(Al–2Cu–2Mg) (Al-2Cu-2Mg) (3%NaCl))

advertisement

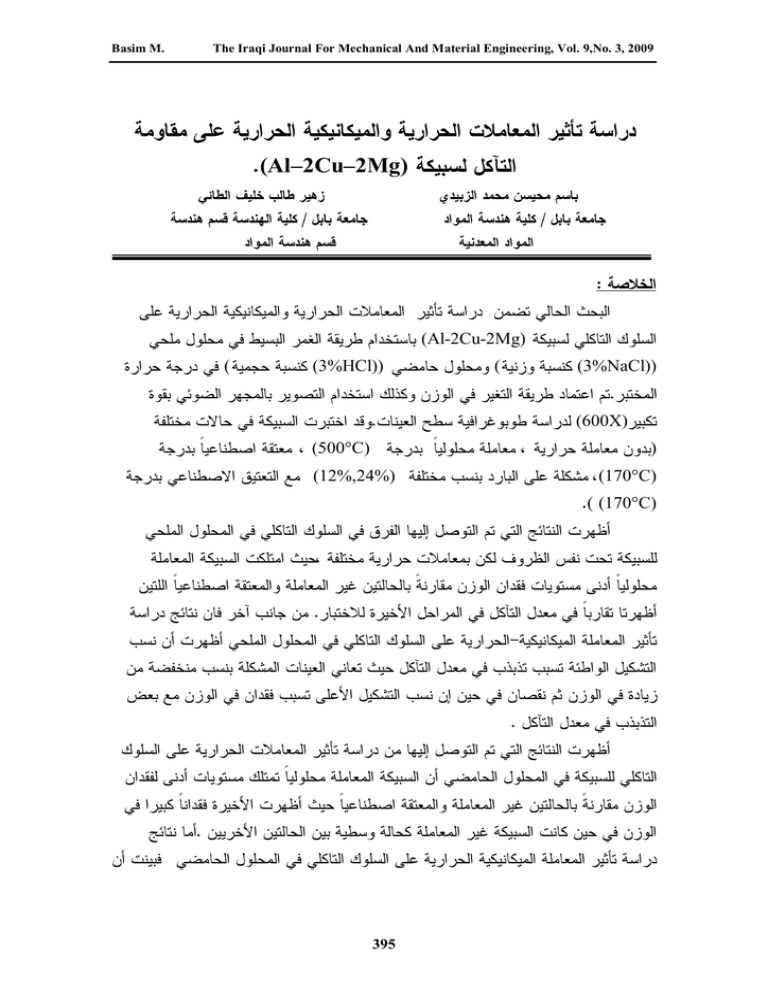

Basim M. The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 (Al–2Cu–2Mg) (Al-2Cu-2Mg) ( (3%HCl)) ( (3%NaCl)) (600X) (500°C) ) (12%,24%) (170°C) ( (170°C) 395 (Al–2Cu–2Mg) The Effect of Heat Treatment and Thermo-Mechanical Treatment on the Corrosion Behavior of (Al-2Cu-2Mg) Alloy Basem Mohysen Mohammed Babylon Un/College of Mat. Eng. Met. Mat. Eng. Dep. Zuheir Talib Khulief Al-Tai Babylon University/College of Eng. Mat. Eng. Dep. Abstract: This study deals with the effect of heat treatment and thermo-mechanical treatment on the corrosion behavior of (Al-2Cu-2Mg) alloy by using simple immersion in salt solution ((3% NaCl) by weight) and acidic solution((3% HCl) by volume) at room temperature. The weight change method and microscopic examination are used in this study. Alloy without treatment, solution heat treated at (500 C), artificial aged at (170 C) and thermo-mechanical treated (12%,24%) are used to complete this study. The result of effects of heat treatment on the corrosion behavior of alloy in salt solution showed different corrosion behavior for the same alloy under the same conditions but at different heat treatments. Solution heat-treated alloy has the lowest loss weight levels compared with the other states untreated and artificial aged alloys which showed convergence in corrosion rate at the final stages of the test .In other hand the results of effects of thermo-mechanical treatment on the corrosion behavior in salt solution showed that the lower cold working percent cause vibration in corrosion rate while high cold working percent cause in reducing weight and lower corrosion rate . The result of effects of heat treatment on the corrosion behavior of alloy in acidic solution showed that the solution-treated alloy have the lowest weight losing compared with the untreated and artificial aged alloys where the last one show a mid state between the other states. In the other hand the results of effects of thermomechanical treatment on the corrosion behavior in acidic solution showed that the corrosion has been dropped with increase the cold work ratio and the results showed decreasing in weight loss with increasing the percent of cold working. (D. A.Little and J. R. Scully) ( C416) (Al-Cu-Mg-Ag) 2001 (SCC) (99.99%) 396 C415 Basim M. The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 (0.006 (NaCl) (C416) – 0.06 M) (C415) (D.A.Little (99.99%) (Eiji Akiyama , K . Asami) 2001 and J. R. Scully, 2001) (1M HCl) Ti , Zr , Nb ,Ta ,Cr (30°C) (H . 2002 (Eiji Akiyama , K . Asami , 2001) (passive film ) (2024-T3) Bohni and T. Suter) (Al-Cu-Mg) (Al-Cu-Fe-Mn) (H . Bohni and T. Suter ,2002) (N. Le Bozec, D. Persson) 2002 ( Filiform Corrosion ) (FTIR Microspectroscopy and Scanning Kelvin Probe) (filament head) (filament tail) (Aluminum Chloride or Aluminum Oxy Chloride) ( Aluminum hydroxide gel containing ( 2002 ) (N. Le Bozec, D. Persson and other,2002) carbonate ) (Filiform (H. N. Mcmurray, G.