Fabrication and Thermal Budget Considerations of Please share

advertisement

Fabrication and Thermal Budget Considerations of

Advanced Ge and InP SOLES Substrates

The MIT Faculty has made this article openly available. Please share

how this access benefits you. Your story matters.

Citation

Pacella, N. Y., M. T. Bulsara, C. Drazek, E. Guiot, and E. A.

Fitzgerald. “Fabrication and Thermal Budget Considerations of

Advanced Ge and InP SOLES Substrates.” ECS Journal of Solid

State Science and Technology 4, no. 7 (May 7, 2015):

P258–P264.

As Published

http://dx.doi.org/10.1149/2.0221507jss

Publisher

Electrochemical Society

Version

Final published version

Accessed

Thu May 26 07:37:13 EDT 2016

Citable Link

http://hdl.handle.net/1721.1/101889

Terms of Use

Creative Commons Attribution-NonCommercial-NoDerivs

License

Detailed Terms

http://creativecommons.org/licenses/by-nc-nd/4.0/

P258

ECS Journal of Solid State Science and Technology, 4 (7) P258-P264 (2015)

Fabrication and Thermal Budget Considerations of Advanced Ge

and InP SOLES Substrates

Nan Y. Pacella,a,z Mayank T. Bulsara,a Charlotte Drazek,b Eric Guiot,b

and Eugene A. Fitzgeralda

a Department

of Materials Science and Engineering, Massachusetts Institute of Technology, Cambridge,

Massachusetts 02139, USA

Parc Technologique des Fontaines, Crolles Cedex, Bernin 38190, France

b SOITEC,

The Silicon on Lattice Engineered Substrate (SOLES) platform enables monolithic integration of III-V compound semiconductor

(III-V) and silicon (Si) complementary metal oxide semiconductor (CMOS) devices. The SOLES wafer provides a device quality

Si-on-Insulator (SOI) layer for CMOS device fabrication and an embedded III-V device template layer which serves as a seed surface

for epitaxial growth of III-V devices. In this work, different approaches for fabricating SOLES wafers comprised of Ge and InP

template layers are characterized and InP-based SOLES structures are demonstrated for the first time. Ge-based SOLES are robust

for long durations at temperatures up to 915◦ C and Ge diffusion can be controlled by engineering the oxide isolation layers adjacent

to the Ge. InP SOLES structures alleviate lattice and thermal expansion mismatches between the template layer and subsequent

device layers. Although allowable processing temperatures for these wafers had been expected to be higher due to the higher melting

temperature of InP, high indium diffusion through the SiO2 and InP melting actually lead to lower thermal stability. This research

elucidates approaches to enhance the process flexibility and wafer integrity of Ge-based and InP-based SOLES.

© The Author(s) 2015. Published by ECS. This is an open access article distributed under the terms of the Creative Commons

Attribution Non-Commercial No Derivatives 4.0 License (CC BY-NC-ND, http://creativecommons.org/licenses/by-nc-nd/4.0/),

which permits non-commercial reuse, distribution, and reproduction in any medium, provided the original work is not changed in any

way and is properly cited. For permission for commercial reuse, please email: oa@electrochem.org. [DOI: 10.1149/2.0221507jss]

All rights reserved.

Manuscript submitted March 24, 2015; revised manuscript received April 24, 2015. Published May 7, 2015.

Monolithic integration of III-V compound semiconductor (III-V)

and silicon (Si) complementary metal-oxide semiconductor (CMOS)

enables advanced circuits with increased performance and functionality and promotes system-level miniaturization. The Silicon on Lattice

Engineered Substrate (SOLES) platform is a Si wafer with embedded

III-V template layer that has been developed for III-V/Si integration and is illustrated in Fig. 1.1,2 A silicon-on-insulator (SOI) layer

on top provides the high quality substrate necessary for CMOS device processing whereas the III-V template acts as a seed layer for

epitaxial III-V device growth. This III-V template layer is accessed

by etching windows through the top Si and buried insulator layers.

The SOLES substrate structure is designed to add functionality to a

CMOS platform while maintaining compatibility with Si processing

infrastructure. Exposure to the III-V template layer is avoided until

the CMOS process sequence is complete and the III-V device epitaxy

and processing can be treated in a similar manner to backend metal

processing.

Much of the development effort for the SOLES substrate platform

to date has been on the Ge SOLES substrate, in which Ge forms the

embedded III-V template layer, due to the current acceptance of Ge in

Si facilities and near lattice match to GaAs. Ge SOLES wafers were

first demonstrated by Dohrman et al. by transferring a Si device layer

onto an epitaxial Ge template layer on Si, which was established using

a Six Ge1-x graded buffer.1 Subsequently, layer transfer processes with

bulk Ge substrates led to the development of Ge SOLES wafers with a

Ge-on-oxide (Ge-OI) layer as the III-V template, as demonstrated by

Letertre.3 These Ge-OI SOLES wafers were successfully processed

for demonstration of differential amplifiers consisting of monolithically integrated InP heterojunction bipolar transistors (HBT) and Si

CMOS.4 Although successfully modified, design of the CMOS process flow was limited due to the low melting point of Ge (938◦ C).

