Redacted for privacy AN ABSTRACT OF THE DISSERTATION OF

advertisement

AN ABSTRACT OF THE DISSERTATION OF

Nasser Salmasi for the degree of Doctor of Philosophy in Industrial Engineering

presented on September 15, 2005.

Title: Multi-Stage Group Scheduling Problems with Sequence Dependent Setups.

Abstract approved:

Redacted for privacy

Rasaratnam Lodndran

The challenges faced by manufacturing companies have forced them to become more

efficient. Cellular manufacturing is a concept that has been accepted as a technique

for increasing manufacturing productivity in batch type production by efficient

grouping of parts (jobs) with some similarities in processing operations into groups

and sequentially matching machine cell capabilities for performing these operations.

In each cell, finding the best sequence of processing the assigned groups to the cell

and the jobs in each group by considering some measure of effectiveness, improves

the efficiency of production.

In this research, it is assumed that n groups are assigned to a cell that has m machines.

Each group includes

bL

jobs (i = 1, 2, ..., n). The set-up time of a group for each

machine depends on the immediately preceding group that is processed on that

machine (i.e., sequence dependent set-up time). The goal is to find the best sequence

of processing jobs and groups by considering minimization of makespan or

minimization of sum of the completion times.

The proposed problems are proven to be NP-hard. Thus, three heuristic algorithms

based on tabu search are developed to solve problems. Also, two different initial

solution generators are developed to aid in the application of the tabu search-based

algorithms.

The lower bounding techniques are developed to evaluate the quality of solutions of

the heuristic algorithms. For minimizing makespan, a lower bounding technique

based on relaxing a few constraints of the mathematical model is developed. For

minimizing sum of the completion times, a lower bounding approach based on

Branch-and-Price (B&P) technique is developed.

Because several versions of tabu search are used to solve the problem, to find the best

heuristic algorithm, random test problems, ranging in size from small, medium, to

large are created and solved by the heuristic algorithms. A detailed statistical

experiment, based on nested split-plot design, is performed to find the best heuristic

algorithm and the best initial solution generator. The results of the experiment show

that the tabu search-based algorithms can provide good quality solutions for the

problems with an average percentage error of 8.15%.

©Copyright by Nasser Salmasi

September 15, 2005

All Rights Reserved

Multi-Stage Group Scheduling Problems with Sequence Dependent Setups

by

Nasser Salmasi

A DISSERTATION

submitted to

Oregon State University

In part fulfillment of

the requirement for the

degree of

Doctor of Philosophy

Presented September 15, 2005

Commencement June 2006

Doctor of Philosophy dissertation of Nasser Salmasi

Presented on September 15, 2005

Approved:

Redacted for privacy

Major Professor, representing j{ndustrial Engineering

Redacted for privacy

Head of the Department of Industrial and Mifacturing Engineering

Redacted for privacy

Dean of th'eJGduate School

I understand that my dissertation will become part of the permanent collection of

Oregon State University libraries. My signature below authorizes release of my

dissertation to any reader upon request.

Redacted for privacy

Nasser Salmasi, Author

ACKNOWLEDGEMENTS

This dissertation is the result of my work as a PhD student at Oregon State

University (OSU). It could not have been completed without the significant

contribution of many people and organizations that have supported and

encouraged me continuously during this period. I would like to acknowledge their

contributions for helping me complete my PhD at OSU.

First of all, I thank my major professor, Dr. Rasaratnam Logendran, for his

excellent guidance and financial support while I was his research assistant on the

NSF grant (Grant No. DMI-0010118). His mentorship was of great value while he

patiently and generously spent time with me in our meetings throughout these

years. I am grateful for his comments, inspiration, and encouragement, all of

which led me to a deeper understanding of the topic of this dissertation.

I specially thank the other members of my PhD committee. I am thankful to Dr.

Jeff Arthur, my minor professor in the area of operations research, for his help

with my research and his wonderful classes. Many thanks also to Dr. David

Porter, my Minor professor in the area of information systems, for his advice and

providing me with a laptop and sharing his research lab with me as a place to

perform my experiments. I must also express my sincere gratitude to Dr. David S.

Kim, the next member of my PhD committee, for his help with my research and

for having me as his teaching assistant. I learned many things by working with

him. Additionally, I am thankful to Dr. Saurabh Sethia for being my Graduate

Council Representative (GCR) during the first two years of this research. I also

thank Dr. Mark Pagell for being my GCR for the final defense.

I wish to thank Dr. Dave Birkes and Mr. Raghavendran Dharmapuri Nagarajan

(Rags) for helping me with the experimental design process.

Many thanks to the department of Industrial and Manufacturing Engineering

(IME) at Oregon State University (OSU), and all of its faculty and staff members

for financially supporting me as a Graduate Teaching Assistant during these

years. Many thanks to Bill Layton, for providing such a stable computer network

that allowed me to worry less about our computer system.

I also appreciate the help of my friends from all over the world. I am grateful for

their support, prayers, encouragement, and advice during these challenging years.

I am especially grateful for the friendship of Dr. Shakib Shaken, who always

generously shared his valuable experience and inforniation with me on every

possible matter.

During my PhD program, I had a wonderful colleague, Cumhur Alper

Gelogullari, whose help always led to identifying a short cut for solving problems.

I must also step back and thank the faculty and staff of Sharif University of

Technology in my home country, Iran, for raising my interest in operations

research, while I earned my Bachelor's and Master's degrees in Industrial

Engineering.

It is clear that I would not have been able to travel down this path without the

help, support, and encouragement of my lovely parents. Their encouragement has

always been my greatest motivational force. There is no way to thank them

enough for their efforts in helping me to earn my PhD degree.

TABLE OF CONTENTS

Page

CHAPTER 1: INTRODUCTION .........................................................

1

CHAPTER 2: LITERATUPE REVIEW .................................................

4

2.1 Sequence Independent Job Scheduling (SIJS)

...........................

4

2.2. Sequence Dependent Job Scheduling (SDJS)

...........................

5

2.3. Sequence Independent Group Scheduling (SIGS) .........................

6

2.4. Sequence Dependent Group Scheduling (SDGS)

........................

8

.....................

9

CHAPTER 3: MOTIVATION AND PROBLEM STATEMENT

3.1 Motivation

....................................................................

............................................................

10

...........................................

13

...........................................................................

13

3.2 Problem Statement

CHAPTER 4: MATHEMATICAL MODELS

4.1 Models

9

......................................................

16

..........................................................................

17

4.2 Complexity of Problems

4.3 Example

CHAPTER 5: HEURISTIC ALGORITHM (TABU SEARCH) ........................

19

TABLE OF CONTENTS (Continued)

5.1 Overview of Tabu Search

.

19

5.2 Tabu Search Mechanism

....................................................

20

5.2.1 Forbidden Strategy

...................................................

20

......................................................

21

.............................

21

...............................................................

24

5.2.2 Freeing Strategy

5.2.3 Short-Term and Long-Term Strategies

5.3 Initial Solution

5.3.1 Initial Solution Techniques for Minimization of Makespan

Criterion................................................................

24

....................................................

24

5.3.1.1 Rank Order

5.3.1.2 Applying the Result of Schaller et al. 'S (2000) Algorithm

as an Initial Solution ...........................

