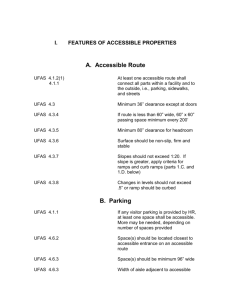

UFAS RETROFIT MANUAL designed to be used in conjunction with the

advertisement