Furthermore the integration of InP HBT layers required the introduction of Inx Al1-x As metamorphic buffer layers, which increases process complexity and impedes thermal heat extraction through the back

side of the Si substrate. Therefore, direct incorporation of InP into the

SOLES wafers is desirable. The high melting point of InP (1062◦ C)

and its complete compatibility with InP HBT structures offers the potential for Si/III-V device integration process design flexibility. The

elimination of compositional grading between the template layer and

z

E-mail: nanyang@alum.mit.edu

device layer would offer the potential for processing simplicity and

better thermal heat extraction efficiency.

The origin and characteristics of the III-V template layer must be

carefully considered. The best quality III-V template layers come from

bulk III-V or Ge substrates. However, these bulk substrates are limited

in their scalability due to the availability and/or expense of larger

wafer sizes and thermal mismatch between the III-V materials and Si

substrates. Epitaxial deposition of template layer films grown on Si

substrates enables, in principle, scaling to any wafer size available for

Si wafers and ensures thermal mismatch compatibility with Si handle

wafers for subsequent wafer bonding and layer transfer.

Thus, two versions of InP SOLES substrates with different constructions are demonstrated here for the first time, both utilizing InP

template layers epitaxially grown on Si. In the first structure, the InP

template is only flanked by SiO2 on one side. A more advanced InP-OI

SOLES, which parallels the Ge-OI SOLES structure in that the InP

is sandwiched between two SiO2 layers, was then created.3 Finally,

properties of the various Ge and InP SOLES structures were studied in

an effort to provide guidelines for process design and further elucidate

paths for enabling more advanced SOLES wafers with even greater

integration capability and flexibility.

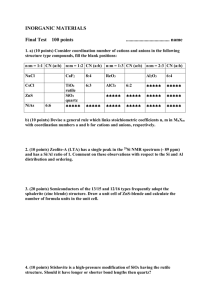

Ge-Based SOLES

Experimental.— The Ge-OI SOLES wafers are fabricated with the

specifications and processing conditions listed in Table I. In all cases,

the SiO2 immediately beneath the top Si layer is thermal oxide. For

structures A, B and C, a plasma-enhanced chemical vapor deposition

(PECVD) SiO2 layer is present on top of the Ge. A key processing step for PECVD oxide is that it is typically densified at high

Figure 1. Schematic of the Silicon on Lattice Engineered Substrate (SOLES)

platform. A III-V template layer is embedded in a Si wafer and separated from

the top Si device layer with a buried silicon dioxide (BOX) dielectric layer.

Downloaded on 2016-03-28 to IP 18.51.1.88 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

ECS Journal of Solid State Science and Technology, 4 (7) P258-P264 (2015)

P259

Table I. Specifications and fabrication conditions for Ge-OI SOLES structures investigated in this work.

Sample

Wafer Size (mm)

Si (nm)

Thermal SiO2 , Top BOX (nm)

PECVD SiO2 , Top BOX (nm)

Ge (nm)

PECVD SiO2 , Bottom BOX (nm)

Thermal SiO2 , Bottom BOX (nm)

Thermal SiO2 Deposition Temperature

Bond Interface

Bonding Process

A

150

B

200

SOLES Layer Structure Target Thicknesses

430

550

500

900

450

100

100

100

200

100

200

100

Top BOX Layer Processing Conditions

n/a

1100◦ C

SiO2 -SiO2

SiO2 -SiO2

Standard

Standard

temperatures and planarized prior to bonding. Note that in Structure

B, the thermal oxide is thinner and grown at higher temperature than

that for structures C and D. In addition, bonding surfaces of wafers C

and D were plasma activated prior to bonding.

Allowable thermal budgets for device processing were determined

for the Ge SOLES samples. The wafers were cleaved into pieces and

annealed in a tube furnace in N2 ambient for 8.5 hours at temperatures

up to 940 ± 5◦ C. This duration was chosen to be consistent with a safe

thermal budget devised for the previous implementation of monolithically integrated InP HBT and Si CMOS, reported by Yang et al.5

Plan-view optical microscopy (Nomarski) and cross sectional transmission electron microscopy (TEM) were used to confirm structural

changes in the wafers after annealing whereas secondary ion mass

spectroscopy (SIMS) was performed in order to determine Ge diffusion profiles in the substrates. TEM samples were made by cleaving

the wafers into small pieces, manually polishing with silicon carbide

lapping film of successively finer grit size, followed by ion milling at

a glancing angle of 15o . A JEOL 2011 High Contrast Digital TEM is

used in this work.

C

200

D

200

700

170

100

100

100

100

700

235

n/a

100

100

100

950◦ C

SiO2 -SiO2

Plasma- activated

950◦ C

SiO2 -Ge

Plasma- activated

devices were to be built on this Si layer. Additional analysis of Ge

diffusion in the SOLES structure provides a better understanding of

how to limit it.

In Ge SOLES structures B and C, with progressively higher annealing temperature, 1) the total planar density of diffused Ge atoms,

NGe (#Ge atoms/cm2 ), at the SiO2 /SiO2 bond interface remains approximately constant, 2) an accumulation of Ge in the thermal oxide

is accompanied by a corresponding depletion of Ge in the PECVD

oxide and 3) Ge progressively accumulates at the Si/SiO2 interface

at higher temperatures. Further, integration under the SIMS curve

reveals that the total concentration of diffused Ge remains approximately constant in Structures B, C and D; however, there is an increase

in total Ge incorporation in the BOX layer of Structure A.

For Structures B, C and D, the constant total NGe in the BOX

indicates that annealing causes a redistribution of Ge species already

present in the oxide layer after SOLES wafer fabrication. Additional

Ge diffusion from the bulk layer is too low to be detected in SIMS.