25

5.3.1.2.1 Step 1. Applying CDS (Campbell-Dudek-Smith,

1970) Based Procedure to Find the Best Job Sequence

for Groups ......................................

25

5.3.1.2.2 Step 2. Applying NEH Based Procedure to Find

the Best Group Sequence ..................................

5.3.2 Initial Solution Techniques for Minimization of the Sum of the

Completion Times Criterion ..................................

5.3.2.1 Rank Order

....................................................

26

27

27

5.3.2.2 Relaxing the Problem to a Single Machine, SIGS

Problem.........................................................

....................................

28

.........................................................

29

................................................

29

5.4 Generation of Neighborhood Solutions

5.5 Steps of Tabu Search

28

5.5.1 Step 1: Initial Solution

TABLE OF CONTENTS (Continued)

5.5.2 Step 2: Evaluate the Objective Function Value of the Seed

30

................................................

30

5.5.3.1 Step 3.1: Find Inside Neighborhood Solutions ............

30

............

30

..................................

32

...............................................

34

5.5.4.1 Step 4.1: Find outside Neighborhood Solutions ..........

34

5.5.3 Step 3: Inside Search

5.5.3.2 Step 3.2: Evaluate the Inside Neighborhoods

5.5.3.3 Step 3.3: Stopping Criteria

5.5.4 Step 4: Outside Search

5.5.4.2 Step 4.2: Evaluate the Objective Function Value of

Outside Neighborhoods

.....................................

5.5.4.3 Step 4.3: Stopping Criteria ..................................

34

36

5.6 Two-Machine SDGS Problem with Minimization of Makespan

Criterion......................................................................

39

5.7 Applied Parameters for Proposed Research Problems....................

40

5.7.1

Empirical Formulae for Two Machine Problems by

Considering Minimization of Makespan Criterion ...............

40

5.7.2 Empirical formulae for Three Machine and Six Machine

Problems by Considering Minimization of Makespan Criterion

40

5.7.3 Empirical Formulae for Two, Three and Six Machine Problems

by Considering Minimization of Sum of the Completion Times

Criterion.................................................................

41

5.8 Application of Tabu Search to an Example Problem by Considering

.....................................

42

...............................................

43

Minimization of Makespan Criterion

5.8.1 Step 1: Initial Solution

TABLE OF CONTENTS (Continued)

5.8.2 Step 2: Evaluate the Objective Function Value of the Initial

Solution................................................................

43

.......................................

43

5.8.3.1 Step 3.1: Evaluate Inside Neighborhoods .................

44

5.8.3 Step 3: Perform Inside Search

5.8.3.2 Step 3.2: Evaluate the Stopping Criteria for Inside

Search..............................................................

45

..............................................

46

.....................................

46

................

46

5.8.3.3 Repeat the Cycle

5.8.4 Step 4: Perform Outside Search

5.8.4.1 Step 4.1: Evaluate Outside Neighborhoods

5.8.4.2 Step 4.2: Evaluate the Stopping Criteria for Outside

Search..............................................................

48

.............................................

48

5.8.4.3: Repeat the Cycle

5.9 Application of Tabu Search to an Example Problem by Considering

.............

..............................................

Minimization of Sum of the Completion Times Criterion

49

5.9.1 Step 1: Initial Solution

49

5.9.2 Step 2: Evaluate the Objective Function Value of the Initial

Solution...................................................................

49

......................................

50

5.9.3.1 Step 3.1: Evaluate Inside Neighborhoods ..................

50

5.9.3 Step 3: Perform Inside Search

5.9.3.2 Step 3.2: Evaluate the Stopping Criteria for Inside

Search..............................................................

52

5.9.3.3: Repeat the Cycle .............................................

52

5.9.4 Step 4: Perform Outside Search......................................

52

................

53

5.9.4.1 Step 4.1: Evaluate Outside Neighborhoods

TABLE OF CONTENTS (Continued)

5.9.4.2 Step 4.2: Evaluate the Stopping Criteria for Outside

Search..............................................................

5.9.4.3: Repeat the Cycle

CHAPTER 6: LOWER BOUNDS

................................................

.......................................................

6.1 Lower Bounding Techniques for Minimization of Makespan ...........

55

55

56

56

6.1.1 Application of the Lower Bounding Technique to a Problem

Instance..................................................................

60

6.2 Lower Bounding Technique for Minimization of Sum of the

..........................................................

60

6.2.1 Simplifying the Two-Machine Problem...........................

65

6.2.1.1 The Relaxing Rule for SP1 in the Two Machine

Problem .........................................................

67

Completion Times

6.2.1.2 The Relaxing Rule for

SP2

in the Two-Machine

Problem ........................................................

69

6.2.2 Simplifying the Three-Machine Problem ..........................

70

6.2.2.1 The Relaxing Rule for SP1 in the Three-Machine

Problem ...........................................................

73

6.2.2.2 The Relaxing Rule for SP2 in the Three-Machine

Problem ...........................................................

73

6.2.2.3 The Relaxing Rule for SP3 in the Three-Machine

Problem..........................................................

75

6.2.3 A Generalized Model for Simplifying the Multiple-Machine

Problems..............................................................

75

TABLE OF CONTENTS (Continued)

6.2.3.1 The Relaxing Rule for

SP1

in the Multiple-Machine

Problem.............................................................

77

6.2.3.2 The Relaxing Rule for SP2 through SPmi in the Multiple

Machine Problem ................................................

77

6.2.3.3 The Relaxing Rule for

SPm

in the Multiple Machine

Problem.............................................................

78

6.2.4 Adding an Auxiliary Constraint to Simplify Finding the

................................................

79

..................................................

79

Sequence of Dummy Jobs

6.2.5 Solving Sub-Problems

...............................................................

80

......................................................

82

6.2.8 The Software Application .............................................

82

........................

82

6.2.lOExample ................................................................

84

6.2.6 Branching

6.2.7 Stopping Criteria

6.2.9 The Lower Bound for the Original Problem

...........................................

87

.....................................................

87

7.2 Test Problems Specifications

...............................................

93

7.3 Two Machine Test Problems

................................................

95

7.4 Three Machine Test Problems ...............................................

96

..................................................

101

CHAPTER 7: EXPERIMENTAL DESIGN

7.1 Steps of the Experiment

7.5 Six Machine Test Problems

TABLE OF CONTENTS (Continued)

CHAPTER 8: RESULTS

8.1 The Results for the Makespan Criterion

8.1.1

.

103

....................................

103

The Results of Two-Machine Problems by Considering

Minimization of Makespan Criterion

................................

103

8.1.1.1 Comparison among Heuristic Algorithms and Lower

Bound...............................................................

104

8.1.1.2 The Experimental Design to Compare the Time Spent

for Heuristic Algorithms for Two Machine Problems by

Considering Minimization of Makespan Criterion ............ 109

8.1.1.3 The Comparison between the Best Tabu Search and the

Results of Schaller et al. (2000) Algorithm .................... 113

8.1.2 The Results of Three-Machine Makespan Criterion ................

113

8.1.2.1 Comparison among Heuristic Algorithms and Lower

Bound for Three Machine Problems by Considering

Minimization of Makespan

.......................................

114

8.1.2.2 The Experimental Design to Compare the Time Spent for

Heuristic Algorithms for Three Machine Problems by

.......................

