AL-Yaqdhan Abdullah AL-Harthy

advertisement

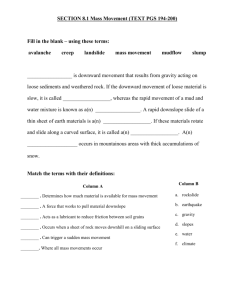

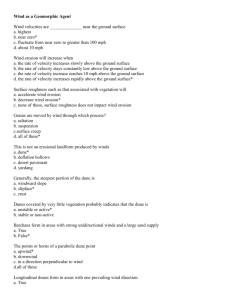

Civil and Architectural Engineering Department-College of Engineering-Sultan Qaboos University Experimental Study of the Performance of Plastic Pipes Buried in Dune Soil AL-Yaqdhan Abdullah AL-Harthy Abstract Bedding and backfill materials play a critical role in the long-term structural integrity of buried pipelines. The safety of buried pipes, as one of the most important urban facilities, under different loading conditions depends highly on the safe design and performance of these buried structures. Type of pipe, backfill materials and cover thickness are the main factors affecting the behavior of the pipes. Material parameters and pipe characteristics are essential for rational analysis. In areas where selected bedding and backfill soil are not available, the use of local soil as a backfill or bedding materials for buried pipes becomes a realistic option. Dune sands cover vast areas in Oman and suitable backfill soils for construction of buried pipes are not available in these areas. Because of the remoteness of these areas, engineers tend to use the local dune sands as backfill soils for buried pipes. This study was intended to study the performance of the pipe installed in dune sand. Different factors were considered such as installation method, cover depth, pipe stiffness and surface applied stress. To achieve this objective, a 1.0 m long X 0.32 m width X 1.0 m height tank model was used. Upvc pipe class O (200 mm dia.) was installed at a selected depth within the tank and a sand backfill was placed below, around and above the pipe in layers. First layer was represented the native soil and it was of a thickness of 200 mm of dune sand. The second layer was a 100 mm bedding sand (dune sand or normal sand). The third layer was dune sand in the boundary of the tank with 250 mm width in each side to make a trench in the middle of the tank. In the middle the pipe was installed and the surrounding area was backfilled by sand (dune sand or normal sand). The thickness backfill above the pipe was varied from 100 mm to 500 mm and was constructed using sand (dune sand or normal sand). Two pieces of L-VDT were used to measure the horizontal and vertical deflection of the pipe and four strain gauges in the four sides of the pipe at the crown, the invert and the spring line. Vertical uniform load was applied to a foundation plate (size 10 cm X 32 cm). Loading test machine was used to apply a constant speed of loading of 2 mm/min. The results of this study were presented in term of surface settlement, vertical deflection, horizontal deflection and bending moments. The surface settlement for dune sand was more than normal sand. The vertical deflection, horizontal deflection and bending moment for dune sand were less than normal sand. The conclusion was the dune sand can be used as embedded sand after proper compaction of the bedding, to minimize the surface settlement.