through the boiler for a net power output of 25...

advertisement

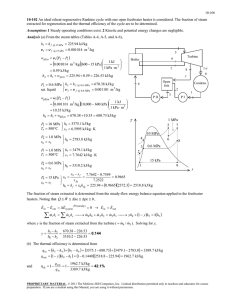

10-73 10-77 A cogeneration plant modified with regeneration is to generate power and process heat. The mass flow rate of steam through the boiler for a net power output of 25 MW is to be determined. Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible. Analysis From the steam tables (Tables A-4, A-5, and A-6), 6 h1 h f @ 10 kPa 191.81 kJ/kg v1 v f @ 10 kPa 0.00101 m 3 /kg wpI,in v 1 P2 P1 1 kJ 0.00101 m /kg 1600 10 kPa 1 kPa m 3 1.61 kJ/kg 3 Turbine Boiler 7 8 Process heater 5 h3 h4 h9 h f v4 v f 858.44 kJ/kg 4 @ 1.6 MPa 0.001159 m /kg 3 PII 3 wpII,in v 4 P5 P4 @ 1.6 MPa Condense r 9 h2 h1 wpI,in 191.81 1.61 193.41 kJ/kg 1 PI fwh 2 T 1 kJ 0.001159 m 3 /kg 9000 400 kPa 1 kPa m 3 8.57 kJ/kg 6 5 h5 h4 wpII,in 858.44 8.57 867.02 kJ/kg P6 9 MPa h6 3118.8 kJ/kg T6 400C s 6 6.2876 kJ/kg K 3,4,9 2 s7 s f 6.2876 2.3435 1 0.9675 P7 1.6 MPa x 7 s fg 4.0765 s7 s6 h h x h 858.44 0.96751934.4 2730.0 kJ/kg f 7 7 fg 9 MPa 1.6 MPa 7 10 kPa 8 s s8 s f 6.2876 0.6492 0.7518 P8 10 kPa x8 s fg 7.4996 s8 s 6 h h x h 191.81 0.75182392.1 1990.2 kJ/kg 8 f 8 fg Then, per kg of steam flowing through the boiler, we have wT,out h6 h7 (1 y )h7 h8 3118.8 2730.0 kJ/kg 1 0.352730.0 1990.2 kJ/kg 869.7 kJ/kg wp,in (1 y ) wpI,in wpII,in 1 0.351.61 kJ/kg 8.57 kJ/kg 9.62 kJ/kg wnet wT,out wp,in 869.7 9.62 860.1 kJ/kg Thus, m W net 25,000 kJ/s 29.1 kg/s wnet 860.1 kJ/kg PROPRIETARY MATERIAL. © 2011 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and educators for course preparation. If you are a student using this Manual, you are using it without permission.