GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY – PHASE I 2011 RATE CASE

advertisement

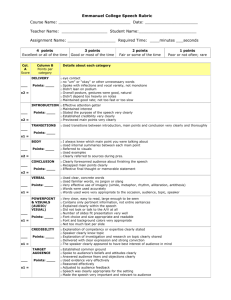

GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Overview The purpose of this evidence is to provide an update to Gazifère’s (the “Company”) Productivity Factor. This estimated factor is to be considered in the Company’s next rate-setting period, 2011-2015. In order to remain consistent with the previous productivity factor estimate from R-3587-2005, Exhibit GI-9, document 2, the same procedure employed by Darryl J. Seal Consulting was used henceforth. After careful review of the updated productivity factor results, the Company is requesting that the productivity factor be determined using the 20042008 timeframe which yields a productivity factor of 0.3% compared to the previously decided 0.2%1. This new five year period by which the productivity factor was estimated is considered to be the best because the resulting factor is reasonable and the five year timeframe was also deemed acceptable by the Régie in its decision D-2006-158. Background Under the Company’s current revenue cap per customer rate-setting mechanism three key elements are explicitly taken into account when determining its revenue requirement: general inflationary increases, customer growth and productivity improvements. Both inflation and customer growth work 1 Decision D-2006-158, p. 17. Original : 2010-03-04 GI-2 Document 2 Page 1 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I to elevate the Company’s revenue requirement while productivity improvements work to offset the increases of the other two factors. Similarly to R-3587-2005, the subsequent productivity estimate to be used in the 2011-2015 term rate-setting mechanism should aim to imitate the overall productivity of the Company with respect to its ability to deliver its services safely and reliably. Since the Company uses both capital and labour in the delivery of its distribution services, the productivity of both of these inputs must be reflected in the productivity element of the rate-setting mechanism. Prior to the revenue cap per customer rate-setting mechanism, the Company had adopted an O&M mechanism in which productivity of labour and materials was accounted for in the formula. The current mechanism considers the productivity of capital as its productivity directly impacts revenue requirement. Total Factor Productivity As was the case during R-3587-2005, overall productivity is measured using Total Factor Productivity (“TFP”). TFP measures the time-dependent relationship between outputs of a producer relative to the production inputs. For the specific case of Gazifère, TFP measures the change over time of the relationship between an output measure (i.e. customers or volumes) and the inputs to providing gas distribution services (i.e. labour, materials and capital). Figure 1 presents the TFP formula: Original : 2010-03-04 GI-2 Document 2 Page 2 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Figure 1 TFP Formula i x TFP i Q X je j j Q = Output Measure Xj = Input Measures ej = input weights TFP is measured as the change in this index over the period i to i+x. Where applicable, the preferred method to measuring outputs and inputs is to measure each in physical units. Using physical units to measure TFP removes the need for inflation considerations which are present when measuring in dollars. However, it is important to understand that measuring in physical units is not without its own issues. For example, measuring labour input by number of employees might not account for the difference in effort used by different employees. However, whenever it is an option, measuring using physical units is preferred. Estimating TFP for Gazifère Estimating the historical TFP for Gazifère requires the collection of detailed records on outputs and inputs for all factors of production. Original : 2010-03-04 GI-2 Document 2 Page 3 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I One of the essential determinations in constructing TFP estimates involves choosing the appropriate time period over which to measure productivity. The time period needs to be adequately long to remove short-term fluctuations in the data to avoid the productivity estimates from being skewed. For example, a large capital project in one year may lead to a decrease in estimated productivity in the year it is recognized, but is not reflective of the overall company experience. However, the chosen time period must also be short enough that it does not incorporate productivity from the distant past. Since an essential objective of this study is to use productivity estimates in a forward-looking framework, productivity gains or losses which may have occurred multiple decades in the past may not provide much information for the productivity expectations in the near future. In the historical analysis of Gazifère’s productivity, the period