120

8.1.2.3 The Comparison Between the Best Tabu Search and the

Results of Schaller et al. (2000) Algorithm .....................

126

8.1.3 The Results of Six-Machine Makespan Criterion ...................

127

Considering Minimization of Makespan

8.1.3.1 Comparison among Heuristic Algorithms and the Lower

Bound...............................................................

127

8.1.3.2 The Experimental Design to Compare the Time Spent for

Heuristic Algorithms for Six Machine Problems by

133

Considering Minimization of Makespan ......................

TABLE OF CONTENTS (Continued)

8.1.3.3 The Comparison Between the Best Tabu Search and the

Results of Schaller et al. (2000) Algorithm for Six-Machine

Problems by Considering Minimization of Makespan

Criterion.............................................................

136

8.2 The Results for Minimization of Sum of the Completion Times

Criterion ........................................................................

137

The Results of Two-Machine Problems by Considering

8.2.1

Minimization of Sum of the Completion Times Criterion

8.2.1.1

.........

137

Comparison among Heuristic Algorithms for Two

Machine Problems by Considering Minimization of Sum of

138

the Completion Times ...........................................

8.2.1.2 The Experimental Design to Compare the Time Spent for

Heuristic Algorithms .............................................

141

...........................

144

8.2.1.3 Evaluating the Quality of Solutions

8.2.2 The Results of Three-Machine Problems by Considering

Minimization of Sum of the Completion Times Criterion

.........

145

8.2.2.1 Comparison among Heuristic Algorithms for Three

Machine Problems by Considering Minimization of Sum of

the Completion Times ............................................. 146

8.2.2.2 The Experimental Design to Compare the Time Spent

for Heuristic Algorithms

.......................................

152

..........................

158

8.2.2.3 Evaluating the Quality of Solutions

8.2.3

The Results of Six-Machine Problems by Considering

Minimization of Sum of the Completion Times Criterion ......

8.2.3.1

159

Comparison among Heuristic Algorithms for Six

Machine Problems by Considering Minimization of

Sum of the Completion Times

...............................

159

TABLE OF CONTENTS (Continued)

Page

8.2.3.2 The Experimental Design to Compare the Time Spent

for Heuristic Algorithms by Considering Minimization of

163

Sum of the Completion Times Criterion ...................

8.2.3.3 Evaluating the Quality of Solutions

CHAPTER 9: DISCUSSION

..........................

.............................................................

9.1 Analyzing the Results of Minimization of Makespan Criterion

......

167

168

168

9.2 Analyzing the Results of Minimization of Sum of the Completion

Times Criterion

.............................................................

170

CHPATER 10: CONCLUSIONS AND SUGGESTIONS FOR FUTHURE

RESEARCH

................................................................

172

10.1 Suggestions for Future Research ............................................

174

10.1.1 Defining Related Research Problems ...............................

174

10.2 Applying New Techniques (tools) to Solve Proposed Problems .......

176

BIBLIOAGRAPHY ...........................................................................

178

APPENDICES ..............................................................................

183

A The ANOVA and Test of Effect Slices Tables for the Result Chapter. ..

184

B The Percentage Errors for Schaller et al. (2000) Algorithm ................

217

LIST OF FIGURES

Pge

Figure

3.1 The Scheduling Tree Diagram

...................................................

12

4.1 The Gantt chart of processing groups as well as jobs in rank order ...

17

5.1 Flow chart for outside search ...................................................

38

.....................................................

39

5.3 The Gantt chart of the initial solution ...........................................

43

...................................

49

5.5 The Gantt chart of the initial solution ...........................................

50

...................................

55

......................

67

....................................................

81

6.3 The objective function value of nodes for an incomplete problem .........

83

5.2 Flow chart for inside search

5.4 The Gantt chart of the tabu search sequence

5.6 The Gantt chart of the tabu search sequence

6.1 The Gantt chart of processing two different sequences

6.2 The branching rule flow chart

8.1 The normal probability plot of the experimental design of finding the best

heuristic algorithm for two machine problem by considering

minimization of makespan

.................................................

8.2 The normal probability plot of the experimental design of finding the most

efficient heuristic algorithm for two machine problem by

considering minimization of makespan ......................................

107

111

8.3 The normal probability plot of the experimental design of finding the best

heuristic algorithm for three machine problem by considering

minimization of makespan

.................................................

8.4 The normal probability plot of the experimental design of finding the most

efficient heuristic algorithm for three machine problem by

considering minimization of makespan ...................................

119

125

8.5 The normal probability plot of the experimental design of finding the best

heuristic algorithm for six machine problem by considering

minimization of makespan

...............................................

131

LIST OF FIGURES

Figure

8.6 The normal probability plot of the experimental design of finding the most

efficient heuristic algorithm for six machine problem by

considering minimization of makespan .................................

135

8.7 The normal probability plot of the experimental design of finding the best

heuristic algorithm for two machine problem by considering

minimization of sum of the completion times

..........................

8.8 The normal probability plot of the experimental design of finding the most

efficient heuristic algorithm for two machine problem by

considering minimization of sum of the completion times criterion..

140

143

8.9 The normal probability plot of the experimental design of finding the best

heuristic algorithm for three machine problem by considering

minimization of sum of the completion times

...........................

150

8.10 The normal probability plot of the experimental design of finding the

most efficient heuristic algorithm for the three machine problem by

considering minimization of sum of the completion times criterion

157

8.11 The normal probability plot of the experimental design of finding the best

heuristic algorithm for six machine problem by considering

minimization of sum of the completion times criterion

................

162

8.12 The normal probability plot of the experimental design of finding the

most efficient heuristic algorithm for six machine problem by

considering minimization of sum of the completion times criterion..

165

LIST OF TABLES

Table

Page

4.lThe run time ofjobs in groups .....................................................

17

4.2 The set up times for groups ........................................................

17

5.1 The outside search parameters for two machine problems with makespan

criterion.........................................................................

40

5.2 The outside search parameters for three machine and six machine

problems with makespan criterion ...........................................

41

5.3 The inside search parameters for three machine and six machine

problems with makespan criterion ..........................................

41

5.4 The outside search parameters for two, three, and six machine problems

with minimization of sum of the completion times criterion.............

42

5.5 The inside search parameters for two, three, and six machine problems

with minimization of sum of the completion times criterion...........

42

5.6 The neighborhoods of the inside initial solution

..............................

44

5.7 The neighborhoods of the outside initial solution ..............................

47

5.8 The neighborhoods of the inside initial solution ...............................

50

.............................

53

.........................................

68

5.9 The neighborhoods of the outside initial solution

6.1 The completion time ofjobs in Si and S2

6.2 The coefficient ofX1Jk's in SPs ...................................................

6.3 The coefficient ofX]k's in SPs

72

....................................................

.........................................................

84

6.5 The branching coefficients OfASq,(j+J)l at the end of the first node ..........

85

6.6 The result of the second node .....................................................

86

........................................................

86

7.1 The set-up time of each machine on two-machine problems .................

94

6.4 The result of the first node

6.7 The result of the third node

LIST OF TABLES

Table

____

7.2 The set-up time of each machine on three-machine problems ..................

94

....................