Results: Structural stability and diffusion in Ge-OI SOLES.—

Thermal budget considerations are extremely important for SOLES

substrates. TEM images of Ge-OI SOLES Structure A, as-fabricated

and after 8.5 h anneal at progressively higher temperatures, are shown

in Fig. 2, top.5 At 940 ± 5◦ C, Ge melting, agglomeration and film delamination can clearly be seen. For Ge-OI SOLES wafers annealed at

920 ± 5◦ C, neither TEM nor Nomarski reveals any structural change

in the buried Ge layer. Thus, 915◦ C was determined to be a conservative safe thermal budget for Ge-OI SOLES structurally.

In addition to major structural changes, Ge diffusion through the

SOLES wafers was considered. SIMS concentration profiles of Ge

in Ge-OI SOLES after 920 ± 5◦ C anneal are shown in Fig. 3. There

is progressive Ge diffusion through the buried SiO2 layers and Ge

accumulation at the bond interfaces and heterointerfaces.

For Structure A, Ge concentrations after annealing according to

the thermal budget of the CMOS process utilized for the integrated

InP HBT previously reported by Liu et al. and Yang et al.4,5 is shown.

Though some Ge diffusion through the BOX does occur, the modified

thermal budget successfully curtails the extent of this diffusion and

eliminates high Ge accumulation levels at the Si/SiO2 interface.5 For

Structures B, C and D, the Ge profile in the as-fabricated wafers

are shown in Fig. 3, together with the Ge diffusion profile after

805 ± 5◦ C, 855 ± 5◦ C and 920 ± 5◦ C. The location of Si/SiO2

and SiO2 /SiO2 interfaces can be easily identified by Ge spikes.

Discussion: Diffusion in Ge-OI SOLES.— As shown in Fig. 3, any

Ge species in the Si device layer of the Ge-OI SOLES is below the

detection limits of SIMS. However, the high Ge concentrations at the

Si/SiO2 interface is of some concern to CMOS devices on the SOI.

Ge atoms create interface states at Si/SiO2 interfaces and would be

especially critical if the most advanced fully-depleted-SOI CMOS

Figure 2. Cross-sectional TEM images of Ge-OI SOLES Structure A (a) asfabricated, (b) after 920 ± 5◦ C anneal and (c) 940 ± 5◦ C anneal, adapted

from,5 and Structures (d) B, (e) C and (f) D after 920 ± 5◦ C 8.5 hour anneal.

All images are taken using the [011] zone axis. The approximate positions of

the bond interfaces are indicated by the white lines.

Downloaded on 2016-03-28 to IP 18.51.1.88 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

P260

ECS Journal of Solid State Science and Technology, 4 (7) P258-P264 (2015)

Figure 3. Ge concentration profiles in Ge-OI SOLES structures from secondary ion mass spectroscopy (SIMS). Overlaid on each plot is the SOLES structure,

with bond interfaces indicated by dashed lines. (a) In Structure A, Ge concentration profile after 920 ± 5◦ C, 8.5 hour anneal (

) and after representative CMOS

) are shown. (b, c, d) In Structures B through D, Ge concentration profiles in as-fabricated wafers (

) and after 805 ± 5◦ C (

), 855 ± 5◦ C

thermal budget (

(

) and 920 ± 5◦ C (

) anneal are shown.

The assumption that there is no substantial Ge diffusion from the

bulk enables modeling of Ge diffusivity in the thermal SiO2 as a

1-D Gaussian distribution and for diffusivity to be extracted. The

diffusivities in Structures B and C vary between 2e-15 and 3e-14

cm2 /s between 800◦ C and 920◦ C and are shown as a function of

temperature in Fig. 4. From this data, a diffusion coefficient, Do =

5.6e-7 cm2 /s and activation energy, EA = 1.7 eV was extracted for Ge

diffusion in Structure B. The diffusivity of Ge in Structure C is an

order of magnitude lower than in Structure B.

Diffusion in SiO2 is often strongly affected by the impurities in,

and bonding structure of, the SiO2 matrix.6–11 The activation energy

Figure 4. Ge diffusivity, D, in thermal SiO2 as a function of temperature for

SOLES Structures B () and C (♦).

of 1.7 eV found in this work is consistent with oxygen-enhanced Ge

diffusion as a Ge-O complex, which has EA = 0.95 eV and >1.55

eV for Ge diffusion in 50nm or 100nm of unencapsulated SiO2 in O2

ambient.7–10

Oxygen-enhanced Ge diffusion was understood by Beyer and von

Borany as the diffusion of a Ge-O complex.8 Ge bonds with oxygen

to create a Ge-O complex which enters the SiO2 matrix and forms

an oxygen-deficient center (ODC) which diffuses through the rapid

breaking and re-forming of bonds at high temperatures. Through this

bond-hopping mechanism, Ge diffuses much faster, with lower activation energy, than in its “elemental” form, in which is must diffuse

through the free volume of SiO2 . Two studies have found diffusivity

below 3e-19 cm2 /s at 920◦ C and EA = 6.6 eV12 and EA = 3.9 eV13

for Ge diffusion without the aid of oxygen, which corresponds to diffusion lengths of less than 9.6 Å. Note that Ge diffusivity values in

the SOLES thermal oxide layers are also orders of magnitude lower

than the 2e-8 cm2 /s diffusivity at 920◦ C previously found in PECVD

SiO2 , which has high H2 concentration.11

At the SiO2 /SiO2 bond interface, a high concentration of Ge species

accumulates. This is likely due to the high density of dangling bonds,

greater free volume at this location and –O-H-O- bridges formed

through the hydrophilic wafer bonding process. The fast diffusing

Ge-O species can easily pick up additional oxygen to form immobile GeO2. 7–10,14–16 After all of the additional oxygen groups at the

bond interface react to form GeO2, Ge concentration at that interface

remains constant.