of analysis covers the fiscal years 1987 through 2008. This sample of data provides a sufficiently long and relevant history from which to estimate the Company’s productivity trends. Multiple sub-periods within the 22 year time period are analyzed in addition to the full sample of data. Output Measures Two methods can be used when measuring the Company’s output: volumes or customers. Original : 2010-03-04 GI-2 Document 2 Page 4 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Gazifère provides distribution services to residential, commercial and industrial markets. Historical volumes to these customers are shown in Table-1 (not weather normalized) and Table-2 (weather normalized). Table-1 3 3 Gazifère Volumes - Not Weather Normalized (10 m ) Col. 1 Col. 2 Col. 3 Col. 4 Col. 5 Fiscal Year Residential Commercial Industrial Total 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 24,884 26,536 27,809 28,616 27,698 34,647 36,853 42,187 38,905 45,723 45,870 43,458 44,709 49,280 50,771 47,584 57,592 57,518 57,984 54,440 59,791 60,023 35,090 36,828 38,460 40,490 40,046 44,606 45,466 51,399 46,081 53,131 54,565 50,990 52,118 54,594 58,267 55,579 65,200 62,964 62,737 57,941 62,123 62,127 61,895 117,048 163,473 176,502 145,575 143,754 53,880 35,131 53,740 80,222 89,059 111,453 96,789 126,915 55,361 60,060 43,227 37,162 29,493 48,399 45,769 55,553 121,869 180,412 229,742 245,608 213,319 223,007 136,199 128,717 138,726 179,076 189,494 205,901 193,616 230,789 164,399 163,223 166,019 157,644 150,214 160,780 167,683 177,703 Original : 2010-03-04 Col. 6 Annual Growth 48.0% 27.3% 6.9% -13.1% 4.5% -38.9% -5.5% 7.8% 29.1% 5.8% 8.7% -6.0% 19.2% -28.8% -0.7% 1.7% -5.0% -4.7% 7.0% 4.3% 6.0% GI-2 Document 2 Page 5 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Table-2 3 3 Gazifère Volumes - Weather Normalized (10 m ) Col. 1 Col. 2 Col. 3 Col. 4 Col. 5 Fiscal Year Residential Commercial Industrial Total 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 26,072 26,786 27,184 27,892 29,275 33,702 35,931 39,058 41,132 43,843 45,679 46,538 48,106 53,102 50,493 51,971 53,275 56,491 56,748 57,562 58,686 59,263 36,513 37,115 37,691 39,570 41,993 43,493 44,558 47,813 48,542 51,125 54,429 54,295 55,946 58,477 58,019 60,426 60,630 61,939 61,386 61,064 60,979 61,405 61,948 117,063 163,462 176,493 145,621 143,718 53,864 35,114 53,807 80,162 89,072 111,503 96,977 127,031 55,352 60,165 43,112 37,109 29,460 48,523 45,672 55,555 124,533 180,964 228,337 243,955 216,889 220,913 134,353 121,985 143,481 175,130 189,180 212,336 201,029 238,610 163,864 172,562 157,017 155,539 147,594 167,149 165,337 176,223 Col. 6 Annual Growth 45.3% 26.2% 6.8% -11.1% 1.9% -39.2% -9.2% 17.6% 22.1% 8.0% 12.2% -5.3% 18.7% -31.3% 5.3% -9.0% -0.9% -5.1% 13.2% -1.1% 6.6% After reviewing Table-1 and Table-2, it is clear that volumetric growth in Gazifère’s distribution franchise has been inconsistent over the 1987-2008 time period. One of the main explanatory factors to why volumetric growth has been so volatile is the impact that weather fluctuations, as measured by degree days, have each year on heat sensitive demand. Furthermore, Gazifère’s industrial demand has changed noticeably from year-to-year as volumes have declined in concert with falling industrial output. Original : 2010-03-04 GI-2 Document 2 Page 6 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I The second output measure which will be considered in this TFP study is customers. Table-3 outlines the historical number of customers for Gazifère (by customer class). Table-3 Gazifère Customers Col. 1 Col. 2 Col. 3 Col. 4 Col. 5 Fiscal Year Residential Commercial Industrial Total 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 9,080 9,192 9,333 9,507 10,092 11,591 12,918 14,368 15,643 16,453 17,413 18,579 19,748 20,834 21,797 22,633 23,934 25,509 26,951 28,438 29,676 30,974 1,366 1,461 1,551 1,621 1,679 1,735 1,862 1,964 2,042 2,100 2,196 2,293 2,359 2,447 2,533 2,562 2,614 2,681 2,731 2,818 2,874 2,904 16 15 14 12 12 12 12 11 11 11 12 13 14 14 13 14 14 13 13 13 12 11 10,462 10,668 10,898 11,140 11,783 13,338 14,792 16,343 17,696 18,564 19,621 20,885 22,121 23,295 24,343 25,209 26,562 28,203 29,695 31,269 32,562 33,889 Col. 6 Annual Growth 2.0% 2.2% 2.2% 5.8% 13.2% 10.9% 10.5% 8.3% 4.9% 5.7% 6.4% 5.9% 5.3% 4.5% 3.6% 5.4% 6.2% 5.3% 5.3% 4.1% 4.1% As compared to volumetric growth, customer growth has been much more stable for Gazifère from 1987-2008, although the time-series still fluctuates from year-to-year. Original : 2010-03-04 GI-2 Document 2 Page 7 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Since customer growth exhibits a more consistent short-run growth rate and the fact that a lot of Gazifère’s incremental resources are related to customer growth, using customers as a gauge of the Company’s output measure for this TFP analysis is preferred. Input Measures The specific inputs to be considered in Gazifère’s TFP analysis, as described