- Williams and S. O. Driscoll) (AA2024T3) Corrosion) (Scanning Kelvin Probe) (20°C) (-400) ( -200 ) (0.5 HCl mol dm) ( Ecorr. ) 397 (Al–2Cu–2Mg) ( Ecorr. ) ( 2002 ) (H.N.Mcmurray, G.- Williams and S. O. Driscoll, 2002) (D.Bengtsson Blucher, J. E. Svensson and L.G. Johansson) (CO2) (NaCl) ( AA1070 ) ( 95 0.3 % ) ( 4,10,22,38,50,60°C) ( CO2 ) (4) ( (D.Bengtsson Blucher, J. E. Svensson and L.G. Johansson,2002) CO2) (Ingrid Rink and D. Martin Knotter) (0.4%) ( 35,45°C ) (Ingrid Rink and D. Martin Knotter,2003) Al2Cu-2Mg (Al-2Cu-2Mg ) 1 Heater RT-1000ºC 398 Basim M. The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 -1 -2 -3 300- 400ºC 15mm (Sola Basic S.B 200-1200ºC Lindberg 500ºC 2 HERGON 500ºC 45min Al–2Cu–2Mg 170ºC MLW Cold work Al–2Cu–2Mg 399 (Al–2Cu–2Mg) PHYWE 170ºC 12,24% Al–2Cu–2Mg (3wt%NaCl) (3vol% HCl ) Sartorius 0.0001 400 Basim M. The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 (Union ME-3154) (600X) (Al- (1) (3wt%NaCl) 2Cu-2Mg) (290 hrs) (2-b) (3wt%NaCl) (1) (45 min.) (500° C) (220 hrs) ( L.Reich ,S.P.Ringer (Al2Cu) ,S(Al2Cu Mg) and K.Hono,1999) (αss) (220 hrs. ) ( L.Reich (S',S") ,S.P.Ringer and K.Hono,1999) ( L.Reich ,S.P.Ringer and K.Hono,1999) (S) (Ingrid Rink and D. Martin Knotter,2003. R.G.Buchheit, 401 (Al–2Cu–2Mg) R.K.Boger, M.W.Donohue,2001. R.G.Buchheit, R.K.Boger,2002 ) 290 hrs (2-c) (NaCl) ( 1) ( 3 hrs ) (170°C) 40 hrs S",S' 170 °C 3 hrs (L.Reich ,S.P.Ringer and K.Hono,1999) S α S",S',S 2-d 290 hrs S",S',S S",S' 170 3wt%NaCl °C 402 Basim M. The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 12% 24% 3wt%NaCl 3 hrs 170°C 4 (3vol% HCl) α S,θ (Ingrid Rink and D. Martin Knotter,2003. HCl R.G.Buchheit, R.K.Boger, M.W.Donohue,2001) 45min. 500°C αss 403 (Al–2Cu–2Mg) (3vol% HCl) 170°C 3hrs. S" , S' S",S' S(Al2CuMg) 500°C 5.5 hrs. ( 3vol% HCl ) 170°C (5-a) (5-c) (5-b) (5-a) (5-b) (5-c) 3 hrs 6 404 170°C (3vol% HCl) Basim M. The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 -D.A.Little and J. R. Scully, “An Electro Chemical Framework to Explain the Intergranular Stress Corrosion Path of two Al–Cu–Mg–Ag Alloys , C415 and C416” , PDF, 2001 . On the web: http://cat.inist.fr/?aModele=afficheN&cpsidt=18489225 -Eiji Akiyama, K. Asami and other, “Enhancement of Corrosion Resistance of Amorphous Aluminum alloys by Alloying Additions”, pdf, 2001. On the web: www.nims.go.jp/pmg/html/akiyama%20Publication%20Record.htm -H. Bohni and T. Suter “Localized Corrosion Studies on a Molecular Level”, PDF, 2002. -N. Le Bozec, D. Persson and other, “Analysis of Filiform Corrosion on Coated Aluminum Alloy by FTIR Micro-spectroscopy and Scanning Kelvin Probe”, PDF, 2002. On the web: link.aip/link/?JES/149/B403/1 -H.N .Mcmurray, G. Williams and S. O. Driscoll ,”Chromate Inhibition of Filiform Corrosion on Organic Coated AA2024T3 Aluminum Alloy Investigated using a Scanning Kelvin Probe” , PDF .2002 . On the web: link.aip.org/link/?ESLF616/B9/1 -D.Bengtsson Blucher, J.E.Svensson and L. G. Johansson, “The NaCl – Induced Atmospheric Corrosion of Aluminum; the Influence of Carbon Dioxide and Temperature”, PDF ,2002 . 