At the Si/SiO2 interface, there is a very strong driving force for

Ge-O to precipitate from the oxide by interacting with a Si-O group

at the interface and form elemental Ge, GeO + SiO → SiO2 + Ge.8

Downloaded on 2016-03-28 to IP 18.51.1.88 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

ECS Journal of Solid State Science and Technology, 4 (7) P258-P264 (2015)

Because it is a fully miscible system, this Ge then diffuses into the

Si, forming SiGe.17 Ge diffusivity in Si is 2.6e-18 cm2 /s at 920◦ C,13

which results in a diffusion depth of 57Å after an 8.5 hour anneal.

Thus, it appears as a spike in the SIMS concentration profile. (Note

that the highest Ge accumulation shown in the SIMS data in Fig. 3 is

2.9e19 cm−3 , for Structure B annealed at 920◦ C. This concentration

corresponds to a Ge concentration of less than 0.06%. The small

amount of strain presented by 0.06% Ge is easily accommodated and

is therefore inconsequential from a structural perspective but presents

a potential electrical challenge to CMOS devices on the SOI.)

One method of mitigating Ge diffusion is by incorporating higher

quality oxide into the SOLES structure. The thermal oxide in SOLES

Structure C is grown at lower temperature and is therefore of higher

quality, with lower OH incorporation18 and higher density.19,20 Ge

diffusivity in Structure C is indeed an order of magnitude lower than

that in Structure B.

In Structure D, thermal oxide was bonded directly to Ge without

an intervening PECVD oxide layer. With the lower quality PECVD

oxide eliminated from the structure, the total concentration of diffused

Ge is much lower than in Samples A, B, and C, which contain PECVD

oxide. The Ge that does incorporate in the BOX may be a result of

plasma activation of the Ge surface prior to wafer bonding, which

creates a thin layer of GeO2 and GeO on the surface of the Ge.21

Structure A is the only Ge SOLES structure investigated in this

work where NGe in the BOX does not remain constant as a function

of anneal temperature. The thicker PECVD SiO2 and continuous incorporation of Ge from the bulk renders the diffusion behavior much

more complex. Ge-O concentration in the PECVD oxide has not saturated during the wafer fabrication process. Thus, after annealing,

additional Ge from the bulk could still enter the SiO2 matrix and form

fast-diffusing Ge-O complexes, increasing total Ge in the oxide. This

data suggests that the quality and history of the PECVD SiO2 dictate

the initial Ge species concentrations in the SOLES structure and the

subsequent Ge concentration profiles.

P261

Figure 5. Schematic of fabrication sequence for InP/Si SOLES and InP-OI

SOLES. InP/Si and InP-OI designate the structure of the buried InP layer. (1)

PECVD SiO2 is deposited on the InP/Si donor wafer, densified and planarized.

(2) This substrate is then bonded to a thermally oxidized SOI donor wafer.

To create InP/Si SOLES, (3a) the Si and SiO2 from the SOI donor wafer are

removed. To create InP-OI SOLES, (3b) the Si substrate and Ge and GaAs

initiation layers from the InP/Si donor wafer are removed. PECVD SiO2 is

deposited on the back side of the InP, densified and planarized. (4) This wafer

is then bonded to a thermally oxidized Si handle wafer and (5) finally, Si and

SiO2 layers from the SOI donor wafer are removed.

InP-Based SOLES

Experimental.— In order to create InP-based SOLES, InP-on-Si

handle wafers are fabricated by first growing InP thin films on 150 mm

Si wafers, 6◦ offcut toward the {111} plane with an Aixtron/Thomas

Swan metallorganic chemical vapor deposition (MOCVD) reactor

designed with the capability of growing Group IV and III-V films in

the same chamber. The Si wafers were cleaned prior to InP epitaxy

with 10 minute piranha etch followed by the removal of native oxide

with a 10:1 H2 O:48% HF. First, a homoepitaxial Si buffer layer was

grown in an H2 ambient at 825◦ C using silane (SiH4) as the precursor.

This homoepitaxial layer is followed by ∼50 nm Ge and ∼100 nm

GaAs interlayers, grown at 350◦ C and 650◦ C respectively under N2

ambient, which promoted better InP film morphology. Precursors for

Ge and GaAs film growth were germane (GeH4), trimethylgallium

(TMGa) and arsine (AsH3 ). InP was then grown using a two-step

growth procedure which included a low temperature initiation layer

and higher temperature bulk growth layer. This growth was performed

using trimethylindium (TMI) and phosphine (PH3 ), again under N2

ambient. Finally, the films were thermal cycled to improve film quality.