earlier, consist of labour, materials and capital. Labour for Gazifère will be measured by using the number of employees in each year. Employees were split into supervisory and non-supervisory classes and weighted by labour costs (i.e. salaries plus benefits) to determine the labour input index. Materials for the Company include all non-capital and non-labour costs. These costs are estimated as the difference between total O&M costs and the labour component. Materials costs are originally provided in nominal dollar terms, but will be transformed into real dollars using the Québec Consumer Price Index. Capital is the most difficult input to construct for the TFP estimates. For the purposes of this TFP analysis, two different approaches were applied. Method 1 uses accounting data for each asset class together with accumulated and annual depreciation, price escalation estimates, and cost of Original : 2010-03-04 GI-2 Document 2 Page 8 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I capital to develop a financial measure of capital employed. Method 2 uses a physical count of assets commissioned in each year. Data on asset values for the following categories were employed for the accounting measurement: Land, Right-of-Way, Structures & Improvements, Services, House Regulators, Mains, Stations, Meters, Leasehold Improvement, Equipment and Furniture, Transportation Equipment, Heavy Work Equipment, Tools & Work Equipment, Communication Equipment, Computer Equipment, and Other Capital. For each asset category, an opening balance for 1987 was determined from records for the net book value. For each following year, assets were increased by additions, decreased for retirements, and adjusted for annual depreciation. These asset values were converted to real dollars using estimates of price inflation for each category2. Each asset class was then weighted by a cost share comprised of data on taxes, depreciation and weighted average cost of capital to determine the capital input index. Please refer to the Data Appendix, page 15, for the detailed data used. An alternative method to using the accounting data for capital measure would be to use physical plant data. For Gazifère, physical plant data is readily available for services, mains and meters. These three assets account for more than 90% of the total assets employed by the Company. 2 Price deflators used were Canadian Gross Domestic Product Price Index, Industrial Product Price Indices specific to certain asset categories, and price indices constructed based on the company’s own cost data. Original : 2010-03-04 GI-2 Document 2 Page 9 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I The physical measure uses a similar approach to that of the accounting estimate of capital. Using a base of installed services, mains and meters in 1987, annual adjustments are made for additions and retirements. Weighting of these asset classes is based on the costs associated with each class, similar to the financial capital index. It is important to acknowledge that the accounting data for the various asset categories contained some anomalous values, such as negative depreciation values and negative retirement values. For this reason, the TFP results which draw on the accounting data for the capital input are deemed less reliable than those obtained using the physical plant data. Creation of Output and Input Indices In order to calculate the TFP measure, inputs and outputs need to be grouped into indices for each. The output index used for Gazifère’s TFP calculation will either be customers or volumes. The data for each customer class will be weighted by a two year moving average of customers in the class to smooth the annual changes. Annual growth is calculated as the difference in natural logarithms for each year 3. From this growth rate, the index is constructed with the base year of 1987 equal to 100. 3 Ex. Annual Growth in Output (t)= ln(customers(t)) – ln(customers(t-1)) Original : 2010-03-04 GI-2 Document 2 Page 10 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I The calculated output indices using customers is shown in Data Appendix 1. The calculated output indices using volumes – both not weather normalized and weather normalized are shown in Data Appendix 2 and Data Appendix 3, respectively. The input index is constructed using the indices for labour, materials and capital. As indicated above, the labour index is created from employment data of full time and part time staff. The employee numbers are weighted by total costs of employment – salaries plus benefits – for each category of employment, then the categories are summed and a resulting growth rate is calculated. Refer to Data Appendix 4 for the labour data calculations. The material index, described above, is defined as total O&M less labour costs. Data Appendix 5 shows the materials cost index. Construction of the capital index was completed using both the accounting data and