94

7.4 Small size problems based on group category (two machine) .....................

95

7.5 Medium size problems based on group category (two machine) ..............

95

7.6 Large size problems based on group category (two machine) .................

95

7.3 The set-up time of each machine on six-machine problems

7.7 The specification of test problems generated for two machine

problem ........................................................................ 96

7.8 Small group, small job size problems (three machine)

.........................

97

.....................

97

.........................

97

.....................

97

..................

97

......................

97

........................

98

.....................

98

..........................

98

......................

98

7.9 Small group, medium job size problems (three machine)

7.10 Small group, large job size problems (three machine)

7.11 Medium group, small job size problems (three machine)

7.12 Medium group, medium job size problems (three machine)

7.13 Medium group, large job size problems (three machine)

7.14 Large group, small job size problems (three machine)

7.15 Large group, medium job size problems (three machine)

7.16 Large group, large job size problems (three machine)

7.17 The test problems generated for three machine problem

7.18 Small size problems based on group category (six machine) .................

101

7.19 Medium size problems based on group category (six machine) .............

101

7.20 Large size problems based on group category (six machine) ..................

101

7.21 The specification of generated test problems for six machine problem

102

8.1 The results of the experiments with test problems for two machine

problems by considering minimization of makespan

.................

105

LIST OF TABLES

Table

Page

8.2 The ANOVA for two machine problem by considering minimization of

makespan for algorithm comparison ......................................

108

8.3 Test of effect slices for two machine problem by considering minimization

of makespan for algorithm comparison ...................................

109

8.4 The time spent for the test problems of two machine problems (in seconds)

by considering minimization of makespan criterion .....................

109

8.5 The results of the experiments with test problems for three machine

problems by considering minimization of makespan criterion ..........

114

8.6 The time spent for the test problems of three machine problems (in

seconds) by considering minimization of makespan criterion ...........

121

8.7 The results of the experiments with test problems for six machine

problems by considering minimization of makespan criterion

.........

128

8.8 The lower bound value of test problems for six machine problems by

considering minimization of makespan criterion .........................

130

8.9 The time spent for the test problems of six machine problems (in seconds)

by considering minimization of makespan criterion .....................

133

8.10 The results of the test problems for

two

machine problems by

considering minimization of sum of the completion times ...............

138

8.11 The time spent for the test problems of two machine problems (in

seconds) by considering minimization of sum of the completion

times...........................................................................

141

8.12 The results of the lower bounding technique for two machine problems

by considering minimization of sum of the completion times

criterion ..........................................................................

145

8.13 The results of the test problems for three machine problems by

considering minimization of sum of the completion times criterion...

146

8.14 The experimental cells of three machine problems by considering

minimization of sum of the completion times criterion in which the

heuristic algorithms do not have the same performance ................

151

LIST OF TABLES

Table

8.15 The time spent for the test problems of three machine problems (in

seconds) by considering minimization of sum of the completion

..................................................................

152

8.16 The results of the lower bounding technique for three machine problems

by considering minimization of sum of the completion times criterion

158

times criterion

8.17 The heuristic algorithms results of the test problems for six machine

problems by considering minimization of sum of the completion

times criterion

......................................................................

160

8.18 The experimental cells of six machine problems by considering

minimization of sum of the completion times criterion in which the

initial solution generators do not have the same performance ..........

163

8.19 The time spent for the test problems for six machine problems (in

seconds) by considering minimization of sum of the completion

times criterion

.................................................................

163

8.20 The experimental cells of six machine problems by considering

minimization of sum of the completion times criterion in which the

heuristic algorithms do not have the same time spent ..................

166

8.21 The result of the lower bounding technique for six machine problems by

considering minimization of sum of the completion times

criterion .........................................................................

167

9.1 The results of test problems for minimization of makespan criterion

......

169

9.2 The result of the most efficient initial solution generator by considering

minimization of makespan criterion ........................................

169

9.3 The results of test problems for minimization of sum of the completion

times criterion .................................................................

171

9.4 The percentage error of the test problems for minimization of sum of the

completion times by removing problems with more than 50%

percentage error

...............................................................

171

Multi-Stage Group Scheduling Problems with Sequence Dependent Setups

CHAPTER 1: iNTRODUCTION

The challenges faced by manufacturing companies have forced them to become more

efficient and more flexible. In the 1970s, a method of manufacturing, called Cellular

Manufacturing (CM), was developed. CM is a suitable approach to increase the

productivity and flexibility of production in a manufacturing company that produces a

variety of products in small batches.

In CM, the parts are assigned to different groups based on their similarities in shape,

material, or similar processing operations. The machines are also assigned to different

cells in order to decompose the production line. The groups are then assigned to a

particular cell, which includes several machines that have the ability to perform the

necessary operations for groups. This decomposition of machines and jobs has several

advantages such as significant reduction in set-up time, work-in-progress inventories,

and simplified flow of parts and tools (Logendran, 2002).

Sequencing and scheduling is a form of decision-making that plays a crucial role in

manufacturing and service industries (Pinedo, 2002). They have been applied to

improve the efficiency of production since the beginning of the last century. Thus, the

next step for increasing the efficiency of production is finding the best sequence of

processing the assigned groups to the cell as well as the jobs of a group in order to

maximize or minimize some measure of effectiveness. This subject is called Group

Scheduling. Two relevant objectives in the investigation of group scheduling problems,

minimization of makespan and minimization of the sum of the completion times, are

considered in this research. The goal of minimization of makespan is to minimize the

completion time of the last job on the last machine. On the other hand, the goal of

minimization of the sum of the completion times is to minimize the average completion

time of all jobs. The purpose of both of these criteria is to deliver orders as quickly as

possible to the customers. In general, the longer the jobs stay on the shop floor, the

higher they cost the company. Suppose that a company receives a large order from a

2

customer to produce several different groups ofjobs. The efficient way of preparing the

order is to compress (minimize) the completion time of the last job processed so that

the entire order can be delivered to the customer as quickly as possible in one shipment.

On the other hand, suppose that the company receives several orders from

different

customers, and that all of them have the same priority (weight) for the company. In this

case, minimization of the sum of the completion times is appropriate to maximize the

efficiency as it would indirectly minimize the work-in-progress inventories.

In group scheduling problems, all jobs that belong to a group require similar set-up on

machines. Thus, a major set-up is required for processing each group on every machine.

The set-up operation of a group includes preparing the machine, bringing required

tools, setting the required jigs and fixtures, inspecting the materials and cleanup

(Allahverdi et al, 1999), which should be considered as a separate operation on

machines for some problems rather than considering it as a part of processing time. The

separable set-up time scheduling problems are divided into two major categories:

sequence dependent, and sequence independent scheduling. If the set-up time of a

group for each machine depends on the immediately preceding group that is processed

on that machine, the problem is classified as "sequence dependent group scheduling,"

Otherwise, it is called "sequence independent group scheduling".

The importance of sequence dependent set-up time scheduling problems has been

discussed in several studies. Allahverdi et al. (1999) mentioned the results of a survey

performed by Panwalker et al. (1973), in which 75% of the manufacturing managers

mentioned that they had the experience of producing parts with sequence dependent

set-up time specifications and almost 15% of them believe that all production

operations belong to sequence dependent scheduling problems. Wortman (1992)

explained the importance of considering sequence dependent set-up times for the

effective management of manufacturing capacity. There are many real world

applications of sequence dependent scheduling problems. Schaller et al. (2000)

discussed an industry case of sequence dependent group scheduling problem in printed

circuit boards (PCBs) in which the major set-up is required to switch from a group of

PCBs to another. Painting industry is another example of such problems.

