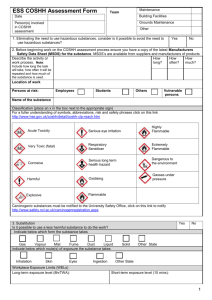

responsible research Managing health and safety in research: guidance for the not-for-profit sector

advertisement