the physical data. Data Appendix 6 shows the calculation using the accounting data, while Data Appendix 7 shows the calculation using the physical data. Finally, the input index is assembled by combining the three input indices. The indices are each weighted by their respective cost contribution. Refer to Data Appendix 8 for the calculations. Original : 2010-03-04 GI-2 Document 2 Page 11 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Summary of Results Table-4 summarizes the results of the TFP study for Gazifère covering the timeframe of 1987 to 2008. The table displays the annual productivity change and averages for various sub-periods, first using Customers as the output index and then using Volumes (both normalized and non weather normalized) as the output index. Finally, the results are also shown using both the accounting data and the physical data for the capital index. Table - 4 Total Factor Productivity Indices Col. 1 Fiscal Year 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 Averages 2004-2008 1999-2008 1994-2008 1989-2008 1988-2008 Col. 2 Accouting Capital 100.0 99.9 105.6 112.4 121.0 106.0 109.8 110.9 115.9 115.8 117.3 118.7 131.6 149.9 132.7 134.7 137.9 140.4 151.1 140.3 143.1 145.7 Col. 3 Col. 4 Output Index: Customers Physical Capital 100.0 -0.1% 98.7 5.5% 101.7 6.3% 99.9 7.3% 98.0 -13.2% 102.5 3.6% 105.7 0.9% 108.2 4.5% 113.6 -0.1% 114.2 1.2% 116.8 1.2% 116.2 10.3% 123.1 13.1% 123.2 -12.2% 124.2 1.5% 122.7 2.3% 121.9 1.8% 124.7 7.3% 124.6 -7.4% 124.6 2.0% 124.7 1.8% 124.0 1.1% 2.0% 1.9% 1.9% 1.8% Original::2010-03-04 2010-03-04 Original Révisé : 2010-05-04 Col. 5 -1.3% 3.0% -1.8% -1.9% 4.5% 3.0% 2.4% 4.8% 0.6% 2.2% -0.5% 5.8% 0.0% 0.8% -1.2% -0.7% 2.3% -0.1% 0.0% 0.1% -0.6% 0.3% 0.6% 1.1% 1.1% 1.0% Col. 6 Col. 7 Col. 8 Col. 9 Output Index: Non-Normalized Volumes Accounting Physical Capital Capital 100.0 100.0 146.2 37.9% 144.3 36.7% 192.6 27.6% 185.5 25.1% 214.6 10.8% 190.6 2.7% 189.6 -12.4% 153.5 -21.6% 153.4 -21.2% 148.3 -3.5% 85.0 -59.1% 81.7 -59.6% 73.2 -15.0% 71.4 -13.5% 76.3 4.2% 74.7 4.5% 93.9 20.8% 92.6 21.4% 95.2 1.4% 94.8 2.4% 98.4 3.3% 96.3 1.6% 96.8 -1.6% 90.6 -6.1% 124.9 25.5% 102.6 12.5% 74.1 -52.3% 69.3 -39.2% 72.1 -2.7% 65.7 -5.5% 71.2 -1.2% 62.9 -4.2% 64.9 -9.3% 57.6 -8.9% 63.1 -2.7% 52.0 -10.1% 59.7 -5.5% 53.0 1.9% 61.0 2.1% 53.2 0.2% 63.3 3.6% 53.8 1.3% -2.4% -4.4% -2.0% -4.2% -2.2% -3.1% -5.8% -2.8% -4.9% -2.9% Col. 10 Col. 11 Col. 12 Output Index: Normalized Volumes Accounting Physical Capital Capital 100.0 100.0 143.5 36.1% 141.7 187.5 26.7% 180.6 208.7 10.7% 185.3 188.7 -10.1% 152.9 148.8 -23.8% 143.9 82.0 -59.5% 78.9 67.9 -19.0% 66.3 77.2 12.9% 75.6 89.9 15.2% 88.7 93.0 3.4% 92.7 99.3 6.5% 97.2 98.4 -0.9% 92.1 126.4 25.1% 103.9 72.4 -55.8% 67.8 74.7 3.2% 68.1 66.0 -12.4% 58.3 62.7 -5.1% 55.7 60.8 -3.1% 50.1 60.8 0.1% 54.0 59.0 -3.2% 51.4 61.5 4.2% 52.3 -1.4% -4.8% -1.9% -4.2% -2.3% Col. 13 - 34.9% 24.2% 2.6% -19.3% -6.1% -60.0% -17.5% 13.3% 15.9% 4.4% 4.8% -5.4% 12.0% -42.7% 0.4% -15.4% -4.7% -10.5% 7.5% -5.1% 1.8% -2.2% -6.2% -2.7% -5.0% -3.1% GI-2 Document 2 Page 12 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Based on the results in Table-4 it is clear that the TFP estimates using volumes as the output index are weak. As mentioned above, the impact of weather changes and variations in industrial volumes can cause the annual estimates to vary significantly resulting in less robust estimates. In addition, the estimates over the majority of the time frames suggest a significantly negative productivity factor. The estimates which use customers as the output index are more acceptable. Depending on the capital index considered, the range of TFP estimates using customers range from a low of 0.3% to a high of 2.0%. As described earlier, due to the nature of some of the data used for the construction of the accounting estimate of the capital index, the productivity values produced using this method are somewhat less reliable than the physical capital methodology. Interpretation of TFP Estimates The TFP estimates in Table-4 provide a rough estimate of the true productivity changes Gazifère has experienced from 1987 to 2008. When determining which factor to use in the Company’s subsequent incentive mechanism, careful consideration must be taken to ensure the factor applied will best represent the expected productivity experience Gazifère will see during its next rate-setting horizon. With the understanding that a similar incentive mechanism will be used during the next rate-setting period, when deciding on an updated productivity factor it is Original : 2010-03-04 GI-2 Document 2 Page 13 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I logical to consider Gazifère’s five most recent years under the similar incentive mechanism. In other words, the time frame of 2004 to 2008 should provide a reasonable estimate of the Company’s productivity factor moving forward with its next incentive mechanism. Furthermore, in keeping