The optimal InP film growth conditions to achieve good film quality were determined using design of experiment (DOE) methodology

with initiation layer V/III precursor ratio, initiation layer thickness,

initiation layer growth temperature, final growth temperature and thermal cycle temperature as the variables. The optimal quality InP film

growth sequence ultimately used in this work consisted of a 100 Å InP

initiation layer grown at 400◦ C with a V/III ratio of 2000, followed by

raising the temperature to 600◦ C for deposition of a thicker “bulk” InP

layer. In order to further improve film quality, samples with progressively greater InP film thickness were grown, encapsulated with SiO2

and then thermal cycled four (4) times between 250◦ C and 800◦ C in a

tube furnace under N2 ambient, as recommended by Hayafuji et al.22

Both the thicker film and thermal cycling increases the probability

of dislocation interaction and annihilation. Finally, film quality was

characterized using both cross-sectional and plan-view TEM on the

[011] zone axis and [220] as well as the full-width at half-maximum

(FWHM) of the InP rocking ω-2 curves in X-ray diffraction (XRD).

InP-based SOLES wafers were then fabricated through wafer

bonding and layer transfer. An oxide-oxide hydrophilic bond was

chosen for ease of implementation and to mirror the process used to

create Ge-based SOLES.1,3 Two versions of InP SOLES were fabricated and designated in this work by the buried InP template structure

as InP-on-Si SOLES and InP-OI SOLES. The fabrication processes

are shown in Fig. 5.

For both structures, the fabrication sequence started with (1)

PECVD deposition of SiO2 on an InP-on-Si handle wafer using an

STS PECVD, oxide densification at 700◦ C in a tube furnace under

N2 ambient and planarization using CMP to achieve surface conditions necessary for bonding. (2) This InP-on-Si handle wafer was then

bonded to a thermally oxidized SOI wafer, creating a BOX layer. Bond

strengthening anneals were then performed at 800◦ C in a tube furnace

in N2 ambient. To create the InP-on-Si SOLES structure, (3a) the Si

and SiO2 from the SOI donor wafer was removed using mechanical

grinding and KOH wet chemical etching.

Fabrication of the InP-OI SOLES was more complex. After the

first bond-strengthening anneal, (3b) the Si substrate and GaAs and

Ge adhesion layers from the InP-on-Si wafer were removed using a piranha etch, after which a PECVD oxide was deposited on the exposed

InP surface. This PECVD oxide film was densified and planarized to

create a smooth bonding surface. (4) This structure was bonded to

a thermally oxidized Si handle wafer to create a second BOX layer.

At this point, (5) the Si substrate and SiO2 from the SOI wafer were

Downloaded on 2016-03-28 to IP 18.51.1.88 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

P262

ECS Journal of Solid State Science and Technology, 4 (7) P258-P264 (2015)

Figure 6. Planview TEM images of InP-on-Si films with InP film thickness

of (a) 1.85um, (b) 3.9um and (c) 4.5um after 800◦ C thermal cycle taken in

bright field, using [220] diffraction condition. (d) FWHM () and TDD ()

for these films. All TEM images share the same scale bar.

finally removed through a combination of mechanical grind and KOH

wet chemical etch to create the final InP-OI SOLES.

Similar to the Ge SOLES structures described above, allowable

thermal budgets were determined for the InP based SOLES structures. InP-on-Si SOLES samples were cleaved into pieces and only

annealed at temperatures up to 860◦ C for 4 hours. The more advanced

InP-OI SOLES structures underwent longer anneals for 8.5 hours at

temperatures up to 940 ± 5◦ C to mirror Ge-OI SOLES. Nomarski,

cross sectional TEM and SIMS were performed to understand the

physical properties.

Results: InP SOLES demonstration and thermal stability.— Using the InP-on-Si growth procedures described above, InP films with

FWHM of 207 arcsec from XRD of the InP peak and TDD of 9.5 ±

0.3E7 cm−2 was achieved for 4.5 μm thick InP films, as shown in Fig.

6. TDD was calculated by counting dislocations captured in ten (10)

bright field PVTEM images taken in the [220] beam condition. The

area of each image is approximately 20 um. Lower thickness films

exhibited higher dislocation density and more stacking faults.

InP-on-Si SOLES and InP-OI SOLES were both successfully made

using wafer bonding and layer transfer. A photograph and crosssectional TEM images of the InP-on-Si SOLES substrate, before final

SiO2 etch, is shown in Fig. 7. Note that 1.85μm InP films are used for

the InP SOLES demonstration here and a high density of dislocations

can be seen in the InP film. The bond interface is indicated by the

white lines.

The InP-on-Si SOLES wafers have thermal stability which is far

below that required for Si CMOS processing. Cross sectional TEM

images of these Ge and GaAs buried layers after annealing at 810◦ C

and 860◦ C are presented in Fig. 8. At the GaAs/InP interface, a distinct

new layer, bounded by a dislocation array at either end and indicated by

the white lines in Figs. 8a and 8b, is formed. With progressively higher

temperature, the thickness of this layer in between the dislocation

array also grows. Further, in the wafer annealed at 860◦ C, a much

more extensive network of dislocations which extends greater than

500nm into the Si substrate in some areas can be seen.

For purposes of this work, the stability of InP SOLES is improved

by developing the InP-OI SOLES structure. TEM and optical microscope images of InP-OI SOLES wafers after progressively higher

Figure 7. (a) Photograph of InP-on-Si SOLES wafer. The SiO2 from the SOI

donor wafer is still intact. Cross sectional TEM images of InP-on-Si SOLES

structure (b) on [011] zone axis and (c) in the [220] diffraction condition to

highlight the dislocation network. The bond interfaces is indicated by the white

line.

temperature 8.5 hour thermal anneal are shown in Fig. 9. Though

some blisters can be seen in the Nomarski images (even in the asfabricated wafers), after extended 800 ± 5◦ C anneal, there were

no observable changes in their density or size. At higher temperatures, however, these blisters grew and led to areas of local film

delamination.

