Investigation of the Impact of Commercial Building Envelope NISTIR 7238

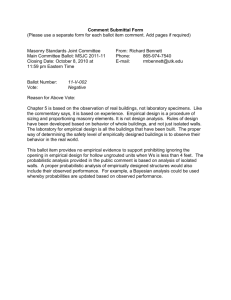

advertisement