high pressure is used for process heating. The net power... 10-74

advertisement

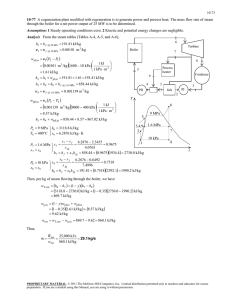

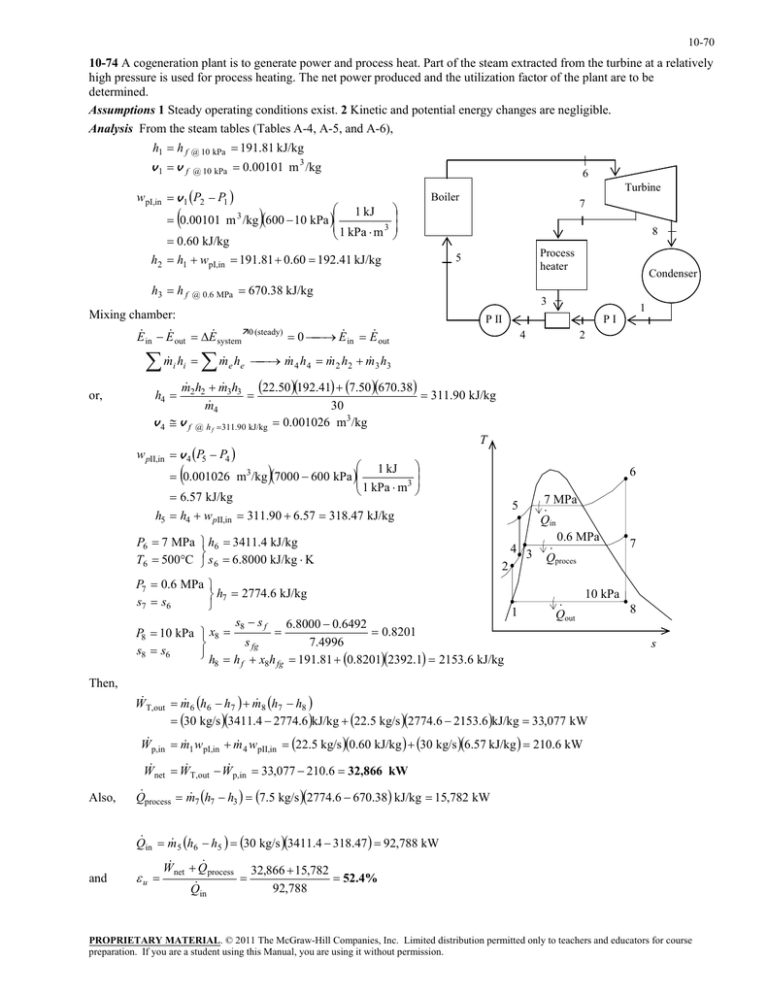

10-70 10-74 A cogeneration plant is to generate power and process heat. Part of the steam extracted from the turbine at a relatively high pressure is used for process heating. The net power produced and the utilization factor of the plant are to be determined. Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible. Analysis From the steam tables (Tables A-4, A-5, and A-6), h1 h f @ 10 kPa 191.81 kJ/kg v1 v f @ 10 kPa 0.00101 m 3 /kg wpI,in v 1 P2 P1 1 kJ 0.00101 m 3 /kg 600 10 kPa 1 kPa m 3 0.60 kJ/kg 6 h2 h1 wpI,in 191.81 0.60 192.41 kJ/kg h3 h f Mixing chamber: E E in @ 0.6 MPa 7 8 Process heater 5 670.38 kJ/kg Condenser 3 1 P II out i i PI E system 0 (steady) 0 E in E out m h m h or, Turbine Boiler e e 4 2 m 4 h4 m 2 h2 m 3 h3 m 2 h2 m 3h3 22.50 192.41 7.50 670.38 311.90 kJ/kg m 4 30 v 4 v f @ h f 311.90 kJ/kg 0.001026 m3/kg T w pII,in v 4 P5 P4 1 kJ 0.001026 m3/kg 7000 600 kPa 1 kPa m3 6.57 kJ/kg h5 h4 w pII,in 311.90 6.57 318.47 kJ/kg h4 P6 7 MPa h6 3411.4 kJ/kg T6 500C s 6 6.8000 kJ/kg K 6 7 MPa · Qin 0.6 MPa 4 3 · Qproces 5 2 P7 0.6 MPa h7 2774.6 kJ/kg s7 s6 1 s8 s f 6.8000 0.6492 0.8201 P8 10 kPa x8 s fg 7.4996 s8 s6 h h x h 191.81 0.82012392.1 2153.6 kJ/kg 8 f 8 fg 7 10 kPa · Qout 8 s Then, W T,out m 6 h6 h7 m 8 h7 h8 30 kg/s 3411.4 2774.6 kJ/kg 22.5 kg/s 2774.6 2153.6kJ/kg 33,077 kW W p,in m 1 wpI,in m 4 wpII,in 22.5 kg/s 0.60 kJ/kg 30 kg/s 6.57 kJ/kg 210.6 kW W net W T,out W p,in 33,077 210.6 32,866 kW Also, Q process m 7 h7 h3 7.5 kg/s 2774.6 670.38 kJ/kg 15,782 kW Q in m 5 h6 h5 30 kg/s 3411.4 318.47 92,788 kW and u W net Q process 32,866 15,782 52.4% 92,788 Q in PROPRIETARY MATERIAL. © 2011 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and educators for course preparation. If you are a student using this Manual, you are using it without permission.