Despite a slight increase in blister density, the InP-OI SOLES

structure is largely robust up to 850 ± 5◦ C with minimal detectable

structural changes in the InP film. Between 850 ± 5◦ C and 915 ±

5◦ C, significant changes do occur. Though some parts of the SOLES

structure remain intact, there are also portions of the sample where

the continuous InP interlayer has transformed to form nanoparticles

in the SiO2. At even higher anneal temperatures, intact InP layers become increasingly difficult to find, even on a TEM scale. Nanoparticle

Figure 8. Cross-sectional TEM images of Ge and GaAs initiation layers in

the InP-on-Si structure after (a) 810◦ C and (b and c) 860◦ C anneal for 4 hours.

Images are taken in bright field using the [220] diffraction condition to better

highlight dislocations.

Downloaded on 2016-03-28 to IP 18.51.1.88 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

ECS Journal of Solid State Science and Technology, 4 (7) P258-P264 (2015)

P263

nition of the new layer may be a result of the miscibility gap in the

quaternary system, as shown by Cohen.24

With higher thermal budget anneals, the dense dislocation network

between Ge and Si also becomes progressively thicker, extending both

up into what was originally the Ge film and down into the Si substrate.

This dislocation movement suggests Ge-Si interdiffusion and strain

relaxation over a larger thickness. No distinct interfacial layer is seen

between Ge and Si, consistent with the complete miscibility of this

materials system.

Given that this highest anneal temperature used in this work for

the InP-on-Si substrate is close to the eutectic temperature of the

GaAs-Ge system, it is possible that localized melting may have given

rise to the interaction between all of the layers at 860◦ C, as shown

in Fig. 8c. Additional work such as energy dispersive spectroscopy

(EDS) or selective area diffraction (SAD) would further confirm this

hypothesis.

Figure 9. Cross-sectional TEM (a-e) and plan view Nomarski microscope

(f-j) images of InP-OI SOLES as-fabricated (a and f) and after 800 ± 5◦ C (b

and g), 850 ± 5◦ C (c and h), 915 ± 5◦ C (d and i) and 1000 ± 5◦ C (e and j)

8.5 hour anneals. TEM images are taken on the [011] zone axis.

formation can be seen in some areas; InP simply de-bonds from the

SiO2 in others (not shown).

In addition to structural integrity, diffusion of In and P up to the

Si device layer is also considered. For InP-OI SOLES, SIMS concentration profiles of In and P after extended 850 ± 5◦ C anneal and of In

after 915 ± 5◦ C anneal are shown in Fig. 10. Extensive In diffusion

is seen throughout the SiO2 film but there is no sign of P diffusion. A

few characteristics of these SIMS scans for InP-OI SOLES should be

noted. Due to sample charging during the SIMS scan (from the thick

SiO2 layer); the Si substrates are removed prior to acquiring SIMS

data. Indium concentration data in the top Si layer is captured from a

front-side scan for the 915 ± 5◦ C sample, whereas the same data for

the 850 ± 5◦ C sample is captured from a back side scan. In both cases,

In is below the detection limit of SIMS. Because back side scans were

performed for these films, the new surface of the 915 ± 5◦ C annealed

sample was positioned at ∼3.5 μm whereas the new surface of the

850 ± 5◦ C annealed sample was positioned at ∼5 μm. The decrease

in Indium concentration at each of these positions may be a surface

artifact.

Discussion: Structural stability of InP-on-Si SOLES.— The dislocation arrays present at the GaAs/InP and Si/Ge interfaces of the

InP-on-Si SOLES structure shown in Fig. 8 suggest that progressive

interdiffusion of the GaAs layer with InP and of the Ge layer with Si

is possible. At the GaAs/InP interface, there is an unidentified layer

bounded by two dislocation arrays. It is possible that this intermediate

layer contains all four elements (In, Ga, As, and P) as reported by

Jin-Phillipp et al. for a bonded InP/GaAs interface.23 The clear defi-

Discussion: Structural stability and diffusion in InP-OI SOLES.—

Nomarski revealed the only macro-scale surface defect in the InPOI SOLES wafer structure after annealing at progressively higher

temperatures to be an increase in blisters, as shown in Fig. 9. One

hypothesis for the source of these blisters is that they arise from

imperfect wafer bonding, possibly due to contamination at the bond

interface. However, the true origin of these blisters requires further

study and would best be understood through TEM or scanning electron

microscopy (SEM) images of samples prepared using focused ionbeam (FIB) to target the precise location of the blister.

On a local scale, the InP-OI SOLES structure was largely robust

up to 850 ± 5◦ C with no detectable structural change in TEM, as seen

in Fig. 9c. Between 850 ± 5◦ C and 915 ± 5◦ C, however, there are

portions of the sample where InP forms nanoparticles in the lower

SiO2 layer, Fig. 9d. At even higher temperatures, the effect is more

catastrophic, as seen in Fig. 9e. The spatial separation of In and P

shown in the SIMS data in Fig. 10 may elucidate the mechanism for

this nanoparticle formation.

