09-01-15 SPEC WRITER NOTES: Delete between // // if not 1.

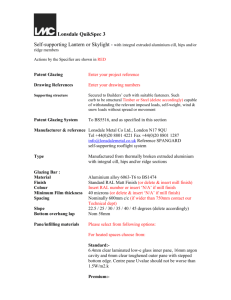

advertisement