405 (Al–2Cu–2Mg) On the web: direct .bl.uk/research/42/15/RN/28088222.html. -Ingrid Rink and D. Martin Knotter, “ Passivation of Aluminum and Aluminum – Copper Alloys in Aqueous Acids”, PDF, 2003. On the web: www.electrochem.org/dl/ma/204/pdfs/0817.PDF - L.Reich ,S.P.Ringer and K.Hono ,”Origin of of the initial rapid age-hardening in an Al-1.7Mg-1.1Cu alloy”. Philosophcal Magazine Letters,79(9):6840.1999. -R.G.Buchheit, R.K.Boger, M.W.Donohue, “Copper Dissolution Phenomena in Al-Cu and Al-Cu-Mg Alloys”,2001. On the web : http//www.mse.ohio-stst.edu/%7Ebruedigm/RGB02.pdf -R.G.Buchheit, R.K.Boger, “Cu Redistribution and Surface Enrichment Due to Dissolution of Al-Cu Alloys”, 2002. On the web: http//www.mse.ohio-stst.edu/%7Ebruedigm/RGB03.pdf (1) Cu Al –2Cu – 2Mg Mg wt% at% wt% at% 2 0.86 2 2.25 Al remainder 2 d(mm) t(mm) D(mm) 2 3 15 3% HCl 3% NaCl untreated 3% HCl 2 3 15 3% NaCl S.H.T at 500 C+A.A at 170C 2 2.6 16.1 S.H.T at 500 C+ C.W=12%+A.A at 170C 2 2.3 17.1 S.H.T at 500 C+ 3% HCl 3% NaCl 3% HCl 406 Basim M. The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 C.W=24%+A.A at 170C 3% NaCl 1.8E-5 water+3% NaCl Weight loss/unit area (g/mm ) 1.6E-5 Untreated Solution Heat Treated at (500 C) 1.4E-5 Artificial Aged at (170) 1.2E-5 1.0E-5 8.0E-6 6.0E-6 4.0E-6 2.0E-6 0.0E+0 -2.0E-6 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 time (hrs.) 1 3wt%NaCl 2-a (600 X) 407 (Al–2Cu–2Mg) 2-b (600 X) (3wt% NaCl) 170 2-d ( 600X ) (3wt% NaCl) °C 2-c (600X) (3wt% NaCl) 500°C 408 The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 1E-5 water+ 3% NaCl C.W 0 %+A.A at 170 C 1E-5 Weight loss / unit area(g/mm ) C.W 12%+A.A at 170 C C.W 24%+A.A at 170 C 8E-6 6E-6 4E-6 2E-6 0E+0 -2E-6 0 40 80 120 160 200 240 280 320 360 400 440 480 time (hrs.) 170 °C 3wt% NaCl 3.6E-5 Water+3% HCl 3.2E-5 Weight loss/unit area (g/mm ) Basim M. Untreated Solution Heat Treated at (500 C) 2.8E-5 Artificial Aged at (170 C) 2.4E-5 2.0E-5 1.6E-5 1.2E-5 8.0E-6 4.0E-6 0.0E+0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 time (hrs.) 4 3vol%HCl 409 (Al–2Cu–2Mg) 5-a (600X ) (3vol% HCl) 5-b (600X ) (3vol% HCl) 500 °C 5-c (600 X) (3vol% HCl) 170°C 410 Basim M. The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 4.0E-5 Water+3% HCl Weight loss/unit area (g/mm ) 3.5E-5 CW 0 % +A.A. at 170 C CW 12% +A.A. at 170 C 3.0E-5 CW 24% +A.A. at 170 C 2.5E-5 2.0E-5 1.5E-5 1.0E-5 5.0E-6 0.0E+0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 time (hrs.) 6 170 °C 3vol%HCl 411