Indium diffusion throughout the SiO2 layer leaves a high concentration of P near the InP/SiO2 interface. The excess P can incorporate

into the Si sites of the SiO2 network and form P2 O5 . Although the

precise configuration of P incorporation in the SiO2 matrix needs to

be confirmed, a P2 O5 structure would be consistent with both the lack

of P diffusion and the anomalous melting and nanoparticle formation.

With reference to the former, the P2 O5 structure is relatively immobile in SiO2 .6 With reference to the latter, SiO2 -P2 O5 has a eutectic

Figure 10. Concentration profiles of In and P in InP-OI SOLES after extended 850 ± 5◦ C, 8.5 hour anneal (

) and of In after 915 ± 5◦ C, 8.5 hour

).

anneal (

Downloaded on 2016-03-28 to IP 18.51.1.88 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

P264

ECS Journal of Solid State Science and Technology, 4 (7) P258-P264 (2015)

temperature at approximately 850◦ C (and 20% P2 O5 ), 25,26 far below

the melting point of either SiO2 or InP alone and corresponding to

the lowest temperature at which nanoparticle formation is seen in

this work. Thus, extreme care must be taken when considering wafer

fabrication thermal budgets for the current InP-OI SOLES structures.

In contrast to the low P diffusion, the SIMS data in Fig. 10 reveals

that indium diffusivity in the buried oxide layers of the InP-OI SOLES

structure is extremely high. Similar to Ge, indium diffusion in SiO2 has

been proposed to occur via slow In+ ion diffusion and fast oxygenenhanced diffusion mechanisms.6 Oxygen-enhanced In diffusivities

have been found to be on the order of 1e-13 cm2 /s in thermal oxide at

temperatures relevant to this work.27,28 For the InP-OI SOLES wafers

demonstrated here, since a majority of the BOX layer is comprised of

PECVD SiO2 , a fast diffusion mechanism such as oxygen-enhanced

diffusion is very likely. Just as higher Ge diffusivity had been found

in PECVD oxide as compared against thermal oxide, very high In

diffusivity is present in the PECVD oxide in this InP-OI SOLES

structure.

Finally note that indium accumulates at the highly imperfect

SiO2 /SiO2 bond interface, similar to Ge, but there is no indium peak

at the Si-SiO2 interface. Given indium’s solid solubility in Si of only

∼1e18 cm−3 ,29 and segregation coefficient of between ∼0.1 and 0.001

in this temperature range studied here,28,30 indium remains in the SiO2

over Si. The lack of In diffusion into the Si device layer is advantageous for the CMOS devices which would be processed on this Si

layer. However, the high In levels in the BOX may still make the

InP-OI SOLES integration platform a challenge for integrating fullydepleted SOI CMOS devices.

Conclusions

SOLES substrates present a viable platform for integrating Si

CMOS and III-V compound semiconductor devices. However, due

to the stringent requirements demanded of SOLES substrates, careful

design of wafer fabrication procedures and device processing steps

is necessary. Two versions of InP SOLES wafers are demonstrated

through bonding of silicon, SOI and InP-on-Si wafers grown using a

two-step growth method. The allowable processing budgets of these

InP SOLES substrates are studied in detail and compared with previously fabricated Ge SOLES substrates in order to elucidate the optimal

methods of fabricating SOLES wafer structures.

The simplest fabrication process for creating a SOLES substrate

entails a single bonding and layer transfer step. A Si device layer

is transferred onto a III-V template supported on Si, as in Ge/SiGe

SOLES1 or InP-on-Si SOLES. For these SOLES substrates, it is the

buried layers between the III-V template and Si substrate that impose the most severe thermal budget constraints to subsequent device

processing.

It is therefore advantageous to simplify the final SOLES structure

by using a double layer transfer process to create SOLES structures

with two BOX layers. Replacing the layers beneath the III-V template

with SiO2 also has the advantage of eliminating the III-V/group IV

interface (for InP-on-Si SOLES substrates) and improving isolation

schemes.

Finally, the quality of the two BOX layers must also be optimized

in order to limit diffusion of the III-V template materials and improve

allowable processing thermal budgets. For Ge-OI SOLES high quality

oxide has been shown here to mitigate Ge diffusion through the SiO2

matrix and accumulation near the Si/SiO2 interface. Further, incorporation of SiNx diffusion barriers were previously demonstrated.5

For InP-OI SOLES substrates, the effect of higher quality oxides and

diffusion barriers in limiting the spatial separation between In and

P and improving thermal stability should be explored. Anomalous

melting of the InP layer below the expected melting temperature of

InP should also be better understood. Finally, the thermal budget of

CMOS processing steps should also be designed to avoid melting of

and minimize diffusion of the III-V template material.

Acknowledgments

This work was funded by the DARPA COSMOS program, ONR

contract number N00014-07-C-0629, and made use of MIT MTL and

CMSE facilities.

References

1. C. Dohrman, K. Chilukuri, D. Isaacson, M. Lee, and E. Fitzgerald, Fabrication

of silicon on lattice-engineered substrate (SOLES) as a platform for monolithic

integration of CMOS and optoelectronic devices. Mater. Sci. Eng. B 135, 235

(2006).

2. K. Chilukuri, M. J. Mori, C. L. Dohrman, and E. a. Fitzgerald, Monolithic CMOScompatible AlGaInP visible LED arrays on silicon on lattice-engineered substrates

(SOLES). Semicond. Sci. Technol. 22, 29 (2007).