with D-2006-158, pp. 15-17, section 3.3.6 “Facteur de productivité”, the productivity factor should continue to be based on the number of customers and the value of the Company’s physical capital. Basing the productivity factor using volumes and accounting capital introduce additional complications not present in the customer and physical capital scenario. Overall, since Gazifère intends to operate under a similar incentive mechanism over the 2011-2015 period, and considering the more reliable estimates provided by basing the productivity factor off of customers and the physical capital index measure, the Company suggests using the 2004-2008 estimate of 0.3% as its productivity factor. Original : 2010-03-04 GI-2 Document 2 Page 14 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appendix Data Appendix 1: Customer Index Data Appendix 2: Volumes Index – Not Weather Normalized Data Appendix 3: Volumes Index – Weather Normalized Data Appendix 4: Labour Index Data Appendix 5: Materials Index Data Appendix 6: Capital Index (Accounting Data) Data Appendix 7: Capital Index (Physical Data) Data Appendix 8: Combined Input Index Original : 2010-03-04 GI-2 Document 2 Page 15 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appendix 1 Customer Index Col. 1 Col. 2 Col. 3 Col. 4 Col. 5 Col. 6 Col. 7 Col. 8 Weights1 Customers Fiscal Year Residential (#) Commercial (#) Industrial (#) Residential (#) Commercial (#) Industrial (#) Weighted Growth2 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 9,080 9,192 9,333 9,507 10,092 11,591 12,918 14,368 15,643 16,453 17,413 18,579 19,748 20,834 21,797 22,633 23,934 25,509 26,951 28,438 29,676 30,974 1,366 1,461 1,551 1,621 1,679 1,735 1,862 1,964 2,042 2,100 2,196 2,293 2,359 2,447 2,533 2,562 2,614 2,681 2,731 2,818 2,874 2,904 16 15 14 12 12 12 12 11 11 11 12 13 14 14 13 14 14 13 13 13 12 11 86.5% 85.9% 85.5% 85.5% 86.3% 87.1% 87.6% 88.2% 88.5% 88.7% 88.9% 89.1% 89.4% 89.5% 89.7% 89.9% 90.3% 90.6% 90.9% 91.0% 91.3% 13.4% 14.0% 14.4% 14.4% 13.6% 12.8% 12.3% 11.8% 11.4% 11.3% 11.1% 10.8% 10.6% 10.5% 10.3% 10.0% 9.7% 9.3% 9.1% 8.9% 8.7% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.0% 0.0% 0.0% 0.0% 0.0% 2.0% 2.1% 2.2% 5.6% 12.4% 10.3% 10.0% 8.0% 4.8% 5.5% 6.2% 5.7% 5.2% 4.4% 3.5% 5.2% 6.0% 5.2% 5.2% 4.1% 4.0% Notes: 1. Weights are calculated as a moving two year average for each class. 2. Weighted growth is calculated as the log difference of the weighted customers. Original : 2010-03-04 Col. 9 GI-2 Document 2 Page 16 de 23 Requête 3724-2010 Customers Index (1987=100) 100.0 102.0 104.2 106.5 112.6 127.5 141.4 156.3 169.2 177.5 187.7 199.8 211.6 222.8 232.8 241.1 254.0 269.7 284.0 299.1 311.4 324.1 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appendix 2 Volumes Index - Not Weather Normalized Col. 1 Col. 2 Col. 3 Col. 4 3 Col. 5 Col. 6 3 Volumes (10 m ) Col. 7 Weights Col. 8 Col. 9 Fiscal Year Residential Commercial Industrial Total Residential Commercial Industrial Weighted Growth2 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 24,884 26,536 27,809 28,616 27,698 34,647 36,853 42,187 38,905 45,723 45,870 43,458 44,709 49,280 50,771 47,584 57,592 57,518 57,984 54,440 59,791 60,023 35,090 36,828 38,460 40,490 40,046 44,606 45,466 51,399 46,081 53,131 54,565 50,990 52,118 54,594 58,267 55,579 65,200 62,964 62,737 57,941 62,123 62,127 61,895 117,048 163,473 176,502 145,575 143,754 53,880 35,131 53,740 80,222 89,059 111,453 96,789 126,915 55,361 60,060 43,227 37,162 29,493 48,399 45,769 55,553 121,869 180,412 229,742 245,608 213,319 223,007 136,199 128,717 138,726 179,076 189,494 205,901 193,616 230,789 164,399 163,223 166,019 157,644 150,214 160,780 167,683 177,703 17.0% 13.2% 11.9% 12.3% 14.3% 19.9% 29.8% 30.3% 26.6% 24.9% 22.6% 22.1% 22.1% 25.3% 30.0% 31.9% 35.6% 37.5% 36.1% 34.8% 34.7% 23.8% 18.4% 16.6% 17.5% 19.4% 25.1% 36.6% 36.4% 31.2% 29.2% 26.7% 25.8% 25.1% 28.6% 34.7% 36.7% 39.6% 40.8% 38.8% 36.6% 36.0% 59.2% 68.4% 71.5% 70.2% 66.3% 55.0% 33.6% 33.2% 42.2% 45.9% 50.7% 52.1% 52.7% 46.1% 35.2% 31.4% 24.8% 21.7% 25.0% 28.7% 29.3% 40.0% 24.3% 6.7% -14.1% 4.5% -52.3% -5.9% 7.7% 25.6% 5.7% 8.3% -6.2% 17.6% -35.7% -0.7% 1.6% -5.2% -4.8% 7.0% 4.2% 5.8% Notes: 1. Weights are calculated as a moving two year average for each class. 