FOCUSING ON THE FUTURE OF BIOLOGICS

advertisement

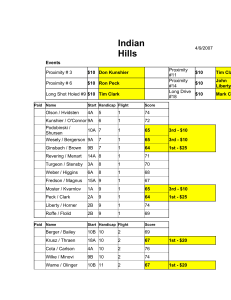

FOCUSING ON THE FUTURE OF BIOLOGICS MANUFACTURING Jeff Odum, CPIP Biotechnology Lead Director of Operations Integrated Project Services The Tale of… Speed Racer published by Digital Magna Publishing Image of “Bigfoot” from National Geographic Files Background 3 Process Development/Pilot Plant Process Development / Pilot Plant Product Function Regulatory: Description Operational Scale Facility Size, sq ft Cell Culture Trains Bioreactor Size, L Capture Column Size, m Wastewater Generation, Gal/Day Electrical Power Consumption, kWh/day Construction Cost, $MM Project Schedule (weeks) (1) Design Construction Commissioning Total (yr) Personnel Lab Manufacturing Clerical, Admin., Mgt Other (Warehouse, Validation, etc) Total Personnel Recombinant protein expressed in bacterial or mammalian cell line. Technology transfer from lab to production environment. Limited production of drug substance for early stage clinical trials "GMP-like" Manufacturing Estimates Low High 15,000 1 500 0.3 15,000 5,000 10 35,000 3 2,000 0.5 45,000 10,000 25 15 25 12 1 25 35 20 2 15 10 8 15 48 40 20 15 18 93 Factors Construction Cost Land Area, Acres Regional / Municipal Factors Land Cost Labor Cost Highly Trained Labor Force Proximity to University Research Centers Proximity to Gov't R&D and Reg. Centers Proximity to Airports Proximity to other Biotech Companies Proximity of Support Businesses (2) Public Services Infrastructure (4) $18MM 5 $40MM 10 Relevance (3) Low Low High High Moderate Moderate High High Moderate GMP Production Facility Process Development / Pilot Plant Product Recombinant protein expressed in bacterial or mammalian cell line. Function Technology transfer from lab to production environment. Limited production of drug substance for early stage clinical trials Regulatory: "GMP-like" Manufacturing Estimates Low High Description Operational Scale Facility Size, sq ft Cell Culture Trains Bioreactor Size, L Capture Column Size, m Wastewater Generation, Gal/Day Electrical Power Consumption, kWh/day Construction Cost, $MM Project Schedule (weeks) (1) Design Construction Commissioning Total (yr) Personnel Lab Manufacturing Clerical, Admin., Mgt Other (Warehouse, Validation, etc) Total Personnel 15,000 1 500 0.3 15,000 5,000 10 35,000 3 2,000 0.5 45,000 10,000 25 15 25 12 1 25 35 20 2 15 10 8 15 48 40 20 15 18 93 Factors Construction Cost Land Area, Acres Regional / Municipal Factors Land Cost Labor Cost Highly Trained Labor Force Proximity to University Research Centers Proximity to Gov't R&D and Reg. Centers Proximity to Airports Proximity to other Biotech Companies Proximity of Support Businesses (2) Public Services Infrastructure (4) Large slide view is available in the back of this tab. $120MM 20 $400MM 50 Relevance (3) Moderate / High High Moderate Moderate Low / Moderate Moderate Moderate / High High High Times, they are changing… • • • Business Drivers Impacting Technologies Greater Demands on Development • • • Higher Titers Greater Efficiency Higher Utilization Evolution of Biomanufacturing Technologies for Mammalian Cells Hybrid Infrastructure: Stainless Steel (SS) High Throughput & Flexible (FVM) Fixed Single Product Facilities FDA Guidance Multi-Prod MFG Intro of 15KL “6 pack” plants Fixed Multi- Product Facilities Flexible Manufacturing Intro of Disposable Tech Next Generation Bioprocessing Emerging Contract Manufacturers 1980 1985 1990 1995 2000 2005 2010 2015 0.01 g/L 0.5 g/L 5 g/L 10 g/L $10,000/g $1000/g $300/g $100/g Titers A: 2 g/L B: 5 g/L 7 Modern Enablers • More Productive Processes • • • • • High Cell Culture Yields Skid Enabled Continuous Processes Fewer Downstream Unit Operations More Efficient Downstream Processes • Single Use Systems • • • Simulated Moving Bed Chromatography Lower Cleaning & Validation Requirements Quick Area Turnover Advanced Infrastructure Strategies • • Process Validation (Design Space) Quality By Design – Solve Future Problems Early Biomanufacturing Tomorrow Vision Develop flexible manufacturing capacity based on disposable technology that can provide bulk drug product for human use breaking with traditional fixed investment paradigm. A fully closed flow path from dispensary to the final Drug Substance container that: – Concept – – – MFG Network Can be operated in an open space with no segregation and reduced overall environmental control, requiring minimized fixed assets Is portable Is accompanied by phase appropriate quality systems Provide a low capital cost option for early clinical manufacturing that can graduate to commercial use. Enable a hybrid manufacturing network of traditional fixed SS and disposable single use bags that can strategically be located across the globe to optimize flexibility and cost structure for: – Commercial, Late Stage, Early Stage, Biosimilars, External/Internal Products 9 Manufacturing Challenges/Opportunities • Multiphase Opportunities ‒ − More Products • Biosimilars • Therapeutic Families • ADM Business Models Faster, Faster • Faster Product Lifecycles • Advances in Clinical Designs • Less “Tech Transfer” Manufacturing StrategyLess Capital Intensive & Faster Delivery Capital Investments Comparison CapEX ($M) Greenfield Expansion Disposable (2x 1KL + 2P) 4.4x 1 Fixed (3x 2KL + 1P) 5.6x 3.4x Fixed (6x 15KL + 1P) 15.6x 10.6x Design Features of “Speed Racer” • • • • • • Closed system processing Controlled non-classified space (CNC) Non-segregation of operations Upgradable in future for classified space and dedicated filling area Fully disposable Integration with existing facility operations (hybrid) Large Operating Spaces • Opportunities • • • Resilience • • Interactions Reliability • • SUS Problems Throughput • • Multi-product Multi-phase? Failure Interaction Efficiency Matrix Operating Spaces • Opportunities • • • Resilience • • Independence Reliability • • SUS Problems Throughput • • Multi-product Multi-phase Failure Separation Efficiency Closed System Operations ‘Closed’ System Can be described as ‘a system that when operated under normal conditions prevents the ingress or egress of adventitious agents’ • This could be met in several ways to ensure microbial control from production environment • Aseptic welding • Aseptic connectors • Pre-sterilized components / equipment • Pre-sanitization with acid or base • Pre-assembly in ‘classified’ area • Reduces / eliminates the need for expensive ‘controlled and classified’ cleanroom environments. • Closed system verification was successfully completed • Use of vendor qualification data in conjunction with • Assembly of closed system, sanitization and controlled transfer of growth promoting media for each unit operation The Future Some Lessons for Speed Racer… • • • • • • • • • • • Dual source of suppliers for all components whenever possible Compatibility of components Supplier relationship and previous experience critical Get the supply chain folks involved early; they need to understand the challenges/issues Get the validation/quality folks involved early; they have to be on the same page Qualify additional vendors Biggest companies are not necessary the best Vendor A bag with Vendor B connectors Use suppliers with local support or local presence Tube Management Dealing with the waste Training Thank you for your attention jodum@ipsdb.com