3. F. Letertre, Formation of III-V Semiconductor Engineered Substrates Using Smart

CutTM Layer Transfer Technology. Mater. Res. Soc. Symp. Proc. 1068, C01 (2008).

4. W. K. Liu, et al., Monolithic integration of InP-based transistors on Si substrates

using MBE. J. Cryst. Growth 311, 1979 (2009).

5. N. Yang, et al., Thermal considerations for advanced SOI substrates designed for

III-V/Si heterointegration. 2009 IEEE Int. SOI Conf. 1 (2009).

6. A. H. Van Ommen, Diffusion of group III and V elements in SiO2 . Appl. Surf. Sci.

30, 244 (1987).

7. N. Arai, H. Tsuji, N. Gotoh, T. Minotani, and T. Ishibashi, Thermal diffusion behavior

of implanted germanium atoms in silicon dioxide film measured by high-resolution

RBS. Surf. Coat. Technol. 201, 8312 (2007).

8. V. Beyer and J. Von Borany, Elemental redistribution and Ge loss during ion-beam

synthesis of Ge nanocrystals in SiO2 films. Phys. Rev. B 77, 1 (2008).

9. V. A. Borodin, K. H. Heinig, and B. Schmidt, Modeling of Ge nanocluster evolution

in ion-implanted SiO2 layer. Nucl. Instruments Methods Phys. Res. 147, 286 (1999).

10. K. H. Heinig, et al., Precipitation, ripening and chemical effects during annealing

of Ge ‡ implanted SiO2 layers. Nucl. Instruments Methods Phys. Res. B 148, 969

(1999).

11. G. Taraschi, SiGe-on-Insulator and Strained-Si-on-Insulator for Strained-Si CMOS

and Nanocrystalline-Ge Waveguides. (Massachusetts Institute of Technology, 2003).

12. M. V. Minke and K. A. Jackson, Diffusion of germanium in silica glass. J. Non. Cryst.

Solids 351, 2310 (2005).

13. M. Ogino, Y. Oana, and M. Watanabe, The Diffusion Coefficient of Germanium in

Silicon. Phys. Status Solidi A 72, 535 (1982).

14. H. G. Chew, et al., Effect of germanium concentration and oxide diffusion barrier

on the formation and distribution of germanium nanocrystals in silicon oxide matrix.

Nanotechnology 17, 1964 (2006).

15. W. K. Choi, et al., Formation of germanium nanocrystals in thick silicon oxide matrix

on silicon substrate under rapid thermal annealing. J. Cryst. Growth 288, 79 (2006).

16. J. Von Borany, et al., Multimodal impurity redistribution and nanocluster formation

in Ge implanted silicon dioxide films. Appl. Phys. Lett. 71, 3215 (1997).

17. A. Markwitz, B. Schmidt, W. Matz, R. Grotzchel, and A. Mucklih, Microstructural

investigation of ion beam synthesised germanium nanoclusters embedded in SiO2

layers. Nucl. Instruments Methods Phys. Res. 142, 338 (1998).

18. A. J. Moulson and J. P. Roberts, Water in Silica Glass. Trans. Faraday Soc. 57, 1208

(1961).

19. E. A. Taft, The Optical Constants of Silicon and Dry Oxygen Oxides of Silicon at

5461A. J. Electrochem. Soc. 968 (1978).

20. C. S. Rafferty, L. M. Landsberger, R. W. Dutton, and W. a. Tiller, Nonlinear viscoelastic dilation of SiO2 films. Appl. Phys. Lett. 54, 151 (1989).

21. D. Pasquariello and K. Hjort, Plasma-Assisted InP-to-Si Low Temperature Wafer

Bonding. IEEE J. Sel. Top. Quantum Electron. 8, 118 (2002).

22. N. Hayafuji, et al., Improvement of InP Crystal Quality on GaAs Substrates by

Thermal Cyclic Annealing. Jpn. J. Appl. Phys. 28, L1721 (1989).

23. N. Y. Jin-Phillipp, W. Sigle, A. Black, D. Babic, and J. E. Bowers, Interface of directly

bonded GaAs and InP. J. Appl. Phys. 89, 1017 (2001).

24. R. M. Cohen, Interdiffusion in alloys of the GaInAsP system. J. Appl. Phys. 73, 4903

(1993).

25. J. M. Eldridge and P. Balk, Formation of phosphosilicate glass films on silicon dioxide. Trans. Metall. Soc. AIME 242, 539 (1968).

26. T. Yamaji and F. Ichikawa, Diffusion of ion-implanted phosphorus within thermally

grown SiO2 in O2 ambient. J. Appl. Phys. 59, 1981 (1986).

27. a. H. Van Ommen, Diffusion of ion-implanted In and Tl in SiO2 . J. Appl. Phys. 57,

5220 (1985).

28. D. A. Antoniadis and I. Moskowitz, Diffusion of indium in silicon inert and oxidizing

ambients. J. Appl. Phys. 53, 9214 (1982).

29. S. Solmi, et al., Investigation on indium diffusion in silicon. J. Appl. Phys. 92, 1361

(2002).

30. I. C. Kizilyalli, T. L. Rich, F. a. Stevie, and C. S. Rafferty, Diffusion parameters of

indium for silicon process modeling. J. Appl. Phys. 80, 4944 (1996).

Downloaded on 2016-03-28 to IP 18.51.1.88 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).