2. Weighted growth is calculated as the log difference of the weighted volumes. Original: :2010-03-04 2010-03-04 Original Révisé : 2010-05-04 Col. 10 1 GI-2 Document 2 Page 17 de 23 Requête 3724-2010 Non-Normalized Volumes Index (1987=100) 100.0 149.1 190.1 203.2 176.5 184.5 109.4 103.2 111.4 144.0 152.3 165.6 155.7 185.7 130.0 129.1 131.2 124.6 118.7 127.3 132.8 140.7 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appendix 3 Volumes Index - Weather Normalized Col. 1 Col. 2 Col. 3 Col. 4 3 Col. 5 Col. 6 3 Volumes (10 m ) Col. 7 Weights Col. 8 Col. 9 Fiscal Year Residential Commercial Industrial Total Residential Commercial Industrial Weighted Growth2 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 26,072 26,786 27,184 27,892 29,275 33,702 35,931 39,058 41,132 43,843 45,679 46,538 48,106 53,102 50,493 51,971 53,275 56,491 56,748 57,562 58,686 59,263 36,513 37,115 37,691 39,570 41,993 43,493 44,558 47,813 48,542 51,125 54,429 54,295 55,946 58,477 58,019 60,426 60,630 61,939 61,386 61,064 60,979 61,405 61,948 117,063 163,462 176,493 145,621 143,718 53,864 35,114 53,807 80,162 89,072 111,503 96,977 127,031 55,352 60,165 43,112 37,109 29,460 48,523 45,672 55,555 124,533 180,964 228,337 243,955 216,889 220,913 134,353 121,985 143,481 175,130 189,180 212,336 201,029 238,610 163,864 172,562 157,017 155,539 147,594 167,149 165,337 176,223 17.3% 13.2% 11.7% 12.4% 14.4% 19.6% 29.3% 30.2% 26.7% 24.6% 23.0% 22.9% 23.0% 25.7% 30.5% 31.9% 35.1% 37.4% 36.3% 35.0% 34.5% 24.1% 18.3% 16.4% 17.7% 19.5% 24.8% 36.0% 36.3% 31.3% 29.0% 27.1% 26.7% 26.0% 28.9% 35.2% 36.7% 39.2% 40.7% 38.9% 36.7% 35.8% 58.6% 68.5% 72.0% 69.9% 66.1% 55.6% 34.7% 33.5% 42.0% 46.5% 50.0% 50.4% 51.0% 45.3% 34.3% 31.3% 25.7% 22.0% 24.8% 28.3% 29.6% 38.2% 23.4% 6.6% -11.8% 1.8% -52.7% -9.9% 16.4% 20.1% 7.7% 11.6% -5.5% 17.2% -39.2% 5.2% -9.5% -1.0% -5.3% 12.7% -1.1% 6.4% Notes: 1. Weights are calculated as a moving two year average for each class. 2. Weighted growth is calculated as the log difference of the weighted volumes. Original: :2010-03-04 2010-03-04 Original Révisé : 2010-05-04 Col. 10 1 GI-2 Document 2 Page 18 de 23 Requête 3724-2010 Normalized Volumes Index (1987=100) 100.0 146.5 185.0 197.6 175.7 178.9 105.6 95.7 112.7 137.8 148.9 167.2 158.2 187.9 127.0 133.8 121.6 120.4 114.3 129.7 128.3 136.8 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appendix 4 Labour Index Col. 1 Col. 2 Col. 3 Col. 4 Col. 5 Col. 6 Col. 7 Col. 8 Col. 9 Weights1 Fiscal Year 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 Total Supervisory Empolyees (FTE's) 11.0 11.0 11.0 13.0 14.0 14.0 14.5 14.3 15.5 16.0 16.0 15.0 15.0 14.0 11.9 12.9 13.8 14.1 16.0 16.1 17.5 18.4 Total nonSupervisory Employees (FTE's) 23.7 22.9 22.0 23.0 23.5 26.1 25.7 29.0 28.2 27.8 26.8 26.9 19.9 19.9 21.8 21.8 23.4 23.9 27.1 27.6 29.5 29.7 Supervisory Costs ($) NonSupervisory Costs ($) Supervisory NonSupervisory Weighted Growth2 Labour Index (1987=100) 485,234 491,573 526,440 664,967 722,189 795,449 928,397 883,682 969,051 997,283 1,097,111 1,062,026 1,146,099 1,020,379 837,504 923,217 1,045,569 1,093,255 1,311,294 1,397,666 1,575,741 1,657,151 708,504 719,414 722,512 783,575 834,970 1,001,732 1,039,952 1,210,717 1,201,000 1,192,536 1,182,261 1,212,563 928,701 971,914 1,102,011 1,214,796 1,375,791 1,438,537 1,725,438 1,839,089 2,073,407 2,180,527 40.6% 41.4% 44.2% 46.2% 45.2% 45.8% 44.6% 43.4% 45.1% 46.9% 47.4% 50.8% 53.3% 47.3% 43.2% 43.2% 43.2% 43.2% 43.2% 43.2% 43.2% 59.4% 58.6% 55.8% 53.8% 54.8% 54.2% 55.4% 56.6% 54.9% 53.1% 52.6% 49.2% 46.7% 52.7% 56.8% 56.8% 56.8% 56.8% 56.8% 56.8% 56.8% -2.0% -2.4% 9.9% 4.6% 5.7% 0.8% 6.1% 1.9% 0.6% -1.9% -2.9% -14.8% -3.7% -2.9% 3.5% 7.0% 2.1% 12.6% 1.3% 7.4% 2.5% 100.0 98.0 95.7 105.6 110.6 117.1 118.0 125.4 127.8 128.7 126.2 122.6 105.7 101.9 99.0 102.5 109.9 112.3 127.3 129.0 138.9 142.5 Notes: 1. Weights are calculated as a moving two year average for each class. 2. Weighted growth is calculated as the log difference of the weighted employees. Original Original: :2010-03-04 2010-03-04 Révisé : 2010-05-04 GI-2 Document 2 Page 19 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appendix 5 Materials Index Col. 1 Fiscal Year 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 Col. 2 Total Regulated O&M Costs ($) 1,952,049 2,136,466 2,140,681 2,393,690 2,652,169 3,004,889 3,400,625 3,723,477 3,825,572 3,958,925 4,199,598 4,383,845 4,279,951 4,359,265 4,631,494 5,150,624 5,726,563 5,862,944 6,599,235 7,344,431 7,935,429 8,534,843 Original : 2010-03-04 Col. 3 Col. 4 Col. 5 Col. 6 Col. 7 Col. 8 Total Labour Costs ($) Total Materials Cost Quebec CPI Total Real Materials Cost ($2002) Growth Materials Index (1987=100) 1,193,738 1,210,987 1,248,952 1,448,542 1,557,159 1,797,181 1,968,349 2,094,399 2,170,051 2,189,819 2,279,372 2,274,589 2,074,800 1,992,293 1,939,515 2,138,013 2,421,360 2,531,791 3,036,732 3,236,755 3,649,148 3,837,678 758,311 925,479 891,729 945,148 1,095,010 1,207,708 1,432,276 1,629,078 1,655,521 1,769,106 1,920,226 2,109,256 2,205,151 2,366,972 2,691,979 3,012,611 3,305,203 3,331,153 3,562,503 4,107,676 4,286,281 4,697,165 69.5 72.2 75.1 78.2 83.8 86.2 87.5 86.9 87.7 89.1 90.6 91.8 93.0 95.2 97.7 99.2 102.2 103.8 106.3 108.7 110.4 112.7 1,091,226 1,281,975 1,186,730 1,208,372 1,306,565 1,401,867 1,636,264 1,874,299 1,888,427 1,985,529 2,120,235 2,298,290 2,371,343 2,487,622 2,754,647 3,037,672 3,234,317 3,208,945 3,350,579 3,778,621 3,882,501 4,166,308 16.1% -7.7% 1.8% 7.8% 7.0% 15.5% 13.6% 0.8% 5.0% 6.6% 8.1% 3.1% 4.8% 10.2% 9.8% 6.3% -0.8% 4.3% 12.0% 2.7% 7.1% 100.0 117.5 108.8 110.7 119.7 128.5 149.9 171.8 173.1 182.0 194.3 210.6 217.3 228.0 252.4 278.4 296.4 294.1 307.0 