.

Buzacott, J. A. and Shanthikumar, J. G., 1993, "Stochastic models of manufacturing

systems", Prentice-Hall International Series in Industrial Engineering.

Buzacott, J. A., 1967, "Automatic transfer lines with buffer stocks", International Journal

of Production Research, Volume 5, Number 3, 183 200.

Feinberg, B.N. and Chiu, S. 5., 1987, "A Method to Calculate Steady State Distributions

of Large Markov Chains," Operations Research, Vol. 35, No. 2, pp. 282-290.

Gershwin B. S., 1992, "Variance of Output of a Tandem Production System", Queueing

Networks with Finite Capacity, Proceedings of the Second International Workshop held

in Research Triangle Park, North Carolina, May 28-29, 1992, 291

302.

Gershwin, B. S., 1987, "An efficient decomposition method for the approximate

evaluation of tandem queues with finite storage space and blocking", Operations

Research, Volume 35, Number 2, March April 1987, 291

305.

Heyman, D. P., "A diffusion model approximation for the GIIG/1 queue in heavy traffic",

Bell System Technical Journal, Volume 54, Number 9, 1637

1646.

Hopp W. J. and Spearman M. L., 1995, "Factory Physics: foundations of manufacturing

management", 2

edition, McGraw-Hill Higher Education.

Kim, D.S., 2003, "The "A/All" Queue: A Queuing Model for an Automated Workstation

Receiving Arrivals from an Automated Workstation", Submitted to TIE Transactions.

52

Kim, D.S. and Alden, J. M., 1997, "Estimating the distribution and variance of time to

produce a fixed lot size given deterministic processing times and random downtimes",

International Journal of Production Research, Volume 35, Number 12, 3405

3414.

Kim, D.S., and Smith, R. L., 1995, "An Exact AggregationlDisaggregation Algorithm for

Large Scale Markov Chains," Naval Research Logistics, Vol. 42, pp. 1115-1128.

Kingman, J. F. C., 1961, "The single server queue in heavy traffic", Proceedings of the

Cambridge Philosophical Society, Mathematical and Physical Sciences, Volume 57, 902

904.

Klincewicz, J. G. and Whitt W., 1984, "On approximations for Queues, II: Shape

constraints", AT&T Bell Laboratories Technical Journal, Volume 63, Number 1, January

1984, 139-162.

Kobayashi, H., 1972, "Applications of the diffusion approximations to queueing

networks: Part I

Equilibrium queue distributions", Journal of the Association for

Computing Machinery, Volume 21, 316-329.

Kramer, W., and Lagenbach-Belz, 1976, "Approximate Formulae for the Delay in the

Queueing system GJJGI1 ", Proceedings of the Eighth International Teletraffic Congress,

Melbourne, 10 17 November 1976, 235.1 235.8.

Lindley, D. V., 1951, "The Theory of Queues with a single server", Proceedings of the

Cambridge Philosophical Society, Mathematical and Physical Sciences, Volume 48, 277

289.

Marchal G. W., 1976, "An approximate formula for waiting time in single server

queues", AIIE Transactions, Volume 8, Number 4, 473

474.

Medhi J., 1991, "Stochastic Models in queueing theory",

2uid

edition, Academic Press.

53

Reiser, M. and Kobayashi, H., 1974, "Accuracy of the diffusion approximation for some

queueing systems", IBM Journal of Research and Development, Volume 18, 110 124.

Sakasegawa, H., 1977, "An approximate formula

Lq

a p'° 1(1 p) ", Annals of the

Institute of Statistical Mathematics, Volume 29, Part A, 67

75.

Shanthikumar, J. G. and Buzacott, J. A., 1980, "On the approximations to the single

server queue", International Journal of Production Research, Volume 18, Number 6, 761

773.

Whitt W., 1982, "Approximating a Point Process by a Renewal Process, I: Two basic

methods", Operations Research, Volume3O, 125-477.

Whitt, W., 1983, "The Queueing Network Analyzer", The Bell System Technical

Journal, Volume 62, Number 9, 2779 2815.

Whitt W., 1984, "On approximations for Queues, I: Extremal Distributions", AT&T Bell

Laboratories Technical Journal, Volume 63, Number 1, January 1984, 115

138.

Whitt W., 1984, "On approximations for Queues, III: Mixtures of Exponential

Distributions", AT&T Bell Laboratories Technical Journal, Volume 63, Number 1,

January 1984, 163

175.

Whitt, W., 1993, "Approximations to the GIJG/1 queue", Production and Operations

management, Volume 2, Number 2, 114 161.

Wolff R. W., 1988, "Stochastic modeling and the theory of queues", Prentice-Hall

International Series in Industrial and Systems Engineering.

54

APPENDICES

55

APPENDIX A

56

A.1 Markov Chain Model of Two Automated Workstations in Series (Kim (2003))

We develop a Markov chain model of two automated workstations in series assuming

there is an infinite supply of unprocessed jobs before the first workstation and infinite

storage space between the workstations. This Markov chain model is a discrete time

model where the fixed processing time t, serves as the discrete time unit (it is assumed

that both workstations produce at the same speed when up). By the discrete nature of the

model, the operating times between failures, and repair times will follow geometric

distributions. In most automated workstations, this type of discrete approximation is

sufficiently accurate since the fixed processing times are normally much smaller than the

time between failures and repair times.

The mechanics of the discrete time Markov chain are as follows:

State transitions occur at the end of each time step.

Any workstation that is down at the beginning of a time step may be repaired even if

the workstation is empty at the beginning of the time step.

A workstation that is up and not empty at the beginning of a time step will complete

its job even if it moves to a down state at the end of the time step.

Any jobs completed at the end of a time step are moved out of the workstations and

new jobs are moved into the workstations even if a workstation moves to a down

state. Note that ajob may be moved out of both workstations, and ajob moved into

both workstations at the end of a time step.

Workstations that are up at the beginning of a time step but idle because they are

starved, cannot change to a down state at the end of a time step.

Since the first workstation always has jobs to process, its output represents the input to

the second workstation (from an automated workstation). We assume that the average

processing capacity of the first workstation is strictly less than that of the second

workstation. This ensures that the queue size (feeding the second workstation) will not

57

steadily increase over time. The objective of the model is to analyze the behavior of the

second workstation and its input queue, which we will refer to as the "system".

We let the state of the Markov chain at time unit n, X, =

workstation i and x,

E {O,1}.

(x1 ,x2, N),

where

= status of

x, = 0 if the workstation is down a the beginning of a time

step, and x, = 1 if the workstation is up a the beginning of a time step.

N is the number

of jobs in workstation 2 plus the number in the buffer between workstation 1 and 2. p is

used to denote the transition probability matrix of this Markov chain.