from tank A to tank B until the pressure in... 8-111

advertisement

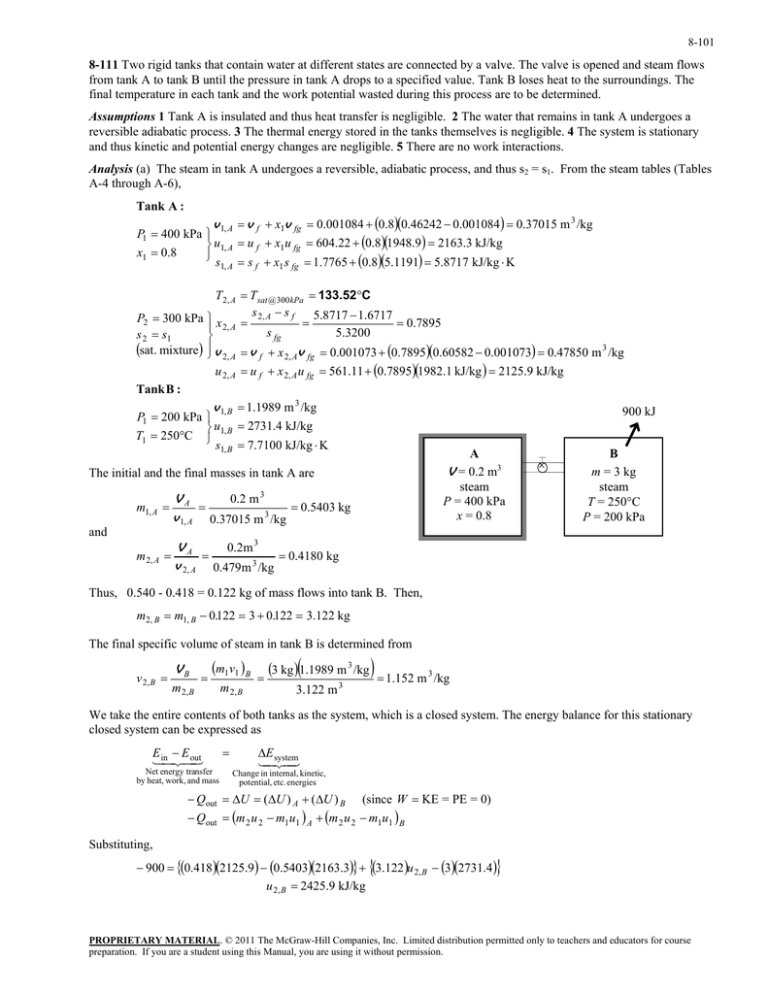

8-101 8-111 Two rigid tanks that contain water at different states are connected by a valve. The valve is opened and steam flows from tank A to tank B until the pressure in tank A drops to a specified value. Tank B loses heat to the surroundings. The final temperature in each tank and the work potential wasted during this process are to be determined. Assumptions 1 Tank A is insulated and thus heat transfer is negligible. 2 The water that remains in tank A undergoes a reversible adiabatic process. 3 The thermal energy stored in the tanks themselves is negligible. 4 The system is stationary and thus kinetic and potential energy changes are negligible. 5 There are no work interactions. Analysis (a) The steam in tank A undergoes a reversible, adiabatic process, and thus s2 = s1. From the steam tables (Tables A-4 through A-6), Tank A : v 1, A v f x1v fg 0.001084 0.80.46242 0.001084 0.37015 m 3 /kg P1 400 kPa u1, A u f x1u fg 604.22 0.81948.9 2163.3 kJ/kg x1 0.8 s s x s 1.7765 0.85.1191 5.8717 kJ/kg K f 1, A 1 fg T2, A Tsat @300kPa 133.52 C P2 300 kPa x s 2, A s f 5.8717 1.6717 0.7895 2, A s fg 5.3200 s 2 s1 sat. mixture v v x v 0.001073 0.78950.60582 0.001073 0.47850 m 3 /kg 2, A f 2, A fg u 2, A u f x 2, A u fg 561.11 0.78951982.1 kJ/kg 2125.9 kJ/kg Tank B : v 1.1989 m 3 /kg P1 200 kPa 1, B u1, B 2731.4 kJ/kg T1 250C s1, B 7.7100 kJ/kg K 900 kJ A V = 0.2 m3 The initial and the final masses in tank A are m1, A steam P = 400 kPa x = 0.8 V 0.2 m 3 A 0.5403 kg v 1, A 0.37015 m 3 /kg B m = 3 kg steam T = 250C P = 200 kPa and m 2, A VA 0.2m 3 0.4180 kg v 2, A 0.479m 3 /kg Thus, 0.540 - 0.418 = 0.122 kg of mass flows into tank B. Then, m2, B m1, B 0122 . 3 0122 . 3.122 kg The final specific volume of steam in tank B is determined from v 2, B VB m 2, B m1v1 B m 2, B 3 kg 1.1989 m 3 /kg 1.152 m 3 /kg 3.122 m 3 We take the entire contents of both tanks as the system, which is a closed system. The energy balance for this stationary closed system can be expressed as E E inout Net energy transfer by heat, work, and mass E system Change in internal, kinetic, potential, etc. energies Qout U (U ) A (U ) B (since W KE = PE = 0) Qout m 2 u 2 m1u1 A m 2 u 2 m1u1 B Substituting, 900 0.4182125.9 0.54032163.3 3.122u 2, B 32731.4 u 2, B 2425.9 kJ/kg PROPRIETARY MATERIAL. © 2011 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and educators for course preparation. If you are a student using this Manual, you are using it without permission. 8-102 Thus, v 2, B 1.152 m 3 /kg u 2, B T2, B 110.1C s 2425.9 kJ/kg 2, B 6.9772 kJ/kg K (b) The total entropy generation during this process is determined by applying the entropy balance on an extended system that includes both tanks and their immediate surroundings so that the boundary temperature of the extended system is the temperature of the surroundings at all times. It gives S S out in Net entropy transfer by heat and mass S gen S system Entropy generation Change in entropy Qout S gen S A S B Tb,surr Rearranging and substituting, the total entropy generated during this process is determined to be S gen S A S B Qout Q m 2 s 2 m1 s1 A m 2 s 2 m1 s1 B out Tb,surr Tb,surr 0.4185.8717 0.54035.8717 3.1226.9772 37.7100 900 kJ 273 K 1.234 kJ/K The work potential wasted is equivalent to the exergy destroyed during a process, which can be determined from an exergy balance or directly from its definition X destroyed T0 S gen , X destroyed T0 S gen (273 K)(1.234 kJ/K ) 337 kJ PROPRIETARY MATERIAL. © 2011 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and educators for course preparation. If you are a student using this Manual, you are using it without permission.