Vakharia et al. (1995) and Schaller et al. (1997, 2000) present branch and bound

approaches to solve the Sequence Dependent Group Scheduling problems (SDGS) with

multiple machines by considering minimization of makespan. They also propose a fast

heuristic algorithm to minimize the makespan for a SDGS problem by applying some

of the existing scheduling heuristic algorithms to find a sequence for processing groups

as well as jobs in a group. Because their algorithm does not consider the relationship

between

groups

and job sequences, it may not provide a good quality solution.

Considering the widespread practical applications of sequence dependent

group

scheduling in industry and the importance of minimizing the makespan and minimizing

the sum of the completion times, developing a heuristic algorithm to solve these

problems in a reasonable time with good quality can help to improve the efficiency of

production.

The industry needs an algorithm which can provide a sequence of processing groups as

well as jobs with a good quality (optimal or near optimal) in a short time. Because the

proposed research problems, as will be discussed in the chapters that follow, belong to

NP-hard problems, the time required to solve the real world problems optimally by

applying an exact algorithm is unreasonably high. Thus, a heuristic algorithm is

necessary to get a solution close enough to the optimal solution in a reasonable time. In

order to evaluate the performance of the heuristic algorithm, a lower bounding

technique is also required to be applied as a yard stick. Thus, a lower bounding

technique is developed for each criterion to estimate the quality of solutions. These

lower bounds are created based on the mathematical models of the proposed research

problems.

4

CHAPTER 2: LITERATURE REVIEW

Basically, the flowshop scheduling problems can be classified as job scheduling

problems and group scheduling problems. A group scheduling problem, as discussed

earlier, occurs when assigned jobs to a cell, based on more similarities in process or

shape are set into different groups and are processed in sequence. If the jobs are

investigated independently, the problem is classified as a job scheduling problem.

Because of some similarity between these two classes of problems, the related articles

about both of them in sequence independent and sequence dependent set-up mode are

investigated.

Cheng et al. (2000) and Allahverdi et al. (1999) did a comprehensive literature review

about job scheduling and group scheduling problems. The articles that are most related

to the proposed research problems (minimization of makespan and minimization of the

sum of the completion times) are presented in four different categories as follows:

2.1 Sequence Independent Job Scheduling (SIJS)

Yoshida and Hitomi (1979) pioneered the investigation of SIJS problems. They

considered the two machine flowshop problem and proposed an algorithm based on

Johnson's (1954) rules to obtain the optimal solution for minimization of makespan.

Lageweg et al. (1978) developed a general lower bound for the permutation flowshop

problem by considering minimization of makespan. Bagga and Khurana (1986)

developed a branch and bound algorithm for a

two

machine flow shop sequence

independent job scheduling problem for minimizing the sum of the completion times.

They also developed a lower bound for their problem. The proposed algorithm is

applied to solve problems with 5 to 9 jobs. Proust et al. (1991) proposed three heuristic

algorithms for minimizing the makespan. The first one is an extension of the CDS

heuristic by Campbell, Dudek, and Smith (1970) for the standard flowshop scheduling

problem. The second is a greedy procedure which augments an available partial

schedule with the job that minimizes a lower bound. The third is constructed by

incorporating the 2-job interchange neighborhood search in the above two heuristics for

5

the problem. All these algorithms were evaluated empirically. They also developed a

branch and bound algorithm which can be used for small size problems. Gupta (1972)

described dominance condition and an optimization algorithm to minimize makespan of

SIJS. The proposed algorithm is applied to solve problems with 3 to 6 jobs and 4 to 6

machines. This algorithm can not be used to solve large size problems. Allahverdi

(2000) addressed the two-machine SIJS problem by considering the mean-flow time

criterion. He developed an algorithm to solve problems optimally up to 35 jobs in a

reasonable time.

2.2 Sequence Dependent Job Scheduling (SDJS)

Corwin and Esogbue (1974) considered the two-machine flow shop job scheduling

problems where only one of the machines is characterized by sequence dependent setup

times and proposed a dynamic programming approach to obtain the optimal solution for

minimizing the makespan. Gupta and Darrow (1986) provided a few heuristic

algorithms to find the minimum makespan for a two-machine SDJS problem. The result

of the experiment shows that their heuristic algorithms have good performances for

problems where set-up times are smaller than run time. Computational experiments are

also performed to find out which proposed heuristic algorithm has the best performance

in different size of problems. The results of the experiments reveal that for different

size of problems, a different heuristic algorithm has a superior performance. Bellman et

al. (1982) developed a dynamic programming model to optimally solve a flow shop

scheduling problem with three machines where only one of the machines requires

sequence dependent set-up time. Test problems up to 12 jobs are solved optimally by

the proposed algorithm. Srikar and Ghosh (1986) proposed a mixed integer linear

programming formulation for SDJS. The model is applied to solve several randomly

generated instances of SDJS that included six machines and six jobs at most. Based on

the results of the computational experiment the time taken to solve the problems was

reasonable. Stafford and Tseng (1990) corrected a minor error in the Srikar-Ghosh

formulation. The corrected model is used to solve problems with 5 machines and 7 jobs

by considering minimization of the sum of the completion times criterion. The problem

took about 6 CPU hours to be solved on a personal computer. Gupta et al. (1995)

developed a branch and bound technique to find the minimum makespan for SDJS

problems. They solved problems up to 20 jobs with the proposed algorithm. Rios-

Mercado and Bard (1998) presented a branch-and-cut (B&C) algorithm for

minimization of makespan of SDJS with m machines. The same authors (1999)

presented a branch and bound algorithm which includes the implementation of both

lower and upper bounding procedures, a dominance elimination criterion, and special

feature such as a partial enumeration strategy for minimization of makespan of SDJS

problems.

Gupta (1988) proposed several heuristic algorithms to find the minimum makespan for

SDJS problems. Simons (1992) developed four heuristics for this problem. The main

idea of two of his heuristics is based on well known Vogel's approximation method in

transportation problems. Parthasarathy and Rajendran (1997) proposed a heuristic

algorithm based on simulated annealing to minimize the weighted tardiness of SDJS.

2.3 Sequence Independent Group Scheduling (SIGS)

Ham et al. (1985) described a two-step procedure to solve SIGS problem optimally by

considering minimization of makespan criterion. Baker (1990) generalized these results

and provided a polynomial time optimization algorithm consisting of two steps for jobs

and group sequences. Hitomi and Ham (1976) proposed a branch and bound procedure

to find the minimum makespan of SIGS problems with multiple-machines. Extensions

of their work are described in Ham et al. (1985). The procedure first creates a sequence

of groups in the job sets, and then develops job sequences within each group. The

proposed model is a family version of the heuristic by Petrov (1968). Logendran and

Sriskandarajah (1993) addressed the blocking version of the problem with only separate

set-up times, i.e., a finished job on the first machine will block the machine from being

set-up for another job, until the set-up operation of the job starts on the second

machine. They proposed a heuristic by ignoring the set-up times, and analyzed the

worst-case performance of the heuristic. Campbell et al. (1970) presented a multiple-

7

pass heuristic for solving flowshop scheduling problems with three or more machines.