346.3 355.8 381.8 GI-2 Document 2 Page 20 de 23 Requête 3724-2010 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appendix 6 Capital Index (Accounting Data): Real Capital Plant (after deprecitation) Col. 1 Col. 2 Col. 3 Col. 4 Land, Right-ofOther Gas Inst. Way & Structure Services & Improvement Real Capital Plant (after depreciation) Col. 5 Col. 6 Col. 7 Col. 8 House Regulators Mains Station Ind. Meters Col. 9 Col. 10 Equipment and Leasehold Imp. Furniture Col. 11 Col. 12 Col. 13 Transportation Equip. Heavy Work Equip. Tools & Work Equip. Col. 14 Communication & Computer Equip. Fiscal Year 401 470, 471 & 472 473 474 475 477 478 482 483 484 485 486 488 & 490 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 111,744 102,092 92,817 85,274 78,232 72,853 67,503 62,579 57,214 52,188 47,422 43,480 39,224 36,209 31,570 27,960 23,359 19,215 15,253 11,460 7,952 4,609 13,747 12,991 12,243 7,542 7,305 7,205 7,095 7,019 6,878 6,759 6,657 6,662 25,227 24,295 23,672 23,755 22,894 22,249 21,575 20,825 20,203 19,455 4,914,938 4,969,985 5,071,578 5,287,269 5,948,467 6,752,249 7,552,552 8,332,305 8,602,949 8,829,502 9,118,946 9,460,235 9,665,843 9,946,094 10,006,019 10,139,750 10,397,363 10,874,651 10,961,116 11,007,031 11,035,099 11,141,143 43,935 93,545 166,046 275,676 431,814 674,736 861,854 1,081,781 1,197,308 1,304,687 1,436,381 1,632,097 1,781,289 2,024,460 2,141,771 2,208,434 2,128,333 2,068,415 2,005,779 1,936,048 1,878,236 1,808,687 5,811,787 5,971,829 6,176,005 6,372,725 7,037,552 7,681,822 8,224,886 8,604,466 8,997,822 9,904,077 10,179,635 11,446,977 11,457,597 12,289,593 12,339,995 12,323,770 12,829,375 13,307,623 13,334,750 13,516,440 13,573,852 13,816,180 364,022 378,661 404,649 450,153 535,529 561,509 581,405 601,834 565,328 849,964 881,171 1,003,376 1,033,395 1,041,096 1,044,278 1,004,486 971,173 900,969 833,817 771,702 713,530 641,531 754,954 805,082 876,149 926,037 1,046,396 1,176,487 1,315,687 1,456,581 1,502,955 1,510,707 1,596,655 1,688,809 1,724,315 1,754,224 1,800,622 1,840,416 1,916,513 1,961,638 1,971,248 2,003,083 2,122,054 2,247,899 23,722 12,977 3,158 58 1 2,912 1,594 3,613 12,719 9,506 20,469 11,439 1,699 1 11,389 8,872 4,956 18,694 16,065 200,608 196,635 208,077 50,250 43,764 101,385 110,748 115,773 106,849 97,773 88,297 78,229 67,848 95,528 92,406 81,936 88,611 75,967 81,945 92,839 84,879 70,189 305,248 305,032 293,490 17,124 13,216 8,708 4,051 48,110 40,261 31,438 24,848 17,626 10,697 67,719 102,849 80,874 64,983 50,049 36,013 24,169 11,076 0 47,089 264,532 409,668 0 0 0 0 22,584 28,150 26,707 25,003 21,563 18,808 18,257 15,460 13,053 40,498 34,557 24,602 21,250 17,611 13,510 14,275 38,775 33,574 14,853 13,084 12,982 28,147 15,761 12,395 30,463 45,505 48,165 40,800 37,152 37,470 60,029 56,361 53,580 39,844 40,044 42,239 33,713 41,924 43,888 38,715 62,128 67,347 81,236 104,742 96,147 89,076 118,586 200,037 187,871 189,939 435,427 409,984 381,547 368,613 325,118 285,240 238,493 194,317 229,560 613,139 476,865 311,730 Capital Index (Accounting Data): Capital Weights Col. 1 Col. 2 Col. 3 Land, Right-ofOther Gas Inst. Way & Structure & Improvement 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 Capital Weights 401 470, 471 & 472 - Col. 4 Col. 5 Services House Regulators Col. 6 Col. 7 Col. 8 Col. 9 Mains Station Ind. Meters 473 - 474 - 475 - 477 - 478 - 482 - Col. 10 Col. 11 Col. 12 Col. 13 Col. 14 Transportation Equip. Heavy Work Equip. Tools & Work Equip. Communication & Computer Equip. 483 - 484 - 485 - 486 - 488 & 490 - Equipment and Leasehold Imp. Furniture 0.013 0.013 0.336 0.003 0.482 0.029 0.062 0.044 0.006 0.003 0.001 0.002 0.008 0.012 0.012 0.339 0.006 0.484 0.029 0.056 0.042 0.005 0.002 0.001 0.002 0.008 0.012 0.011 0.332 0.011 0.486 0.032 0.059 0.041 0.008 0.002 0.000 0.002 0.007 0.010 0.009 0.317 0.016 0.485 0.038 0.062 0.041 0.011 0.000 0.000 0.002 0.009 0.009 0.007 0.317 0.023 0.478 0.037 0.065 0.038 0.010 0.001 0.001 0.001 0.012 0.008 0.005 0.321 0.029 0.478 0.037 0.071 0.029 0.009 0.003 0.002 0.000 0.008 0.007 0.003 0.321 0.035 0.483 0.039 0.069 0.018 0.009 0.003 0.000 0.002 0.013 0.006 0.002 0.345 0.037 0.467 0.032 0.065 0.015 0.007 0.003 0.000 0.003 0.018 0.005 0.002 0.350 0.036 0.481 0.030 0.061 0.016 0.004 0.002 0.001 0.003 0.008 0.004 0.003 0.331 0.034 0.508 0.032 0.054 0.022 0.004 0.002 0.001 0.002 0.003 0.004 0.003 0.316 0.032 0.518 0.032 0.047 0.030 0.005 0.001 0.001 0.002 0.009 0.003 0.004 0.308 0.031 0.527 0.032 0.045 0.029 0.005 0.002 0.001 0.002 0.011 0.003 0.007 0.314 0.032 0.527 0.032 0.044 0.022 0.004 0.005 0.001 0.002 0.006 0.003 0.008 0.321 0.034 0.517 0.032 0.043 0.023 0.004 0.004 0.001 0.002 0.006 0.003 0.009 0.321 0.034 0.514 0.032 0.044 0.027 0.004 0.004 0.001 0.002 0.007 0.002 0.008 0.329 0.033 0.510 0.031 0.041 0.026 0.004 0.004 0.001 0.002 0.008 0.002 0.008 0.340 0.031 0.503 0.030 0.037 0.028 0.004 0.003 0.001 0.001 0.011 0.002 0.008 0.345 0.029 0.499 0.029 0.038 0.032 0.004 0.003 0.001 0.000 0.009 0.002 0.007 