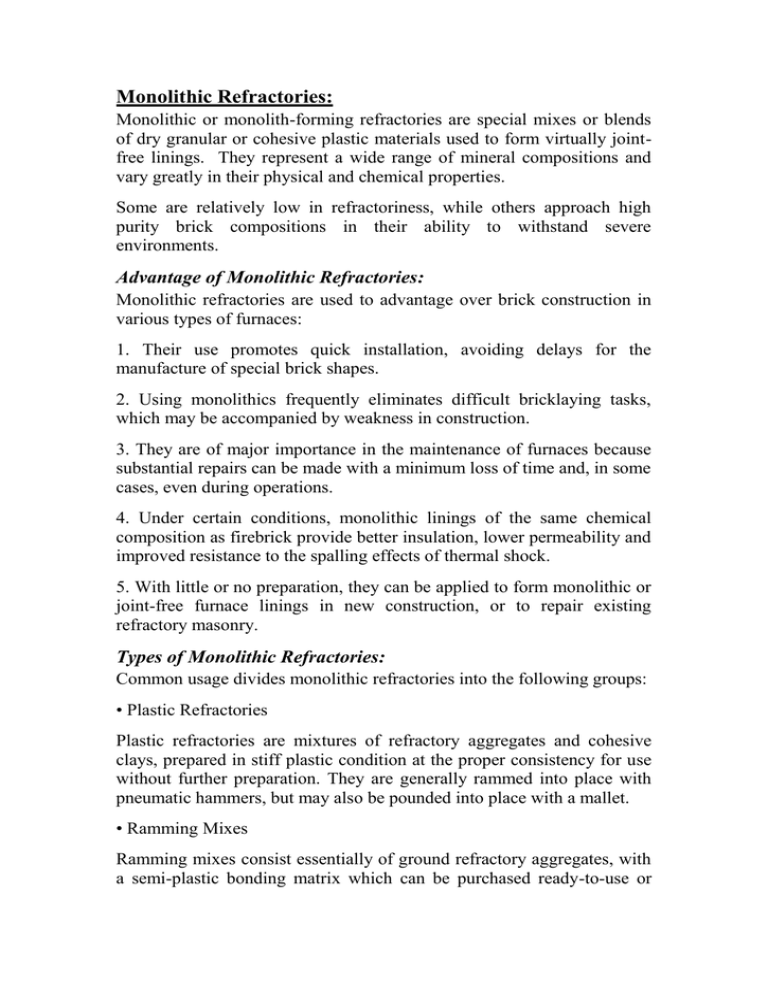

Monolithic Refractories:

advertisement

Monolithic Refractories: Monolithic or monolith-forming refractories are special mixes or blends of dry granular or cohesive plastic materials used to form virtually jointfree linings. They represent a wide range of mineral compositions and vary greatly in their physical and chemical properties. Some are relatively low in refractoriness, while others approach high purity brick compositions in their ability to withstand severe environments. Advantage of Monolithic Refractories: Monolithic refractories are used to advantage over brick construction in various types of furnaces: 1. Their use promotes quick installation, avoiding delays for the manufacture of special brick shapes. 2. Using monolithics frequently eliminates difficult bricklaying tasks, which may be accompanied by weakness in construction. 3. They are of major importance in the maintenance of furnaces because substantial repairs can be made with a minimum loss of time and, in some cases, even during operations. 4. Under certain conditions, monolithic linings of the same chemical composition as firebrick provide better insulation, lower permeability and improved resistance to the spalling effects of thermal shock. 5. With little or no preparation, they can be applied to form monolithic or joint-free furnace linings in new construction, or to repair existing refractory masonry. Types of Monolithic Refractories: Common usage divides monolithic refractories into the following groups: • Plastic Refractories Plastic refractories are mixtures of refractory aggregates and cohesive clays, prepared in stiff plastic condition at the proper consistency for use without further preparation. They are generally rammed into place with pneumatic hammers, but may also be pounded into place with a mallet. • Ramming Mixes Ramming mixes consist essentially of ground refractory aggregates, with a semi-plastic bonding matrix which can be purchased ready-to-use or prepared by adding water in the mixer at the construction site. Ramming mixes are placed with pneumatic hammers in 1-1.5 inch layers. They supply a denser, stronger refractory body than plastics, but need some sort of form to restrain them when rammed. • Gunning Mixes Gunning mixes consist of graded refractory aggregate and a bonding compound, and may contain plasticizing agents to increase their stickiness when pneumatically placed onto a furnace wall. Typically, gunning mixes are supplied dry. To use, they are predamped in a batch mixer, then continuously fed into a gun. Water is added to the mix at the nozzle to reach the proper consistency. • Castables Castables consist of graded dry refractory aggregates combined with a suitable hydraulic-activated bonding agent. Castables are furnished dry and form a strong cold set upon mixing with water. They are usually poured or cast in much the same manner as ordinary concrete, but are sometimes vibrated, trowelled, rammed or tamped into place, or applied with air placement guns. They form strong monolithic linings, possessing combinations of properties that make them ideal for many applications. 1. Plastic Refractories: Plastic refractories are used to form refractory monolithic linings in various kinds of furnaces, and are especially adaptable for making quick, economical emergency repairs. They are easily rammed to any shape or contour. The high refractoriness, the range of compositions, and the ease with which they can be rammed into place make plastics suitable for many important applications. Plastic refractories are often highly resistant to destructive spalling. Plastics can include all the fireclay, clay-graphite, high-alumina, high- alumina graphite and chrome types adapted for many different operating conditions. Products: (Heat-setting superduty fireclay plastics, Cold setting superduty fireclay plastics, Superduty heat-setting plastics with graphite, Plastics in the 50% alumina class, Heat-setting 60% alumina class plastics, Air-setting high-alumina plastics, Phosphate-bonded highalumina plastics, phosphate-bonded alumina- chrome plastics). 2. Castable Refractories: Castables are generally referred to as refractory concretes. They are available in a wide variety of base materials and typically consist of a refractory aggregate, special purpose additives and a cement binder. The bonding systems used are often used to classify the types of castables into four categories: (conventional, low cement, ultra-low cement and limefree castables). a) Conventional castables have a cement-bonded matrix where, typically, a calcium-aluminate type of cement fills in the spaces between aggregates. This kind of castable is the most versatile for placement purposes in that normally it can be poured, vibrated, rammed or gunned into place while maintaining its designed properties. b) Low cement castables are materials with lime contents of roughly between 1% to 3%. High densities and strength are achieved by careful particle packing and the use of additives to reduce the water needed to cast. c) Ultra-low cement castables contain from 0.2% to 0.8% lime. Like low cement castables, they consist of sized particles to achieve maximum particle packing. Because of the low cement content, these mixes are not usually as strong in the low to intermediate temperature range as other types of castables; but they tend to have higher hot strength and refractoriness compared to chemically similar mixes with conventional or low cement bonds. d) Lime-free castables have been developed with bonding systems containing no cement. These castables have desirable properties for use in certain chemical applications and where the highest possible hot strength and high temperature load resistance is required, such as metallurgical operations and other high temperature furnace applications. Some of these materials can approach the properties of pressed and fired brick. Products: (Fireclay Castables, High-Alumina Castables, Silica Castables, Basic Refractory Castables). 3. Refractory Gunning Mixes: In some industrial furnaces, turnaround time and installation costs are the major factors when choosing a refractory lining. In other cases, repairs need to be made with little or no downtime. In both circumstances, pneumatic convey-ing of material, or gunning, is often the method of choice. Dense, homogeneous monolithic linings can be gunned without the use of forms and with a marked savings in time. Gun mixes include siliceous, fireclay, high-alumina, dead-burned magnesite and chrome types. Many castables, ramming mixes and specially designed plastics can also be applied successfully with pneumatic guns. Acid gun mixes are normally predamped and fed through a continuous dual chamber or rotary gun. Magnesite and hot gun mixes are not predamped and are placed in a batch pressure gun. Gun mixes should wet up well, have as wide a water range as possible, and provide excellent coverage in a variety of applications. Products: (Fireclay Gunning Mixes, High-Alumina Gunning Mixes, Silica and Silicon Carbide Gunning Mixes, Basic Refractory Gunning Mixes). 4. Refractory Ramming Mixes: Refractory ramming mixes consist of refractory aggregates and a semiplastic bonding phase. When properly installed, ramming mixes offer a way of placing a cementless monolithic lining at high density and relatively low porosity. A well balanced selection of ramming materials includes compositions with base materials of silica, high-alumina, corundum, mullite, deadburned magnesite, chrome ore, zircon and others. These materials are particularly suited for forming dense monolithic, lining construction and numerous other monolithic constructions. Ramming mixes are typically supplied in both wet and dry forms, depending on the binder system. Products: (High-Alumina Ramming Mixes, Basic Refractory Ramming Mixes).