Vakharia and Chang (1990) modified this heuristic for scheduling groups in a flowshop

manufacturing cell. They also performed a computational experiment to compare this

heuristic algorithm with a simulated annealing heuristic algorithm. The results show

that the simulated annealing heuristic provides good quality solutions at reasonable

computational expense. Skorin-Kapov and Vakharia (1993) developed a tabu search

approach to minimize the completion time of SIGS. They performed a computational

experiment to compare the performance of tabu search algorithm versus simulated

annealing algorithm by Vakharia and Chang (1990). The results of their computational

experiment reveal that the tabu search has a better performance by generating better

solutions in less computational time. The computational experiment is performed with

problems including 3 to 10 groups, 3 to 10 machines, and 3 to 10 jobs. The authors

investigated six versions of tabu search. The experiment is performed with three

different set-up times in which the distribution of set-up times was greater than the run

times of jobs in all of them. Based on their computational experiments, LTM-max (tabu

search by considering long term memory to intensify the search) has the best

performance among fixed tabu-list size versions. Their experiments also show that

variable tabu-list size versions provide better solutions than fixed size versions. Sridhar

and Rajendran (1994) also developed a genetic algorithm for minimizing the makespan

for SIGS. Helal and Rabelo (2004) classified the published heuristics for SIGS

problems into three categories, single path, multiple pass, and iterative heuristics based

on the complexity of the method. They also compare the performance of simulated

annealing versus tabu search for some test problems in which the largest problem

includes 8 groups, 8 jobs in a group, and 8 machines. The results show that the tabu

search algorithm has a slightly better performance than simulated annealing by

considering minimization of makespan criterion. Schaller (2000) performed a design of

experiment to compare the performance of tabu search (developed by Skorin-Kapov

and Vakharia, 1993) and genetic algorithm (Sridhar and Rajendran, 1994) and reported

that the tabu search has a better performance.

2.4 Sequence Dependent Group Scheduling (SDGS)

Jordan (1996) discussed the extension of a genetic algorithm to solve the two machine

SDGS problem to minimize the weighted sum of earliness and tardiness penalties.

Vakharia et al. (1995) and Schaller et al. (1997, 2000) present branch and bound

approaches as well as several heuristics to solve the SDGS with multiple machines. The

highlight of their research is published in a paper by Schaller et al. (2000). They

propose a heuristic algorithm to minimize the makespan for a SDGS problem. In this

algorithm, the sequence of groups and jobs that belong to a group are investigated

independently. Finding a solution for the proposed problem requires two aspects:

finding the sequence of jobs within each group, and finding the sequence of groups.

While there is interaction between these two aspects, the authors assumed that these

sequences can be developed independent of each other. They applied a few existing

heuristic algorithms such as Campbell-Dudek-Smith (CDS) (1970) procedure to find

the best sequence of jobs in a group. The sequence of groups is investigated by

applying a few algorithms based on the procedure by Gupta and Darrow (1986), and

Baker's (1990) scheduling algorithm. The authors also provide a lower bounding

technique to evaluate the quality of their solutions by generalizing the machine based

bound of traditional flowshop scheduling problems.

Reddy and Narendran (2003) investigated the SDGS problems by considering dynamic

conditions. The process time of jobs was assumed to have an exponential distribution.

They also relaxed the assumption of availability of all jobs at the beginning of the

scheduling. Simulation experiments are applied to find the best sequence of jobs and

groups to minimize the tardiness as well as the number of tardy jobs.

CHAPTER 3: MOTIVATION AND PROBLEM STATEMENT

3.1 Motivation

Allahverdi et al. (1999) provide some explanations about the applications of sequence

dependent scheduling problems. Panwalker et al. (1973) discovered that about 75% of

the managers reported at least some operations they schedule require sequence

dependent set-up times, while approximately 15% reported all operations requiring

sequence dependent set-up times. Flynn (1987) determined that application of both

sequence dependent set-up procedures and group technology principles increase output

capacity in a cellular manufacturing shop, and Wortman (1992) explained the

importance of considering sequence dependent set-up times for the effective

management of manufacturing capacity.

Ham et al. (1985) discussed about the importance of applying group technology

(combining jobs into groups). They said "Development and implementation of

Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) in the

manufacturing industry lead to more integrated applications of group technology

concept. It has been recognized that group technology is an essential element of the

foundation for successful development and implementation of CAD/CAM through

application of the part-family concept based on some similarities between jobs. This

approach creates a compatible, economic basis for evolution of computer automation in

batch manufacturing through increased use of hierarchical computer control and multi

station NC manufacturing systems."

The above literature review reveals that while a considerable body of literature on

sequence dependent and sequence independent job scheduling has been created, there

still exist several potential areas worthy of further research on sequence dependent and

sequence independent group scheduling (Cheng et al., 2000). Considering the

widespread practical applications of sequence dependent group scheduling in industry

(as discussed its necessity in above paragraphs), especially in hardware manufacturing,

ILi

and the importance of minimizing the makespan and minimizing the sum of the

completion times, further research on these subjects is still required.

3.2 Problem Statement

In this research, it is assumed that n groups (G1, G2, ..., G) are assigned to a cell that

has m machines

(M1,

M2,..., Mm). Each group includes bjobs (i =

1, 2, ..., n).

The set-

up time of a group for each machine depends on the immediately preceding group that

is processed on that machine (sequence dependent set-up time). The purpose of this

research is to find the best sequence of processing jobs as well as groups by considering

minimizing some measure of effectiveness. Two such measures include the

minimization of makespan and minimization of the sum of the completion times. The

assumptions made in this research are:

All jobs and groups are processed in the same sequence on all machines

(permutation scheduling). This is the only way of production in some industries.

For instance, if a conveyer is used to transfer jobs among machines, then all jobs

should be processed in the same sequence on all machines.

All jobs in each group are available at the beginning of the schedule. This is

commonly known as static job releases. It means that the flow time of a job is the

same as its completion time on the last machine.

All jobs and groups have the same importance (weight) for the company.

All machines are available at the beginning of planning horizon.

This problem belongs to static flowshop problems. Figure 3.1 shows the classification

of all scheduling problems, including the proposed research problem.

The size of the problems which are investigated during this research are as follows:

Number of groups: Group scheduling problems including

2

to 16 groups are

investigated. Based on the reviewed papers, the previous research has focused on

problems with at most ten groups.

11

Number of jobs in a group: Problems including 2 to 10 jobs in a group are

considered in this research. Based on the papers reviewed, the previous

investigations have been limited to at most ten jobs in a group (Schaller et al.,

2000).

Number of machines in a cell: As discussed before, the goal of applying cellular

manufacturing is to decompose the production activities and simplify them. Thus, if

in a cell, too many machines are assigned, then the goal of applying cellular

manufacturing is violated. Based on this fact, in many cases the number of

machines in a cell does not exceed six. Thus, problems up to six machines in a cell

are investigated in this research.

Another assumption considered in this research is that in all cases the required set-up

time for a group on a machine is considerably greater than the run time of jobs on

machines. In many production lines the required set-up time of a machine is larger than

the run time of individual jobs.