0.350 0.027 0.500 0.028 0.037 0.031 0.005 0.002 0.001 0.001 0.009 Original : 2010-03-04 0.002 0.005 0.348 0.025 0.497 0.026 0.035 0.002 0.003 0.350 0.024 0.489 0.025 0.034 GI-2 Document 2 Page 21 de 23 Requête 3724-2010 0.035 0.006 0.003 0.001 0.002 0.017 0.040 0.006 0.002 0.001 0.002 0.021 Col. 15 Weighted Change in Capital Index -0.5% -2.4% -12.5% -8.1% 40.9% 6.8% 8.9% 5.1% 6.3% 5.6% 6.5% -3.8% -12.1% 22.4% -0.6% 1.0% 6.2% -8.0% 16.0% 0.2% 0.3% Col. 16 Capital Index 100.0 99.5 97.1 85.7 79.1 119.1 127.4 139.3 146.5 156.1 165.1 176.2 169.6 150.3 188.1 187.0 188.8 200.9 185.4 217.5 217.9 218.6 GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appedix 7 Capital Index (Physical Data) Col. 1 Col. 2 Fiscal Year Services (#) 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 9,164 9,381 9,622 9,979 11,087 12,580 13,942 15,274 16,223 17,090 18,232 19,411 20,424 21,669 22,600 23,701 25,141 26,933 28,398 29,609 30,834 32,351 Col. 3 Total Mains (meters) 331,086 334,886 340,166 342,148 369,568 394,364 416,676 433,002 448,210 474,821 485,640 543,358 551,951 600,339 615,171 632,686 667,822 700,393 718,788 745,178 766,916 796,222 Col. 4 Col. 5 Col. 6 Capital Cost Col. 7 Col. 8 Col. 9 Weights1 Col. 10 Meters (#) Services ($) Mains ($) Meters ($) Services Mains Meters 10,766 11,010 11,202 11,642 12,720 14,388 16,049 17,523 18,125 18,452 19,729 20,843 21,549 22,150 22,880 23,691 24,708 25,498 26,075 26,929 28,431 30,232 861,499 992,552 966,196 956,817 962,107 1,311,633 1,222,759 1,415,264 2,034,860 2,230,934 2,615,284 2,585,309 2,655,134 2,952,477 3,076,607 3,318,122 3,471,644 3,640,082 3,792,305 3,838,411 3,933,115 4,368,557 1,248,775 1,410,540 1,387,407 1,428,723 1,512,086 1,915,606 1,861,801 2,109,025 2,556,751 3,310,040 4,129,373 4,389,287 4,560,454 4,836,592 4,883,720 5,360,911 5,174,345 5,357,844 5,389,090 5,506,617 5,583,443 6,013,457 158,695 182,034 143,048 197,906 176,566 291,174 268,275 295,521 352,389 386,867 396,401 382,284 387,295 406,227 405,872 472,716 381,233 401,437 408,022 400,589 370,442 434,450 38.2% 38.5% 37.9% 36.7% 36.9% 36.9% 36.8% 39.4% 39.2% 37.1% 35.9% 35.0% 35.5% 36.4% 36.5% 37.3% 38.6% 39.1% 39.5% 39.6% 40.1% 54.8% 55.1% 55.4% 56.2% 55.6% 55.0% 55.4% 53.2% 54.0% 56.9% 58.8% 59.8% 59.5% 58.7% 58.5% 58.0% 57.2% 56.6% 56.4% 56.5% 56.0% 7.0% 6.4% 6.7% 7.2% 7.6% 8.1% 7.9% 7.4% 6.8% 6.0% 5.4% 5.1% 5.0% 4.9% 5.0% 4.7% 4.2% 4.3% 4.2% 3.9% 3.9% Notes: 1. Weights are calculated as a moving two year average for each class. 2. Weighted growth is calculated as the log difference of the weighted capital costs. Original : 2010-03-04 GI-2 Document 2 Page 22 de 23 Requête 3724-2010 Col. 11 Col. 12 Weighted Growth2 1.7% 1.9% 2.0% 8.8% 9.2% 7.7% 6.2% 4.5% 5.3% 4.1% 9.1% 2.9% 7.2% 3.1% 3.6% 5.5% 5.5% 3.6% 3.8% 3.4% 4.3% Capital Index (1987=100) 100.0 101.7 103.7 105.7 115.5 126.6 136.8 145.5 152.1 160.4 167.0 183.0 188.4 202.5 209.0 216.5 228.8 241.8 250.8 260.5 269.6 281.4 n MPE t 1 Forecast t Actual t Actual t n GAZIFÈRE INC. TOTAL FACTOR PRODUCTIVITY 2011 RATE CASE – PHASE I Data Appedix 8 Combined Input Index Col. 1 Col. 2 Col. 3 Col. 4 Col. 5 Col. 6 Input Indices Fiscal Year Labour Materials 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 100.0 98.0 95.7 105.6 110.6 117.1 118.0 125.4 127.8 128.7 126.2 122.6 105.7 101.9 99.0 102.5 109.9 112.3 127.3 129.0 138.9 142.5 100.0 117.5 108.8 110.7 119.7 128.5 149.9 171.8 173.1 182.0 194.3 210.6 217.3 228.0 252.4 278.4 296.4 294.1 307.0 346.3 355.8 381.8 Original : 2010-03-04 Capital Capital (Accounting (Physical Data) Data) 100.0 100.0 99.5 101.7 97.1 103.7 85.7 105.7 79.1 115.5 119.1 126.6 127.4 136.8 139.3 145.5 146.5 152.1 156.1 160.4 165.1 167.0 176.2 183.0 169.6 188.4 150.3 202.5 188.1 209.0 187.0 216.5 188.8 228.8 200.9 241.8 185.4 250.8 217.5 260.5 217.9 269.6 218.6 281.4 Col. 7 Col. 8 Input Weights Col. 9 Col. 10 Weighted Input Index (Capital Accounting Data) Col. 11 Col. 12 Weighted Input Index (Capital Physical Data) Labour Materials Capital Weighted Input Growth Weighted Input Index Weighted Input Growth Weighted Input Index 25.0% 24.5% 26.1% 27.1% 26.2% 26.3% 26.5% 24.3% 21.8% 19.6% 18.2% 16.9% 15.4% 14.2% 13.7% 14.5% 15.2% 16.4% 17.6% 18.3% 18.6% 17.5% 18.1% 17.8% 18.4% 18.0% 18.5% 19.9% 18.7% 17.1% 16.2% 16.1% 16.8% 17.3% 18.2% 19.2% 20.0% 20.4% 20.3% 21.5% 22.3% 22.4% 57.5% 57.5% 56.1% 54.6% 55.9% 55.2% 53.6% 56.9% 61.0% 64.2% 65.7% 66.2% 67.4% 67.6% 67.1% 65.5% 64.4% 63.3% 61.0% 59.4% 59.0% 2.0% -3.3% -4.1% -1.7% 25.6% 6.8% 9.1% 3.5% 4.9% 4.3% 5.0% -4.5% -7.9% 16.6% 2.0% 2.9% 4.1% -2.1% 12.6% 2.1% 2.2% 100.0 102.0 98.7 94.7 93.1 120.3 128.7 141.0 146.0 153.3 160.0 168.3 160.8 148.6 175.5 179.0 184.3 192.1 188.0 213.2 217.6 222.5 3.3% -0.8% 4.0% 7.5% 7.9% 7.3% 7.6% 3.1% 4.2% 3.3% 6.8% -0.1% 5.1% 3.6% 4.7% 5.9% 3.7% 5.2% 5.1% 4.0% 4.6% 100.0 103.3 102.5 106.6 114.9 124.4 133.8 144.4 149.0 155.5 160.7 172.0 171.8 180.9 187.5 196.6 208.5 216.4 228.0 240.0 249.8 261.5 GI-2 Document 2 Page 23 de 23 Requête 3724-2010