It is clear that any one of the n groups of jobs in the current planning horizon can be

preceded by the last group that was processed in the previous planning horizon. This

"last group" is referred as the reference group 'R' in this research. The reference group

is a group which was processed as the last group on a machine in the previous planning

horizon. Thus the required set-up time of each group compared to the reference group

should be considered to find the best sequence.

12

Scheduling

Problems

Static

Scheduling

Dynamic

Scheduling

Multi machine

Problems

Machine

Problems

Parallel

Machine

Problems

Shop

Scheduling

Problems

Job Shop

Problems

Flowshop

Problems

Job

Scheduling

Sequence

Independent Setup time Problems

Group

Scheduling

Sequence

dependent Set-up

time Problems

Figure 3.1 The Scheduling Tree Diagram

Sequence

Independent Setup time Problems

=

Sequeiwe

dependent Set-up

time Problems

13

CHAPTER 4: MATHEMATICAL MODELS

The mathematical programming models for minimization of makespan and

minimization of the sum of the completion times criteria for a multi-stage (two or more

machines) SDGS problem are demonstrated below. The models belong to Mixed

Integer Linear Programming (MILP) models.

4.1 Models

The parameters, decision variables, and the mathematical models are as follows:

Parameters:

a:

Number of groups

Numberofjobsingroupp

bmax:

Number of machines

The maximum number of jobs in groups, max{b}

p = 1,2,.. .,a

N:

Number of jobs in all groups

N =

tpjk.

Run time ofjobj in group p on machine k

m:

p1,2,...,a

fFor Real Jobs; Run time of job

tpjk

p1k.

.

For Dummy jobs,

j in group p on machine k

-M

j = 1,2,.. .,bmax

k=1,2,...,m

p=

1,2,. . .

j

1,2,.. .,bmax

k = 1,2,. . . ,m

The setup time for group 1 on machine k if group p is the

preceding group

p,l = 1,2,. ,a

k

1,2,. . . ,m

The summation of run times in group p on machine k

Tk

=

.

.

1pjk

Decision Variables:

i= 1,2,...,a

The completion time ofjobj in

th

slot on machine k

Ii; Ifgrouppisassignedtosloti

WIP

tO; Otherwise

The completion time of

I=

0,1,2,...,a

p 0,1,2,.. .,a

tO; Otherwise

Ii; Ifjobqisprocessedafterjobjinsloti

Yijq

j = 1,2,.. .,bmax

k=1,2,...,m

th

slot on machine k

j

i=

1,2,...,a

j,q = 1,2,..

q

I

= 0,1,2,. . . ,a

14

The setup time for a group assigned to slot i on machine

e'k.

i= 1,2,...,a

k

i=0,1,2,...,a-1

1; If group p is assigned to slot i and group 1 is

AS ip(i + 1)1 =

assigned to slot

i

p0,1,2,...,a-1

+1

1=

pl

0; Otherwise

1,2,..,a

Model

Minimizez' =

Minimize z2 =

(1.1)

(makespan objective function)

Cak

a

j1

bm

(sum of the completion times objective

j1

function)

'1 2

Subject to:

=

1

Wj =1

p=1,2,...a

(2)

i1,2,...,a

(3)

p=1

p=O

=1

lI

ASip(ll)l

i0,1,2,...,a-1

=

i0,1,2,..,a-1

>AS(i_1)pilSp1k

p,l= 1,2,...,a

k=1,2,...m

i=1,2,...,a

p=O 1=1

= C(_I)l + Set1i +

T1

a

Xyk

(4)

1)

Wip

ASl(l)l

Setk

(p

C(1_1)k+ Set

ik+ >Wiptpjk

p=1

Xk XJ'k + MYW

>Wiptjk

Wipt'.k

i =

1,2,.. .,a

j

(7)

(8)

(9)

1,2,...,bmax

i =

(10)

1,2,.. .,a

k = 1,2,3...m

Wj, AS1(j+l)l = 0,1

(11)

j1,2,...,bmax

k2,3...m

i=1,2,...,a

0

(6)

k'1,2,3...m

i r1,2,...,a

!;wip tpjk

Cjk = max {Xk}

Xjk, CIk ,Setlk

0,1,2,3,...,a

(5)

j,j'=1,2,...bmaxj<j'

XjkXjk + M(l

Xk Xu(k_1)

i

pl

pl

y=0,1

k2,3...m

(12)

(13)

(/<j')

The mathematical model for each of the two objective functions is a Mixed Integer

Linear Programming (MILP) model. It is assumed that there exist slots for groups and

each group should be assigned to one of them. In real world problems, groups have

different number of jobs. Because each group can be assigned to any slot, to simplify

creating the mathematical model, it is assumed that every group has the same number

15

of jobs, comprised of real and dummy jobs. This number is equal to

bmax

which is also

the maximum number of real jobs in a group. If a group has fewer real jobs than

the difference, i.e.,

bm

bmax,

number of real jobs, is assumed to be occupied by dummy

jobs. The objective function can either be minimize the makespan of jobs on the last

machine (1.1) or minimize the sum of the completion times of processing all jobs on

the last machine (1.2).

Based on the model, there are 'a' slots and each group should be assigned to one of

them. It is clear that each slot should contain just one group and every group should be

assigned to only one slot. Constraints (2) and (3) support this fact.

The set-up time of a group on a machine is dependent on that group and the group

processed immediately preceding it. Constraint (4) is included in the model to support

this fact. If group p is assigned to slot i and group 1 is assigned to slot i+1, then

AS(+J)l

must be equal to one. Likewise, if group p is not assigned to slot i or group 1 is not

assigned to slot i + 1, then

AS1(l+J)l

must be equal to zero. Constraints (5) and (6) ensure

that each is true. Constraint (7) calculates the required set-up time of groups on

machines. The required set-up time for a group on a machine is calculated based on the

assigned group to the slot and the group assigned to the preceding slot.

The completion time of the group assigned to a slot on the first machine is calculated in

constraint (8). The completion time of a group assigned to a slot is equal to the

summation of the completion time of the group assigned to the preceding slot, the

required set-up time for the group of this slot, and the summation of run time of all jobs

in the group.

Constraint (9) is added to the model to find the completion time of jobs on machines.

The completion time of a job that belongs to a group is greater than the summation of

the completion time of the group processed in the previous slot, the set-up time for the

group, and the run time of the job.

16

Constraints (10) and (11) are a kind of either/or constraints. They are added to the

model to find the sequence of processing jobs that belong to a group. Ifjobj in a group

is processed after jobj' of the same group, then the difference between the completion

time ofjobj and jobj' on all machines should be greater than or equal to the run time of

jobj.

A machine can start processing a job only if it is finished on the previous machine. It

means that the completion time of a job on a machine should be greater than or equal to

the summation of the completion time of the job on the preceding machine plus the run

time of the job on that machine. Constraint (12) is added to the model to support this

fact. It is clear that the completion time of a group on a machine is equal to the

completion time of the last job of the group which is processed by the machine.

Constraint (13) is added to the model for this reason. These models can be used as a

base to estimate the quality of heuristic algorithms.

4.2 Complexity of Problems

Gupta and Darrow (1986) proved that the two machine sequence dependent job

scheduling (SDJS) problem is a NP-hard problem. Garey et al. (1976) also proved that:

the flowshop job scheduling problem by considering minimization of makespan

criterion for more than two machines (m? 3) is an NP-hard problem.

the flow-shop job scheduling problem by considering minimization of the sum of

the completion times criterion with more than one machine (m? 2) belongs to NPhard problems as well.

Based on these insights, it is easy to see that the proposed problems in this research are

easily reducible to the ones already proven NP-hard. Thus, the fact that the proposed

problems are NP-hard, follows immediately.

17

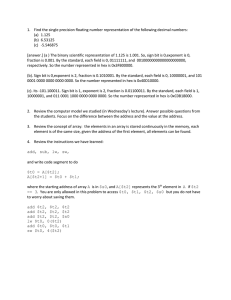

4.3 Example

An example is shown to demonstrate the problem. Suppose three groups including 3, 2,

and 3 jobs in each are assigned to a cell with two machines to process. The required run

time of each job on each machine are given in Table 4.1. For instance the first job of

the first group (J11) has a run time of 3 on M1 and a run time of 4 on M2.

Table 4.lThe run time ofjobs in groups

G1

G3

G2

M1

M2

M1

M2

J11

3

4

4

3

J12

2

5

3

1

J13

2

1

J22

J31

J33

M1

M2

5

2

3

5

4

2

The set-up time of each group on each machine based on the preceding processed group is

shown in Table 4.2. In this table R stands for the reference group. As explained before, the

reference group is a group which was processed as the last group on the machines in the

previous planning horizon.

Table 4.2 The set up times for groups

M1

_

G1

G22

G3

M2

G2

G3

4

2

---

3

1

3

2

5

G1

__3

G32

R

4

3

G2

G3

5

2

---

3

4

1

1

A possible schedule of processing groups as well as jobs is processing them according

to their rank order:

G1 (J11- J12- .113) - G2 (.121- .122) - G3 (J31- J32- J33).

The Gantt-chart of

this schedule is demonstrated in Figure 4.1. In this Gantt chart the set-up time of each

group is shown by S,,k.

M1

M2

S011

'i

S012

.112

13

'ii

S121

J

Ji2

.113

J22

S231

S121

J21

J31

'22

J32

J33

S232

I

Figure 4.1 The Gantt chart of processing groups as well as jobs in rank order

I

Based on this Gantt-chart, the completion time of each job on the last machine is as

follows:

J11: 9

J21: 23

J31: 29

J12:

J22:

J32:

14

J13:

15

24

34

J33:

36

The makespan of a schedule as discussed before is the completion time of the last job

on the last machine. In this schedule, this is equal to 36. The sum of the completion

times of a schedule is the summation of completion time of jobs on the last machine.

Thus, the sum of the completion times of this schedule for this problem is equal to 184.

If the problem is solved optimally by the mathematical models, the optimal solution for

minimization of makespan is equal to 34 and for minimization of the sum of the

completion times is equal to 165.

19

CHAPTER 5: HEURISTIC ALGORITHM (TABU SEARCH)

Because the proposed research problems are NP-hard, the mathematical model cannot

be applied to solve industry size problems in a reasonable time. It also requires a

powerful computer and advanced linear programming software which may not be

available in every company.

The requirement of applying the proposed ideas (i.e., finding the best sequence of

processing groups as well as jobs in a group to improve the efficiency) in industry is

finding a technique that is capable of solving large size problems in a reasonable time.

Thus, a heuristic algorithm should be developed for finding a solution close enough to

the optimal solution of mathematical models in a short time.

One category of these heuristic algorithms is diversification/intensification techniques.

The most popular algorithms that belong to this category are tabu search, genetic

algorithm, and simulated annealing. According to previous research (Skorin-Kapov and

Vakharia (1993), Nowicki and Smutnicki (1996), Logendran and Sonthinen (1997)),

Schaller (2000), and Helal and Rabelo (2004) tabu search has shown more promising

performance than the others for scheduling problems.

5.1 Overview of Tabu Search

The tabu search is a heuristic algorithm which is developed independently by Glover

(1986) and Hansen (1986) for solving combinatorial optimization problems. The

principles and mathematical description of this concept can be found in Glover (1989,

1990a, and 1990b), Laguna et al. (1991), Reeves (1993), Widmar and Hertz (1989), and

Taillard (1990). This technique has been used to find a good quality solution for many

scheduling problems.

Finding a solution for the proposed research problems involves two levels. The first

level investigates to find the best sequence of groups. During the first level, a sequence

of groups is chosen. The second level investigates to find the sequence of jobs in each

group based on the chosen group sequence by the first level. If the tabu search heuristic

20

is applied to solve proposed research problems, it should cover both levels. Thus, a

two-level tabu search is developed to solve proposed research problems. In the first

(outside) level, the best sequence of groups is investigated. When a sequence of groups

by the outside level is chosen, the second (inside) level finds the best sequence of jobs

that belong to each group by considering the desired measure of effectiveness. The

solution is comprised of the sequence of groups and the sequence of jobs in each group

that provides the best objective function value based on the chosen criterion.

The tabu search method is used for the outside search to move from a group sequence

to another one. This is done for the inside search by moving from a sequence of jobs in

a group sequence to another sequence of jobs in the same group sequence. The

relationship between the outside and inside search is that once the outside search is

performed to get a new group sequence, the search process is switched to inside search.

The inside search is performed to find the best sequence of jobs in groups by

considering the proposed group sequence by outside search. When the inside search

stopping criteria is satisfied, the best found job sequence is considered. Then the search

returns back to the outside search to find a new group sequence. The outside search

stops when the outside search stopping criteria are satisfied. The best found solution is

reported as the final solution.

5.2 Tabu Search Mechanism

Based on Glover (1989, 1990(b)), a simple tabu search algorithm consists of three main

strategies: Forbidden strategy, Freeing Strategy, and Short term strategy. Pham and

Karaboga (1998) provided a brief explanation about these strategies as follows:

5.2.1 Forbidden Strategy

The forbidden strategy controls the entries to the tabu-list. It is mainly applied to avoid

cycling problems by forbidding certain moves which are called tabu. It prevents the

search return to a previously visited point. Ideally all previous visited points should be

stored in tabu-list, but this needs too much memory and computational effort. Thus, this

21

is done just for a few very last moves by preventing the choice of moves that represent

the reversal of any decision taken during a sequence of the last T iterations. These

solutions are stored in the tabu-list. This leads the search to move progressively away

from all solutions of the previous T iterations. T is called the "tabu-list length" or

"tabu-list size". The probability of cycling depends on the value of T. If T is too small,

the probability of cycling is too high. If it is too large then the search might be driven

away from good solution regions before these regions are completely explored.

During this process, an aspiration criterion is applied to make a move free if it is of

good quality and can prevent cycling. While the aspiration criterion has a role of

guiding the search, tabu restrictions have a role in constraining the search space. A

solution is acceptable if the tabu restrictions are satisfied. However, a tabu solution is

also assumed acceptable if an aspiration criterion applied regardless of the tabu status.

The move attributes are recorded and used in tabu search to impose constraints that

prevent moves from being chosen that would reverse the changes represented by these

attributes.

5.2.2 Freeing Strategy

The freeing strategy is used to decide what exits the tabu-list. The strategy deletes the

tabu restrictions of the solutions so that they can be reconsidered in further steps of the

search. The attributes of the tabu solution remain on the tabu-list for a duration of T